-

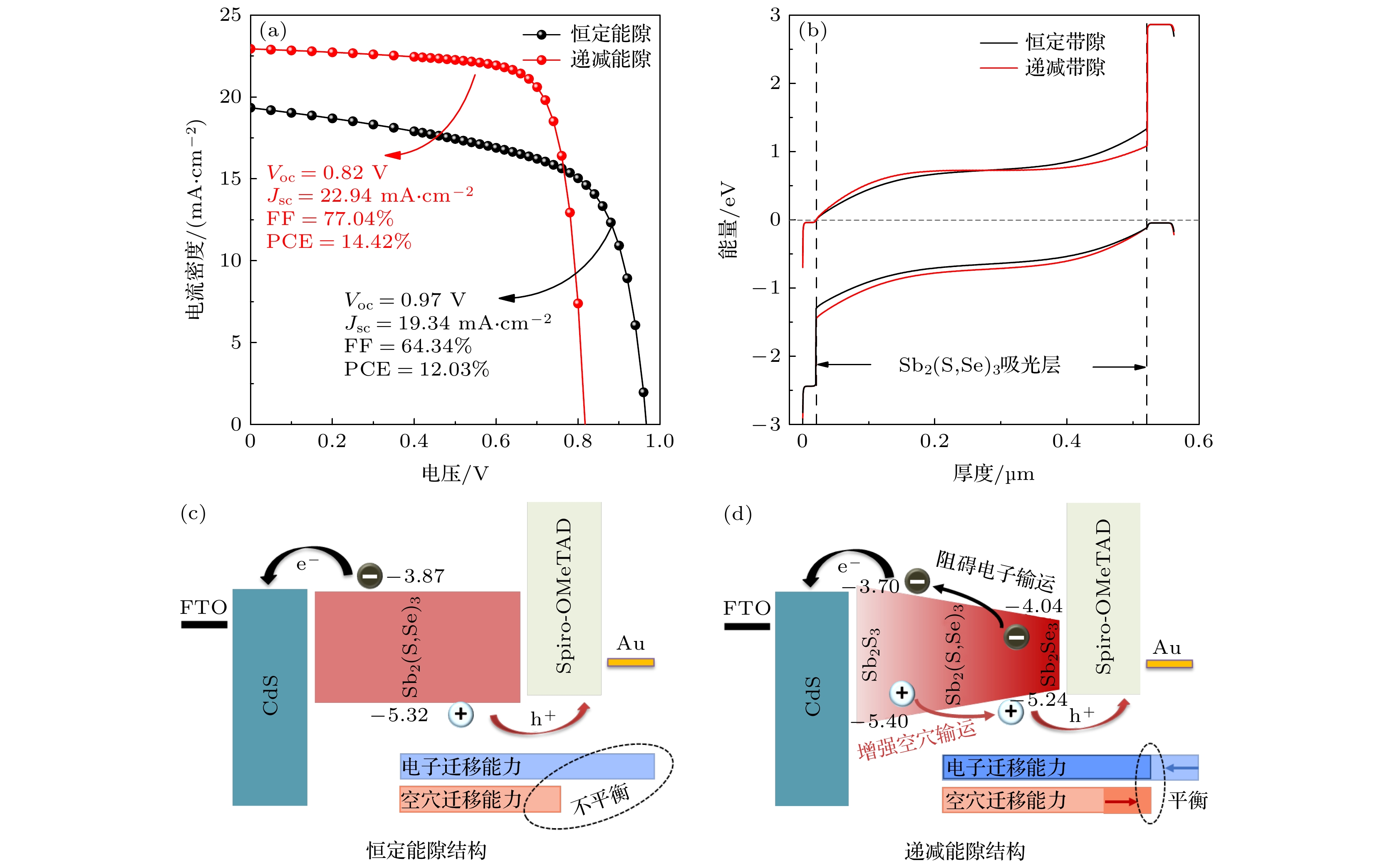

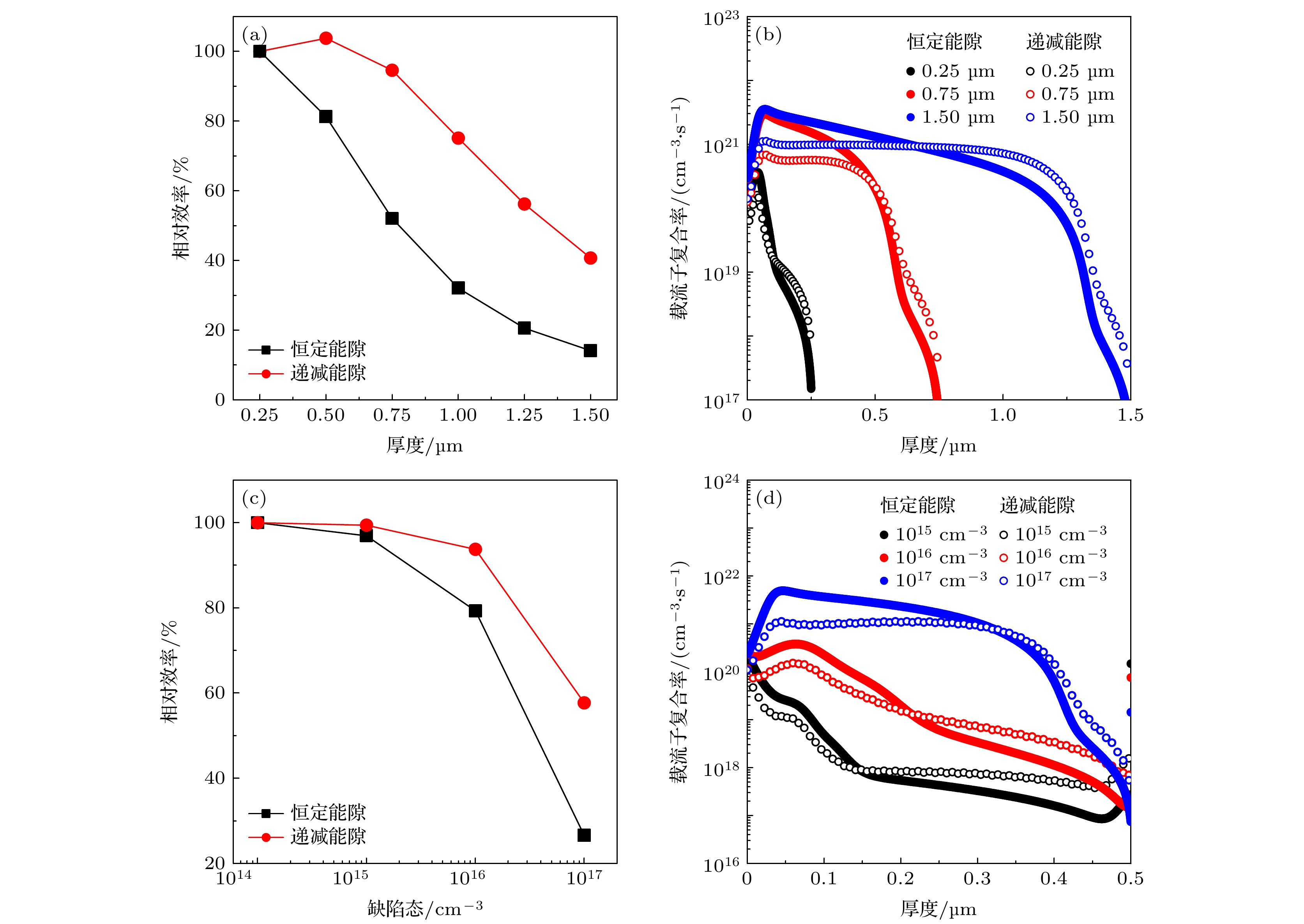

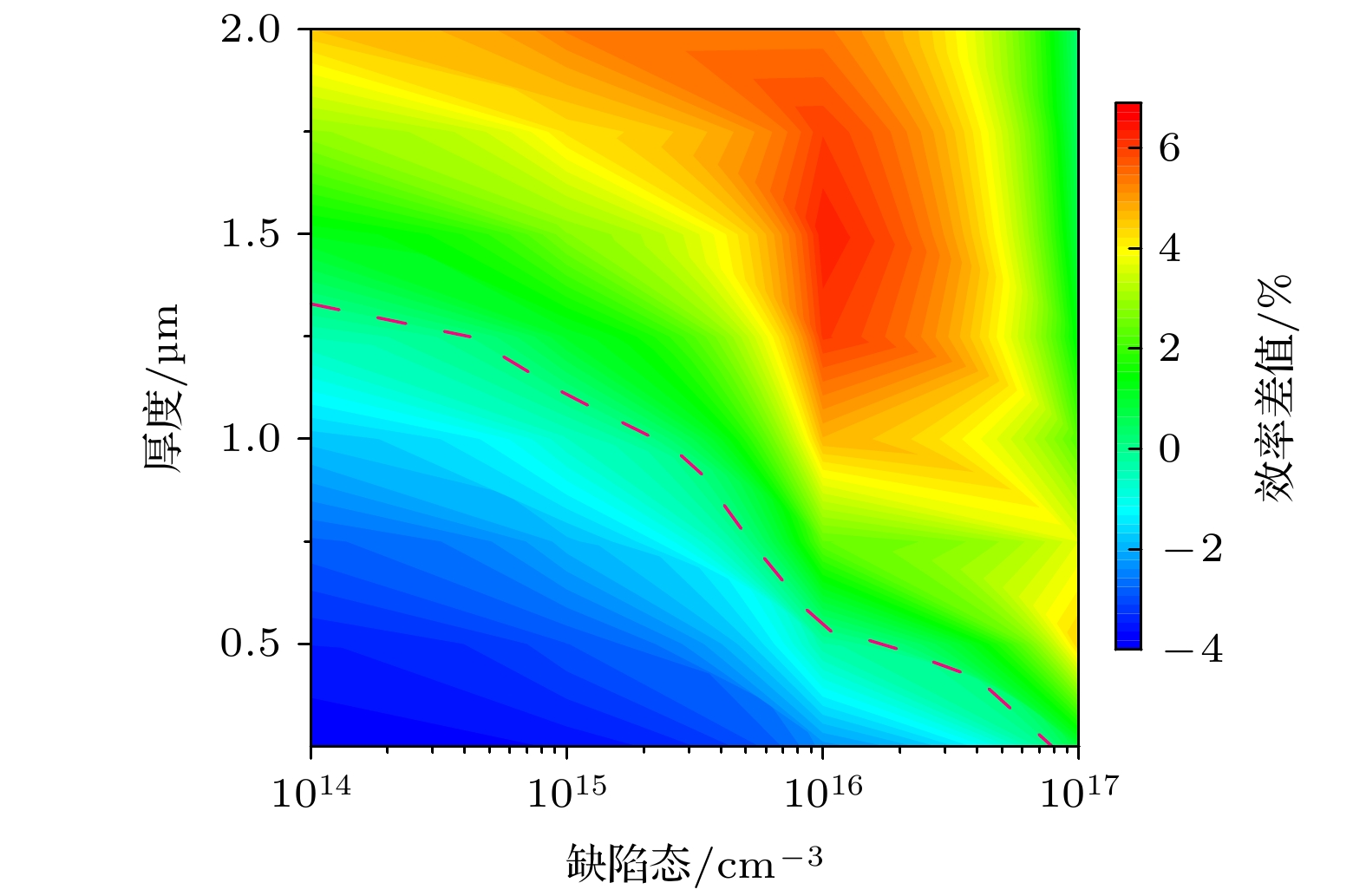

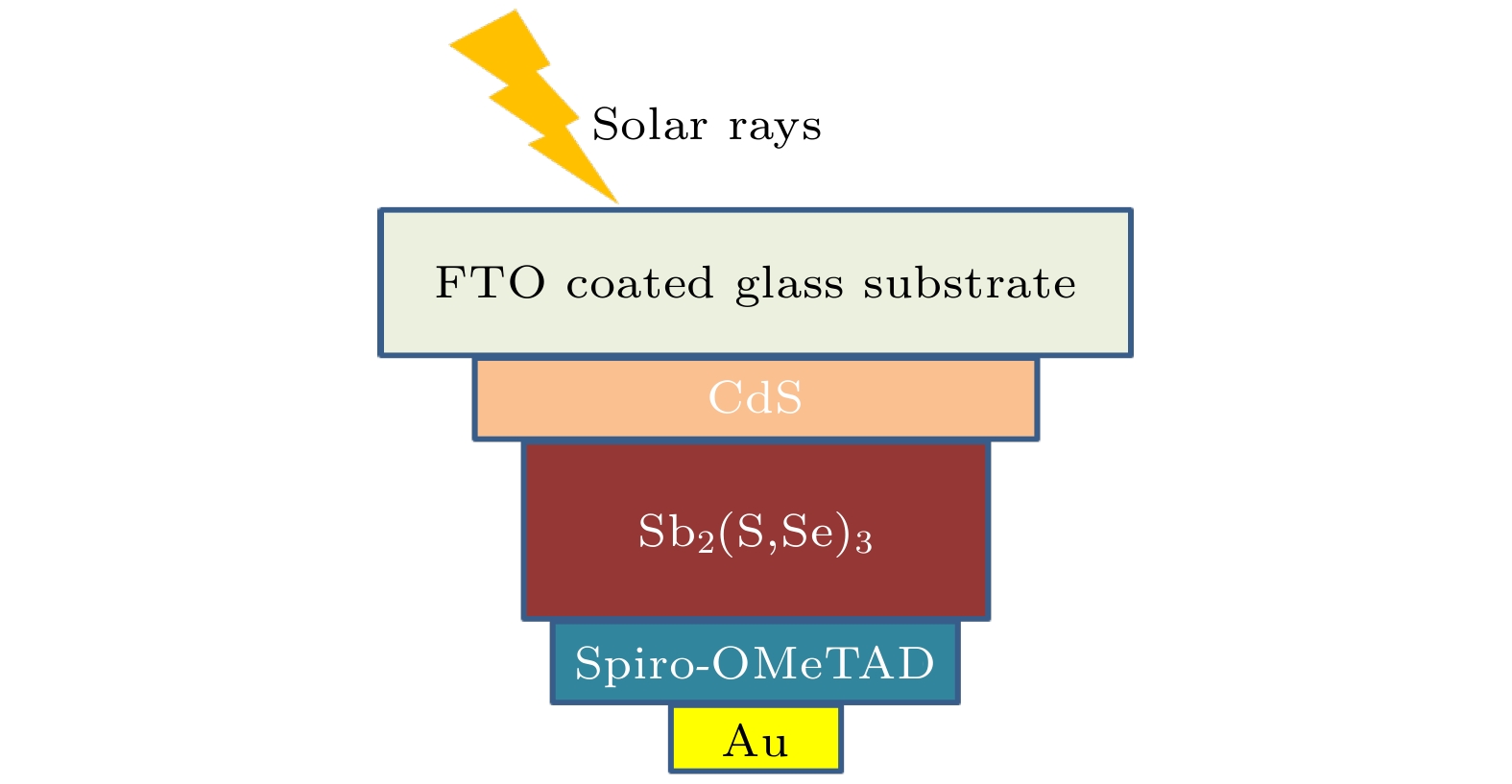

硫硒化锑(Sb2(S,Se)3)薄膜太阳电池因其原材料丰富、制备方法简单、性能稳定等优势近年来得到了快速发展. 本文基于Sb2(S,Se)3吸光层能隙可调的特点, 应用wx-AMPS软件对具有渐变能隙Sb2(S,Se)3太阳电池进行建模仿真和结构设计, 并与50% Se含量的恒定能隙Sb2(S,Se)3太阳电池进行了对比分析. 结果显示, 递减能隙结构所形成的附加电场能够促进空穴的输运, 抑制载流子的复合, 相比与恒定能隙Sb2(S,Se)3太阳电池可以得到更高的短路电流密度和填充因子, 使光电转换效率由12.03%提升至14.42%. 此外, 递减能隙结构通过抑制载流子的复合, 有效地缓解Sb2(S,Se)3太阳电池因厚度厚或者缺陷态高所引起的性能下降. 在厚度为1.5 μm, 缺陷态密度在1016 cm–3时. 采用递减能隙Sb2(S,Se)3太阳电池的效率比恒定能隙Sb2(S,Se)3太阳电池高6.34%. 研究结果表明通过吸光层的能隙结构设计能够发挥Sb2(S,Se)3等多元合金或化合物的能隙可调的优势, 是提高太阳电池器件性能的有效技术路线之一.Sb2(S,Se)3 thin film solar cells have been developed rapidly in recent years due to their abundant raw materials, simple preparation method, stable performance, etc. In this study, based on the characteristic of tunable band gap of Sb2(S,Se)3 light absorption layer, wx-AMPS software is used to simulate and design the Sb2(S,Se)3 solar cell with narrowing band gap structure, and compared with the Sb2(S,Se)3 solar cell with constant band gap (50% selenium content). The results show that the additional electric field formed by the narrowing band gap can promote the holes’ transport and inhibit the carrier’s recombination. Compared with the constant band gap structure, the narrowing band gap structure can increase the short-circuit current density of Sb2(S,Se)3 solar cells from 19.34 to 22.94 mA·cm–2, the filling factor from 64.34% to 77.04%, and the photoelectric conversion efficiency from 12.03% to 14.42%. Then, the effect of electron mobility on the performance of Sb2(S,Se)3 solar cells with narrowing band gap is studied. It is found that when the hole mobility is 0.1 cm2·V–1·s–1, the advantage of narrowing band gap can gradually appear after the electron mobility is higher than 0.25 cm2·V–1·s–1. The performance of Sb2(S,Se)3 solar cell is enhanced with the electron mobility further increasing. However, when the electron mobility is higher than 5 cm2·V–1·s–1, the device performance is saturated. Moreover, we demonstrate that the degradation caused by thick or high defect state of Sb2(S,Se)3 solar cell can be effectively alleviated by applying the narrowing band gap due to the suppression of the carrier recombination. When the thickness is 1.5 μm and the defect density is 1016 cm–3, the photoelectric conversion efficiency of Sb2(S,Se)3 solar cell with narrowing band gap is 6.34% higher than that of the constant bandgap. Our results demonstrate that the band gap engineering of the light absorption layer is one of the effective technical routes to optimizing the performance of Sb2(S,Se)3 solar cells. Since the photo-absorption material such as amorphous/microcrystalline silicon germanium, Copper indium gallium selenide and perovskite have the characteristic of tunable band gap. The design of the gradient band gap structure can also be applied to the optimization of the above alloy or compound solar cells.

-

Keywords:

- Sb2(S,Se)3 /

- narrowing band gap structure /

- solar cell /

- wx-AMPS

[1] Giraldo S, Jehl Z, Placidi M, Izquierdo-Roca V, Perez-Rodriguez A, Saucedo E 2019 Adv. Mater. 31 1806692

Google Scholar

Google Scholar

[2] Ramanujam J, Bishop D M, Todorov T K, Gunawan O, Rath J, Nekovei R, Artegiani E, Romeo A 2020 Mater. Sci. 110 100619

Google Scholar

Google Scholar

[3] Lei H W, Chen J J, Tan Z J, Fang G J 2019 Solar RRL 3 1900026

Google Scholar

Google Scholar

[4] Liang G X, Luo Y D, Chen S, Tang R, Zheng Z H, Li X J, Liu X S, Liu Y K, Li Y F, Chen X Y, Su Z H, Zhang X H, Ma H L, Fan P 2020 Nano Energy 73 104806

Google Scholar

Google Scholar

[5] 薛丁江, 石杭杰, 唐江 2015 64 038406

Google Scholar

Google Scholar

Xue D J, Shi H J, Tang J 2015 Acta Phys. Sin. 64 038406

Google Scholar

Google Scholar

[6] Tang R, Zheng Z H, Su Z H, Li X J, Wei Y D, Zhang X H, Fu Y Q, Luo J T, Fan P, Liang G X 2019 Nano Energy 64 103929

Google Scholar

Google Scholar

[7] Kondrotas R, Chen C, Tang J 2018 Joule 2 857

Google Scholar

Google Scholar

[8] Mavlonov A, Razykov T, Raziq F, Gan J, Chantana J, Kawano Y, Nishimura T, Wei H, Zakutayev A, Minemoto T, Zu X, Li S, Qiao L 2020 Sol. Energy 201 227

Google Scholar

Google Scholar

[9] Luo Y D, Tang R, Chen S, Hu J G, Liu Y K, Li Y F, Liu X S, Zheng Z H, Su Z H, Ma X F, Fan P, Zhang X H, Ma H L, Chen Z G, Liang G X 2020 Chem. Eng. J. 293 124599

Google Scholar

Google Scholar

[10] Maximilian A, Silvana B, Miguel A L M, Thomas J L, Stefan G 2015 Phys. Rev. B 92 14101

Google Scholar

Google Scholar

[11] Yang B, Qin S, Xue D J, Chen C, He Y S, Niu D M, Huang H, Tang J 2017 Prog. Photovoltaics Res. Appl. 25 113

Google Scholar

Google Scholar

[12] Tang R F, Wang X M, Lian W T, Huang J L, Wei Q, Huang M L, Yin Y W, Jiang C H, Yang S F, Xing G H, Chen S Y, Zhu C F, Hao X J, Green M A, Chen T 2020 Nat. Energy 5 587

Google Scholar

Google Scholar

[13] Li K H, Lu Y, Ke X X, Li S, Lu S C, Wang C, Wang S Y, Chen C, Tang J 2020 Solar RRL 4 2000220

Google Scholar

Google Scholar

[14] Pham D P, Kim S, Park J, Le A T, Cho J, Jung J, Iftiquar S M, Yi J 2016 Mater. Sci. Semicond. Process. 56 183

Google Scholar

Google Scholar

[15] 陈俊帆, 任慧志, 侯福华, 周忠信, 任千尚, 张德坤, 魏长春, 张晓丹, 侯国付, 赵颖 2019 68 028101

Google Scholar

Google Scholar

Chen J F, Ren H Z, Hou F H, Zhou Z X, Ren Q S, Zhang D K, Wei C C, Zhang X D, Hou G H, Zhao Y 2019 Acta Phys. Sin. 68 028101

Google Scholar

Google Scholar

[16] Mattheis J, Rostan P J, Rau U, Werner J H 2007 Sol. Energy Mater. Sol. Cells 91 689

Google Scholar

Google Scholar

[17] Fan Q H, Chen C Y, Liao X B, Xiang X B, Zhang S B, Ingler W, Adiga N, Hu Z H, Cao X M, Du W H, Deng X M 2010 Sol. Energy Mater. Sol. Cells 94 1300

Google Scholar

Google Scholar

[18] Liu Y T, Chen Y H, Lin C C, Fan C M, Liu J C, Tung Y L, Tsai S Y 2017 Mater. Res. Express 4 075505

Google Scholar

Google Scholar

[19] Choi Y C, Lee Y H, Im S H, Noh J H, Mandal T N, Yang W S, Seok S 2014 Adv. Energy Mater. 4 1301680

Google Scholar

Google Scholar

[20] Zhang Y, Li J M, Jiang G S, Liu W F, Yang S F, Zhu C F, Chen T 2017 Solar RRL 1 1700017

Google Scholar

Google Scholar

[21] Zhu H, Kalkan A K, Hou J, Fonash S J 1999 Proceedings of NCPV 15 th Program Review Meeting Denver, Colorado, USA, September 9−11 1998 p309

[22] Liu Y M, Sun Y, Rockett A 2012 Sol. Energy Mater. Sol. Cells 98 124

Google Scholar

Google Scholar

[23] Wang X M, Tang R F, Wu C Y, Zhu C F, Chen T 2018 J. Energy Chem. 27 713

Google Scholar

Google Scholar

[24] 曹宇, 祝新运, 陈翰博, 王长刚, 张鑫童, 侯秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X X, Chen H B, Wang C G, Zhang X T, Hou B D, Shen M R, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[25] Teimouri R, Heydari Z, Ghaziani M P, Madani M, Abdy H, Kolahdouz M, Asl-Soleimani E 2020 Superlattices Microstruct. 145 106627

Google Scholar

Google Scholar

[26] Islam M T, Thakur A K 2020 Sol. Energy 202 304

Google Scholar

Google Scholar

[27] Li Z Q, Ni M, Feng X D 2020 Mater. Res. Express 7 016416

Google Scholar

Google Scholar

[28] Cai Z H, Dai C M, Chen S Y 2020 Solar RRL 4 1900503

Google Scholar

Google Scholar

[29] Chen S, Qiao X, Wang F, Luo Q, Zhang X, Wan X, Xu Y, Fan X 2016 Nanoscale 8 2277

Google Scholar

Google Scholar

[30] Lee C T, Lu K F, Tseng C Y 2015 Sol. Energy 114 1

Google Scholar

Google Scholar

[31] 曹宇, 薛磊, 周静, 王义军, 倪牮, 张建军 2016 65 146801

Google Scholar

Google Scholar

Cao Y, Xue L, Zhou J, Wang Y J, Ni J, Zhang J J 2016 Acta Phys. Sin. 65 146801

Google Scholar

Google Scholar

[32] Deng H, Yuan S J, Yang X K, Zhang J, Khan J, Zhao Y, Isaq M, Ye W, Cheng Y B, Song H S, Tang J 2018 Prog. Photovoltaics Res. Appl. 26 281

Google Scholar

Google Scholar

[33] Bernhard N, Bauer G H, Bloss W H 1995 Prog. Photovoltaics Res. Appl. 3 149

Google Scholar

Google Scholar

[34] Cao Y, Zhou J, Wang Y J, Ni J, Zhang J J 2015 J. Alloy. Compd. 632 456

Google Scholar

Google Scholar

[35] Wang X M, Tang R F, Jiang C H, Lian W T, Ju H X, Jiang G S, Li Z Q, Zhu C F, Chen T 2020 Adv. Energy Mater. 10 2002341

Google Scholar

Google Scholar

[36] Cao Y, Zhu X Y, Jiang J H, Liu C Y, Zhou J, Ni J, Zhang J J, Pang J B 2020 Sol. Energy Mater. Sol. Cells 206 110279

Google Scholar

Google Scholar

[37] Chen C, Tang J 2020 ACS Energy Lett. 5 2294

Google Scholar

Google Scholar

[38] Zhou J, Chen H B, Zhang X T, Chi K L, Cai Y M, Cao Y, Pang J B 2021 J. Alloys Compd. 862 158703

Google Scholar

Google Scholar

[39] Cao Y, Liu C Y, Jiang J H, Zhu X Y, Zhou J, Ni J, Zhang J J, Pang J B, Rummeli M H, Zhou W J, Liu H, Cuniberti G 2021 Solar RRL 5 2000800

Google Scholar

Google Scholar

-

图 2 递减能隙与恒定能隙的Sb2(S,Se)3太阳电池 (a) J-V曲线 ; (b) 能带图; (c) 恒定能隙Sb2(S,Se)3太阳电池能带结构示意图; (d)递减能隙Sb2(S,Se)3太阳电池能带结构示意图

Fig. 2. Sb2(S,Se)3 solar cells with narrowing and constant band gap structure: (a) J-V curves; (b) energy band diagram; (c) energy band scheme of constant band gap Sb2(S,Se)3 solar cell; (d) energy band scheme of narrowing band gap Sb2(S,Se)3 solar cell.

图 6 (a) 恒定能隙与递减能隙Sb2(S,Se)3太阳电池的相对效率随厚度的变化, 此处相对效率指的是以厚度为0.25 μm Sb2(S,Se)3太阳电池效率为基准计算出的效率比值; (b) 恒定能隙与递减能隙Sb2(S,Se)3太阳电池的载流子复合率分布随厚度的变化; (c) 恒定能隙与递减能隙Sb2(S,Se)3太阳电池的相对效率随缺陷态密度的变化, 此处相对效率指的是以缺陷态密度为1014 cm–3 Sb2(S,Se)3太阳电池效率为基准计算出的效率比值; (d) 恒定能隙与递减能隙Sb2(S,Se)3太阳电池的载流子复合率分布随缺陷态密度的变化

Fig. 6. (a) Relative PCE of constant band gap and narrowing band gap Sb2(S,Se)3 solar cells with different thicknesses. Here, the relative PCE refers to the PCE ratio calculated by applying the PCE of Sb2(S,Se)3 solar cell with 0.25 μm thick as the denominator; (b) the carrier recombination rate distribution of constant band gap and narrowing band gap Sb2(S,Se)3 solar cells with different thicknesses; (c) the relative PCE of constant band gap and narrowing band gap Sb2(S,Se)3 solar cells with different defect densities. Here, the relative PCE refers to the PCE ratio calculated by applying the PCE of Sb2(S,Se)3 solar cell with the defect density of 1014 cm–3 as the denominator; (d) the carrier recombination rate distribution of constant band gap and narrowing band gap Sb2(S,Se)3 solar cells with different defect densities.

表 1 Sb2(S,Se)3 太阳电池材料参数

Table 1. Material parameters of the Sb2(S,Se)3 solar cells.

参数 CdS Sb2(S,Se)3 Spiro-OMeTAD 介电常数 10 10—19 3 电子亲和

势/eV3.7—3.87 3.7—4.04 1.99—2.41 电子迁移率

(cm2·V–1·s–1)100 4 0.0001 空穴迁移率/

(cm2·V–1·s–1)25 0.1 0.0001 施主掺杂

浓度/cm–31 × 1019 0 0 受主掺杂

浓度/cm–30 1 × 1013 3 × 1018 禁带宽度/eV 2.4 1.2—1.7 2.91 导带有效

态密/cm–32.2 × 1018 2.2 × 1018 2.2 × 1018 价带有效

态密/cm–31.8 × 1019 1.8 × 1019 1.8 × 1019 缺陷态密

度/cm–31 × 1017 3 × 1016 1 × 1016 表 2 不同μe的Sb2(S,Se)3递减能隙结构太阳电池的性能参数

Table 2. Photovoltaic performance of the narrowing band gap structure Sb2(S,Se)3 solar cell with different μe.

μe/(cm2·V–1·s–1) Voc/V Jsc/(mA·cm–2) FF/% PCE/% 0.1 0.93 20.00 52.50 9.74 0.25 0.87 21.77 63.39 12.05 1 0.83 22.77 73.44 13.89 5 0.82 22.95 77.18 14.46 10 0.81 22.95 77.72 14.51 -

[1] Giraldo S, Jehl Z, Placidi M, Izquierdo-Roca V, Perez-Rodriguez A, Saucedo E 2019 Adv. Mater. 31 1806692

Google Scholar

Google Scholar

[2] Ramanujam J, Bishop D M, Todorov T K, Gunawan O, Rath J, Nekovei R, Artegiani E, Romeo A 2020 Mater. Sci. 110 100619

Google Scholar

Google Scholar

[3] Lei H W, Chen J J, Tan Z J, Fang G J 2019 Solar RRL 3 1900026

Google Scholar

Google Scholar

[4] Liang G X, Luo Y D, Chen S, Tang R, Zheng Z H, Li X J, Liu X S, Liu Y K, Li Y F, Chen X Y, Su Z H, Zhang X H, Ma H L, Fan P 2020 Nano Energy 73 104806

Google Scholar

Google Scholar

[5] 薛丁江, 石杭杰, 唐江 2015 64 038406

Google Scholar

Google Scholar

Xue D J, Shi H J, Tang J 2015 Acta Phys. Sin. 64 038406

Google Scholar

Google Scholar

[6] Tang R, Zheng Z H, Su Z H, Li X J, Wei Y D, Zhang X H, Fu Y Q, Luo J T, Fan P, Liang G X 2019 Nano Energy 64 103929

Google Scholar

Google Scholar

[7] Kondrotas R, Chen C, Tang J 2018 Joule 2 857

Google Scholar

Google Scholar

[8] Mavlonov A, Razykov T, Raziq F, Gan J, Chantana J, Kawano Y, Nishimura T, Wei H, Zakutayev A, Minemoto T, Zu X, Li S, Qiao L 2020 Sol. Energy 201 227

Google Scholar

Google Scholar

[9] Luo Y D, Tang R, Chen S, Hu J G, Liu Y K, Li Y F, Liu X S, Zheng Z H, Su Z H, Ma X F, Fan P, Zhang X H, Ma H L, Chen Z G, Liang G X 2020 Chem. Eng. J. 293 124599

Google Scholar

Google Scholar

[10] Maximilian A, Silvana B, Miguel A L M, Thomas J L, Stefan G 2015 Phys. Rev. B 92 14101

Google Scholar

Google Scholar

[11] Yang B, Qin S, Xue D J, Chen C, He Y S, Niu D M, Huang H, Tang J 2017 Prog. Photovoltaics Res. Appl. 25 113

Google Scholar

Google Scholar

[12] Tang R F, Wang X M, Lian W T, Huang J L, Wei Q, Huang M L, Yin Y W, Jiang C H, Yang S F, Xing G H, Chen S Y, Zhu C F, Hao X J, Green M A, Chen T 2020 Nat. Energy 5 587

Google Scholar

Google Scholar

[13] Li K H, Lu Y, Ke X X, Li S, Lu S C, Wang C, Wang S Y, Chen C, Tang J 2020 Solar RRL 4 2000220

Google Scholar

Google Scholar

[14] Pham D P, Kim S, Park J, Le A T, Cho J, Jung J, Iftiquar S M, Yi J 2016 Mater. Sci. Semicond. Process. 56 183

Google Scholar

Google Scholar

[15] 陈俊帆, 任慧志, 侯福华, 周忠信, 任千尚, 张德坤, 魏长春, 张晓丹, 侯国付, 赵颖 2019 68 028101

Google Scholar

Google Scholar

Chen J F, Ren H Z, Hou F H, Zhou Z X, Ren Q S, Zhang D K, Wei C C, Zhang X D, Hou G H, Zhao Y 2019 Acta Phys. Sin. 68 028101

Google Scholar

Google Scholar

[16] Mattheis J, Rostan P J, Rau U, Werner J H 2007 Sol. Energy Mater. Sol. Cells 91 689

Google Scholar

Google Scholar

[17] Fan Q H, Chen C Y, Liao X B, Xiang X B, Zhang S B, Ingler W, Adiga N, Hu Z H, Cao X M, Du W H, Deng X M 2010 Sol. Energy Mater. Sol. Cells 94 1300

Google Scholar

Google Scholar

[18] Liu Y T, Chen Y H, Lin C C, Fan C M, Liu J C, Tung Y L, Tsai S Y 2017 Mater. Res. Express 4 075505

Google Scholar

Google Scholar

[19] Choi Y C, Lee Y H, Im S H, Noh J H, Mandal T N, Yang W S, Seok S 2014 Adv. Energy Mater. 4 1301680

Google Scholar

Google Scholar

[20] Zhang Y, Li J M, Jiang G S, Liu W F, Yang S F, Zhu C F, Chen T 2017 Solar RRL 1 1700017

Google Scholar

Google Scholar

[21] Zhu H, Kalkan A K, Hou J, Fonash S J 1999 Proceedings of NCPV 15 th Program Review Meeting Denver, Colorado, USA, September 9−11 1998 p309

[22] Liu Y M, Sun Y, Rockett A 2012 Sol. Energy Mater. Sol. Cells 98 124

Google Scholar

Google Scholar

[23] Wang X M, Tang R F, Wu C Y, Zhu C F, Chen T 2018 J. Energy Chem. 27 713

Google Scholar

Google Scholar

[24] 曹宇, 祝新运, 陈翰博, 王长刚, 张鑫童, 侯秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X X, Chen H B, Wang C G, Zhang X T, Hou B D, Shen M R, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[25] Teimouri R, Heydari Z, Ghaziani M P, Madani M, Abdy H, Kolahdouz M, Asl-Soleimani E 2020 Superlattices Microstruct. 145 106627

Google Scholar

Google Scholar

[26] Islam M T, Thakur A K 2020 Sol. Energy 202 304

Google Scholar

Google Scholar

[27] Li Z Q, Ni M, Feng X D 2020 Mater. Res. Express 7 016416

Google Scholar

Google Scholar

[28] Cai Z H, Dai C M, Chen S Y 2020 Solar RRL 4 1900503

Google Scholar

Google Scholar

[29] Chen S, Qiao X, Wang F, Luo Q, Zhang X, Wan X, Xu Y, Fan X 2016 Nanoscale 8 2277

Google Scholar

Google Scholar

[30] Lee C T, Lu K F, Tseng C Y 2015 Sol. Energy 114 1

Google Scholar

Google Scholar

[31] 曹宇, 薛磊, 周静, 王义军, 倪牮, 张建军 2016 65 146801

Google Scholar

Google Scholar

Cao Y, Xue L, Zhou J, Wang Y J, Ni J, Zhang J J 2016 Acta Phys. Sin. 65 146801

Google Scholar

Google Scholar

[32] Deng H, Yuan S J, Yang X K, Zhang J, Khan J, Zhao Y, Isaq M, Ye W, Cheng Y B, Song H S, Tang J 2018 Prog. Photovoltaics Res. Appl. 26 281

Google Scholar

Google Scholar

[33] Bernhard N, Bauer G H, Bloss W H 1995 Prog. Photovoltaics Res. Appl. 3 149

Google Scholar

Google Scholar

[34] Cao Y, Zhou J, Wang Y J, Ni J, Zhang J J 2015 J. Alloy. Compd. 632 456

Google Scholar

Google Scholar

[35] Wang X M, Tang R F, Jiang C H, Lian W T, Ju H X, Jiang G S, Li Z Q, Zhu C F, Chen T 2020 Adv. Energy Mater. 10 2002341

Google Scholar

Google Scholar

[36] Cao Y, Zhu X Y, Jiang J H, Liu C Y, Zhou J, Ni J, Zhang J J, Pang J B 2020 Sol. Energy Mater. Sol. Cells 206 110279

Google Scholar

Google Scholar

[37] Chen C, Tang J 2020 ACS Energy Lett. 5 2294

Google Scholar

Google Scholar

[38] Zhou J, Chen H B, Zhang X T, Chi K L, Cai Y M, Cao Y, Pang J B 2021 J. Alloys Compd. 862 158703

Google Scholar

Google Scholar

[39] Cao Y, Liu C Y, Jiang J H, Zhu X Y, Zhou J, Ni J, Zhang J J, Pang J B, Rummeli M H, Zhou W J, Liu H, Cuniberti G 2021 Solar RRL 5 2000800

Google Scholar

Google Scholar

计量

- 文章访问数: 8319

- PDF下载量: 162

- 被引次数: 0

下载:

下载: