-

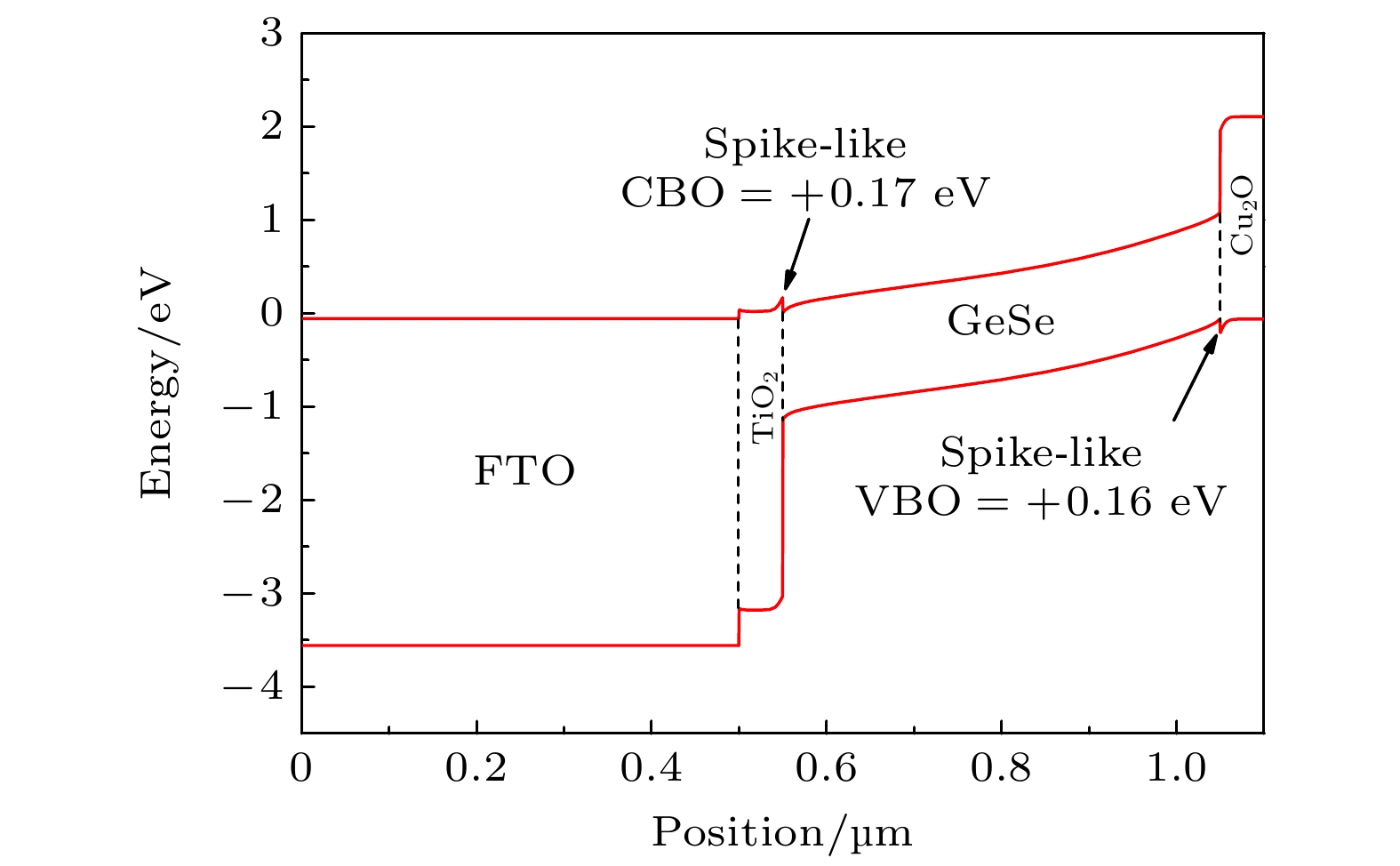

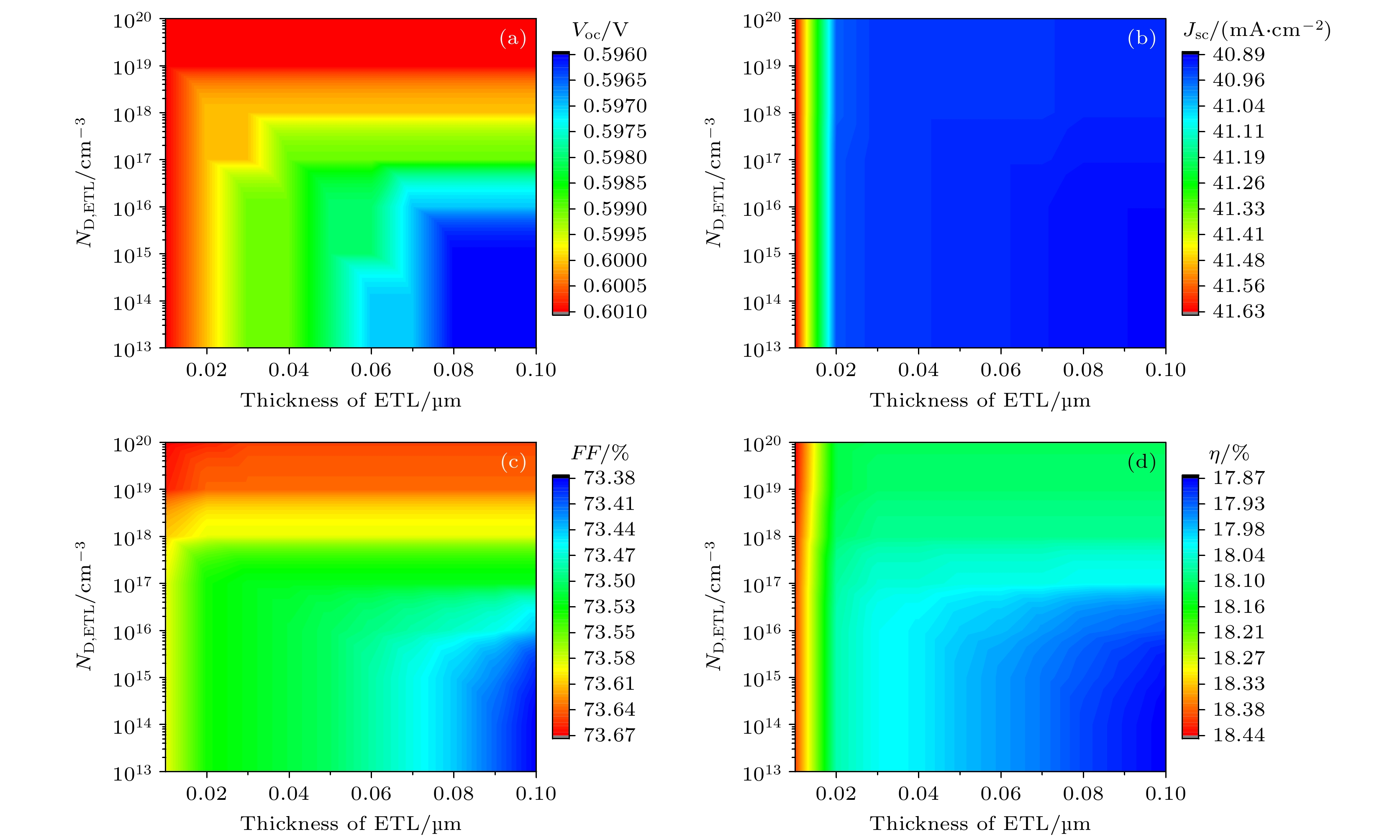

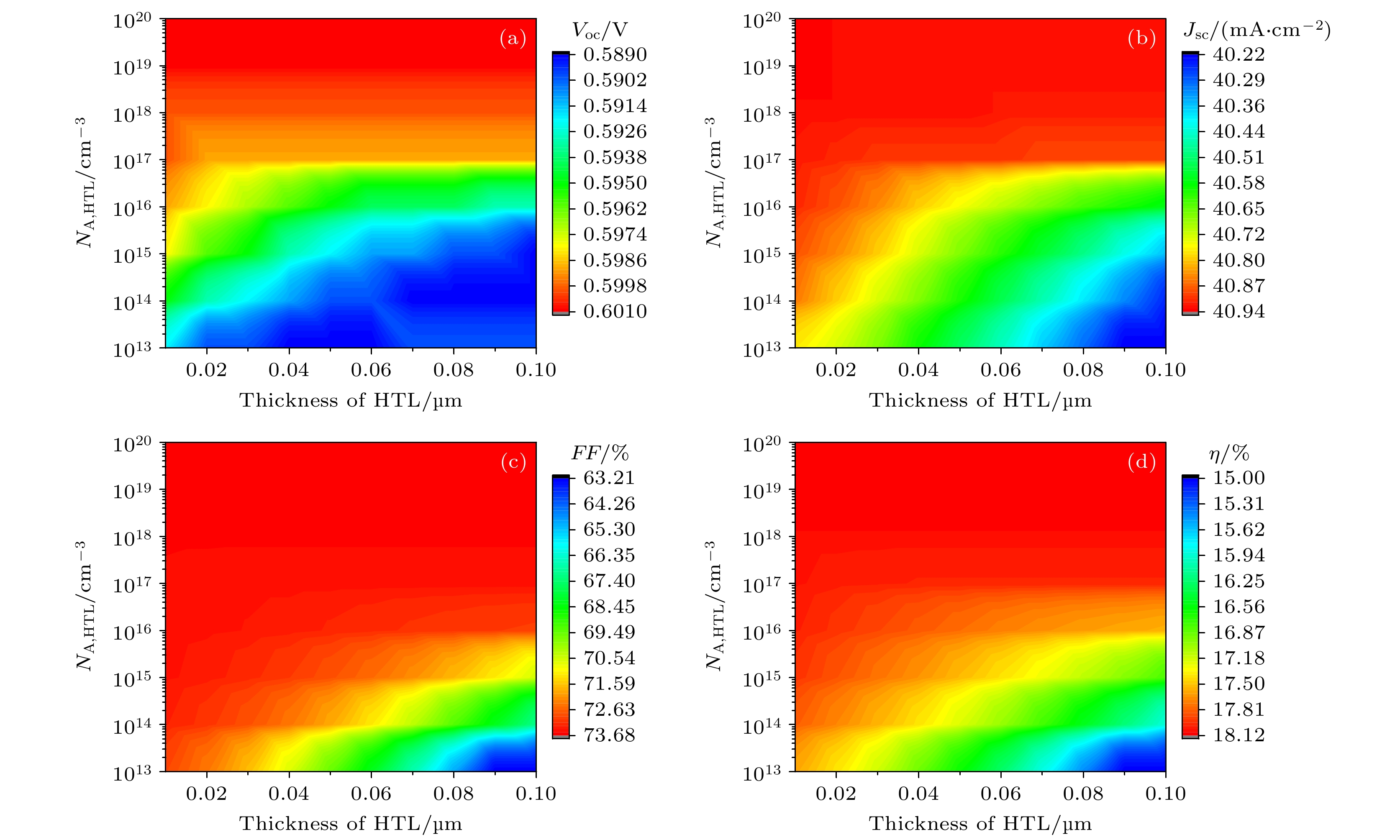

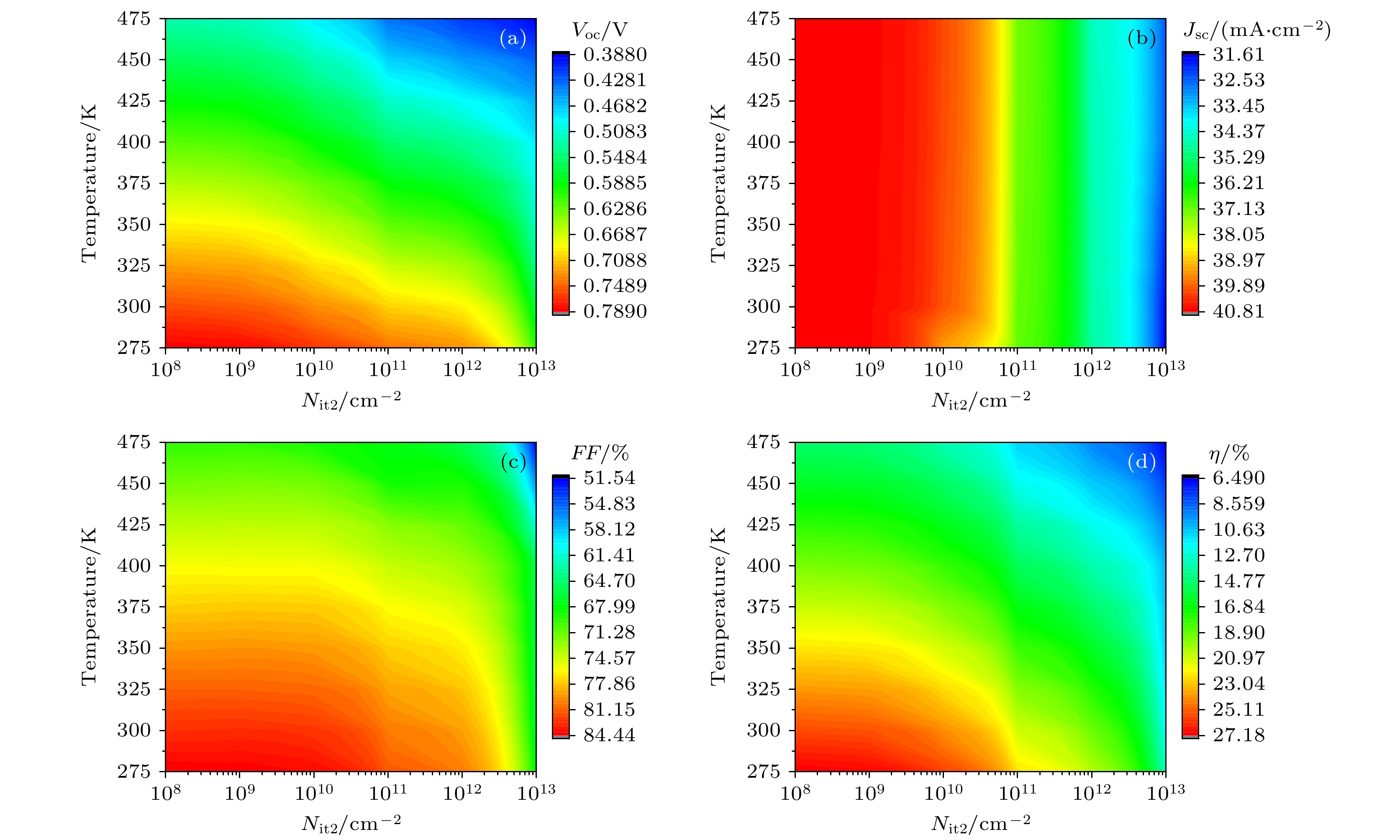

薄膜太阳电池技术中研究的热点之一是寻找能够替代碲化镉和铜铟镓硒的吸收层材料, 近来具有优异材料和光电特性的硒化亚锗(germanium selenide, GeSe)进入了科研人员的视野. 影响异质结太阳电池性能的主要是各功能层材料的材料特性和构筑的器件结构以及结构中异质结界面处的界面特性. 本文以GeSe为吸收层, 配备了性能稳定的无机材料TiO2和Cu2O分别作为太阳电池的电子输运层和空穴输运层, 构筑了结构为FTO/TiO2/GeSe/Cu2O/Metal的异质结太阳电池. 选用TiO2和Cu2O作为载流子输运层是因为两者分别与吸收层GeSe形成小的尖峰状的导带带阶和价带带阶, 不会妨碍多子输运的同时能有效抑制界面处载流子的复合. 接着利用wxAMPS软件模拟分析了有关功能层材料参数和异质结界面特性以及工作温度对太阳电池性能参数的影响, 结合实际应用选定相关材料参数, 优化后300 K温度下GeSe异质结太阳电池的开路电压Voc为0.752 V, 短路电流Jsc为40.71 mA·cm–2, 填充因子FF为82.89%, 转换效率η为25.39%. 研究结果表明结构为FTO/TiO2/GeSe/Cu2O/Au的太阳电池有成为高效、低毒和低成本的太阳电池的潜力, 同时模拟分析也为设计和制备异质结太阳电池提供一定借鉴.One of the research hotspots in thin film solar cell technology is to seek the suitable absorber layer materials to replace cadmium telluride and copper indium gallium selenium. Recently, germanium selenide (GeSe) with excellent photoelectric property has entered the field of vision of photovoltaic researchers. The main factors affecting the performance of heterojunction solar cell are the material properties of each functional layer, the device configuration, and the interface characteristics at the heterostructure. In this study, we utilize GeSe as the absorber layer, and assemble it with stable TiO2 as electron transport layer and with Cu2O as hole transport layer, respectively, into a heterojunction solar cell with the FTO/TiO2/GeSe/Cu2O/Metal structure. The TiO2 and Cu2O can form small spike-like conduction band offset and valence band offset with the absorber layer, respectively, which do not hinder majority carrier transport but can effectively suppress carrier recombination at the heterointerface. Subsequently, the wxAMPS software is used to simulate and analyze the effects of functional layer material parameters, heterointerface characteristics, and operating temperature on the performance parameters of the proposed solar cell. Considering the practical application, the relevant material parameters are selected carefully. After being optimized at 300 K, the proposed GeSe heterojunction solar cell can reach an open circuit voltage of 0.752 V, a short circuit current of 40.71 mA·cm–2, a filling factor of 82.89%, and a conversion efficiency of 25.39%. It is anticipated from the results that the GeSe based heterojunction solar cell with a structure of FTO/TiO2/GeSe/Cu2O/Au has the potential to become a high-efficiency, low toxicity, and low-cost photovoltaic device. Simulation analysis also provides some references for designing and preparing the heterojunction solar cells.

-

Keywords:

- germanium selenide /

- TiO2 /

- Cu2O /

- solar cell /

- simulation

[1] Lee T D, Ebong A U 2017 Renewable Sustainable Energy Rev. 70 1286

Google Scholar

Google Scholar

[2] Green M A, Hishikawa Y, Dunlop E D, Levi D H, Hohl-Ebinger J, Ho-Baillie A W Y 2018 Prog. Photovoltaics Res. Appl. 26 427

Google Scholar

Google Scholar

[3] 刘浩, 薛玉明, 乔在祥, 李微, 张超, 尹富红, 冯少君 2015 64 068801

Google Scholar

Google Scholar

Liu H, Xue Y M, Qiao Z X, Li W, Zhang C, Yin F H, Feng S J 2015 Acta Phys. Sin. 64 068801

Google Scholar

Google Scholar

[4] Chen C, Tang J 2020 ACS Energy Lett. 5 2294

Google Scholar

Google Scholar

[5] Yang W, Zhang X, Tilley S D 2021 Chem. Mater. 33 3467

Google Scholar

Google Scholar

[6] Liu S C, Yang Y, Li Z B, Xue D J, Hu J S 2020 Mater. Chem. Front. 4 775

Google Scholar

Google Scholar

[7] Li K, Tang J 2021 Sci. China, Ser. B Chem. 64 1605

Google Scholar

Google Scholar

[8] 闫彬, 薛丁江, 胡劲松 2022 化学学报 80 797

Google Scholar

Google Scholar

Yan B, Xue D J, Hu J S 2022 Acta Chim. Sin. 80 797

Google Scholar

Google Scholar

[9] Zi W, Mu F, Lu X M, Cao Y, Xie Y P, Fang L, Cheng N, Zhao Z Q, Xiao Z Y 2020 Sol. Energy 199 837

Google Scholar

Google Scholar

[10] Xu D J, Liu S C, Dai C M, Chen S Y, He C, Zhao L, Hu J S, Wan L J 2017 J. Am. Chem. Soc. 139 958

Google Scholar

Google Scholar

[11] Chen B W, Chen G L, Wang W H, Cai H L, Yao L Q, Chen S Y, Huang Z G 2018 Sol. Energy 176 98

Google Scholar

Google Scholar

[12] Chen B W, Ruan Y R, Li J M, Wang W H, Liu X L, Cai H L, Yao L Q, Zhang J M, Chen S Y, Chen G Y, Chen G L 2019 Nanoscale 11 3968

Google Scholar

Google Scholar

[13] Wu J M, Lü Y P, Wu H, Zhang H S, Wang F, Zhang J, Wang J Z, Xu X H 2022 Rare Met. 41 2992

Google Scholar

Google Scholar

[14] Liu S C, Li Z B, Wu J P, Zhang X, Feng M J, Xue D J, Hu J S 2021 Sci. China Mater. 64 2118

Google Scholar

Google Scholar

[15] Liu S C, Dai C M, Min Y M, Hou Y, Proppe A H, Zhou Y, Chen C, Chen S Y, Tang J, Xue D J, Sargent E H, Hu J S 2021 Nat. Commun. 12 670

Google Scholar

Google Scholar

[16] 肖友鹏, 高超, 王涛, 周浪 2017 66 158801

Google Scholar

Google Scholar

Xiao Y P, Gao C, Wang T, Zhou L 2017 Acta Phys. Sin. 66 158801

Google Scholar

Google Scholar

[17] 曹宇, 祝新运, 陈瀚博, 王长刚, 张鑫童, 候秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X Y, Chen H B, Wang C G, Zhang X T, Hou B D, Shen M R, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[18] 肖友鹏, 王怀平, 李刚龙 2021 70 018801

Google Scholar

Google Scholar

Xiao Y P, Wang H P, Li G L 2021 Acta Phys. Sin. 70 018801

Google Scholar

Google Scholar

[19] 肖友鹏, 王怀平 2022 光学学报 42 2331002

Google Scholar

Google Scholar

Xiao Y P, Wang H P 2022 Acta Opt. Sin. 42 2331002

Google Scholar

Google Scholar

[20] Gharibshahian I, Orouji A A, Sharbati S 2020 Sol. Energy Mater. Sol. Cells 212 110581

Google Scholar

Google Scholar

[21] Ahmed S R A, Sunny A, Rahman S 2021 Sol. Energy Mater. Sol. Cells 221 110919

Google Scholar

Google Scholar

[22] Huang L K, Sun X X, Li C, Xu R, Xu J, Du Y Y, Wu Y X, Ni J, Cai H K, Li J, Hu Z Y, Zhang J J 2016 Sol. Energy Mater. Sol. Cells 157 1038

Google Scholar

Google Scholar

[23] Rai S, Pandey B K, Dwivedi D K 2020 Opt. Mater. 100 109631

[24] Ahmed A, Riaz K, Mehmood H, Tauqeer T, Ahmad Z 2020 Opt. Mater. 105 109897

Google Scholar

Google Scholar

[25] Liu S C, Mi Y, Xue D J, Chen Y X, He C, Liu X F, Hu J S, Wan L J 2017 Adv. Electron. Mater. 3 1700141

Google Scholar

Google Scholar

[26] Mohammadi M H, Fathi D, Eskandari M 2020 Sol. Energy 204 200

Google Scholar

Google Scholar

[27] Lin L, Jiang L, Li P, Fan B, Qiu Y 2019 J. Phys. Chem. Solids 124 205

Google Scholar

Google Scholar

[28] Raoui Y, Ez-Zahraouy H, Tahiri N, Bounagui O E, Ahmad S, Kazim S 2019 Sol. Energy 193 948

Google Scholar

Google Scholar

[29] Kondrotas R, Chen C, Tang J 2018 Joule 2 857

Google Scholar

Google Scholar

[30] Zhao P, Lin Z, Wang J, Yue M, Su J, Zhang J, Chang J, Hao Y 2019 ACS Appl. Energy Mater. 2 4504

Google Scholar

Google Scholar

[31] Ali M H, Mamun M A A, Haque M D, Rahman M F, Hossain M K, Islam A Z M T 2023 ACS Omega 8 7017

Google Scholar

Google Scholar

[32] Sze S M, Ng K K 2007 Physics of Semiconductor Devices (3rd Ed.) (New York: John Wliey & Sons) p264

-

表 1 模拟使用的主要材料参数

Table 1. Simulation parameters for GeSe based solar cell in this study.

参数 FTO TiO2 GeSe Cu2O 厚度/µm 0.5[22] Variable Variable Variable 相对介电常数 εr 9[22,23] 10[24] 15.3[8,25] 7.11[27] 禁带宽度 Eg/eV 3.5[22,23] 3.2[23,24] 1.14[8,12,25] 2.17[27,28] 电子亲和能 χ/eV 4[22,23] 3.9[23,24] 4.07[13] 3.2[27,28] 导带有效态密度 Nc/(1017 cm–3) 22.0[22] 220.0[24] 40.0[26] 2.0[27] 价带有效态密度 Nv/(1019 cm–3) 1.8[22] 1.8[24] 1.75[26] 1.1[27] 施主载流子浓度 ND/(1019 cm–3) 2[22] Variable 0 0 受主载流子浓度 NA/cm–3 0 0 Variable Variable 电子迁移率 µn/(cm2·V–1·s–1) 20[22,23] 20[23] 11.2[8,25] 200[27] 空穴迁移率 µp/(cm2·V–1·s–1) 10[22,23] 10[23] 12.7[8,25] 80[27] 缺陷密度 Nt/(1015 cm–3) 1[22,23] 1[23,24] Variable 1[27] 表 2 不同背接触功函数GeSe基太阳电池的性能参数

Table 2. Photovoltaic performance parameters of the GeSe based solar cell with different back contact work function.

Voc/V Jsc (mA·cm–2) FF/% η/% 4.5 eV 0.599 40.63 47.96 11.67 4.6 eV 0.697 40.66 55.45 15.70 4.7 eV 0.751 40.68 63.52 19.42 4.8 eV 0.755 40.70 74.73 22.96 4.9 eV 0.753 40.70 82.11 25.16 5.0 eV 0.752 40.71 82.88 25.38 5.1 eV 0.752 40.71 82.89 25.39 5.2 eV 0.752 40.71 82.89 25.39 表 3 模拟所得优化材料和异质结界面参数

Table 3. Optimized values of the different material parameters and heterointerface properties.

参数 TiO2 GeSe Cu2O Nit1 Nit2 Au 厚度/μm 0.05 0.4 0.05 载流子浓度/cm–3 1018 1017 1018 体缺陷密度/cm–3 1015 1015 1015 界面态密度/cm–2 109 109 背接触功函数/eV 5.1 -

[1] Lee T D, Ebong A U 2017 Renewable Sustainable Energy Rev. 70 1286

Google Scholar

Google Scholar

[2] Green M A, Hishikawa Y, Dunlop E D, Levi D H, Hohl-Ebinger J, Ho-Baillie A W Y 2018 Prog. Photovoltaics Res. Appl. 26 427

Google Scholar

Google Scholar

[3] 刘浩, 薛玉明, 乔在祥, 李微, 张超, 尹富红, 冯少君 2015 64 068801

Google Scholar

Google Scholar

Liu H, Xue Y M, Qiao Z X, Li W, Zhang C, Yin F H, Feng S J 2015 Acta Phys. Sin. 64 068801

Google Scholar

Google Scholar

[4] Chen C, Tang J 2020 ACS Energy Lett. 5 2294

Google Scholar

Google Scholar

[5] Yang W, Zhang X, Tilley S D 2021 Chem. Mater. 33 3467

Google Scholar

Google Scholar

[6] Liu S C, Yang Y, Li Z B, Xue D J, Hu J S 2020 Mater. Chem. Front. 4 775

Google Scholar

Google Scholar

[7] Li K, Tang J 2021 Sci. China, Ser. B Chem. 64 1605

Google Scholar

Google Scholar

[8] 闫彬, 薛丁江, 胡劲松 2022 化学学报 80 797

Google Scholar

Google Scholar

Yan B, Xue D J, Hu J S 2022 Acta Chim. Sin. 80 797

Google Scholar

Google Scholar

[9] Zi W, Mu F, Lu X M, Cao Y, Xie Y P, Fang L, Cheng N, Zhao Z Q, Xiao Z Y 2020 Sol. Energy 199 837

Google Scholar

Google Scholar

[10] Xu D J, Liu S C, Dai C M, Chen S Y, He C, Zhao L, Hu J S, Wan L J 2017 J. Am. Chem. Soc. 139 958

Google Scholar

Google Scholar

[11] Chen B W, Chen G L, Wang W H, Cai H L, Yao L Q, Chen S Y, Huang Z G 2018 Sol. Energy 176 98

Google Scholar

Google Scholar

[12] Chen B W, Ruan Y R, Li J M, Wang W H, Liu X L, Cai H L, Yao L Q, Zhang J M, Chen S Y, Chen G Y, Chen G L 2019 Nanoscale 11 3968

Google Scholar

Google Scholar

[13] Wu J M, Lü Y P, Wu H, Zhang H S, Wang F, Zhang J, Wang J Z, Xu X H 2022 Rare Met. 41 2992

Google Scholar

Google Scholar

[14] Liu S C, Li Z B, Wu J P, Zhang X, Feng M J, Xue D J, Hu J S 2021 Sci. China Mater. 64 2118

Google Scholar

Google Scholar

[15] Liu S C, Dai C M, Min Y M, Hou Y, Proppe A H, Zhou Y, Chen C, Chen S Y, Tang J, Xue D J, Sargent E H, Hu J S 2021 Nat. Commun. 12 670

Google Scholar

Google Scholar

[16] 肖友鹏, 高超, 王涛, 周浪 2017 66 158801

Google Scholar

Google Scholar

Xiao Y P, Gao C, Wang T, Zhou L 2017 Acta Phys. Sin. 66 158801

Google Scholar

Google Scholar

[17] 曹宇, 祝新运, 陈瀚博, 王长刚, 张鑫童, 候秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X Y, Chen H B, Wang C G, Zhang X T, Hou B D, Shen M R, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[18] 肖友鹏, 王怀平, 李刚龙 2021 70 018801

Google Scholar

Google Scholar

Xiao Y P, Wang H P, Li G L 2021 Acta Phys. Sin. 70 018801

Google Scholar

Google Scholar

[19] 肖友鹏, 王怀平 2022 光学学报 42 2331002

Google Scholar

Google Scholar

Xiao Y P, Wang H P 2022 Acta Opt. Sin. 42 2331002

Google Scholar

Google Scholar

[20] Gharibshahian I, Orouji A A, Sharbati S 2020 Sol. Energy Mater. Sol. Cells 212 110581

Google Scholar

Google Scholar

[21] Ahmed S R A, Sunny A, Rahman S 2021 Sol. Energy Mater. Sol. Cells 221 110919

Google Scholar

Google Scholar

[22] Huang L K, Sun X X, Li C, Xu R, Xu J, Du Y Y, Wu Y X, Ni J, Cai H K, Li J, Hu Z Y, Zhang J J 2016 Sol. Energy Mater. Sol. Cells 157 1038

Google Scholar

Google Scholar

[23] Rai S, Pandey B K, Dwivedi D K 2020 Opt. Mater. 100 109631

[24] Ahmed A, Riaz K, Mehmood H, Tauqeer T, Ahmad Z 2020 Opt. Mater. 105 109897

Google Scholar

Google Scholar

[25] Liu S C, Mi Y, Xue D J, Chen Y X, He C, Liu X F, Hu J S, Wan L J 2017 Adv. Electron. Mater. 3 1700141

Google Scholar

Google Scholar

[26] Mohammadi M H, Fathi D, Eskandari M 2020 Sol. Energy 204 200

Google Scholar

Google Scholar

[27] Lin L, Jiang L, Li P, Fan B, Qiu Y 2019 J. Phys. Chem. Solids 124 205

Google Scholar

Google Scholar

[28] Raoui Y, Ez-Zahraouy H, Tahiri N, Bounagui O E, Ahmad S, Kazim S 2019 Sol. Energy 193 948

Google Scholar

Google Scholar

[29] Kondrotas R, Chen C, Tang J 2018 Joule 2 857

Google Scholar

Google Scholar

[30] Zhao P, Lin Z, Wang J, Yue M, Su J, Zhang J, Chang J, Hao Y 2019 ACS Appl. Energy Mater. 2 4504

Google Scholar

Google Scholar

[31] Ali M H, Mamun M A A, Haque M D, Rahman M F, Hossain M K, Islam A Z M T 2023 ACS Omega 8 7017

Google Scholar

Google Scholar

[32] Sze S M, Ng K K 2007 Physics of Semiconductor Devices (3rd Ed.) (New York: John Wliey & Sons) p264

计量

- 文章访问数: 3680

- PDF下载量: 82

- 被引次数: 0

下载:

下载: