-

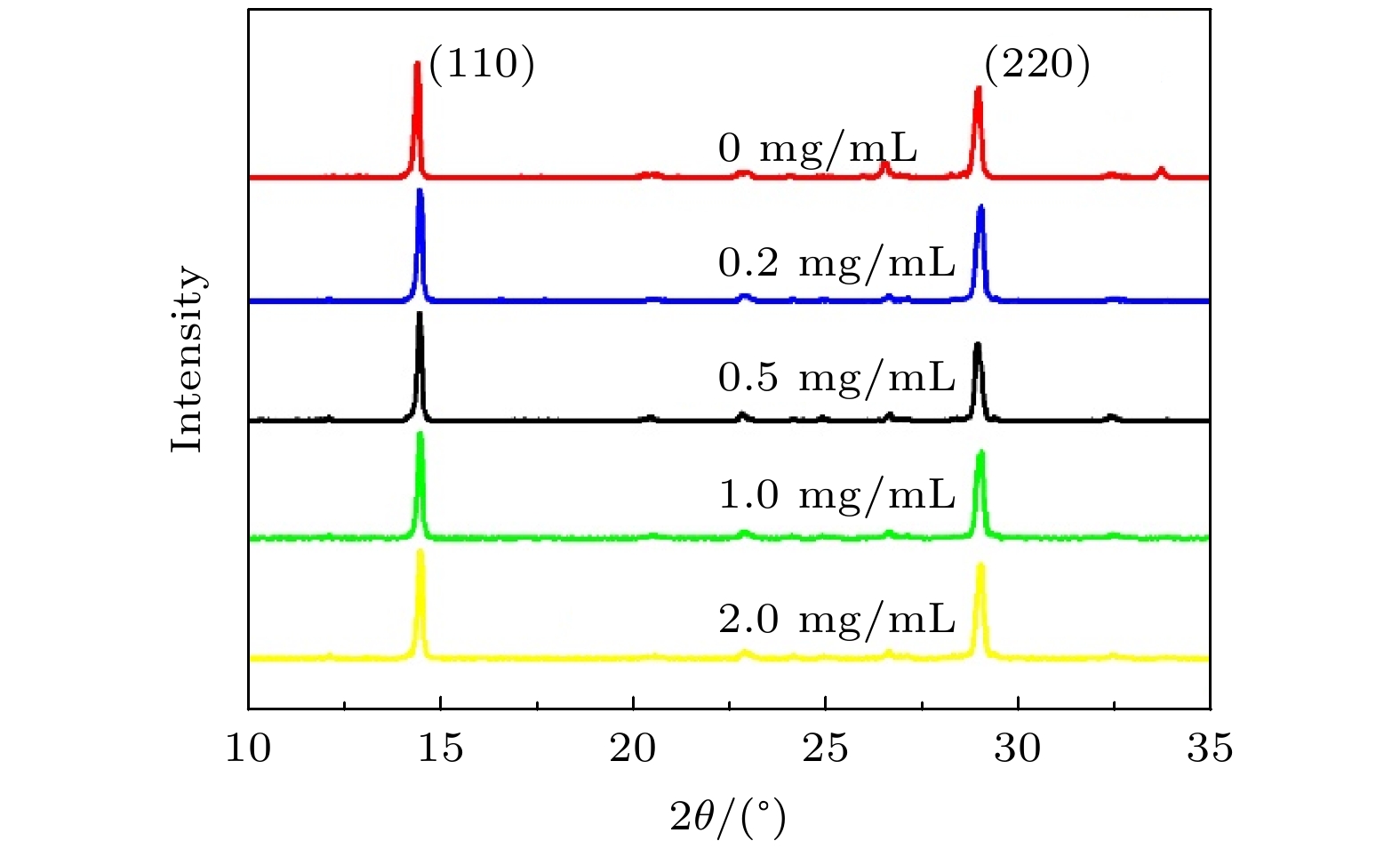

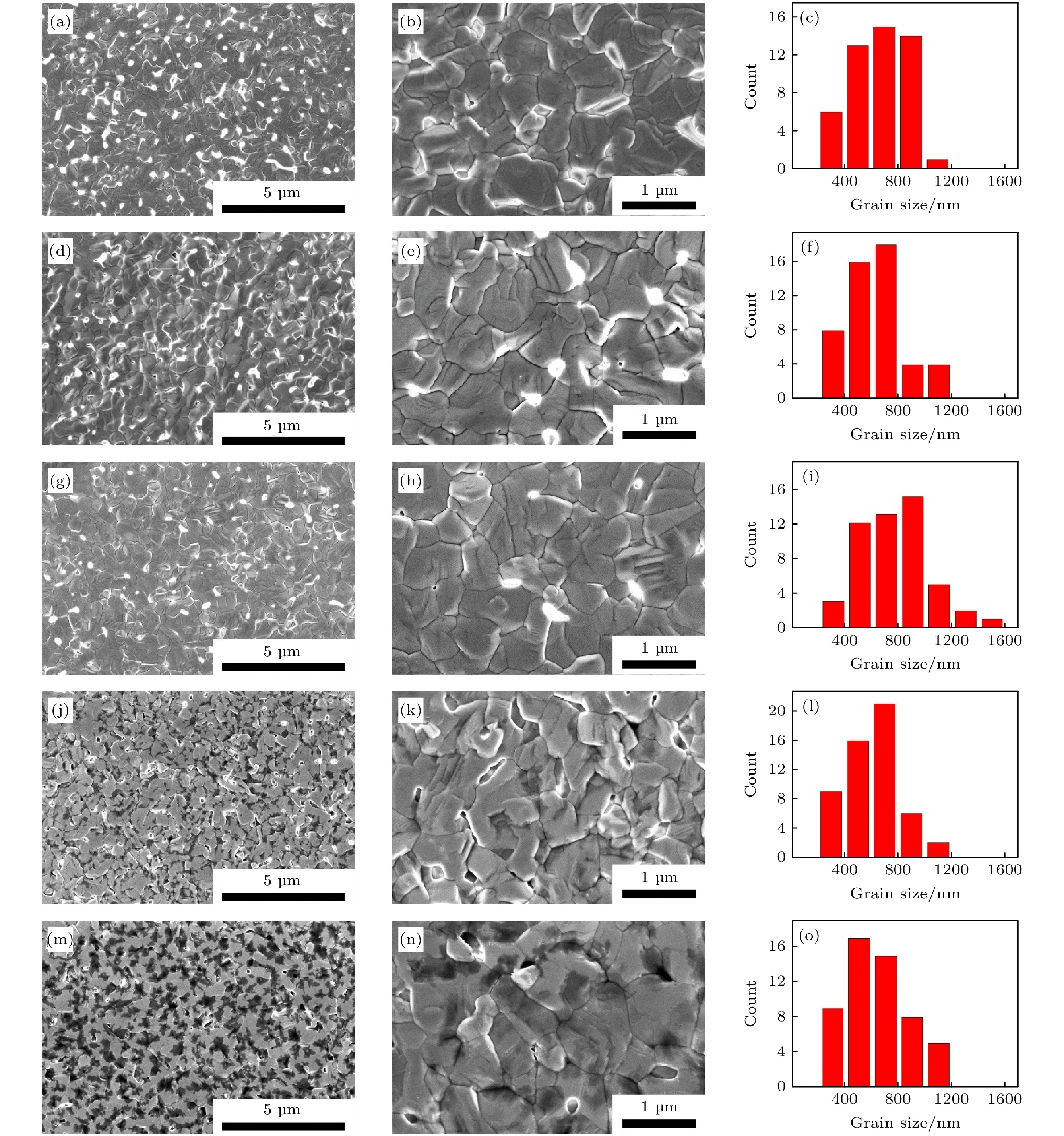

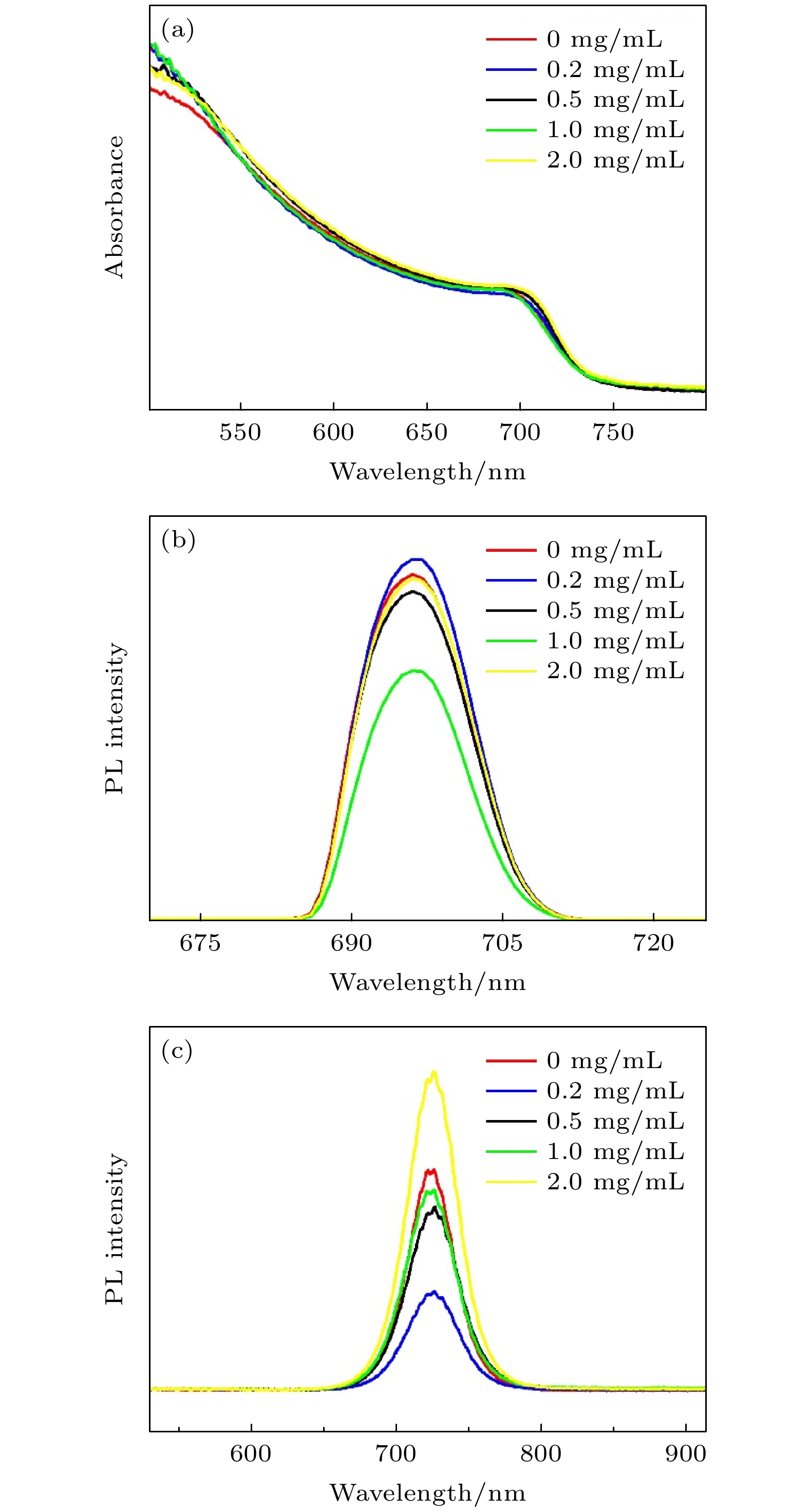

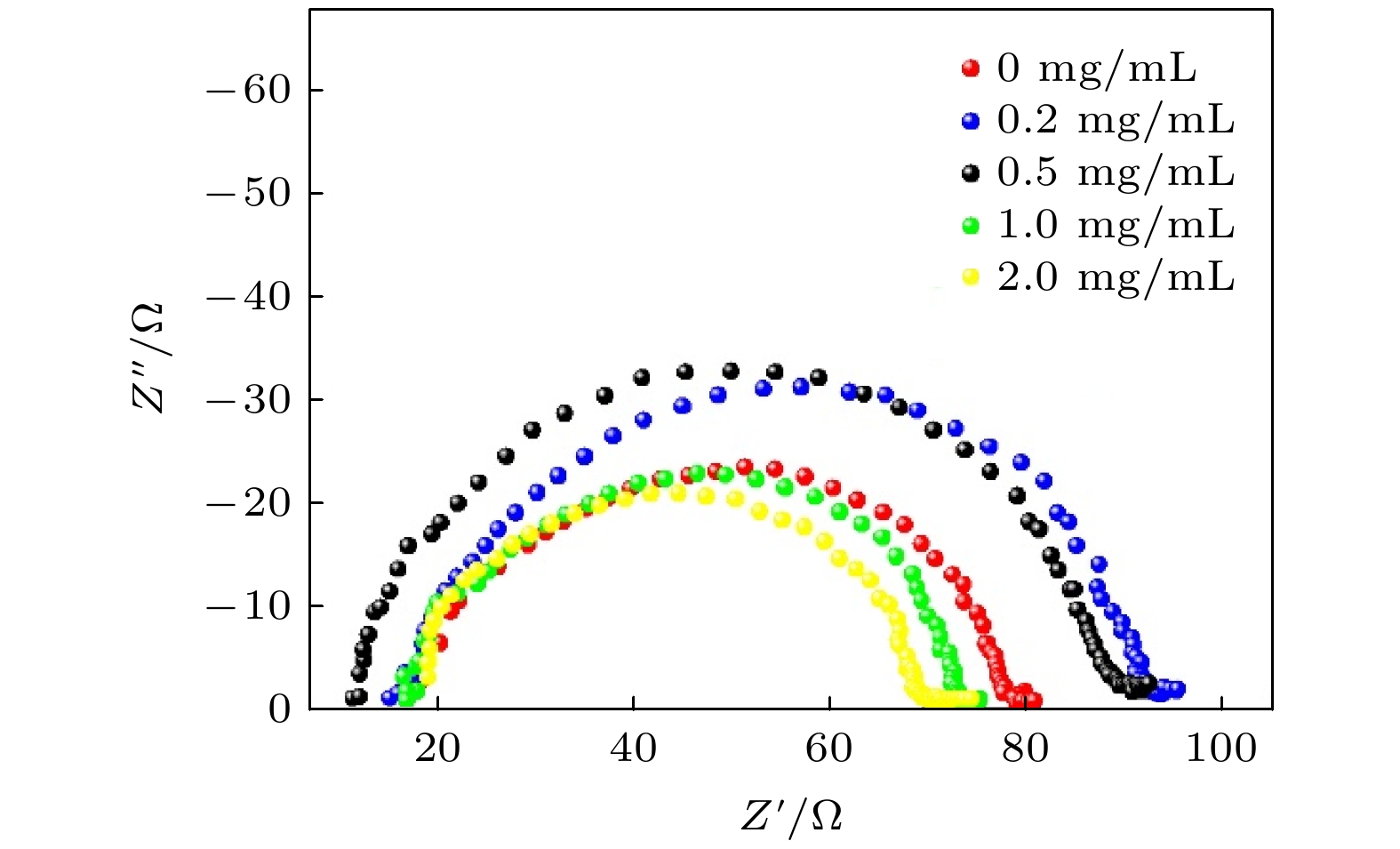

基于铯铅碘(CsPbI3)材料的全无机钙钛矿太阳电池是一种廉价且有潜力的光伏器件, 然而该电池的转换效率仍然较低, 研究结果表明钝化CsPbI3薄膜的表面电子陷阱态可有效提高电池性能. 本文报道了一种新型廉价2-溴对苯二甲酸钝化材料对CsPbI3钙钛矿太阳电池性能的影响, 研究结果表明, 随着2-溴对苯二甲酸浓度的增加, 钙钛矿太阳电池的光电转换效率先增加后减少, 当钝化材料的浓度达到0.2 mg/mL时, CsPbI3电池获得最优转换效率13.5%. 通过对2-溴对苯二甲酸钝化后的钙钛矿薄膜进行相结构和微结构分析, 结果表明钝化并未引起钙钛矿薄膜的物相和微结构的变化, 但表面钝化显著提高了CsPbI3薄膜的荧光发射强度和TiO2/CsPbI3界面的电子传输能力. 本研究有望为钙钛矿太阳电池中应用的钝化材料的低成本开发提供基础依据.

-

关键词:

- 全无机钙钛矿太阳电池 /

- 钝化 /

- 高效率 /

- 2-溴对苯二甲酸

All-inorganic perovskite cesium lead iodine (CsPbI3) without any volatile organic components has attracted much attention due to its superior stability, high absorption efficiency and suitable band gap. However, the power-conversion efficiencies of CsPbI3 based perovskite solar cells (PSCs) are substantially low compared with those of the organic-inorganic hybrid lead halide PSCs. The surface passivation of the CsPbI3 film by long-chain halide salts has been found to be an effective method of improving the performance. In this paper, we report the concentration effect of an inexpensive 2-bromoterephthalic acid (BBr) as passivation material on the performance of CsPbI3 perovskite solar cells. The experimental results show that the conversion efficiency of perovskite solar cells first increases and then decreases as the concentration of BBr increases from 0 to 2 mg/mL. The best conversion efficiency of CsPbI3 perovskite solar cells reaches 13.5% at 0.2 mg/mL BBr. The results from X-ray diffraction and scanning electron microscopy suggest that there is no change in the phase or microstructure of the CsPbI3 perovskite film after surface passivation by BBr. By further analyzing the photoluminescence data of the CsPbI3 film with and without capping hole transport layer, it can be found that the passivation of BBr with the concentration of 0.2 mg/mL can enhance the fluorescence excitation intensity of the CsPbI3 film and accelerate the exciton separation at the interface between CsPbI3 film and hole transport layer. Based on the electrochemical impedance spectroscopy data, we find that the electron transport ability at the interface between TiO2 and CsPbI3 can be significantly improved after surface passivation, which is induced by the acceleration of the exciton separation at the interface between CsPbI3 film and hole transport layer. The decrease of the PSCs performance when the concentration of the BBr precursor increases from 0.5 mg/mL to 2 mg/mL can be attributed to the local agglomeration of the BBr material, resulting in the block of charge transportation. This research is expected to provide basic support for the low-cost development of the passivation materials for perovskite solar cells.-

Keywords:

- inorganic perovskite solar cells /

- passivation /

- high efficiency /

- 2-bromoterephthalic acid

[1] Kim H S, Lee C R, Im J H, Lee K B, Moehl T, Marchioro A, Moon S J, Humphry B R, Yum J H, Moser J E, Grätzel M, Park N G 2012 Sci. Rep. 2 591

Google Scholar

Google Scholar

[2] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[3] Liu M Z, Johnston M B, Snaith H J 2013 Nature 501 395

Google Scholar

Google Scholar

[4] Yang W S, Park B W, Jung E H, Jeon N J, Kim Y C, Lee D U, Shin S S, Seo J W, Kim E K, Noh J H, Seok S I 2017 Science 356 1376

Google Scholar

Google Scholar

[5] Leijtens T, Eperon G E, Noel N K, Habisreutinger S N, Petrozza A, Snaith H J 2015 Adv. Energy Mater. 5 1500963

Google Scholar

Google Scholar

[6] Li X M, Cao F, Yu D, Chen J, Sun Z, Shen Y L, Zhu Y, Wang L, Wei Y, Wu Y, Zeng H B 2017 Small 13 1603996

Google Scholar

Google Scholar

[7] Liang J, Wang C X, Wang Y R, Xu Z R, Lu Z P, M Y, Zhu H F, Hu Y, Xiao C C, Yi X, Zhu G Y, Lv H L, Ma L B, Chen T, Tie Z X, Jin Z, Liu J 2016 J. Am. Chem. Soc. 138 15829

Google Scholar

Google Scholar

[8] Pan W C, Wu H D, Luo J J, Deng Z Z, Ge C, Chen C, Jiang X W, Yin W J, Niu G D, Zhu L J, Yin L X, Zhou Y, Xie Q G, Ke X X, Sui M L, Tang J 2017 Nat. Photonics 11 726

Google Scholar

Google Scholar

[9] Zhao X G, Yang D W, Sun Y H, Li T S, Zhang L J, Yu L P, Zunger A 2017 J. Am. Chem. Soc. 139 6718

Google Scholar

Google Scholar

[10] Choi H S, Jeong J K, Kim H B, Kim S B, Walker B, Kim G H, Kim J Y 2014 Nano Energy 7 80

Google Scholar

Google Scholar

[11] Eperon G E, Paternò G M, Sutton R J, Zampetti A, Haghighirad A A, Cacialli F, Snaith H J 2015 J. Mater. Chem. A 3 19688

Google Scholar

Google Scholar

[12] Swarnkar A, Marshall A R, Sanehira E M, Chernomordik B D, Moore D T, Christians J A, Chakrabarti T, Luther J M 2016 Science 354 92

Google Scholar

Google Scholar

[13] Li Y F, Zhang C H, Zhang, X X, Huang D, Shen Q, Cheng Y C, Huang W 2017 Appl. Phys. Lett. 111 162106

Google Scholar

Google Scholar

[14] Long L X, Cao D, Fei J P, Wang J F, Zhou Y, Jiang Z T, Jiao Z W, Shu H B 2019 Chem. Phys. Lett. 734 136719

Google Scholar

Google Scholar

[15] Zeng Q S, Zhang X Y, Feng X L, Lu S Y, Chen Z, Yong X, Redfern S A T, Wei H T, Wang H Z, Shen H Z, Zhang W, Zheng W T, Zhang H, Tse J S, Yang B 2018 Adv. Mater. 30 1705393

Google Scholar

Google Scholar

[16] Yang Y Q, Wu J H, Wang X B, Guo Q Y, Liu X P, Sun W H, Wei Y L, Huang Y F, Lan Z, Huang M L, L in, J M, Chen H W, Wei Z H 2020 Adv. Mater. 32 1904347

Google Scholar

Google Scholar

[17] Wu M, Yan K Y, Wang Y, Kang X W 2020 J. Energy Chem. 48 181

Google Scholar

Google Scholar

[18] Wang Y, Liu X M, Zhang T Y, Wang X T, Kan M, Shi J L, Zhao Y X 2019 Angew. Chem. Int. Ed. 58 16691

Google Scholar

Google Scholar

[19] Sim K M, Abhishek S, Angshuman N, Chung D S 2018 Laser Photonics Rev. 12 1700209

Google Scholar

Google Scholar

[20] Wang Y, Zhang T Y, Kan M, Li Y H, Wang T, Zhao Y X 2018 Joule 2 2065

Google Scholar

Google Scholar

[21] Ding X, Cai M, Liu X, Ding Y, Liu X, Wu Y, Hayat T, Alsaedi A, Dai S 2019 ACS Appl. Mater. Interfaces 11 37720

Google Scholar

Google Scholar

[22] Ye Q F, Zhao Y, Mu S Q, Ma F, You J B 2019 Adv. Mater. 31 1905143

Google Scholar

Google Scholar

[23] Wang Y, Zhang T, Kan M, Zhao Y 2018 J. Am. Chem. Soc. 140 12345

Google Scholar

Google Scholar

[24] Li Y, Ding B, Chu Q Q, Yang G J, Wang M, Li C X, Li C J 2017 Sci. Rep. 7 46141

Google Scholar

Google Scholar

-

图 5 BBr钝化后CsPbI3薄膜的表面形貌表征结果和晶粒尺寸统计结果, 其中前驱体浓度分别为 (a)−(c) 0 mg/mL, (d)−(f) 0.2 mg/mL, (g)−(i) 0.5 mg/mL, (j)−(l) 1.0 mg/mL, (m)−(o) 2.0 mg/mL

Fig. 5. SEM images and grain size of CsPbI3 films after BBr passivation with different precursor concentrations: (a)−(c) 0 mg/mL; (d)−(f) 0.2 mg/mL; (g)−(i) 0.5 mg/mL; (j)−(l) 1.0 mg/mL; (m)−(o) 2.0 mg/mL

表 1 代表性光电特性曲线的具体光伏参数

Table 1. Photovoltaic parameters of representative characteristic curves.

电池类型/

(mg·mL–1)Voc/V Jsc/(mA·cm–2) FF/% PCE/% 0 0.999 16.85 76.69 12.91 0.2 1.015 17.02 78.14 13.50 0.5 0.924 16.90 75.32 11.77 1.0 0.910 16.78 73.01 11.15 2.0 0.918 16.69 68.89 10.55 -

[1] Kim H S, Lee C R, Im J H, Lee K B, Moehl T, Marchioro A, Moon S J, Humphry B R, Yum J H, Moser J E, Grätzel M, Park N G 2012 Sci. Rep. 2 591

Google Scholar

Google Scholar

[2] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[3] Liu M Z, Johnston M B, Snaith H J 2013 Nature 501 395

Google Scholar

Google Scholar

[4] Yang W S, Park B W, Jung E H, Jeon N J, Kim Y C, Lee D U, Shin S S, Seo J W, Kim E K, Noh J H, Seok S I 2017 Science 356 1376

Google Scholar

Google Scholar

[5] Leijtens T, Eperon G E, Noel N K, Habisreutinger S N, Petrozza A, Snaith H J 2015 Adv. Energy Mater. 5 1500963

Google Scholar

Google Scholar

[6] Li X M, Cao F, Yu D, Chen J, Sun Z, Shen Y L, Zhu Y, Wang L, Wei Y, Wu Y, Zeng H B 2017 Small 13 1603996

Google Scholar

Google Scholar

[7] Liang J, Wang C X, Wang Y R, Xu Z R, Lu Z P, M Y, Zhu H F, Hu Y, Xiao C C, Yi X, Zhu G Y, Lv H L, Ma L B, Chen T, Tie Z X, Jin Z, Liu J 2016 J. Am. Chem. Soc. 138 15829

Google Scholar

Google Scholar

[8] Pan W C, Wu H D, Luo J J, Deng Z Z, Ge C, Chen C, Jiang X W, Yin W J, Niu G D, Zhu L J, Yin L X, Zhou Y, Xie Q G, Ke X X, Sui M L, Tang J 2017 Nat. Photonics 11 726

Google Scholar

Google Scholar

[9] Zhao X G, Yang D W, Sun Y H, Li T S, Zhang L J, Yu L P, Zunger A 2017 J. Am. Chem. Soc. 139 6718

Google Scholar

Google Scholar

[10] Choi H S, Jeong J K, Kim H B, Kim S B, Walker B, Kim G H, Kim J Y 2014 Nano Energy 7 80

Google Scholar

Google Scholar

[11] Eperon G E, Paternò G M, Sutton R J, Zampetti A, Haghighirad A A, Cacialli F, Snaith H J 2015 J. Mater. Chem. A 3 19688

Google Scholar

Google Scholar

[12] Swarnkar A, Marshall A R, Sanehira E M, Chernomordik B D, Moore D T, Christians J A, Chakrabarti T, Luther J M 2016 Science 354 92

Google Scholar

Google Scholar

[13] Li Y F, Zhang C H, Zhang, X X, Huang D, Shen Q, Cheng Y C, Huang W 2017 Appl. Phys. Lett. 111 162106

Google Scholar

Google Scholar

[14] Long L X, Cao D, Fei J P, Wang J F, Zhou Y, Jiang Z T, Jiao Z W, Shu H B 2019 Chem. Phys. Lett. 734 136719

Google Scholar

Google Scholar

[15] Zeng Q S, Zhang X Y, Feng X L, Lu S Y, Chen Z, Yong X, Redfern S A T, Wei H T, Wang H Z, Shen H Z, Zhang W, Zheng W T, Zhang H, Tse J S, Yang B 2018 Adv. Mater. 30 1705393

Google Scholar

Google Scholar

[16] Yang Y Q, Wu J H, Wang X B, Guo Q Y, Liu X P, Sun W H, Wei Y L, Huang Y F, Lan Z, Huang M L, L in, J M, Chen H W, Wei Z H 2020 Adv. Mater. 32 1904347

Google Scholar

Google Scholar

[17] Wu M, Yan K Y, Wang Y, Kang X W 2020 J. Energy Chem. 48 181

Google Scholar

Google Scholar

[18] Wang Y, Liu X M, Zhang T Y, Wang X T, Kan M, Shi J L, Zhao Y X 2019 Angew. Chem. Int. Ed. 58 16691

Google Scholar

Google Scholar

[19] Sim K M, Abhishek S, Angshuman N, Chung D S 2018 Laser Photonics Rev. 12 1700209

Google Scholar

Google Scholar

[20] Wang Y, Zhang T Y, Kan M, Li Y H, Wang T, Zhao Y X 2018 Joule 2 2065

Google Scholar

Google Scholar

[21] Ding X, Cai M, Liu X, Ding Y, Liu X, Wu Y, Hayat T, Alsaedi A, Dai S 2019 ACS Appl. Mater. Interfaces 11 37720

Google Scholar

Google Scholar

[22] Ye Q F, Zhao Y, Mu S Q, Ma F, You J B 2019 Adv. Mater. 31 1905143

Google Scholar

Google Scholar

[23] Wang Y, Zhang T, Kan M, Zhao Y 2018 J. Am. Chem. Soc. 140 12345

Google Scholar

Google Scholar

[24] Li Y, Ding B, Chu Q Q, Yang G J, Wang M, Li C X, Li C J 2017 Sci. Rep. 7 46141

Google Scholar

Google Scholar

计量

- 文章访问数: 5722

- PDF下载量: 79

- 被引次数: 0

下载:

下载: