-

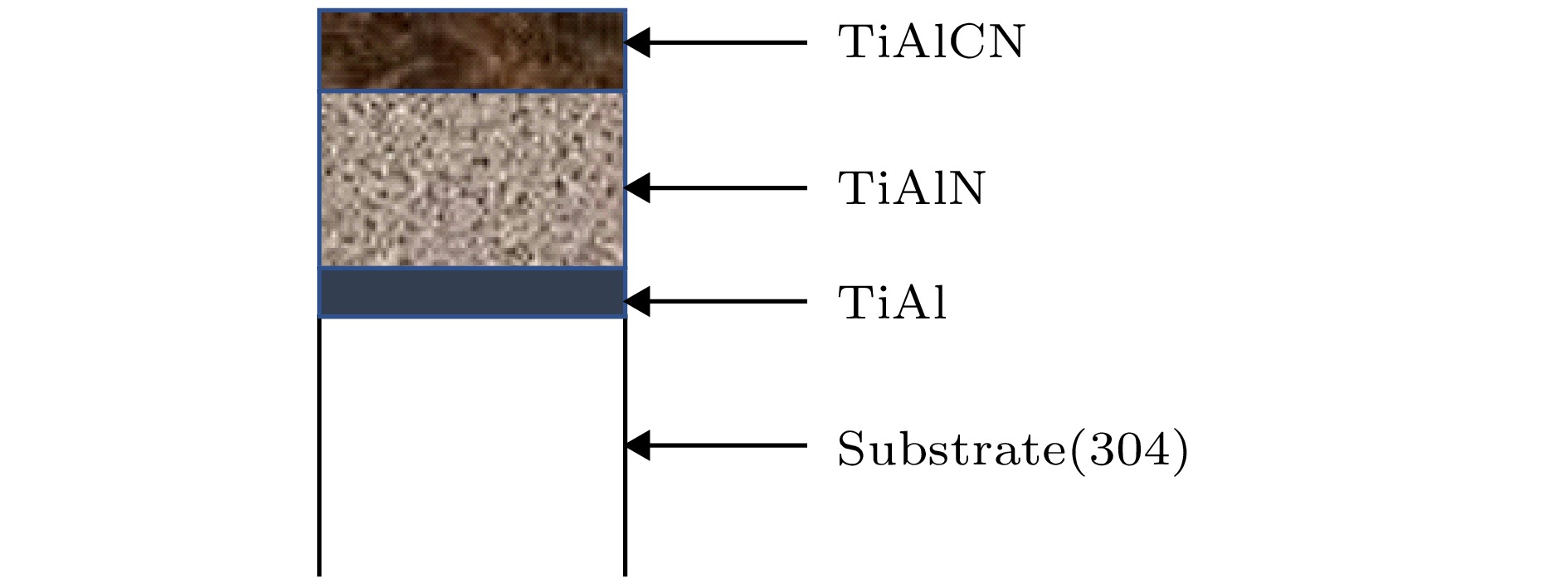

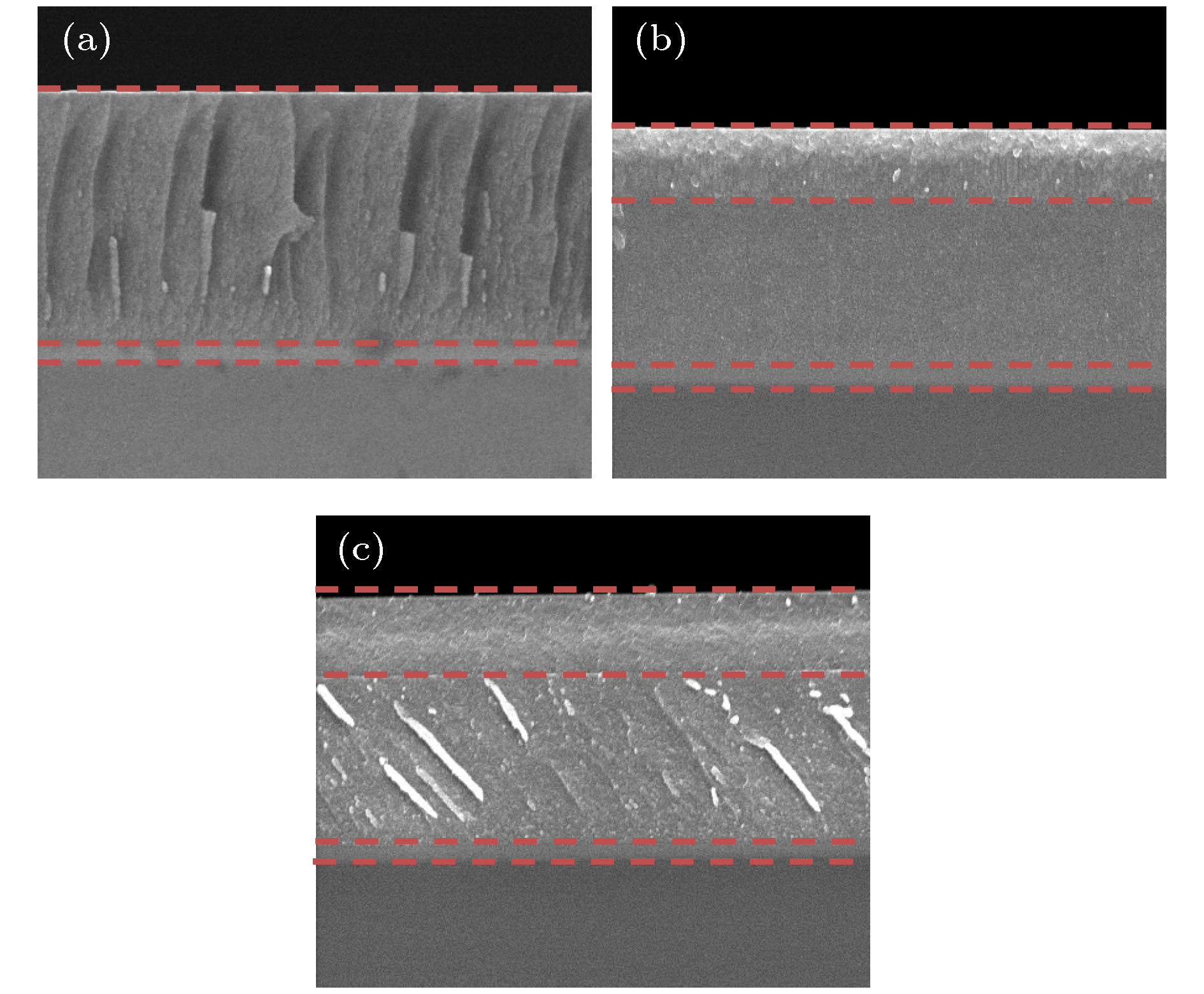

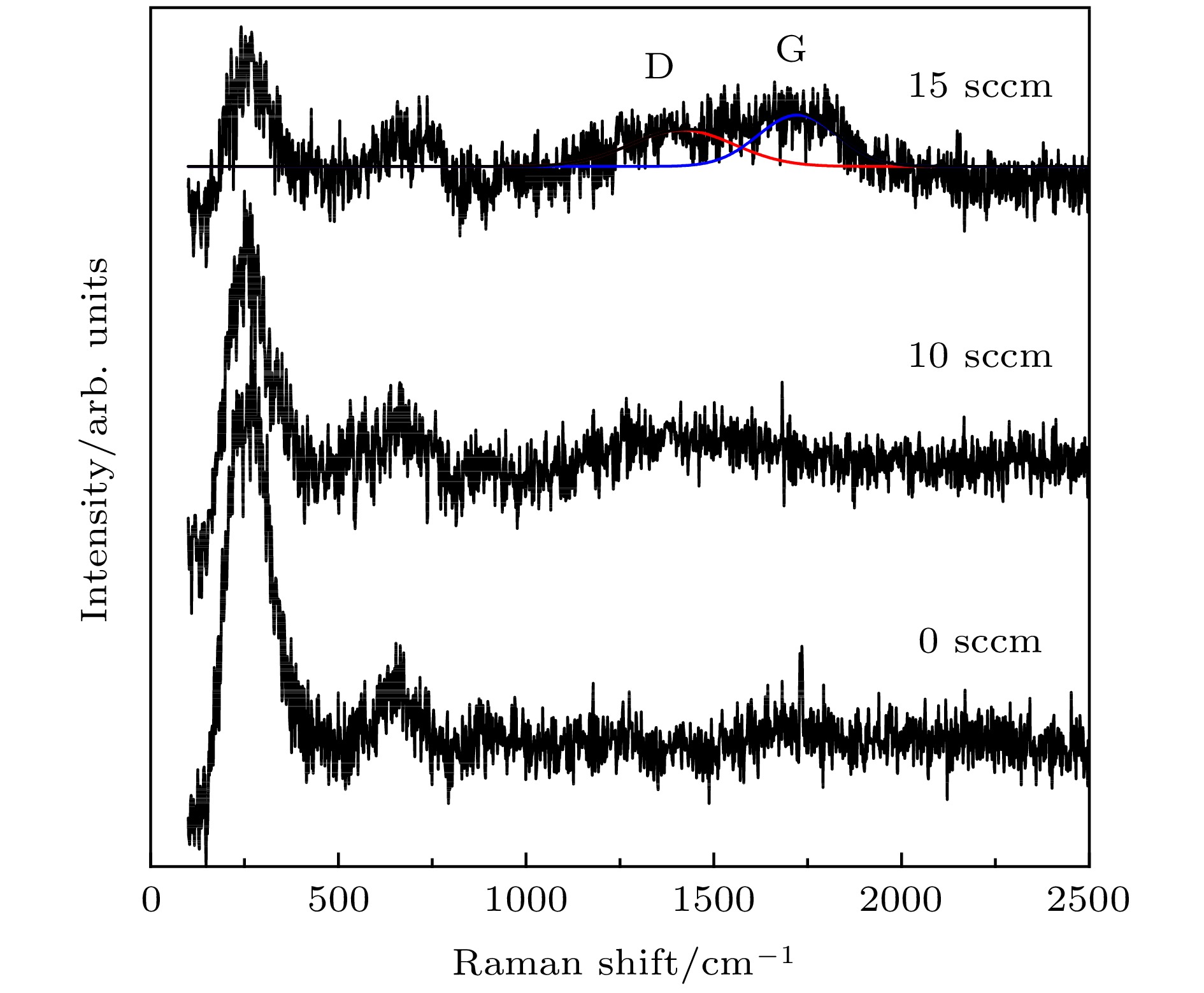

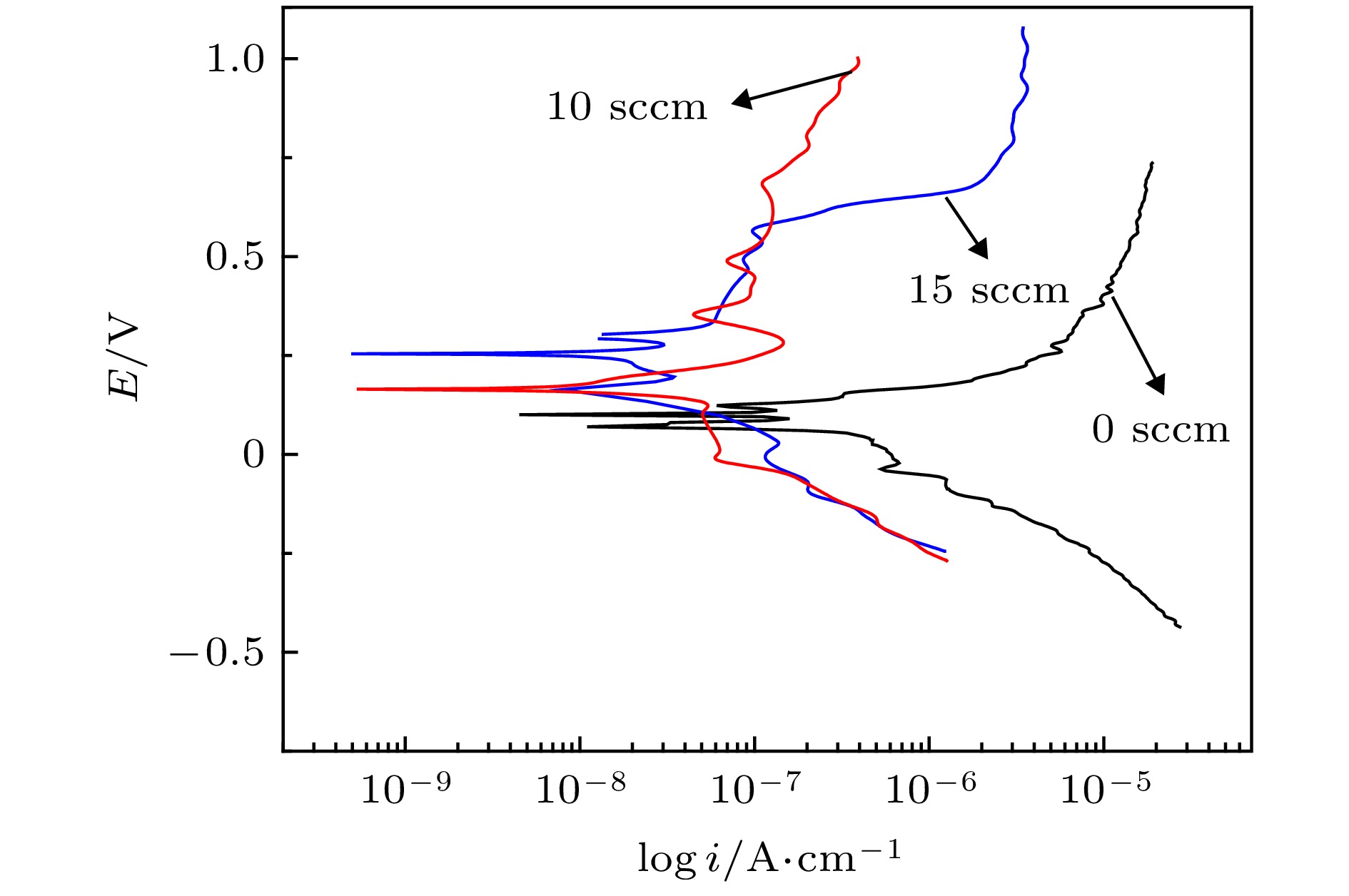

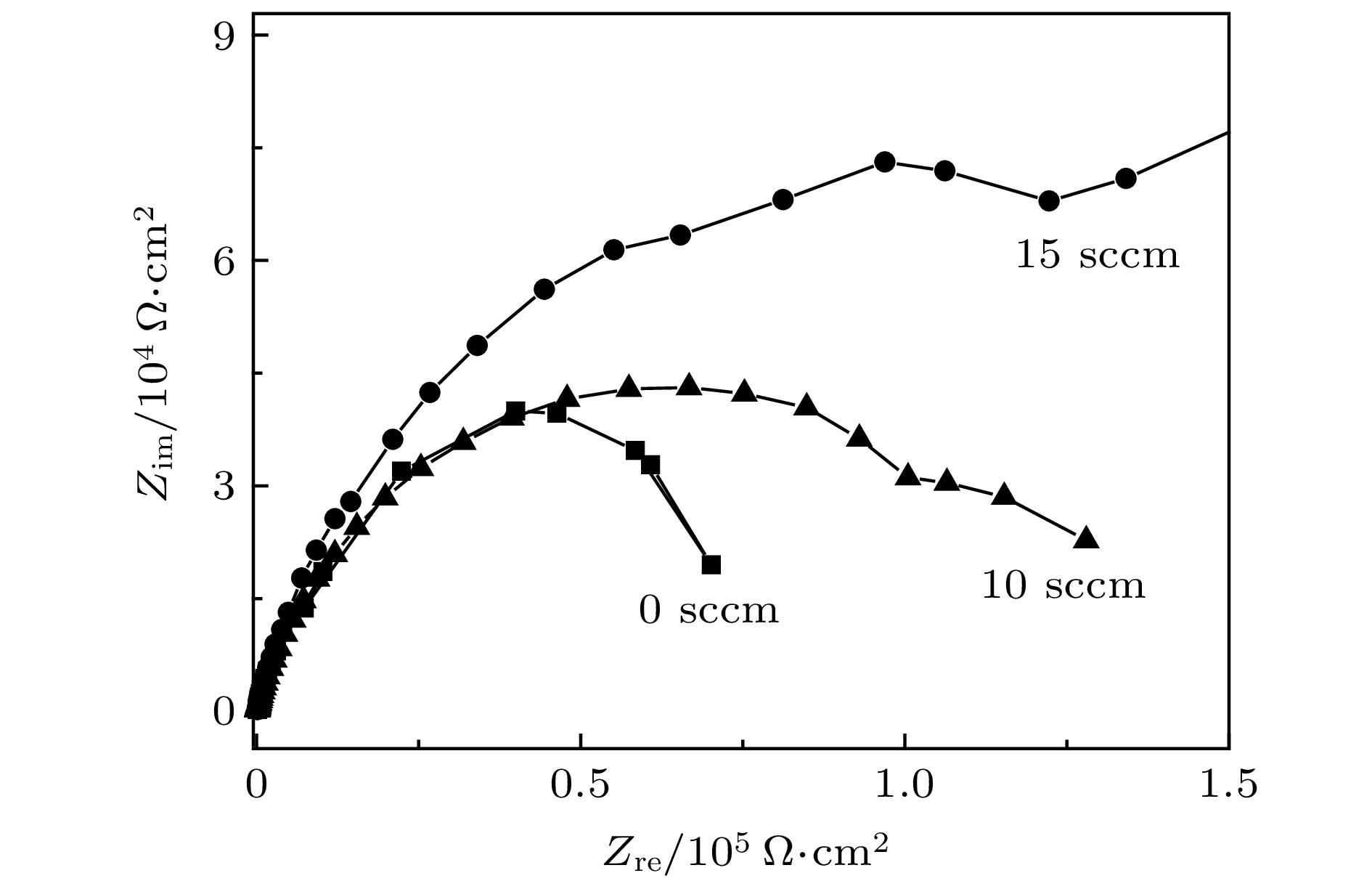

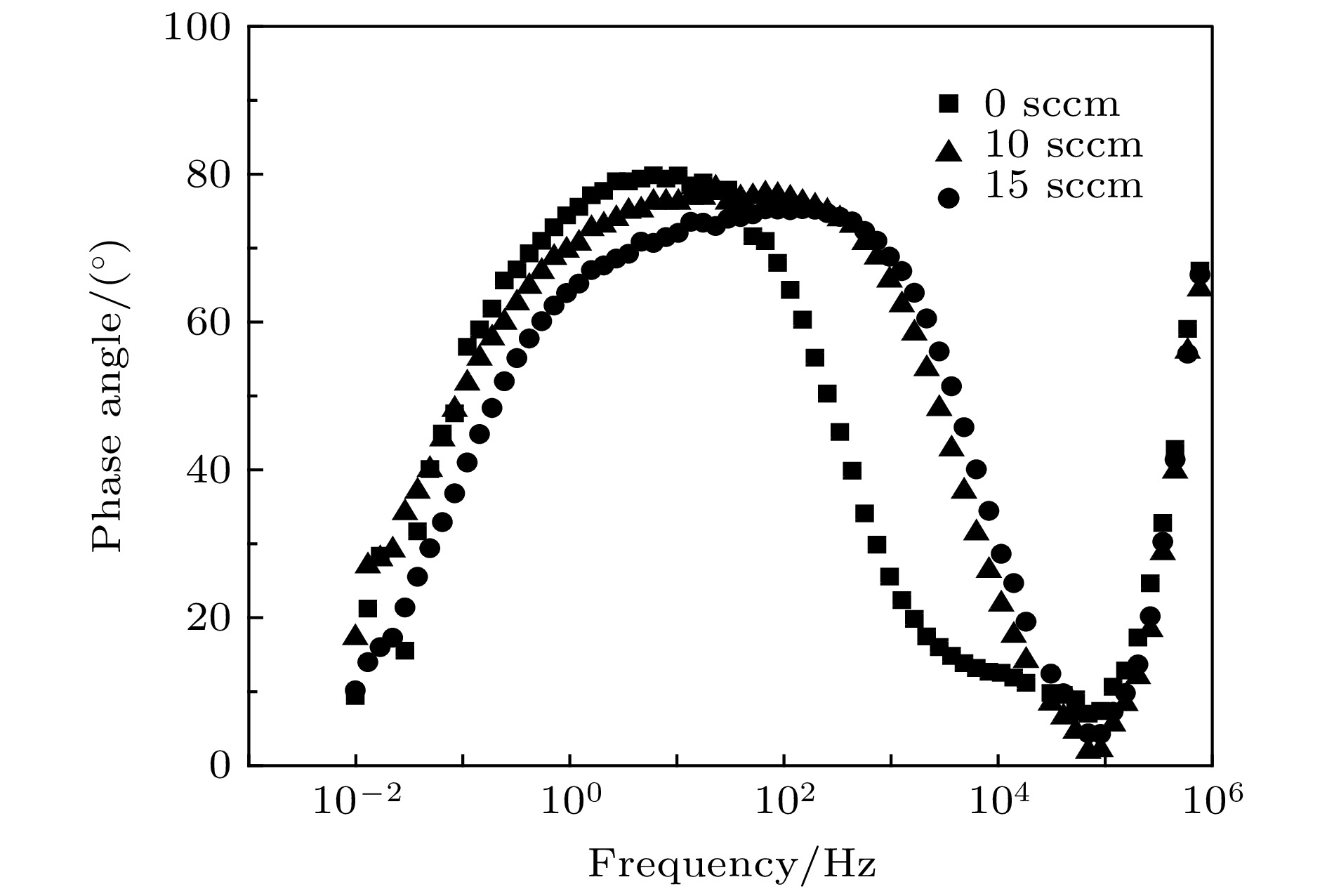

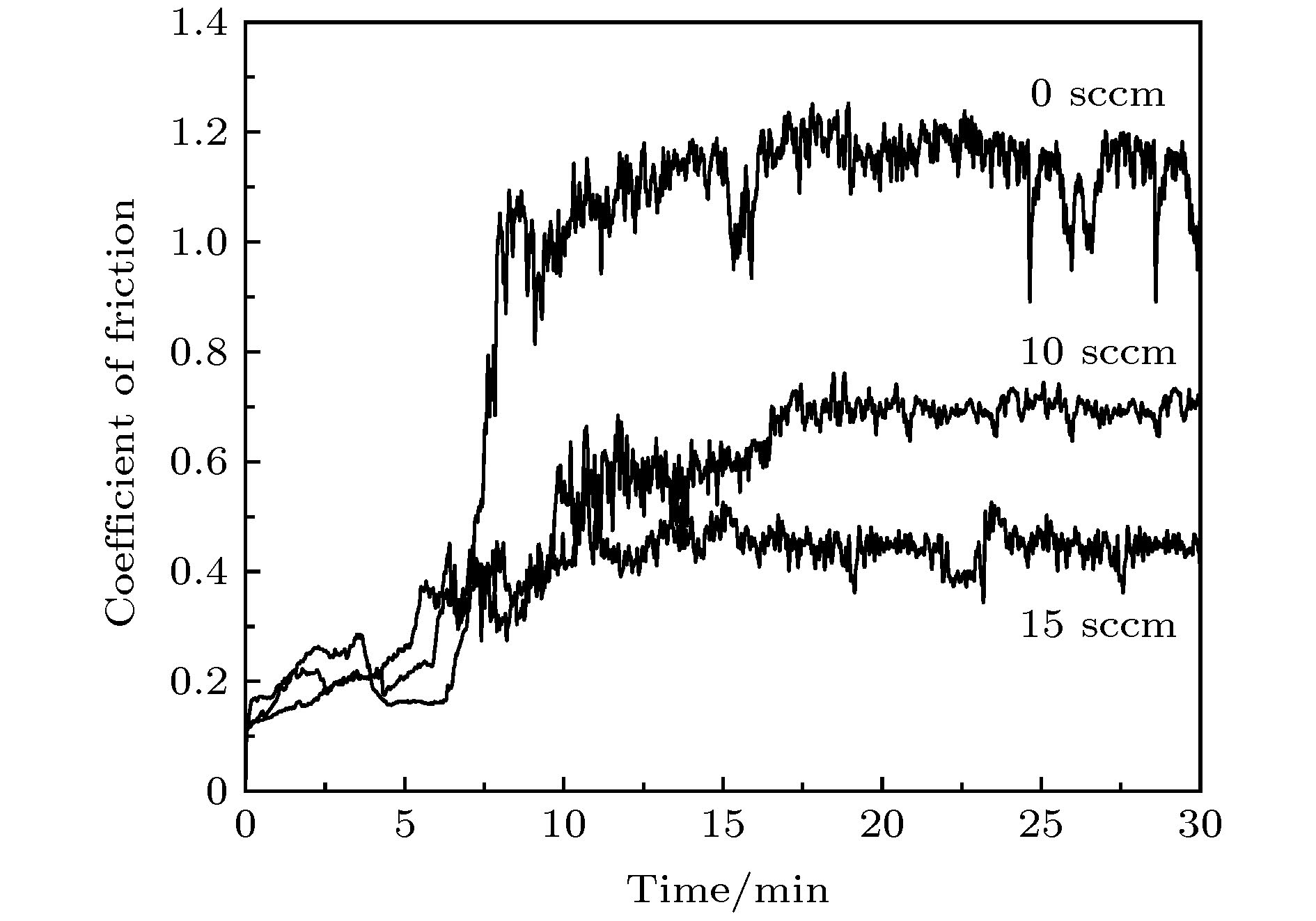

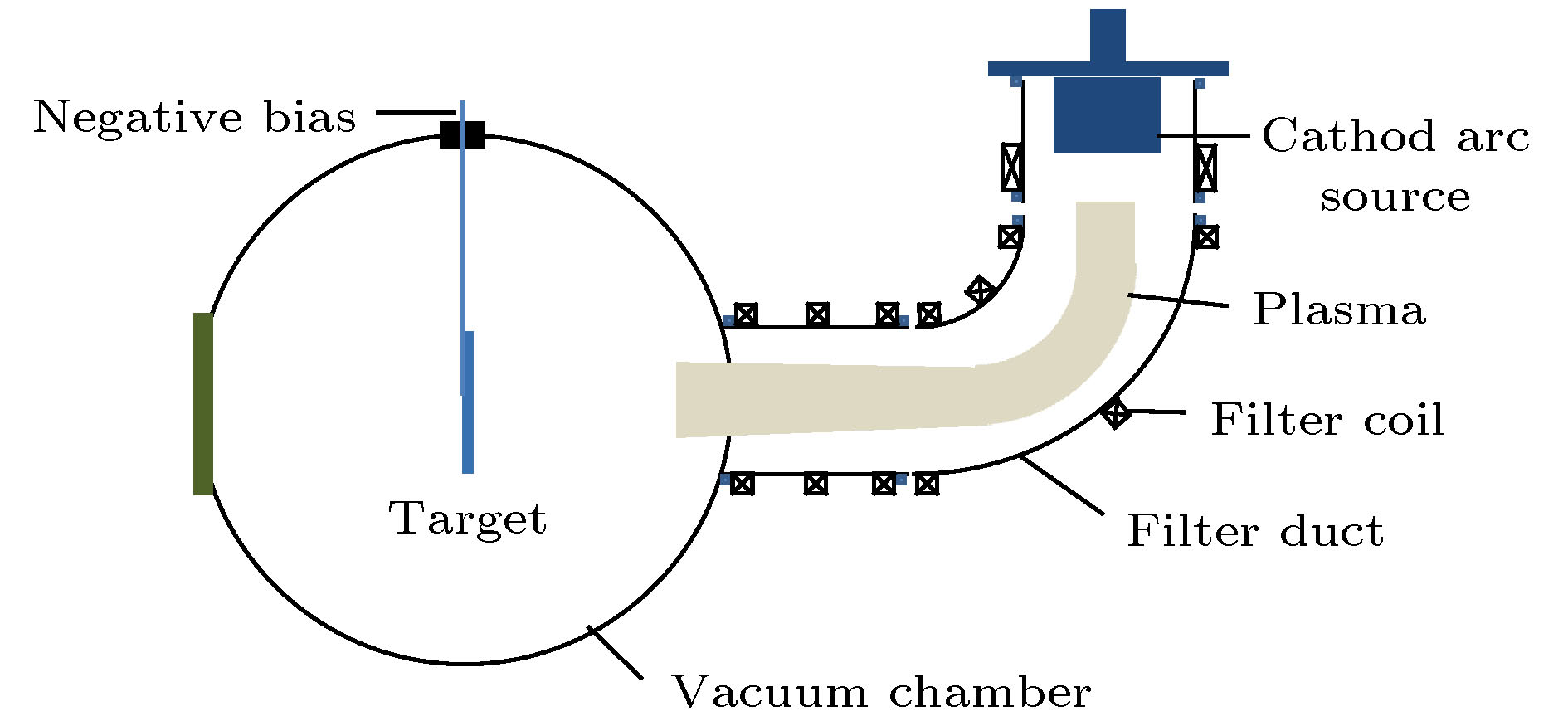

本文基于新型的磁过滤沉积技术(FCVA)研究了TiAlCN/TiAlN/TiAl多元复合涂层结构及不同C含量对其防腐耐磨性能的影响. 同时使用SEM, XRD, XPS, 电化学测试和摩擦磨损设备对其宏/微观性能进行了系统表征. 实验结果表明: 随C含量增加, C元素的存在形式从TiAlCN固溶相转化为TiAlCN固溶/非晶碳共存. 典型的TiAlCN固溶/非晶碳纳米复合结构TiAlCN/TiAlN/TiAl涂层不仅具有超高硬度和高韧性, 而且涂层中均匀无特征结构的非晶碳具有优异的自润滑效果, 通过结合各层的优势, 该结构涂层在3.5%NaCl电化学腐蚀试验中, Ecorr提高了5.6倍, 为0.271V, Icorr降低为原来的1/52, 为8.092 × 10–9 A·cm–2; 在干摩擦实验中, 摩擦系数降低了1/3, 为0.43, 磨损率降低了1/1.4, 为1.13 × 10–5 mm3·N–1·m–1.

-

关键词:

- TiAlCN/TiAlN/TiAl多元复合涂层 /

- TiAlCN固溶/非晶碳复合结构 /

- 干摩擦 /

- 腐蚀

The experiment is based on novel magnetic filtered cathodic vacuum arc (FCVA) technology, the effects of the structure and C contents of TiAlCN/TiAlN/TiAl composite coating on anticorrosion and wear resistance were studied. The macro/micro properties of the coatings were systematically characterized by SEM, XRD, XPS, electrochemical tests and friction equipment. The results show that, with the increase of C content,the form of C element in the coatings transforms from the TiAlCN solid solution to the coexistence of crystallized TiAlCN/amorphous carbon. The TiAlCN/TiAlN/TiAl coating with TiAlCNcrystallized/amorphous carbon nanocomposite structure demonstrated excellent performanceby combining the advantages of each layer, which the hardness reaches an ultrahigh leveland the amorphous carbonwith excellent self-lubricating effect exists in the coating structure. In 3.5% NaCl electrochemical corrosion test, Ecorr increased by 5.6 times to 0.271 V, Icorr decreased by 1/52 to 8.092 ×10–9 A·cm–2. During the dry sliding, friction coefficient decreased by 1/3 to 0.43, and wear rate decreased by 1/1.4 to 1.13×10–5 mm3·N–1·m–1.-

Keywords:

- TiAlCN/TiAlN/TiAlmultilayer composite coatings /

- crystallized TiAlCN/amorphous carbon /

- friction /

- corrosion

[1] 王均涛, 刘平, 李伟, 郑康培 2010 热加工工艺 20 104

Google Scholar

Google Scholar

Wang J T, Liu P, Li W, Zheng K P 2010 Hot Working Technology 20 104

Google Scholar

Google Scholar

[2] PalDey S, Deevi S C 2003 Sci. Eng. A 342 58

Google Scholar

Google Scholar

[3] Hsu C H, Lee C Y, Lee C C 2009 Thin Solid Films 17 5212

[4] Brogren M, Harding G L, Karmhag R, Ribbing C G, Niklasson G A, Stenmark L 2000 Thin Solid Films 370 268

Google Scholar

Google Scholar

[5] Hovsepian PEh, Münz W D, Medlock A, Gregory G 2000 Surf. Coat. Technol. 133–134 508

[6] Warcholinski B, Gilewicz A 2011 Wear 271 2812

Google Scholar

Google Scholar

[7] Zheng J Y, Hao J Y, Li u X, Gong Q Y, Liu W M 2012 Surf. Coat. Technol. 209 110

Google Scholar

Google Scholar

[8] Agudelo L C, Ospina R, Castillo H A, Devia A 2008 Phys. Scr. T131 014006

Google Scholar

Google Scholar

[9] Kamath G, Ehiasarian A P, Purandare Y, Hovsepian PEh 2011 Surf. Coat. Technol. 205 2823

Google Scholar

Google Scholar

[10] Hovsepian PEh, Ehiasarian A P, Deeming A, Schimpf C 2008 Vacuum 82 1312

Google Scholar

Google Scholar

[11] Yang L J, Zhang Z H, Dang X A, Li L 2014 Mater. Sci. Forum 789 449

Google Scholar

Google Scholar

[12] AL-Bukhaiti M A, Al-hatab K A, Tillmann W, Hoffmann F, Sprute T 2014 Appl. Surf. Sci. 318 180

Google Scholar

Google Scholar

[13] Kawata K, Sugimura H, Takai O 2001 Thin Solid Films 390 64

Google Scholar

Google Scholar

[14] 单磊, 王永欣, 李金龙 2013 中国表面工程 26 86

Google Scholar

Google Scholar

Shan L, Wang Y X, Li J L 2013 China Surface Engineering 26 86

Google Scholar

Google Scholar

[15] Kuptsov K A, Kiryukhantsev-Korneev P V, Sheveryko A N, ShtanskyDV 2013 Surf. Coat. Technol. 216 273

Google Scholar

Google Scholar

[16] 李刘合, 张海泉, 崔旭明 2001 08 1549

Google Scholar

Google Scholar

Li L H, Zhang H Q, Cui X M 2001 Acta Phys. Sin. 08 1549

Google Scholar

Google Scholar

[17] Ferrari A C, Kleinsorge B, Morrison N A, Hart A 1999 J. Appl. Phys. 857 191

[18] Zhang X H, Jiang J Q, Zeng Y Q, Lin J L, Wang F L, Moore J J 2008 Surf. Coat. Technol. 203 594

Google Scholar

Google Scholar

[19] Zeng Y Q, Qiu Y D, Mao X Y, Tan X Y, Tan Z, Zhang X H, Chen J, Jiang J Q 2015 Thin Solid Films 584 283

Google Scholar

Google Scholar

[20] Dreiling I, Stiens D, Chasse T 2010 Surf. Coat. Technol. 205 1339

Google Scholar

Google Scholar

[21] Rodríguez R J, García J A, Medrano A, Rico M, Sánchez R, Martínez R, Labrugère C, Lahaye M, Guette A 2002 Vacuum 67 559

Google Scholar

Google Scholar

[22] 段晋辉, 梁银, 裴旺, 杨喜昆 2016 金属热处理 41 139

Du J H, Liang Y, Pei W, Yang X K 2016 Heat Treatment of Metals 41 139

[23] Jang C S, Jeon J H, Song P K, Kang M C, Kim K H 2005 Surf. Coat. Technol. 200 1501

Google Scholar

Google Scholar

[24] Zehnder T, Schwaller P, Munnik F, Mikhailov S, Patscheider J 2004 J. Appl. Phys 95 4327

Google Scholar

Google Scholar

[25] Matthews A, Franklin S, Holmberg K 2007 J. Phys. D: Appl. Phys. 40 5463

Google Scholar

Google Scholar

[26] Musil J, Jirout M 2007 Surf. Coat. Technol. 201 5148

Google Scholar

Google Scholar

[27] Massiani Y, Medjahed A, Crousier J P, Gravier P, Rebatel I 1991 Surf. Coat. Technol. 45 115

Google Scholar

Google Scholar

[28] 陈淑年, 廖斌, 吴先映, 陈琳, 黄杰, 何光宇 2019 中国表面工程 3 49

Google Scholar

Google Scholar

Chen S N, Liao B, Wu X Y, Chen L, Huang J, He G Y 2019 China Surface Engineering 3 49

Google Scholar

Google Scholar

[29] Vacandio F, Massiani Y, Gravier P, Rossi S, Bonora P L, Fedrizzi L 2001 Electrochim. Acta 46 3827

Google Scholar

Google Scholar

[30] 郑建云, 郝俊英, 刘小强, 龚秋雨, 刘维民 2013 摩擦学学报 33 87

Zheng J Y, Hao J Y, Liu X Q, Gong Q Y, Liu W M 2013 Tribology 33 87

[31] Eriksson A O, Ghafoor N, Jensen J, Näslund L Å, Johansson M P, Sjölen J, Odén M, Hultman L, Rosen J 2012 Surf. Coat. Technol. 213 145

Google Scholar

Google Scholar

[32] Chen L, Yang B, Xu Y X, Pei F, Zhou L C, Du Y 2014 Thin Solid Films 556369

[33] HoörlingA, Hultman L, Odén M, Sjölén J, Karlsson L 2002 J. Vac. Sci. Technol. A 20 1815

[34] Cheng H H, Lee C Y, Lee C C 2009 ThinSolid Films 517 5212

Google Scholar

Google Scholar

[35] Xie Z W, Wang L P, Wang X F, Huang L, Lu Y, Yan J C 2011 Trans. Nonferrous Met. Soc. China 21 470

Google Scholar

Google Scholar

[36] Sampath Kumar T, Balasivanandha Prabu S, Manivasagam G 2014 J. Mater. Eng. Perform 23 2877

Google Scholar

Google Scholar

[37] 王泓 2002 博士学位论文 (西安: 西北工业大学)

Wang H 2002 Ph. D. Dissertation (Xian: Northwestern Polytechnical University) (in Chinese)

-

表 1 不同C2H2流量沉积的TiAlCN/TiAlN/TiAl涂层的元素相对含量

Table 1. Chemical composition of TiAlCN/TiAlN/TiAl coatings deposited at various C2H2.

Sample C2H2/sccm Ti/at.% Al/at.% N/at.% C/at.% TiAlN/TiAl S1 0 30.87 22.85 46.28 — TiAlCN/TiAlN/TiAl S2 10 28.64 21.52 41.23 8.61 TiAlCN/TiAlN/TiAl S3 15 27.60 22.95 37.07 12.39 表 2 不同C2H2流量沉积的TiAlCN/TiAlN/TiAl涂层的显微硬度、杨氏模量和H/E比值

Table 2. Microhardness、Modules and ratio of H/E of TiAlCN/TiAlN/TiAl coatings deposited at various C2H2.

Sample C2H2/sccm E/GPa H/GPa H/E TiAlN/TiAl S1 0 290.20 30.53 0.105 TiAlCN/TiAlN/TiAl S2 10 310.65 41.16 0.133 TiAlCN/TiAlN/TiAl S3 15 316.14 44.36 0.140 -

[1] 王均涛, 刘平, 李伟, 郑康培 2010 热加工工艺 20 104

Google Scholar

Google Scholar

Wang J T, Liu P, Li W, Zheng K P 2010 Hot Working Technology 20 104

Google Scholar

Google Scholar

[2] PalDey S, Deevi S C 2003 Sci. Eng. A 342 58

Google Scholar

Google Scholar

[3] Hsu C H, Lee C Y, Lee C C 2009 Thin Solid Films 17 5212

[4] Brogren M, Harding G L, Karmhag R, Ribbing C G, Niklasson G A, Stenmark L 2000 Thin Solid Films 370 268

Google Scholar

Google Scholar

[5] Hovsepian PEh, Münz W D, Medlock A, Gregory G 2000 Surf. Coat. Technol. 133–134 508

[6] Warcholinski B, Gilewicz A 2011 Wear 271 2812

Google Scholar

Google Scholar

[7] Zheng J Y, Hao J Y, Li u X, Gong Q Y, Liu W M 2012 Surf. Coat. Technol. 209 110

Google Scholar

Google Scholar

[8] Agudelo L C, Ospina R, Castillo H A, Devia A 2008 Phys. Scr. T131 014006

Google Scholar

Google Scholar

[9] Kamath G, Ehiasarian A P, Purandare Y, Hovsepian PEh 2011 Surf. Coat. Technol. 205 2823

Google Scholar

Google Scholar

[10] Hovsepian PEh, Ehiasarian A P, Deeming A, Schimpf C 2008 Vacuum 82 1312

Google Scholar

Google Scholar

[11] Yang L J, Zhang Z H, Dang X A, Li L 2014 Mater. Sci. Forum 789 449

Google Scholar

Google Scholar

[12] AL-Bukhaiti M A, Al-hatab K A, Tillmann W, Hoffmann F, Sprute T 2014 Appl. Surf. Sci. 318 180

Google Scholar

Google Scholar

[13] Kawata K, Sugimura H, Takai O 2001 Thin Solid Films 390 64

Google Scholar

Google Scholar

[14] 单磊, 王永欣, 李金龙 2013 中国表面工程 26 86

Google Scholar

Google Scholar

Shan L, Wang Y X, Li J L 2013 China Surface Engineering 26 86

Google Scholar

Google Scholar

[15] Kuptsov K A, Kiryukhantsev-Korneev P V, Sheveryko A N, ShtanskyDV 2013 Surf. Coat. Technol. 216 273

Google Scholar

Google Scholar

[16] 李刘合, 张海泉, 崔旭明 2001 08 1549

Google Scholar

Google Scholar

Li L H, Zhang H Q, Cui X M 2001 Acta Phys. Sin. 08 1549

Google Scholar

Google Scholar

[17] Ferrari A C, Kleinsorge B, Morrison N A, Hart A 1999 J. Appl. Phys. 857 191

[18] Zhang X H, Jiang J Q, Zeng Y Q, Lin J L, Wang F L, Moore J J 2008 Surf. Coat. Technol. 203 594

Google Scholar

Google Scholar

[19] Zeng Y Q, Qiu Y D, Mao X Y, Tan X Y, Tan Z, Zhang X H, Chen J, Jiang J Q 2015 Thin Solid Films 584 283

Google Scholar

Google Scholar

[20] Dreiling I, Stiens D, Chasse T 2010 Surf. Coat. Technol. 205 1339

Google Scholar

Google Scholar

[21] Rodríguez R J, García J A, Medrano A, Rico M, Sánchez R, Martínez R, Labrugère C, Lahaye M, Guette A 2002 Vacuum 67 559

Google Scholar

Google Scholar

[22] 段晋辉, 梁银, 裴旺, 杨喜昆 2016 金属热处理 41 139

Du J H, Liang Y, Pei W, Yang X K 2016 Heat Treatment of Metals 41 139

[23] Jang C S, Jeon J H, Song P K, Kang M C, Kim K H 2005 Surf. Coat. Technol. 200 1501

Google Scholar

Google Scholar

[24] Zehnder T, Schwaller P, Munnik F, Mikhailov S, Patscheider J 2004 J. Appl. Phys 95 4327

Google Scholar

Google Scholar

[25] Matthews A, Franklin S, Holmberg K 2007 J. Phys. D: Appl. Phys. 40 5463

Google Scholar

Google Scholar

[26] Musil J, Jirout M 2007 Surf. Coat. Technol. 201 5148

Google Scholar

Google Scholar

[27] Massiani Y, Medjahed A, Crousier J P, Gravier P, Rebatel I 1991 Surf. Coat. Technol. 45 115

Google Scholar

Google Scholar

[28] 陈淑年, 廖斌, 吴先映, 陈琳, 黄杰, 何光宇 2019 中国表面工程 3 49

Google Scholar

Google Scholar

Chen S N, Liao B, Wu X Y, Chen L, Huang J, He G Y 2019 China Surface Engineering 3 49

Google Scholar

Google Scholar

[29] Vacandio F, Massiani Y, Gravier P, Rossi S, Bonora P L, Fedrizzi L 2001 Electrochim. Acta 46 3827

Google Scholar

Google Scholar

[30] 郑建云, 郝俊英, 刘小强, 龚秋雨, 刘维民 2013 摩擦学学报 33 87

Zheng J Y, Hao J Y, Liu X Q, Gong Q Y, Liu W M 2013 Tribology 33 87

[31] Eriksson A O, Ghafoor N, Jensen J, Näslund L Å, Johansson M P, Sjölen J, Odén M, Hultman L, Rosen J 2012 Surf. Coat. Technol. 213 145

Google Scholar

Google Scholar

[32] Chen L, Yang B, Xu Y X, Pei F, Zhou L C, Du Y 2014 Thin Solid Films 556369

[33] HoörlingA, Hultman L, Odén M, Sjölén J, Karlsson L 2002 J. Vac. Sci. Technol. A 20 1815

[34] Cheng H H, Lee C Y, Lee C C 2009 ThinSolid Films 517 5212

Google Scholar

Google Scholar

[35] Xie Z W, Wang L P, Wang X F, Huang L, Lu Y, Yan J C 2011 Trans. Nonferrous Met. Soc. China 21 470

Google Scholar

Google Scholar

[36] Sampath Kumar T, Balasivanandha Prabu S, Manivasagam G 2014 J. Mater. Eng. Perform 23 2877

Google Scholar

Google Scholar

[37] 王泓 2002 博士学位论文 (西安: 西北工业大学)

Wang H 2002 Ph. D. Dissertation (Xian: Northwestern Polytechnical University) (in Chinese)

计量

- 文章访问数: 11793

- PDF下载量: 144

- 被引次数: 0

下载:

下载: