-

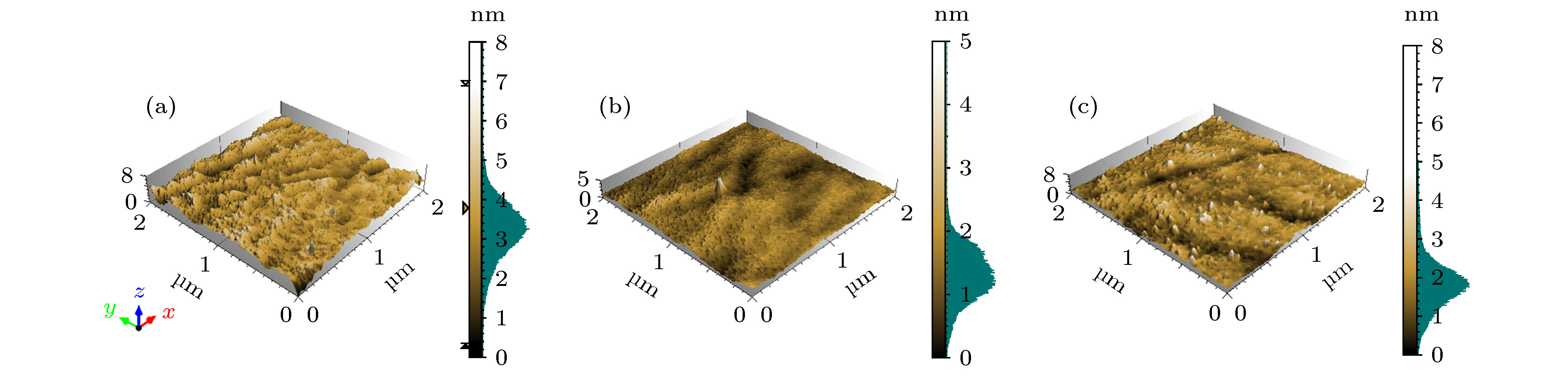

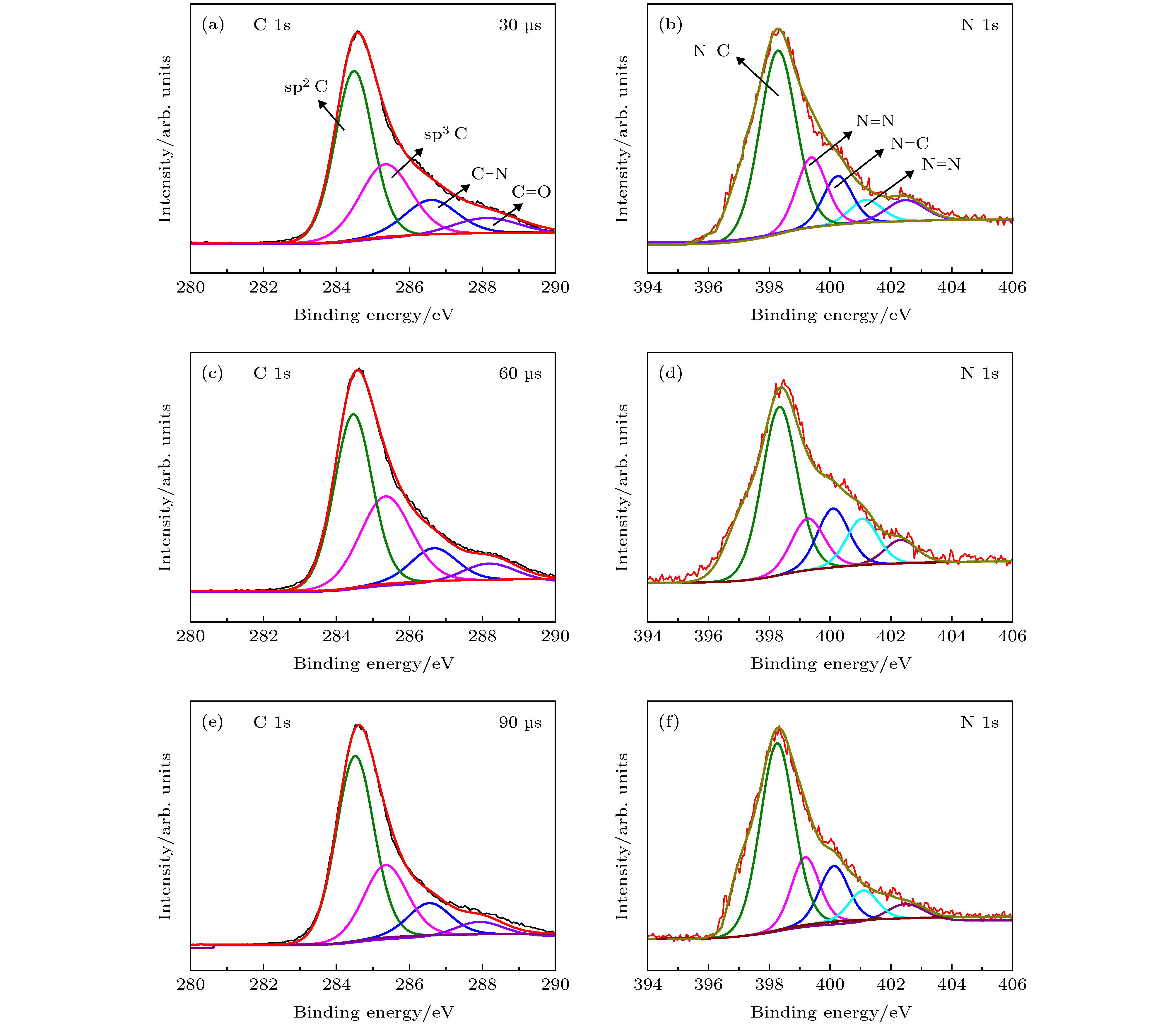

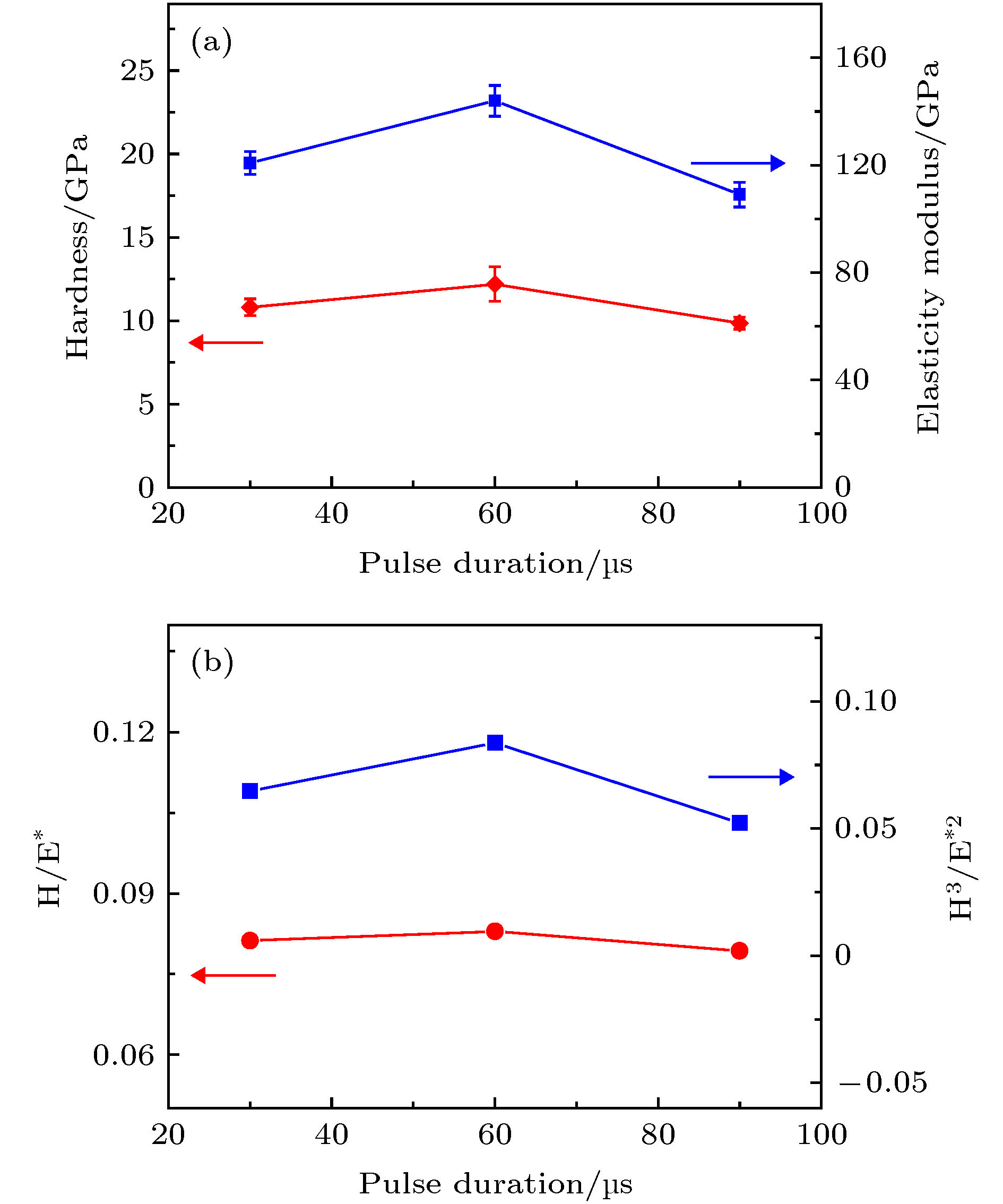

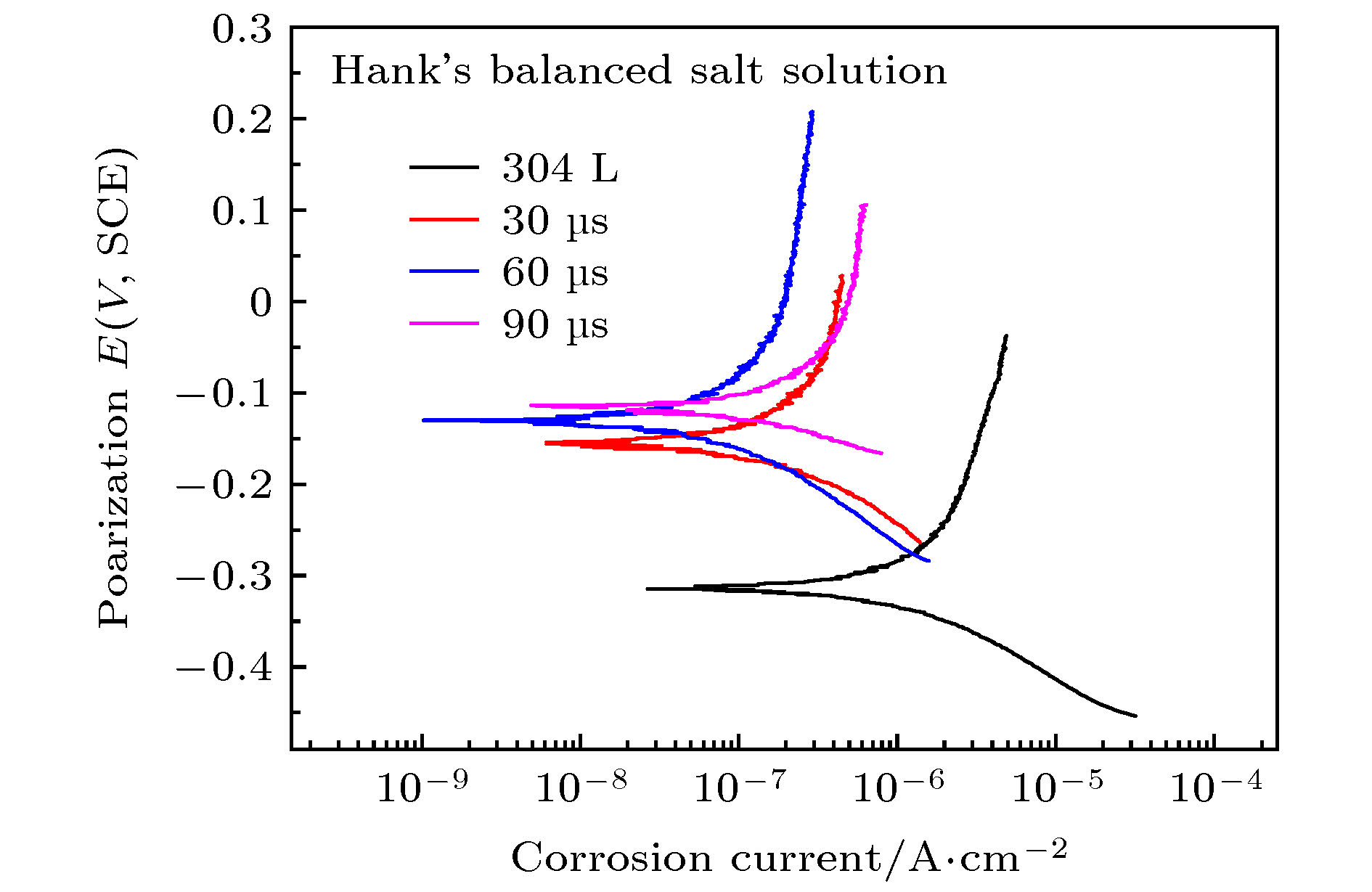

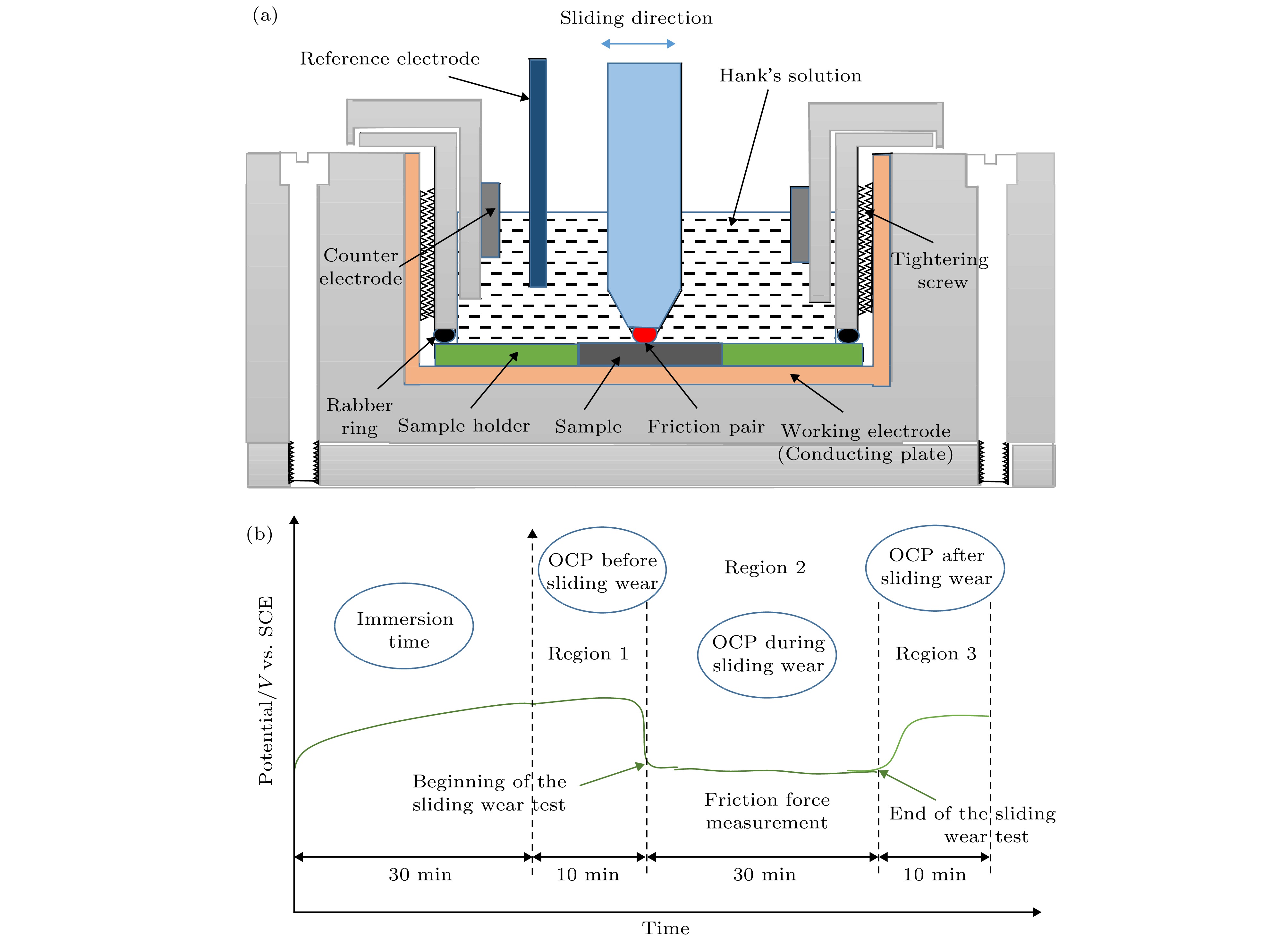

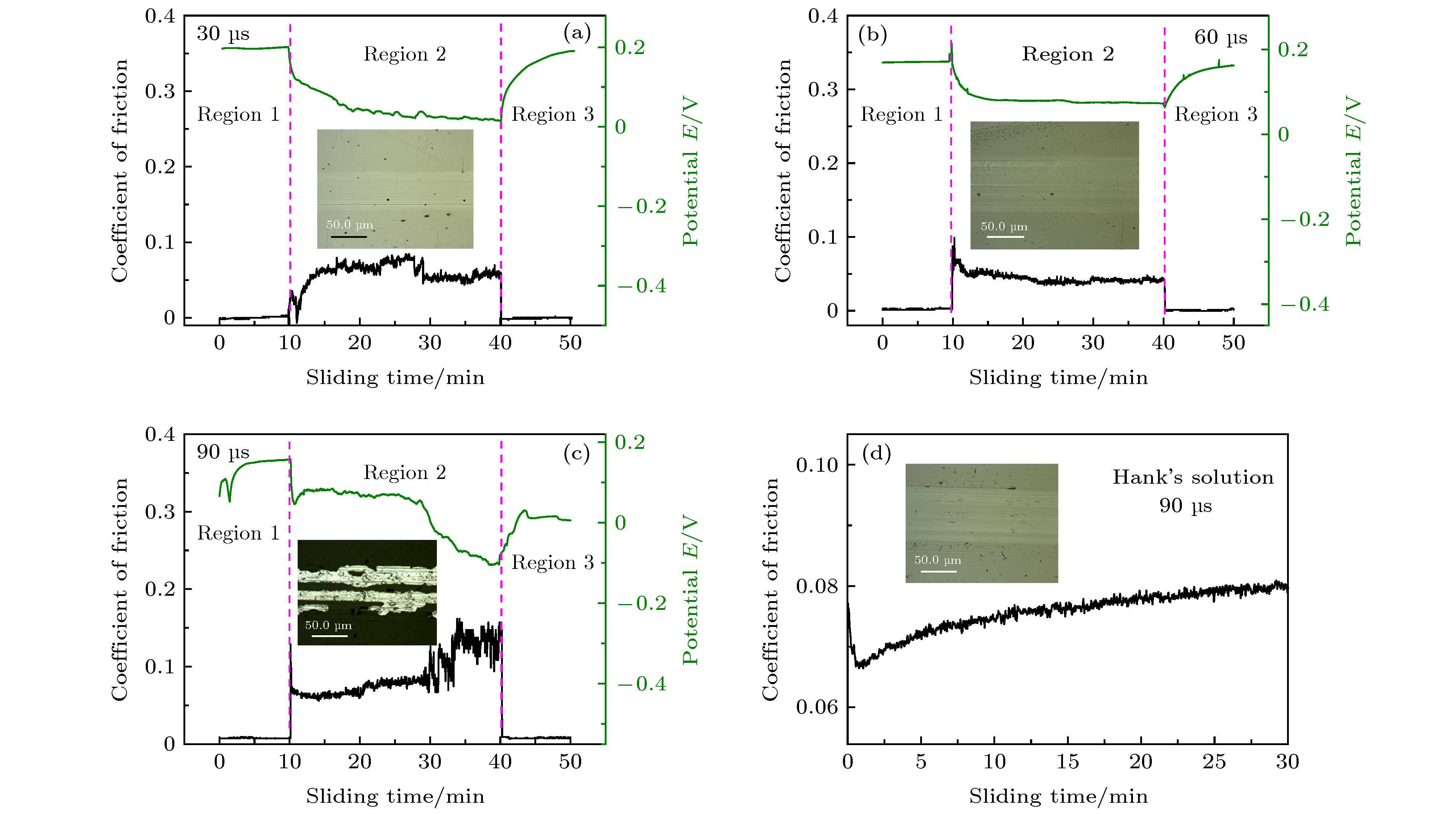

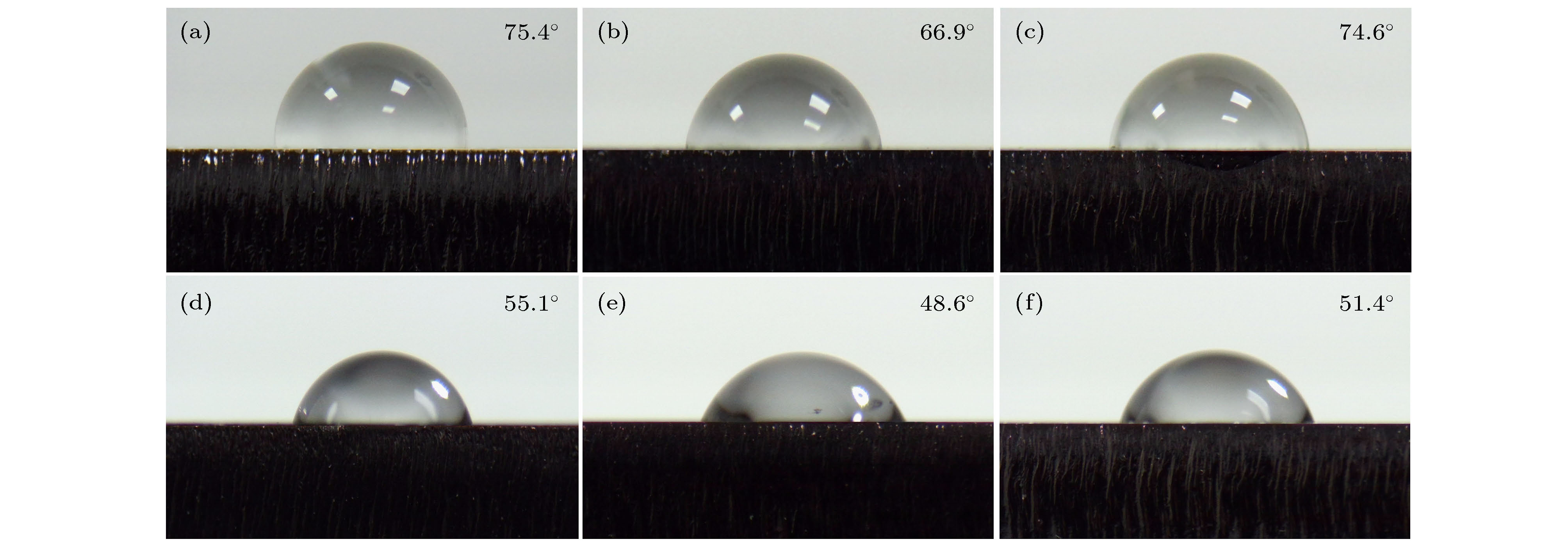

掺氮类金刚石薄膜在生物应用中很有前景, 研究其摩擦和腐蚀的协同作用有很大的实际意义. 论文使用高功率脉冲磁控溅射(high-power impulse magnetron sputtering, HiPIMS)技术, 在奥氏体不锈钢和单晶硅片上以Ar气和氮气为前驱气体, 室温下制备了致密的掺氮类金刚石薄膜. 使用配备三电极电化学池的往复型摩擦磨损试验机, 在Hank’s平衡盐溶液中研究了不同靶脉冲持续时间制备的薄膜的摩擦腐蚀性能, 并在滑动之前、期间和之后监测了薄膜的开路电位(open circuit potential, OCP). 电化学工作站用于表征摩擦前薄膜的电化学行为. 结果表明: 60 μs制备的掺氮类金刚石薄膜展示了优异的耐磨蚀性能, 其摩擦系数最低(0.05)且在摩擦阶段OCP显示了最高的稳定值(39 mV), 这主要归功于其致密的结构和较大的表面能; 而90 μs下制备的薄膜由于可以形成交联结构的sp3键含量明显下降, 从而导致薄膜孔隙率增加, 薄膜的抗腐蚀性下降, 在磨蚀过程中由于电解液在孔隙的腐蚀使得薄膜/基体的界面结合强度减弱, 在摩擦的综合作用下, 薄膜脱落, 发生失效.Nitrogen-doped diamond like carbon film is promising in biological applications, studying the synergistic tribocorrosion performance is indispensable. In this paper, Nitrogen-doped diamond like carbon films were deposited on AISI 304L austenitic stainless steels and Si substrate by using the high power impulse magnetron sputtering technique using Ar and N2 as precursors at room temperature. The effect of target pulse duration on the structure, mechanical properties, corrosion resistance and tribocorrosion properties in Hank's equilibrium salt solution and the corresponding mechanism were studied. The results of scanning electron microscopy, atomic force microscopy, X-ray photoelectron spectroscopy and nano-hardness test showed that the nitrogen-doped diamond like carbon coatings prepared at a target pulse duration of 60 μs showed the sp3 bonding content of 33.9% with the hardness of 12.4 GPaand the root mean square roughness of 0.63 nm. With the increase in pulse duration to 90 μs, the sp2 bonding increased, meanwhile the surface roughness increased. The results of potentiodynamic polarization indicated that the Nitrogen-doped diamond like carbon coating prepared at 60μs had best corrosion resistance with the corrosion current density of 7.65 × 10–8 A·cm–2. The effect of the target pulse duration on tribocorrosionbehaviour of the Nitrogen-doped diamond like carboncoating was investigated in Hank’s solution by a reciprocating tribometer equipped with a three-electrode electrochemical cell.The coatings at 60 μs exhibited excellent tribocorrosion properties with high open circuit potential of 39 mV, low COF of 0.05 without pitting corrosion due to high corrosionresistance, low contact angel and dense microstructure.The results indicated that corrosion can be accelerated by friction, but it also affect the mechanical properties of the Nitrogen-doped diamond like carbon coatings. The increase in pulse duration to 90 μs, leading to the reduction of sp3 bonds which can form a cross-linking structure. The degraded cross-linking structure decreased the corrosion resistance of the coating via the increased porosity in the coating, which weakened the interfacial strength of the coating, and ultimately led to failure of the coatingunder the action of wear.

-

Keywords:

- high power impulse magnetron sputtering /

- Nitrogen-doped diamond like carbon coating /

- tribocorrosion behavior /

- corrosion

[1] Tyagi A, Walia R S, Murtaza Q, Pandey S M, Bajaj B 2019 Int. J. Refract. Met. Hard Mater. 78 107

Google Scholar

Google Scholar

[2] Corona-Gomez J, Shiri S, Mohammadtaheri M, Yang Q 2017 Surf. Coat. Technol. 332 120

Google Scholar

Google Scholar

[3] Son M J, Zhang T F, Jo Y J, Kim K H 2017 Surf. Coat. Technol. 329 77

Google Scholar

Google Scholar

[4] Wang C, Yang S, Zhang J 2008 J. Non. Cryst. Solids 354 1608

Google Scholar

Google Scholar

[5] Muhl S, Mendez J M 1999 Diam. Relat. Mater. 8 1809

Google Scholar

Google Scholar

[6] Zheng C L, Cui F Z, Meng B, Ge J, Liu D P, Lee I S 2005 Surf. Coat. Technol. 193 361

Google Scholar

Google Scholar

[7] Dress D, Celis J P, Dekempeneer E, Meneve J 1996 Surf. Coat. Technol. 85-86 575

[8] Ronkainen H, Varjus S, Holmberg K 1998 Wear 222 120

Google Scholar

Google Scholar

[9] Park S J, Lee K R, Ahn S H, Kim J G 2008 Diam. Relat. Mater. 17 247

Google Scholar

Google Scholar

[10] Ohana T, Nakamura T, Suzuki M, Tanaka A, Koga Y 2004 Diam. Relat. Mater. 13 1500

Google Scholar

Google Scholar

[11] Lü Y, Li J, Liu X, Li H, Zhou H, Chen J 2012 Appl. Surf. Sci. 258 3864

Google Scholar

Google Scholar

[12] Cheng H C, Chiou S Y, Liu C M, Lin M H, Chen C C, Ou K L 2009 J. Alloy. Compd. 477 931

Google Scholar

Google Scholar

[13] Kim D H, Kim H E, Lee K R, Whang C N, Lee I S 2002 Mater. Sci. Eng. C 22 9

Google Scholar

Google Scholar

[14] Manhabosco T M, Müller I L 2009 Tribol. Lett. 33 193

Google Scholar

Google Scholar

[15] Azzi M, Paquette M, Szpunar J A, Klemberg-Sapieha J E, Martinu L 2009 Wear 267 860

Google Scholar

Google Scholar

[16] Sharifahmadian O, Mahboubi F 2019 Ceram. Int. 45 16424

Google Scholar

Google Scholar

[17] Guerino M, Massi M, Maciel H S 2003 Microelectronic. J. 34 639

Google Scholar

Google Scholar

[18] Bootkul D, Supsermpol B, Saenphinit N, Aramwit C, Intarasiri S 2014 Appl. Surf. Sci. 310 284

Google Scholar

Google Scholar

[19] Ricard A, Nouvellon C, Konstantinidis S, Dauchot J, Wautelet M, Hecq M 2002 J. Vac. Sci. Technol. A 20 1488

Google Scholar

Google Scholar

[20] Christou C, Barber Z H 2000 J. Vac. Sci. Technol. A 18 2897

Google Scholar

Google Scholar

[21] Kouznetsov V, Macak K, Schneider J M, Helmersson U, Petrov I 1999 Surf. Coat. Technol. 122 290

Google Scholar

Google Scholar

[22] Sarakinos K, Alami J, Konstantinidis S 2010 Surf. Coat. Technol. 204 1661

Google Scholar

Google Scholar

[23] Alami J, Sarakinos K, Uslu F, Wuttig M 2009 J. Phys. D: Appl. Phys 42 015304

Google Scholar

Google Scholar

[24] Wu Z R, Zhang M, Cui F Z 2007 Surf. Coat. Technol. 201 5710

Google Scholar

Google Scholar

[25] Bouchetfabre B, Lazar G, Ballutaud D, Godet C, Zellama K 2008 Diam. Relat. Mater. 17 700

Google Scholar

Google Scholar

[26] Ujvári T, Szikora B, Tóth A, Mohai M, Bertóti I 2002 Diam. Relat. Mater. 11 1200

[27] Gago R, Jiménez I, Cáceres D, Agulló-Rueda F, Sajavara T, Albella J M, Climent-Font A, Vergara I, Räisänen J, Raühala E 2001 Chem. Mater. 13 129

Google Scholar

Google Scholar

[28] Ferrari A, Rodil S, Robertson J 2003 Phys. Rev. B 67 155306

Google Scholar

Google Scholar

[29] Wei S, Shao T, Peng D 2010 Diam. Relat. Mater. 19 648

Google Scholar

Google Scholar

[30] Niu L F, Zhang S J, Li D J, Zhang J K, Yang S G, Tian Z, Huang Z G, Zhang H L J 2001 Adhes. Sci. Technol. 15 1121

Google Scholar

Google Scholar

[31] Matthews A, Franklin S, Holmberg K 2007 J. Phys. D. Appl. Phys. 40 5463

Google Scholar

Google Scholar

[32] Philippon D, Godinho V, Nagy P M, Delplancke-Ogletree M P, Fernández A 2011 Wear 270 541

[33] Beake B D, Vishnyakov V M, Valizadeh R, Colligon J S 2006 J. Phys. D: Appl. Phys. 39 1392

Google Scholar

Google Scholar

[34] Ou Y X, Chen H, Li Z Y, Lin J, Lei M K 2018 J. Am. Ceram. Soc. 101 5166

Google Scholar

Google Scholar

[35] Martini E M A, Muller I L 2000 Corros. Sci. 42 443

Google Scholar

Google Scholar

[36] Parfenov E V, Yerokhin A L, Matthews A 2007 Thin Solid Films 516 428

Google Scholar

Google Scholar

[37] Matthes B, Broszeit E, Aromaa J, Ronkainen H, Hannula SP, Leyland A, Matthews A 1991 Surf. Coat. Technol. 49 489

Google Scholar

Google Scholar

[38] Pu J, Wang J, He D, Wan S 2016 Surf. Interface Anal. 48 360

Google Scholar

Google Scholar

[39] Stansbury E E, Buchanan R A 1981 ASM International (USA: Materials Park, OH) p55

[40] Písařík P, Mikšovský J, Remsa J, Zemek J, Tolde Z, Jelínek M 2018 Appl. Phys. A 124 85

[41] Wang Y, Wang L, Wang S C, Zhang G, Wood R J K, Xue Q 2010 Tribol. Lett. 40 301

Google Scholar

Google Scholar

-

图 8 (a)—(c)磨蚀实验中OCP和摩擦系数随着滑行时间的变化以及磨痕的光学图片; (d)摩擦实验中90 μs制备膜的摩擦系数和磨痕图

Fig. 8. (a)–(c) The changes of OCP and coefficient of friction as a function of sliding times and the inserted optical micrographs of tribocorrosion tracks for coatings; (d) the normal coefficient of friction and micrographs of wear tracks.

表 1 不锈钢衬底和N-DLC膜的动电位极化曲线的拟合结果

Table 1. The fitting results of the potentiodynamic polarization curves of the N-DLC films and substrate.

样品 Ecorr/V icorr/A·cm–2 ba/mV bc/mV Rp/Ω·cm2 P 304 L –0.31 1.69 × 10–6 323.47 117.75 2.21 × 107 — 30 μs –0.15 9.87 × 10–8 289.51 119.61 3.72 × 108 0.042 60 μs –0.13 7.65 × 10–8 408.84 113.72 5.05 × 108 0.026 90 μs –0.12 1.55 × 10–7 298.24 82.91 2.05 × 108 0.079 -

[1] Tyagi A, Walia R S, Murtaza Q, Pandey S M, Bajaj B 2019 Int. J. Refract. Met. Hard Mater. 78 107

Google Scholar

Google Scholar

[2] Corona-Gomez J, Shiri S, Mohammadtaheri M, Yang Q 2017 Surf. Coat. Technol. 332 120

Google Scholar

Google Scholar

[3] Son M J, Zhang T F, Jo Y J, Kim K H 2017 Surf. Coat. Technol. 329 77

Google Scholar

Google Scholar

[4] Wang C, Yang S, Zhang J 2008 J. Non. Cryst. Solids 354 1608

Google Scholar

Google Scholar

[5] Muhl S, Mendez J M 1999 Diam. Relat. Mater. 8 1809

Google Scholar

Google Scholar

[6] Zheng C L, Cui F Z, Meng B, Ge J, Liu D P, Lee I S 2005 Surf. Coat. Technol. 193 361

Google Scholar

Google Scholar

[7] Dress D, Celis J P, Dekempeneer E, Meneve J 1996 Surf. Coat. Technol. 85-86 575

[8] Ronkainen H, Varjus S, Holmberg K 1998 Wear 222 120

Google Scholar

Google Scholar

[9] Park S J, Lee K R, Ahn S H, Kim J G 2008 Diam. Relat. Mater. 17 247

Google Scholar

Google Scholar

[10] Ohana T, Nakamura T, Suzuki M, Tanaka A, Koga Y 2004 Diam. Relat. Mater. 13 1500

Google Scholar

Google Scholar

[11] Lü Y, Li J, Liu X, Li H, Zhou H, Chen J 2012 Appl. Surf. Sci. 258 3864

Google Scholar

Google Scholar

[12] Cheng H C, Chiou S Y, Liu C M, Lin M H, Chen C C, Ou K L 2009 J. Alloy. Compd. 477 931

Google Scholar

Google Scholar

[13] Kim D H, Kim H E, Lee K R, Whang C N, Lee I S 2002 Mater. Sci. Eng. C 22 9

Google Scholar

Google Scholar

[14] Manhabosco T M, Müller I L 2009 Tribol. Lett. 33 193

Google Scholar

Google Scholar

[15] Azzi M, Paquette M, Szpunar J A, Klemberg-Sapieha J E, Martinu L 2009 Wear 267 860

Google Scholar

Google Scholar

[16] Sharifahmadian O, Mahboubi F 2019 Ceram. Int. 45 16424

Google Scholar

Google Scholar

[17] Guerino M, Massi M, Maciel H S 2003 Microelectronic. J. 34 639

Google Scholar

Google Scholar

[18] Bootkul D, Supsermpol B, Saenphinit N, Aramwit C, Intarasiri S 2014 Appl. Surf. Sci. 310 284

Google Scholar

Google Scholar

[19] Ricard A, Nouvellon C, Konstantinidis S, Dauchot J, Wautelet M, Hecq M 2002 J. Vac. Sci. Technol. A 20 1488

Google Scholar

Google Scholar

[20] Christou C, Barber Z H 2000 J. Vac. Sci. Technol. A 18 2897

Google Scholar

Google Scholar

[21] Kouznetsov V, Macak K, Schneider J M, Helmersson U, Petrov I 1999 Surf. Coat. Technol. 122 290

Google Scholar

Google Scholar

[22] Sarakinos K, Alami J, Konstantinidis S 2010 Surf. Coat. Technol. 204 1661

Google Scholar

Google Scholar

[23] Alami J, Sarakinos K, Uslu F, Wuttig M 2009 J. Phys. D: Appl. Phys 42 015304

Google Scholar

Google Scholar

[24] Wu Z R, Zhang M, Cui F Z 2007 Surf. Coat. Technol. 201 5710

Google Scholar

Google Scholar

[25] Bouchetfabre B, Lazar G, Ballutaud D, Godet C, Zellama K 2008 Diam. Relat. Mater. 17 700

Google Scholar

Google Scholar

[26] Ujvári T, Szikora B, Tóth A, Mohai M, Bertóti I 2002 Diam. Relat. Mater. 11 1200

[27] Gago R, Jiménez I, Cáceres D, Agulló-Rueda F, Sajavara T, Albella J M, Climent-Font A, Vergara I, Räisänen J, Raühala E 2001 Chem. Mater. 13 129

Google Scholar

Google Scholar

[28] Ferrari A, Rodil S, Robertson J 2003 Phys. Rev. B 67 155306

Google Scholar

Google Scholar

[29] Wei S, Shao T, Peng D 2010 Diam. Relat. Mater. 19 648

Google Scholar

Google Scholar

[30] Niu L F, Zhang S J, Li D J, Zhang J K, Yang S G, Tian Z, Huang Z G, Zhang H L J 2001 Adhes. Sci. Technol. 15 1121

Google Scholar

Google Scholar

[31] Matthews A, Franklin S, Holmberg K 2007 J. Phys. D. Appl. Phys. 40 5463

Google Scholar

Google Scholar

[32] Philippon D, Godinho V, Nagy P M, Delplancke-Ogletree M P, Fernández A 2011 Wear 270 541

[33] Beake B D, Vishnyakov V M, Valizadeh R, Colligon J S 2006 J. Phys. D: Appl. Phys. 39 1392

Google Scholar

Google Scholar

[34] Ou Y X, Chen H, Li Z Y, Lin J, Lei M K 2018 J. Am. Ceram. Soc. 101 5166

Google Scholar

Google Scholar

[35] Martini E M A, Muller I L 2000 Corros. Sci. 42 443

Google Scholar

Google Scholar

[36] Parfenov E V, Yerokhin A L, Matthews A 2007 Thin Solid Films 516 428

Google Scholar

Google Scholar

[37] Matthes B, Broszeit E, Aromaa J, Ronkainen H, Hannula SP, Leyland A, Matthews A 1991 Surf. Coat. Technol. 49 489

Google Scholar

Google Scholar

[38] Pu J, Wang J, He D, Wan S 2016 Surf. Interface Anal. 48 360

Google Scholar

Google Scholar

[39] Stansbury E E, Buchanan R A 1981 ASM International (USA: Materials Park, OH) p55

[40] Písařík P, Mikšovský J, Remsa J, Zemek J, Tolde Z, Jelínek M 2018 Appl. Phys. A 124 85

[41] Wang Y, Wang L, Wang S C, Zhang G, Wood R J K, Xue Q 2010 Tribol. Lett. 40 301

Google Scholar

Google Scholar

计量

- 文章访问数: 13122

- PDF下载量: 204

- 被引次数: 0

下载:

下载: