-

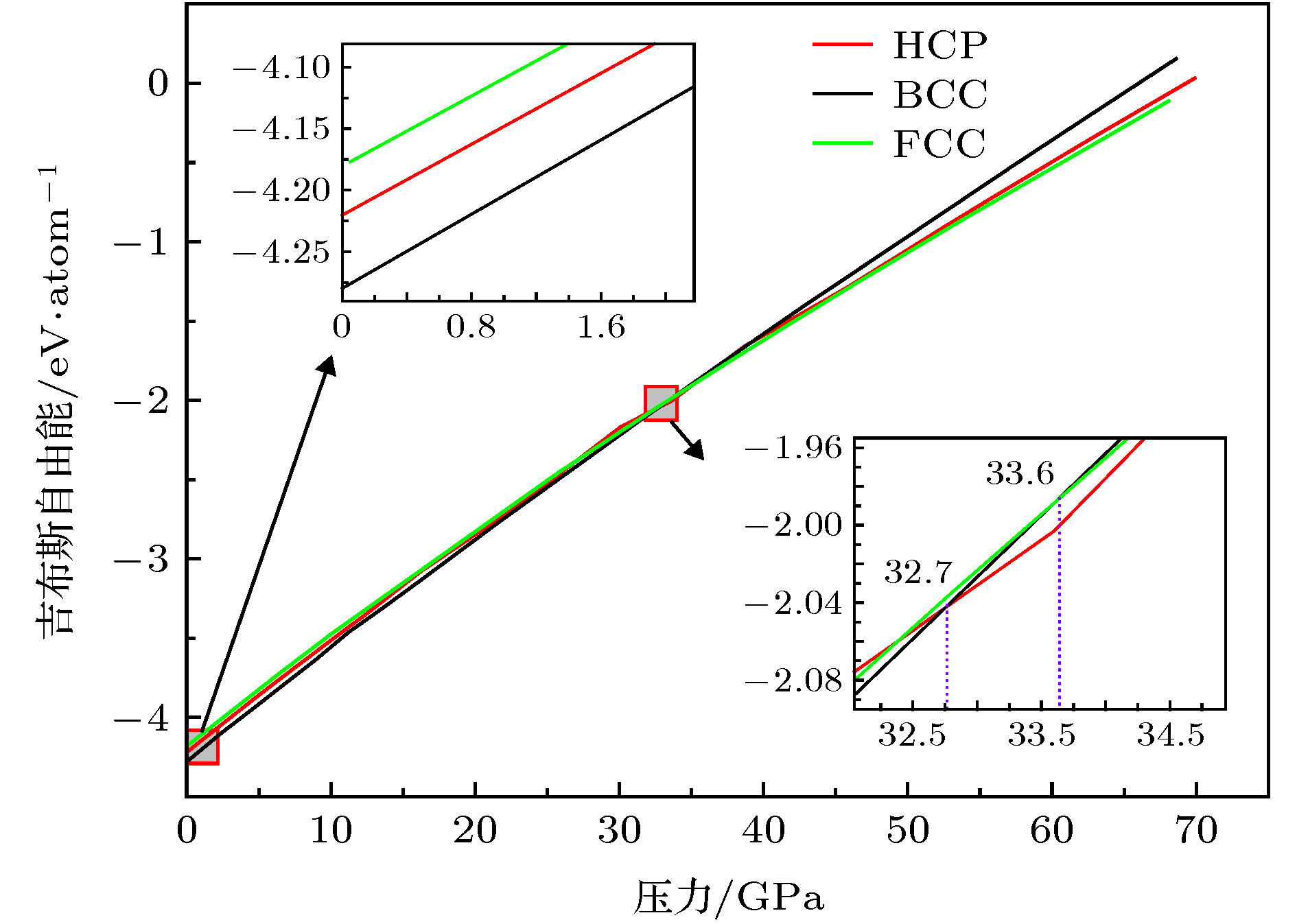

铁的冲击相变过程是科研工作者们关注的热点领域之一. 铁沿[100]晶向冲击时会发生体心立方相到密排六方相的转变; 而沿[101]晶向冲击时, 相变产物除了密排六方相之外还出现一定量的面心立方相. 人们已经明确了体心立方到密排六方相的转变机制, 然而对于面心立方相的形成机制问题至今还在探索. 本文通过分子动力学方法模拟了体心立方单晶铁沿[101]晶向的冲击过程, 模拟结果显示体心立方相将转变为高压密排结构(密排六方相和面心立方相); 并分析了面心立方相的形成机制: 在冲击过程中, 单晶铁沿[101]和

$ \bar101] $ 晶向突然收缩, 同时沿[010]晶向突然扩张, 从而导致体心立方到面心立方相的转变. 此外, 本文进一步研究了不同应力状态下单晶铁的相变机制, 发现沿[101]晶向单轴压缩以及沿[101]和$ [\bar101] $ 晶向双轴压缩时铁将发生体心立方到面心立方相的转变; 而沿[101]和[010]晶向双轴以及三轴压缩时将会发生体心立方到密排六方相的转变. 最后进一步计算了三个相的吉布斯自由能随压力的变化, 并对冲击模拟结果进行了能量分析, 给出了沿[101]晶向冲击条件下高压密排相产生的原因.The impact phase transformation of body-centered-cubic iron is one of the hotspots in current research. Many studies demonstrated that when iron is impacted along the [100] direction, body-centered-cubic phase will transform into hexagonal close-packed phase; while when it is impacted along the [101] direction, a certain amount of face-centered-cubic phase will also appear besides hexagonal close-packed phase. The transformation from body-centered-cubic to hexagonal close-packed phase has been clarified, however, the transformation from body-centered-cubic to face-centered-cubic phase still needs further exploring. In the present work, molecular dynamics simulation is used to study the phase transformation of body-centered-cubic iron impacted along the [101] direction. The results show that the body-centered-cubic phase will transform into a close-packed structure including hexagonal close-packed phase and face-centered-cubic phase). The formation mechanism of face-centered-cubic phase is as follow. In the loading process, single crystal iron suddenly contracts along the [101] and$ [\bar101] $ directions, and expands along the [010] direction, leading to the transformation from body-centered-cubic phase to face-centered-cubic phase. The formation mechanism of hexagonal close-packed phase can be divided into two stages: first, (101) plane is compressed into close-packed plane, then hexagonal close-packed phase is obtained by the relative sliding of adjacent close-packed planes. To further investigate the formation mechanism of the close packed structure, the effect of stress state on the phase transformation of body-centered-cubic iron is further studied. Under one-dimensional (along the [101] direction) or two-dimensional loading (along [101] and$ [\bar101] $ directions), the body-centered-cubic iron transforms into face-centered-cubic iron. In the loading process the lattice constants along the three dimensions are monitored. When the transformation from body-centered-cubic phase to face-centered-cubic phase finishes, the ratio of lattice constants along three directions is 1∶1∶1.31 under one-dimensional loading; while the ratio of lattice constants is 1∶1∶1 under two-dimensional loading. Obviously, the body-centered-cubic phase transforms into distorted face-centered-cubic phase under one-dimensional loading. Under two-dimensional (along the [101] and [010] direction) and three-dimensional loading (along the [101], [010] and$ [\bar101] $ direction), the body-centered-cubic phase transforms into hexagonal close-packed phase. Gibbs free energy value for each of BCC, HCP and FCC phase is calculated. The calculation results show that the BCC phase is stable under low pressure, while the HCP and FCC phase are stable under high pressure. Finally, based on Gibbs free energy and the effect of stress state on the phase transformation, the phase transformation mechanism of body-centered-cubic iron under [101] impaction is investigated, and a reasonable explanation for the phase transformation is obtained.-

Keywords:

- molecular dynamics simulation /

- phase transformation /

- impact /

- iron

[1] Bancroft D, Peterson E L, Minshall S 1956 J. Appl. Phys. 27 291

Google Scholar

Google Scholar

[2] Wang F M, Ingalls R 1998 Phys. Rev. B 57 5647

Google Scholar

Google Scholar

[3] Kalantar D H, Belak J F, Collins G W, Colvin J D, Davies H M, Eggert J H, Germann T C, Hawreliak J, Holian B L, Kadau K, Lomdahl P S, Lorenzana H E, Meyers M A, Rosolankova K, Schneider M S, Sheppard J, Stölken J S, Wark J S 2005 Phys. Rev. Lett. 95 075502

Google Scholar

Google Scholar

[4] Hawreliak J, Colvin J D, Eggert J H, Kalantar D H, Lorenzana H E, Stölken J S 2006 Phys. Rev. B 74 184107

Google Scholar

Google Scholar

[5] Yaakobi B, Boehly T R, Meyerhofer D D, Collins T J B, Remington B A, Allen P G, Pollaine S M, Lorenzana H E, Eggert J H 2005 Phys. Rev. Lett. 95 075501

Google Scholar

Google Scholar

[6] Hawreliak J A, El-Dasher B, Lorenzana H, Kimminau G, Higginbotham A, Nagler B, Vinko S M, Murphy W J, Whitcher T, Wark J S, Rothman S, Park N 2011 Phys. Rev. B 83 144114

Google Scholar

Google Scholar

[7] Kadau K, Germann T C, Lomdahl P S, Holian B L 2002 Science 296 1681

Google Scholar

Google Scholar

[8] Kadau K, Germann T C, Lomdahl P S, Holian B L 2005 Phys. Rev. B 72 064120

Google Scholar

Google Scholar

[9] Kadau K, Germann T C, Lomdahl P S, Albers R C, Wark J S, Higginbotham A, Holian B L 2007 Phys. Rev. Lett. 98 135701

Google Scholar

Google Scholar

[10] 马文, 经福谦, 张亚林, 祝文军 2011 60 066404

Google Scholar

Google Scholar

Ma W, Jing F Q, Zhang Y L, Zhu W J 2011 Acta Phys. Sin. 60 066404

Google Scholar

Google Scholar

[11] Wang B T, Shao J L, Zhang G C, Li W D, Zhang P 2009 J. Phys. Condens. Matter 21 495702

Google Scholar

Google Scholar

[12] Gunkelmann N, Bringa E M, Tramontina D R, Ruestes C J, Suggit M J, Higginbotham A, Wark J S, Urbassek H M 2014 Phys. Rev. B 89 140102

Google Scholar

Google Scholar

[13] Shao J L, Wang P, Zhang F G, He A M 2018 J. Phys. Condens. Matter 30 255401

Google Scholar

Google Scholar

[14] Shao J L, Wang P, Zhang F G, He A M 2018 Sci. Rep. 8 7650

Google Scholar

Google Scholar

[15] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[16] Chamati H, Papanicolaou N I, Mishin Y, Papaconstantopoulos D A 2006 Surf. Sci. 600 1793

Google Scholar

Google Scholar

[17] Holian B L, Lomdahl P S 1998 Science 280 2085

Google Scholar

Google Scholar

[18] 邵建立, 王裴, 秦承森, 周洪强 2008 57 1254

Google Scholar

Google Scholar

Shao J L, Wang P, Qin C S, Zhou H Q 2008 Acta Phys. Sin. 57 1254

Google Scholar

Google Scholar

[19] 崔新林, 李英骏, 祝文军, 祁美兰, 王海燕, 贺红亮, 刘建军 2009 高压 23 37

Google Scholar

Google Scholar

Cui X L, Li Y J, Zhu W J, Qi M L, Wang H Y, He H L, Liu J J 2009 Chin. J. High Pressure Phys. 23 37

Google Scholar

Google Scholar

[20] 何安民, 邵建立, 秦承森, 王裴 2009 58 5667

Google Scholar

Google Scholar

He A M, Shao J L, Qin C S, Wang P 2009 Acta Phys. Sin. 58 5667

Google Scholar

Google Scholar

[21] Stukowski A 2012 Modell. Simul. Mater. Sci. Eng. 20 045021

Google Scholar

Google Scholar

[22] Stukowski A 2010 Modell Simull. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[23] Smith R F, Eggert J H, Swift D C, Wang J, Duffy T S, Braun D G, Rudd R E, Reisman D B, Davis J P, Knudson M D, Collins G W 2013 J. Appl. Phys. 114 223507

Google Scholar

Google Scholar

[24] Amadou N, Resseguier T D, Brambrink E, Vinci T, Mounaix A B, Huser G, Morard G, Guyot F, Miyanishi K, Ozaki N, Kodama R, Koenig M 2016 Phys. Rev. B 93 214108

Google Scholar

Google Scholar

[25] Gunkelmann N, Tramontina D R, Bringa E M, Urbassek H M 2014 New J. Phys. 16 093032

Google Scholar

Google Scholar

[26] Amadou N, de Resseguier T, Dragon A, Brambrink E 2018 Phys. Rev. B 98 024104

Google Scholar

Google Scholar

[27] 邵建立, 秦承森, 王裴 2008 金属学报 44 1085

Google Scholar

Google Scholar

Shao J L, Qin C S, Wang P 2008 Acta Metall. Sin. 44 1085

Google Scholar

Google Scholar

[28] Dewaele A, Denoual C, Anzellini S, Occelli F, Mezouar M, Cordier P, Merkel S, Véron M, Rausch E 2015 Phys. Rev. B 91 174105

Google Scholar

Google Scholar

[29] Xie H X, Yu T, Fang W, Yin F X, Khan D F 2016 Chin. Phys. B 25 126201

Google Scholar

Google Scholar

[30] Cui X L, Zhu W J, He H L, Deng X L, Li Y J 2008 Phys. Rev. B 78 024115

Google Scholar

Google Scholar

[31] 贺红亮, 祝文军, 邓小良, 李英骏, 崔新林 2006 55 5545

Google Scholar

Google Scholar

He H L, Zhu W J, Deng X L, Li Y J, Cui X L 2006 Acta Phys. Sin. 55 5545

Google Scholar

Google Scholar

[32] 崔新林, 祝文军, 贺红亮, 邓小良, 李英骏 2007 高压 21 433

Google Scholar

Google Scholar

Cui X L, Zhu W J, He H L, Deng X L, Li Y J 2007 Chin. J. High Pressure Phys. 21 433

Google Scholar

Google Scholar

[33] Dremov V V, Ionov G V, Sapozhnikov F A, Smirnov N A, Karavaev A V, Vorobyova M A, Ryzhkov M V 2015 EPJ Web Conf. 94 04023

Google Scholar

Google Scholar

[34] Djohari H, Milstein F, Maroudas D 2009 Phys. Rev. B 79 174109

Google Scholar

Google Scholar

[35] Wang S J, Sui M L, Chen Y T, Lu Q H, Ma E, Pei X Y, Li Q Z, Hu H B 2013 Sci. Rep. 3 1086

Google Scholar

Google Scholar

[36] Guo Y F, Wang Y S, Zhao D L, Wu W P 2007 Acta Mater. 55 6634

Google Scholar

Google Scholar

-

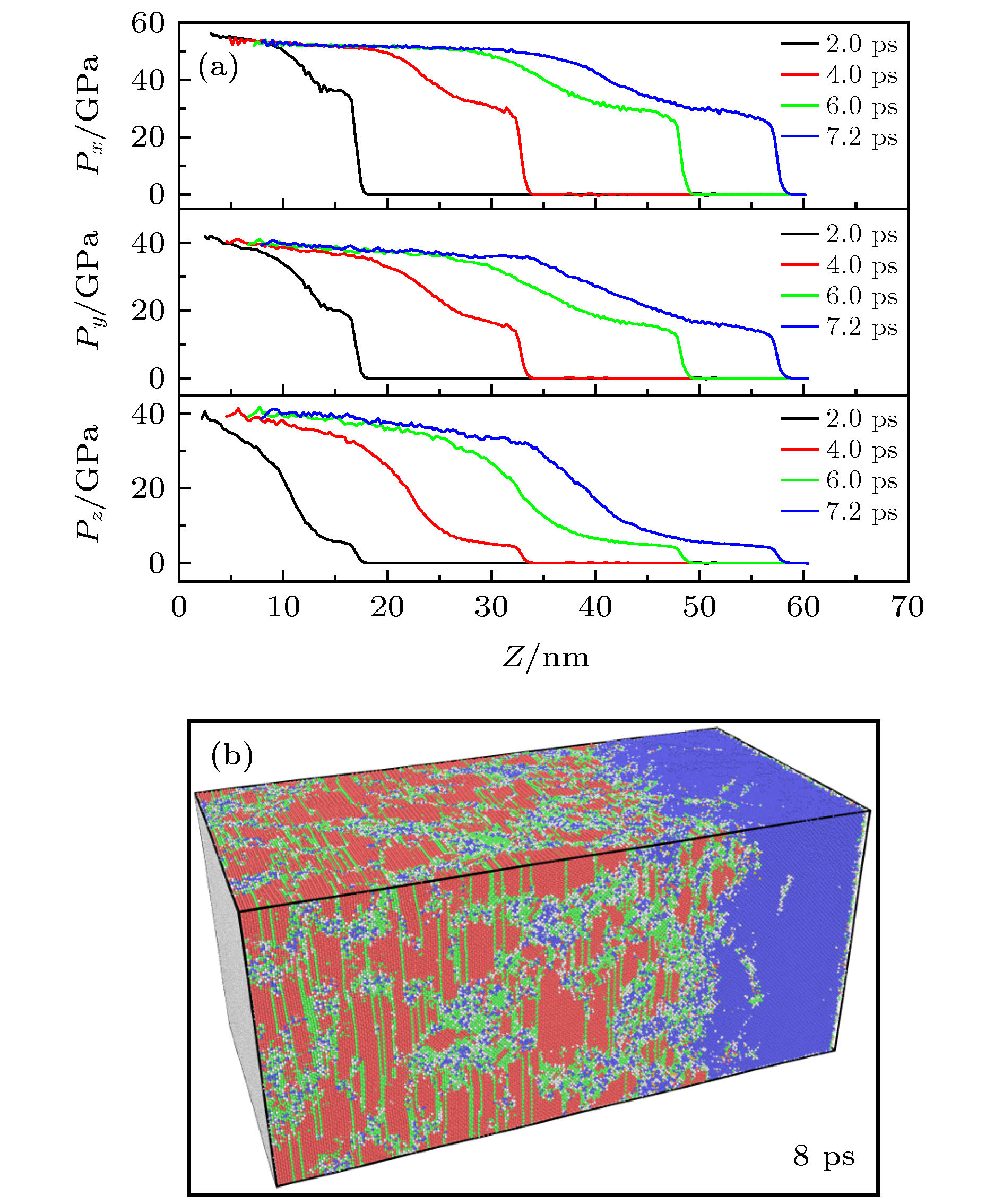

图 2 单晶铁沿[101]方向的冲击压缩过程(冲击速度为1.05 km/s) (a) 冲击过程中不同时刻模型中的压应力; (b) 8 ps时刻的模型, 图中蓝色、红色分别代表BCC和HCP相, 绿色代表FCC相或者HCP相的层错

Fig. 2. The simulation of a single crystal iron model which was impacted along [101] crystal direction (the impact speed was 1.05 km/s): (a) The stress in the impacted sample at different times; (b) the impacted sample at 8 ps. Blue and red parts represent BCC and HCP phase, respectively; green part represents FCC or stacking fault of HCP phase.

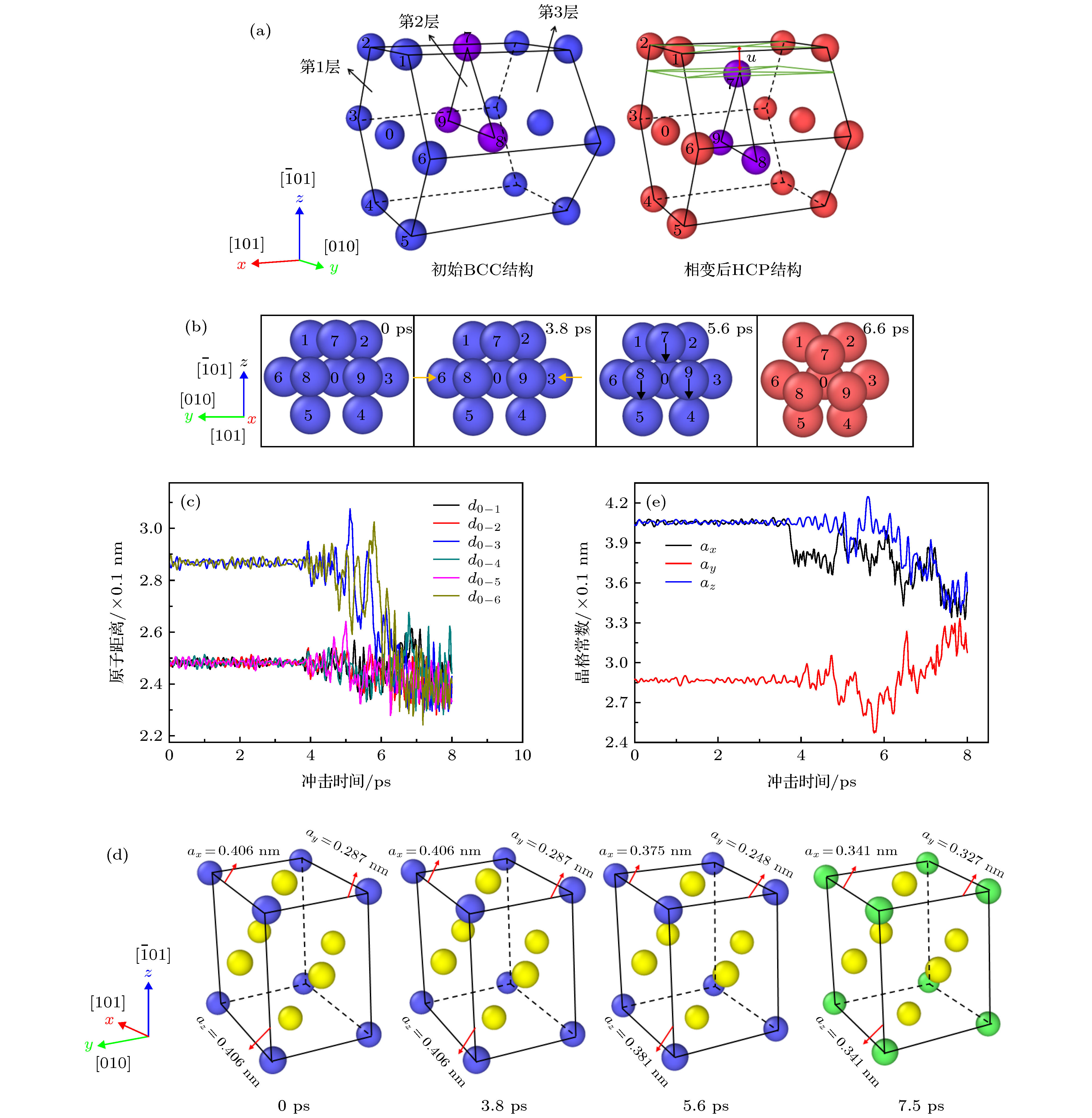

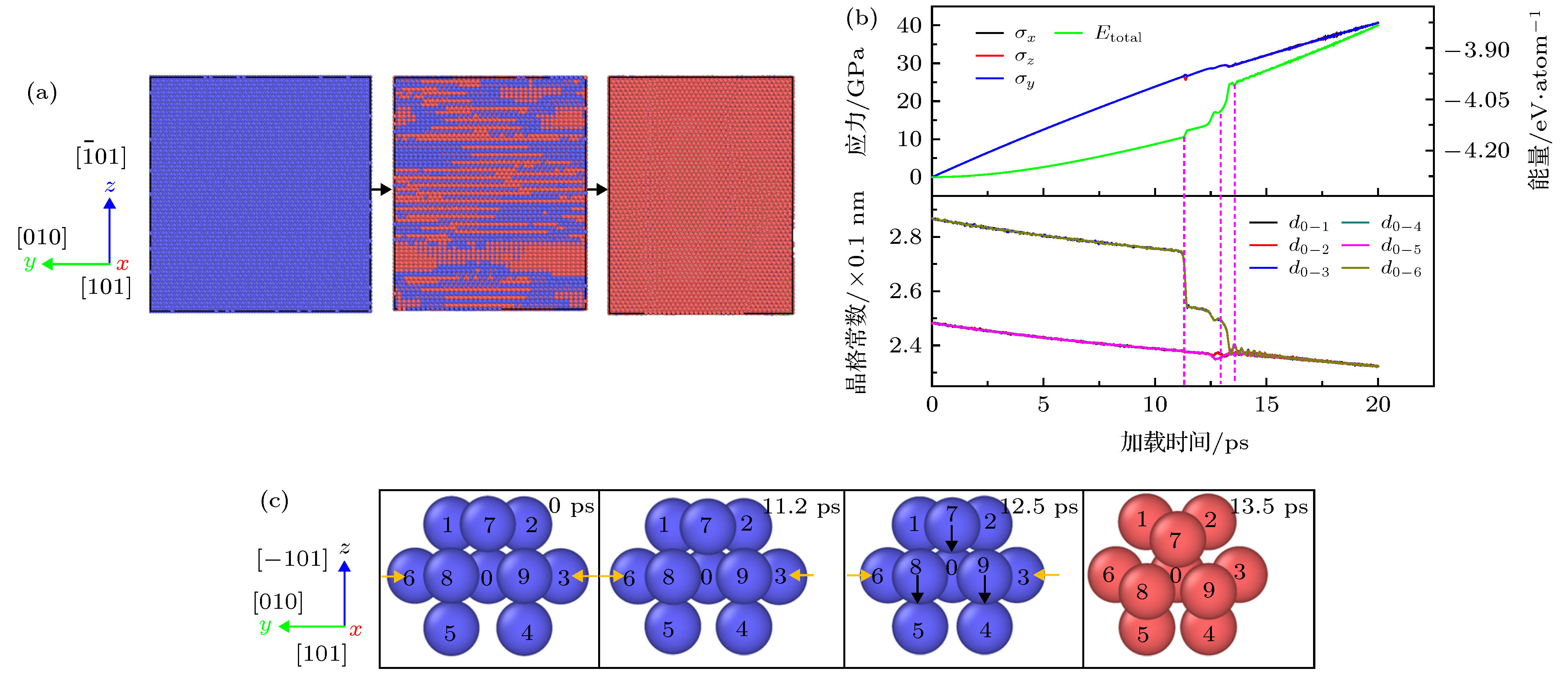

图 4 BCC铁沿[101]晶向冲击条件下HCP和FCC相的形成机制 (a) 一个结构单元的BCC-HCP相变机制; (b) (101)面的原子运动规律(黄色箭头代表(101)面原子收缩方向, 黑色箭头代表(101)面相对滑移方向(1—6号原子和7—9号原子分别对应(a)中的第一层和第二层原子面; u为(101)面相对滑移距离.); (c) 原子间距离随冲击时间的变化; (d) BCC-FCC相变机制(为了方便观察, 将结构单元中的面心原子设置为黄色); (e) 晶格常数随冲击时间的变化

Fig. 4. The formation mechanisms of HCP and FCC phase under impact of BCC iron along [101] direction: (a) The BCC-HCP phase transition mechanism of a structural unit; (b) the atomic motion of (101) plane (yellow arrow represents the contraction direction of (101) plane, and black arrow represents the relative sliding direction of (101) plane (atoms 1—6 and 7—9 correspond to the first and second atomic planes in (a) respectively; u is the relative sliding distance of (101) plane); (c) the change of atomic distance with impact time; (d) BCC-FCC phase transition mechanism (set the face center atom in the structural unit to yellow for easy observation); (e) the change of lattice constant with impact time.

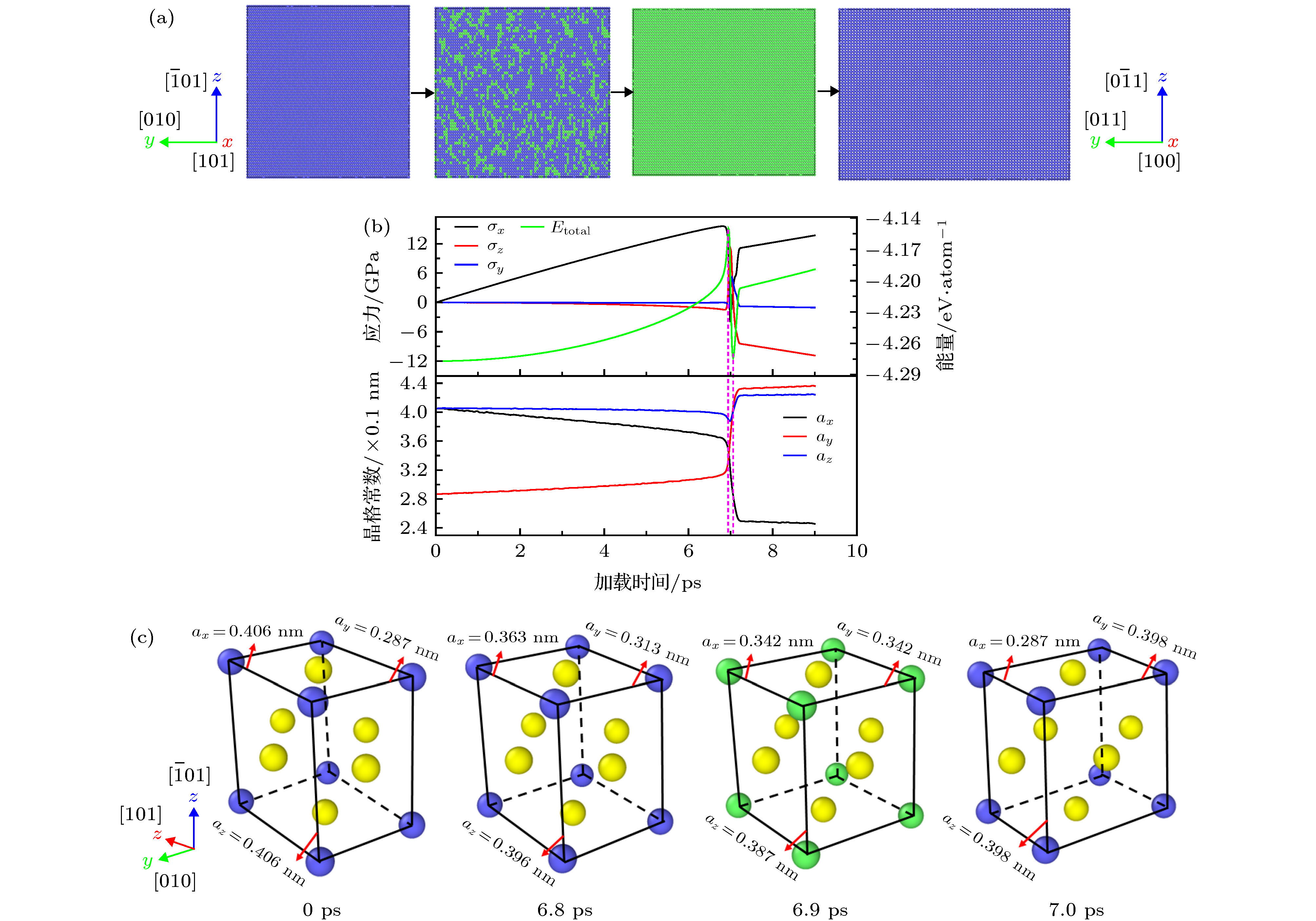

图 5 BCC铁沿[101]晶向在单轴压缩下的相变机制 (a) 压缩过程中的三个快照; (b)应力、晶格常数以及单个原子能量(

$ {E}_{\mathrm{t}\mathrm{o}\mathrm{t}\mathrm{a}\mathrm{l}} $ )随加载时间的变化; (c) 一个结构单元的相变过程(为了方便观察, 将结构单元中的面心原子设置为黄色)Fig. 5. The transformation mechanism of BCC iron under uniaxial compression along [101] direction: (a) Three snapshots during compression (b) the variation of stress, lattice constant and energy of single atom (

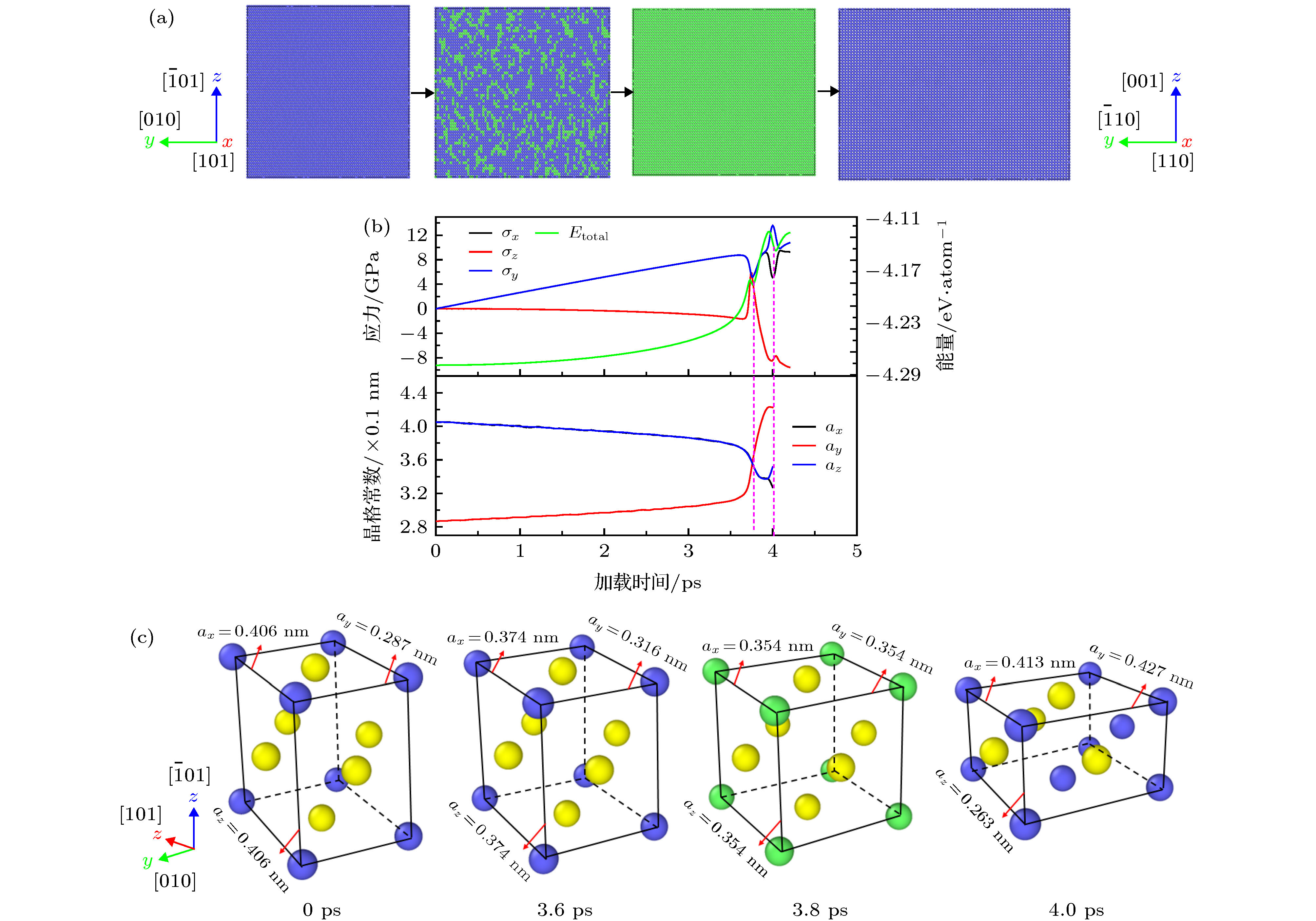

$ {E}_{\mathrm{t}\mathrm{o}\mathrm{t}\mathrm{a}\mathrm{l}} $ ) with loading time; (c) the phase transition process of a structural unit (set the face center atom in the structural unit to yellow for easy observation).图 6 BCC铁沿[101]和

$ [\bar101] $ 方向同时压缩下的相变机制 (a) 压缩过程中的三个快照; (b) 应力、晶格常数以及单个原子能量随加载时间的变化; (c)一个结构单元的相变过程(结构单元中的面心原子设置为黄色)Fig. 6. The phase transformation mechanism of BCC iron under simultaneous compression along [101] and

$ [\bar101] $ directions: (a) Three snapshots during compression; (b) the variation of stress, lattice constant and energy of single atom with loading time; (c) the phase transition process of a structural unit (set the face center atom in the structural unit to yellow for easy observation).图 7 沿[101]和[010]方向同时压缩下BCC铁的相变机理 (a) 压缩期间的三个快照(蓝色和红色球分别代表BCC相和HCP相的铁原子); (b) 应力、原子距离以及单个原子能量随加载时间的变化(原子距离与(c)中原子相对应); (c) BCC-HCP相变机制(黄色箭头代表(101)面原子收缩方向, 黑色箭头代表(101)面相对滑移方向)

Fig. 7. The transformation mechanism of BCC iron under simultaneous compression along [101] and [010] directions: (a) Three snapshots during compression (blue and red spheres represent the iron atoms of BCC and HCP phases respectively); (b) the variation of stress, atomic distance and energy of single atom with loading time (the atomic distance corresponds to the atom in (c)); (c) BCC-HCP phase transformation process (yellow arrow represents the contraction direction of (101) plane, and black arrow represents the relative sliding direction of (101) plane).

图 8 BCC铁在三轴压缩下的相变机理 (a) 压缩过程中的三个快照(蓝色和红色的球分别代表BCC相和HCP相的铁原子); (b) 应力、原子距离以及单个原子能量随加载时间的变化(原子距离与(c)中原子相对应); (c) BCC-HCP相变机制(黄色箭头代表(101)面原子收缩方向, 黑色箭头代表(101)面相对滑移方向)

Fig. 8. The phase transformation mechanism of BCC iron under triaxial compression: (a) Three snapshots during compression (blue and red spheres represent the iron atoms of BCC and HCP phases respectively); (b) the variation of stress, atomic distance and energy of single atom with loading time (the atomic distance corresponds to the atom in (c)); (c) BCC-HCP phase transformation process ( yellow arrow indicates the contraction direction of (101) plane atom, and black arrow indicates the relative sliding direction of (101) plane atom).

-

[1] Bancroft D, Peterson E L, Minshall S 1956 J. Appl. Phys. 27 291

Google Scholar

Google Scholar

[2] Wang F M, Ingalls R 1998 Phys. Rev. B 57 5647

Google Scholar

Google Scholar

[3] Kalantar D H, Belak J F, Collins G W, Colvin J D, Davies H M, Eggert J H, Germann T C, Hawreliak J, Holian B L, Kadau K, Lomdahl P S, Lorenzana H E, Meyers M A, Rosolankova K, Schneider M S, Sheppard J, Stölken J S, Wark J S 2005 Phys. Rev. Lett. 95 075502

Google Scholar

Google Scholar

[4] Hawreliak J, Colvin J D, Eggert J H, Kalantar D H, Lorenzana H E, Stölken J S 2006 Phys. Rev. B 74 184107

Google Scholar

Google Scholar

[5] Yaakobi B, Boehly T R, Meyerhofer D D, Collins T J B, Remington B A, Allen P G, Pollaine S M, Lorenzana H E, Eggert J H 2005 Phys. Rev. Lett. 95 075501

Google Scholar

Google Scholar

[6] Hawreliak J A, El-Dasher B, Lorenzana H, Kimminau G, Higginbotham A, Nagler B, Vinko S M, Murphy W J, Whitcher T, Wark J S, Rothman S, Park N 2011 Phys. Rev. B 83 144114

Google Scholar

Google Scholar

[7] Kadau K, Germann T C, Lomdahl P S, Holian B L 2002 Science 296 1681

Google Scholar

Google Scholar

[8] Kadau K, Germann T C, Lomdahl P S, Holian B L 2005 Phys. Rev. B 72 064120

Google Scholar

Google Scholar

[9] Kadau K, Germann T C, Lomdahl P S, Albers R C, Wark J S, Higginbotham A, Holian B L 2007 Phys. Rev. Lett. 98 135701

Google Scholar

Google Scholar

[10] 马文, 经福谦, 张亚林, 祝文军 2011 60 066404

Google Scholar

Google Scholar

Ma W, Jing F Q, Zhang Y L, Zhu W J 2011 Acta Phys. Sin. 60 066404

Google Scholar

Google Scholar

[11] Wang B T, Shao J L, Zhang G C, Li W D, Zhang P 2009 J. Phys. Condens. Matter 21 495702

Google Scholar

Google Scholar

[12] Gunkelmann N, Bringa E M, Tramontina D R, Ruestes C J, Suggit M J, Higginbotham A, Wark J S, Urbassek H M 2014 Phys. Rev. B 89 140102

Google Scholar

Google Scholar

[13] Shao J L, Wang P, Zhang F G, He A M 2018 J. Phys. Condens. Matter 30 255401

Google Scholar

Google Scholar

[14] Shao J L, Wang P, Zhang F G, He A M 2018 Sci. Rep. 8 7650

Google Scholar

Google Scholar

[15] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[16] Chamati H, Papanicolaou N I, Mishin Y, Papaconstantopoulos D A 2006 Surf. Sci. 600 1793

Google Scholar

Google Scholar

[17] Holian B L, Lomdahl P S 1998 Science 280 2085

Google Scholar

Google Scholar

[18] 邵建立, 王裴, 秦承森, 周洪强 2008 57 1254

Google Scholar

Google Scholar

Shao J L, Wang P, Qin C S, Zhou H Q 2008 Acta Phys. Sin. 57 1254

Google Scholar

Google Scholar

[19] 崔新林, 李英骏, 祝文军, 祁美兰, 王海燕, 贺红亮, 刘建军 2009 高压 23 37

Google Scholar

Google Scholar

Cui X L, Li Y J, Zhu W J, Qi M L, Wang H Y, He H L, Liu J J 2009 Chin. J. High Pressure Phys. 23 37

Google Scholar

Google Scholar

[20] 何安民, 邵建立, 秦承森, 王裴 2009 58 5667

Google Scholar

Google Scholar

He A M, Shao J L, Qin C S, Wang P 2009 Acta Phys. Sin. 58 5667

Google Scholar

Google Scholar

[21] Stukowski A 2012 Modell. Simul. Mater. Sci. Eng. 20 045021

Google Scholar

Google Scholar

[22] Stukowski A 2010 Modell Simull. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[23] Smith R F, Eggert J H, Swift D C, Wang J, Duffy T S, Braun D G, Rudd R E, Reisman D B, Davis J P, Knudson M D, Collins G W 2013 J. Appl. Phys. 114 223507

Google Scholar

Google Scholar

[24] Amadou N, Resseguier T D, Brambrink E, Vinci T, Mounaix A B, Huser G, Morard G, Guyot F, Miyanishi K, Ozaki N, Kodama R, Koenig M 2016 Phys. Rev. B 93 214108

Google Scholar

Google Scholar

[25] Gunkelmann N, Tramontina D R, Bringa E M, Urbassek H M 2014 New J. Phys. 16 093032

Google Scholar

Google Scholar

[26] Amadou N, de Resseguier T, Dragon A, Brambrink E 2018 Phys. Rev. B 98 024104

Google Scholar

Google Scholar

[27] 邵建立, 秦承森, 王裴 2008 金属学报 44 1085

Google Scholar

Google Scholar

Shao J L, Qin C S, Wang P 2008 Acta Metall. Sin. 44 1085

Google Scholar

Google Scholar

[28] Dewaele A, Denoual C, Anzellini S, Occelli F, Mezouar M, Cordier P, Merkel S, Véron M, Rausch E 2015 Phys. Rev. B 91 174105

Google Scholar

Google Scholar

[29] Xie H X, Yu T, Fang W, Yin F X, Khan D F 2016 Chin. Phys. B 25 126201

Google Scholar

Google Scholar

[30] Cui X L, Zhu W J, He H L, Deng X L, Li Y J 2008 Phys. Rev. B 78 024115

Google Scholar

Google Scholar

[31] 贺红亮, 祝文军, 邓小良, 李英骏, 崔新林 2006 55 5545

Google Scholar

Google Scholar

He H L, Zhu W J, Deng X L, Li Y J, Cui X L 2006 Acta Phys. Sin. 55 5545

Google Scholar

Google Scholar

[32] 崔新林, 祝文军, 贺红亮, 邓小良, 李英骏 2007 高压 21 433

Google Scholar

Google Scholar

Cui X L, Zhu W J, He H L, Deng X L, Li Y J 2007 Chin. J. High Pressure Phys. 21 433

Google Scholar

Google Scholar

[33] Dremov V V, Ionov G V, Sapozhnikov F A, Smirnov N A, Karavaev A V, Vorobyova M A, Ryzhkov M V 2015 EPJ Web Conf. 94 04023

Google Scholar

Google Scholar

[34] Djohari H, Milstein F, Maroudas D 2009 Phys. Rev. B 79 174109

Google Scholar

Google Scholar

[35] Wang S J, Sui M L, Chen Y T, Lu Q H, Ma E, Pei X Y, Li Q Z, Hu H B 2013 Sci. Rep. 3 1086

Google Scholar

Google Scholar

[36] Guo Y F, Wang Y S, Zhao D L, Wu W P 2007 Acta Mater. 55 6634

Google Scholar

Google Scholar

计量

- 文章访问数: 14997

- PDF下载量: 139

- 被引次数: 0

下载:

下载: