-

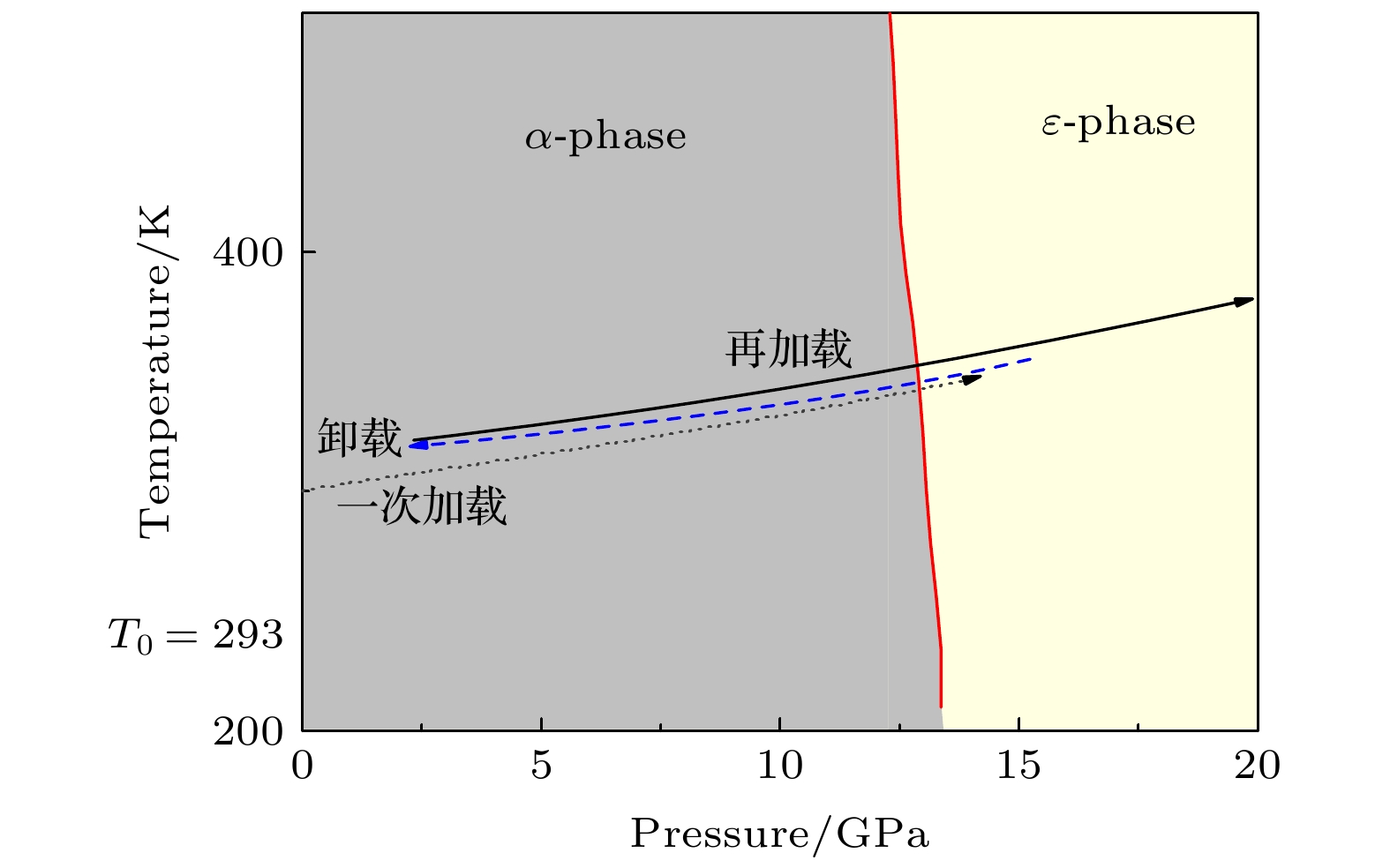

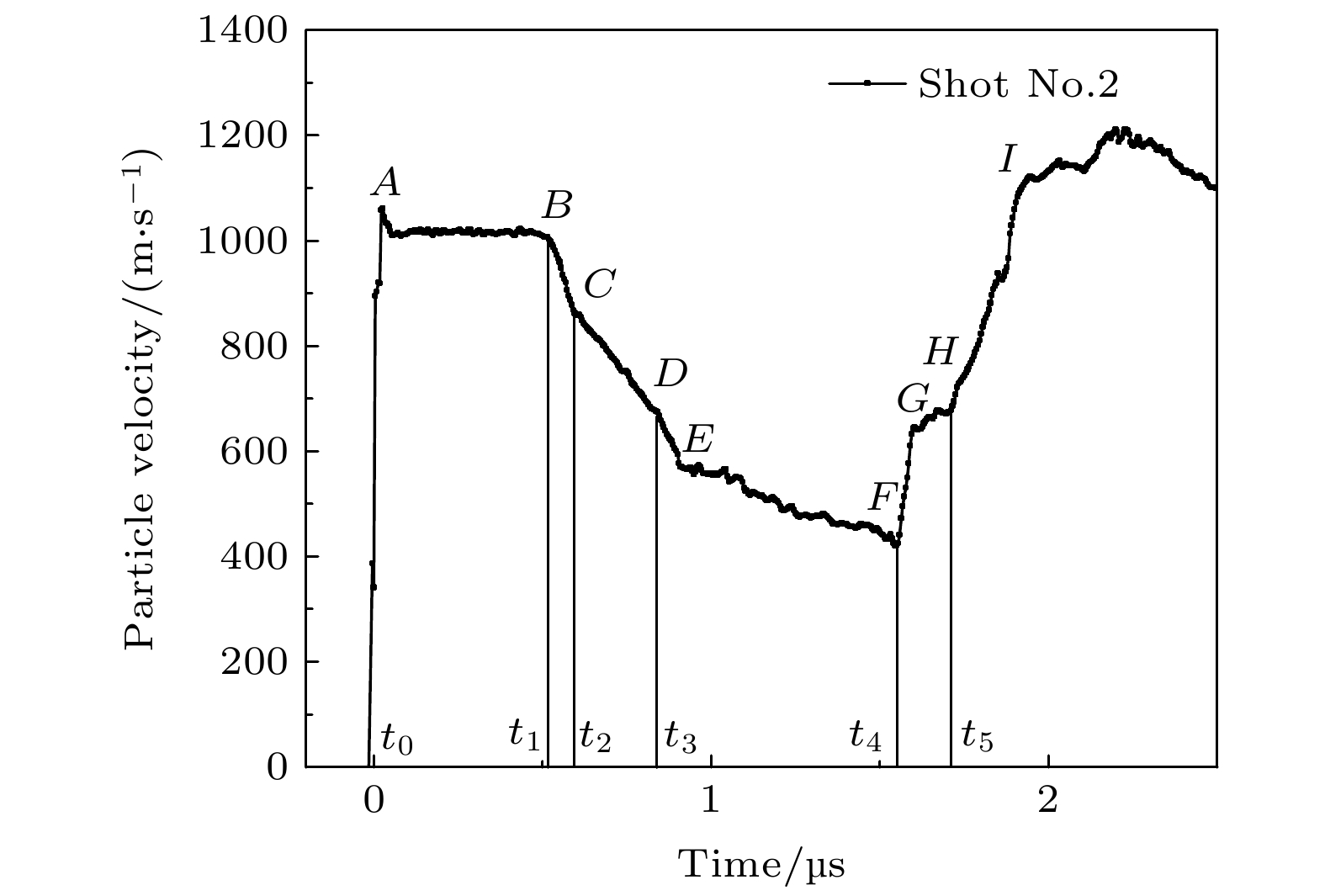

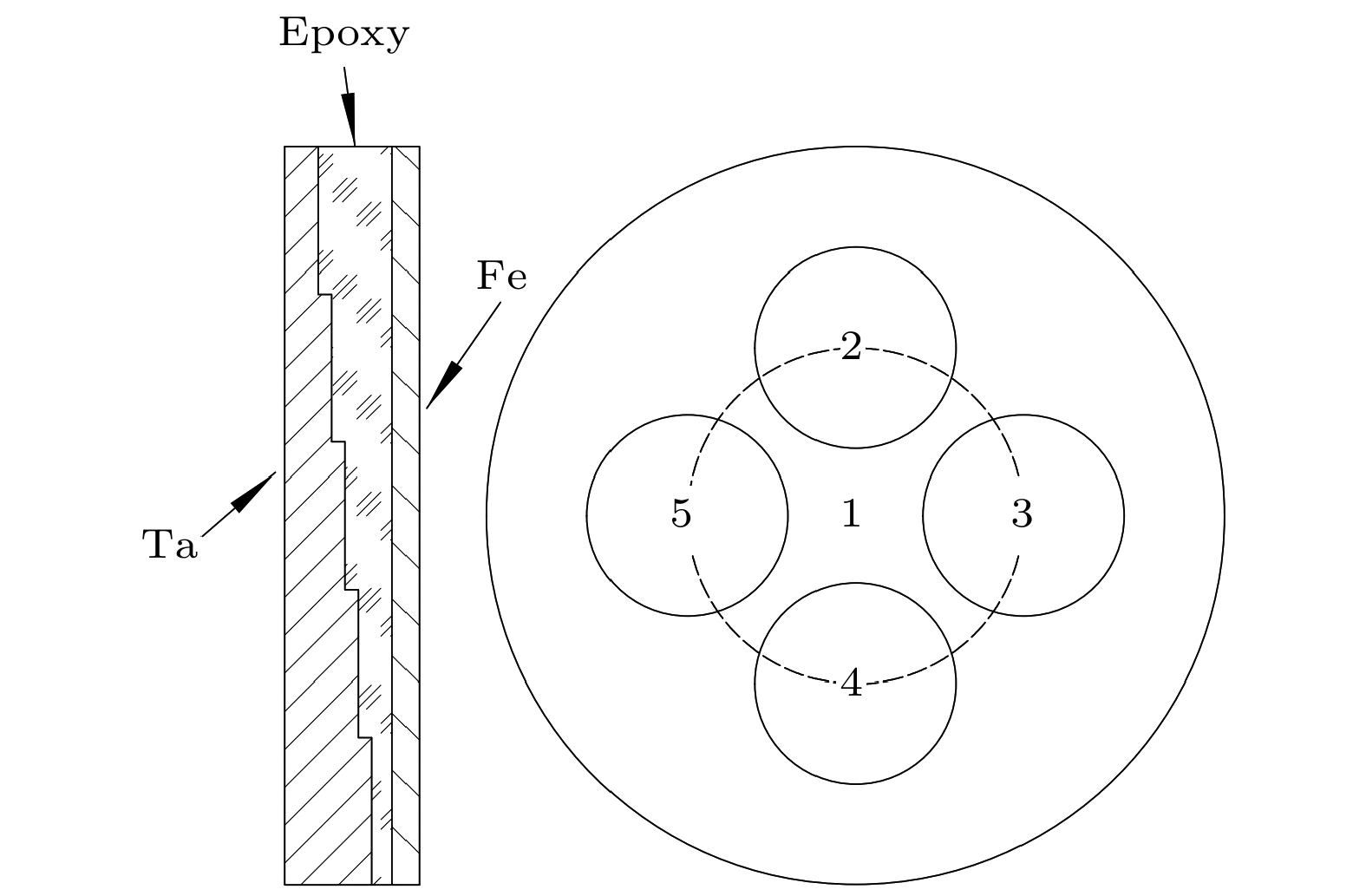

采用气炮作为加载手段, 结合反向碰撞技术和多台阶三层组合飞片技术, 通过精细的样品/窗口波剖面测量, 对典型加载-卸载-再加载路径下铁的相变动力学特性进行了研究. 观测到一次卸载阶段的多波结构及再加载段的双波结构. 获得首次逆相变阈值约为(11.3 ± 0.5) GPa, 首次加卸载相变特征时间为30 ns; 再加载相变起始压力为10—12 GPa, 且随着再加载初始态ε相质量分数降低而降低. 实验显示二次相变压力阈值与ε相残余质量分数以及逆相变子相所含孪晶、缺陷相关, 同时二次加载相转变速率比首次加载更快. 上述结果揭示了多晶铁相变动力学行为与加载路径的强耦合, 为相关研究提供了新的视角和实验支撑.The dynamics of iron under extreme conditions like high temperature and high pressure has been well studied for several decades. But, there have been not many reports about the phase transition kinetics coupled with complicated thermodynamic paths, especially loading-unloading-reloading path, which is closer to the real applications. A three-layer structure impactor with five stages performed in the front-surface experiment is made up to approach the special path. We choose epoxy to be the adhesive as it has low impedance and high strength. Tantalum, the standard material of high impedance which also has single wave structure, is selected for reloading process. The wave profile shows a 3-wave structure in the first unloading period and the inverse phase transition threshold is calculated to be about 11.3 GPa. This onset pressure of reverse phase transition is not consistent with Barker’s result, higher than his result (about 2.5 GPa). By comparing with recalculated result of Jensen’s data, we find that our result is consistent with theirs.In this work the inverse phase transition ends at about 10 GPa, the value from this way which is higher than Barker’s finding, even higher than his result of the threshold pressure of reverse phase transition. And at this state there remains 12%–15% of ε phase. So it cannot be seen as the completed reverse phase transformation. The phase transition onset pressure is 10–12 GPa on the reloading path and it is about 1–2 GPa lower than the first phase transition. By simulating the wave profile, the discrepancy of using different phase transformation characteristic time τ as 30 ns and 5 ns is analyzed. It can be seen that the phase transition rate of reloading is faster than that of the first loading process. These phenomena may be caused by the twins and the dislocations which are produced by the inverse phase transition. Also, as unloading time becomes longer, the mass fraction of ε phase becomes lesser and the onset pressure of α → ε phase transition becomes lower. This because with more ε phases transforming into α phase, more twins and dislocations will be produced in material. Therefore, it brings the lower onset pressure.

-

Keywords:

- iron /

- shock loaded /

- kinetics of phase transition /

- reload

[1] Tonkov E Y, Ponyatovsky E G 2004 Phase Transformations of Elements Under High Pressure (Boca Raton: CRC Press) pp53−254, 39−240

[2] Minshall S 1955 J. Appl. Phys. 26 463

Google Scholar

Google Scholar

[3] Bancroft D, Peterson E L, Minshall S 1956 J. Appl. Phys. 27 291

Google Scholar

Google Scholar

[4] Barker L M, Hollenbach R E 1972 J. Appl. Phys. 43 4669

Google Scholar

Google Scholar

[5] Barker L M, Hollenbach R E 1974 J. Appl. Phys. 45 4872

Google Scholar

Google Scholar

[6] Balchan A S, Drickamer H G 1961 Rev. Sci. Instrum. 32 308

Google Scholar

Google Scholar

[7] Jamison J C, Lawson A W 1962 J. Appl. Phys. 33 776

Google Scholar

Google Scholar

[8] Takahashi T, Bassett W A 1964 Science 145 483

Google Scholar

Google Scholar

[9] Clenden R L, Drickamer H G 1964 J. Phys. Chem. Solids 25 865

Google Scholar

Google Scholar

[10] Jensen B J, GrayⅢ G T, Hixson R S 2009 J. Appl. Phys. 105 103502

Google Scholar

Google Scholar

[11] Bastea M, Bastea S, Becker R 2009 Appl. Phys. Lett. 95 241911

Google Scholar

Google Scholar

[12] Smith R F, Eggert J H, Swift D C, et al. 2013 J. Appl. Phys. 114 223507

Google Scholar

Google Scholar

[13] 施尚春, 陈攀森, 黄跃 1991 高压 5 205

Google Scholar

Google Scholar

Shi S C, Chen P S, Huang Y 1991 Chin. J. High Pressure Phys. 5 205

Google Scholar

Google Scholar

[14] Tan H, Weng J D, Wang X Proceedings of the 8th National Conference on Explosion Mechanics Ji’an, China, September 20−25, 2007 p75

[15] 谭华 2018 实验冲击波物理 (北京: 国防工业出版社) 第203−218页

Tan H 2018 Experimental Shock Wave Physics (Vol. 1) (Beijing: National Defense Industry Press) pp3−18

[16] Hayes D B W 1975 J. Appl. Phys. 46 3438

Google Scholar

Google Scholar

[17] Boettger J C, Wallace D C 1997 1997 Phys. Rev. B 55 2840

[18] 种涛, 唐志平, 谭福利, 王桂吉, 赵剑衡 2018 高压 32 014102

Chong T, Tang Z P, Tan F L, Wang G J, Zhao J H 2018 Chin. J. High Pressure Phys. 32 014102

[19] Dougherty L M, GrayⅢ G T, Cerreta E K, McCabe R J, Field R D, Bingert J F 2009 Scr. Mater. 60 772

Google Scholar

Google Scholar

[20] Wang S J, Sui M L, Chen Y T, Lu Q H, M E, Pei X Y, Li Q Z, Hu H B 2013 Sci. Rep. 3 1086

Google Scholar

Google Scholar

[21] 唐志平 2008 冲击相变(北京: 科学出版社) 第87−106页

Tang Z P 2008 Shock Phase Transiformation (Vol. 1) (Beijing: Higher Education Press) (in Chinese)

-

图 5 典型飞片/窗口界面粒子速度剖面(A点为碰撞时刻, B点为稀疏波到达窗口界面, C点为弹塑性卸载拐折点, D点为逆相变起始点, E点为卸载过程终点, F点为二次加载起始点, G为相变临界点, H为再加载P2波到达时刻)

Fig. 5. Particle velocity of impactor/window interface (A is the impact moment, B is the rarefaction wave arrival time, C is the elastoplastic unloading crutch point, D is the start point of reverse phase transition, E is the ending of unloading, F is the start point of reloading, G is the phase transition point of the reloading process, H is the reloading P2 wave arrival time).

表 1 实验材料Hugoniot参数

Table 1. Hugoniot parameter of materials.

材料 $ {{\rho }}_{0}/{({\rm{g}} \cdot {\rm{cm}}}^{-3}) $ $ {{C}}_{0} $/$ ({\rm{km}} \cdot {\rm{s}}^{-1}) $ λ Ta 16.65 3.43 1.19 Epoxy 1.19 2.73 1.49 Fe样品 7.86 3.93 1.58 LiF窗口 2.64 5.21 1.34 表 2 实验各部件名义尺寸

Table 2. Gauges of components.

部件 $ {{\rho }}_{0}/\left({{\rm{g}} \cdot {\rm{cm}}}^{-3}\right) $ 直径

/mm厚度

/mm对应Epoxy

厚度/mmTa 1号台阶 16.65 55 2 2.2 Ta 2号台阶 16.65 15 2.5 1.7 Ta 3号台阶 16.65 15 2.8 1.4 Ta 4号台阶 16.65 15 3.2 1.0 Ta 5号台阶 16.65 15 3.5 0.7 Epoxy 1.19 55 — — Fe样品 7.86 55 1.5 — LiF窗口 2.64 55 20 — 表 3 实验shot No.2测量及计算结果

Table 3. The data of experiment shot No.2.

$ {W}/(\mathrm{m}\cdot {\mathrm{s}}^{-1}) $ $ {{u}}_{\mathrm{w},\mathrm{H}}/(\mathrm{m}\cdot {\mathrm{s}}^{-1}) $ $ {{u}}_{\mathrm{m}}/(\mathrm{m}\cdot {\mathrm{s}}^{-1}) $ $ {{P}}_{\mathrm{m}}/\mathrm{G}\mathrm{P}\mathrm{a} $ $ {{p}}_{\mathrm{D}}/\mathrm{G}\mathrm{P}\mathrm{a} $ $ {{p}}_{\mathrm{E}}/\mathrm{G}\mathrm{P}\mathrm{a} $ $ {\Delta {t}}_{\mathrm{D}\mathrm{E}}/\text{μ}\mathrm{s} $ Shot No.1 1475 ± 15 986 ± 10 489 ± 10 17.0 ± 0.1 11.2 ± 0.4 10.0 ± 0.2 0.08 Shot No.2 1521 ± 15 1015 ± 10 506 ± 10 17.6 ± 0.1 11.4 ± 0.4 10.0 ± 0.2 0.07 表 4 shot No.1和shot No.2各台阶对应卸载尾段残余ε相质量分数及二次加载相变压力

Table 4. The mass fraction of ε phase in the end of unloading process and reload phase transition pressure on each stage.

Shot No.1 Shot No.2 台阶编号 ε相质量

分数/%二次加载相

变压力/GPaε相质量

分数/%二次加载相

变压力/GPa5 52 11.5 77 12.0 4 27 10.9 36 11.1 3 21 10.6 26 10.8 2 16 10.4 20 10.5 1 12 10.1 15 10.2 -

[1] Tonkov E Y, Ponyatovsky E G 2004 Phase Transformations of Elements Under High Pressure (Boca Raton: CRC Press) pp53−254, 39−240

[2] Minshall S 1955 J. Appl. Phys. 26 463

Google Scholar

Google Scholar

[3] Bancroft D, Peterson E L, Minshall S 1956 J. Appl. Phys. 27 291

Google Scholar

Google Scholar

[4] Barker L M, Hollenbach R E 1972 J. Appl. Phys. 43 4669

Google Scholar

Google Scholar

[5] Barker L M, Hollenbach R E 1974 J. Appl. Phys. 45 4872

Google Scholar

Google Scholar

[6] Balchan A S, Drickamer H G 1961 Rev. Sci. Instrum. 32 308

Google Scholar

Google Scholar

[7] Jamison J C, Lawson A W 1962 J. Appl. Phys. 33 776

Google Scholar

Google Scholar

[8] Takahashi T, Bassett W A 1964 Science 145 483

Google Scholar

Google Scholar

[9] Clenden R L, Drickamer H G 1964 J. Phys. Chem. Solids 25 865

Google Scholar

Google Scholar

[10] Jensen B J, GrayⅢ G T, Hixson R S 2009 J. Appl. Phys. 105 103502

Google Scholar

Google Scholar

[11] Bastea M, Bastea S, Becker R 2009 Appl. Phys. Lett. 95 241911

Google Scholar

Google Scholar

[12] Smith R F, Eggert J H, Swift D C, et al. 2013 J. Appl. Phys. 114 223507

Google Scholar

Google Scholar

[13] 施尚春, 陈攀森, 黄跃 1991 高压 5 205

Google Scholar

Google Scholar

Shi S C, Chen P S, Huang Y 1991 Chin. J. High Pressure Phys. 5 205

Google Scholar

Google Scholar

[14] Tan H, Weng J D, Wang X Proceedings of the 8th National Conference on Explosion Mechanics Ji’an, China, September 20−25, 2007 p75

[15] 谭华 2018 实验冲击波物理 (北京: 国防工业出版社) 第203−218页

Tan H 2018 Experimental Shock Wave Physics (Vol. 1) (Beijing: National Defense Industry Press) pp3−18

[16] Hayes D B W 1975 J. Appl. Phys. 46 3438

Google Scholar

Google Scholar

[17] Boettger J C, Wallace D C 1997 1997 Phys. Rev. B 55 2840

[18] 种涛, 唐志平, 谭福利, 王桂吉, 赵剑衡 2018 高压 32 014102

Chong T, Tang Z P, Tan F L, Wang G J, Zhao J H 2018 Chin. J. High Pressure Phys. 32 014102

[19] Dougherty L M, GrayⅢ G T, Cerreta E K, McCabe R J, Field R D, Bingert J F 2009 Scr. Mater. 60 772

Google Scholar

Google Scholar

[20] Wang S J, Sui M L, Chen Y T, Lu Q H, M E, Pei X Y, Li Q Z, Hu H B 2013 Sci. Rep. 3 1086

Google Scholar

Google Scholar

[21] 唐志平 2008 冲击相变(北京: 科学出版社) 第87−106页

Tang Z P 2008 Shock Phase Transiformation (Vol. 1) (Beijing: Higher Education Press) (in Chinese)

计量

- 文章访问数: 6895

- PDF下载量: 114

- 被引次数: 0

下载:

下载: