-

筒形阴极由于具有向内放电的特性, 可改善高功率脉冲磁控溅射技术放电不稳定、溅射材料离化率差异大等缺陷. 然而其产生的等离子体仅能依靠浓度差扩散的方式向基体运动, 沉积速率并没有明显改善, 尤其是在远离阴极区域. 使用外扩型磁场对离子运动进行引导, 可实现等离子体的聚焦和远距离输运, 从而减少离子损失, 提高沉积效率. 本文从模拟和实验的角度对磁场的布局与设置进行研究, 并获得不同磁场条件下的等离子体空间和时间输运特性及其对薄膜沉积的影响. 结果表明电磁场的引入不仅可以大幅提高筒形阴极内等离子体的引出效率, 实现不同程度的引出或聚焦, 而且对等离子体放电也产生明显的增强或减弱, 可根据不同的需求或材料进行精确调控. 通过控制磁场, 可获得较强的HiPIMS放电和较高的沉积速率, 实验结果与仿真预测相符合. 该工作完善了HiPIMS沉积技术在沉积效率上的不足, 拓宽了筒形阴极的溅射工艺窗口和适用范围, 有助于HiPIMS更进一步的推广与应用.High-power impulse magnetron sputtering (HiPIMS) is a new magnetron sputtering technique which can produce high-density plasmas with a high ionization rate and prepare coatings with a good performance such as large density and high adhesion. To obtain stable discharge and universal materials’ ionization rates, a cylindrical cathode is proposed based on the hollow cathode effect. However, the unusual plasma transport results in a large loss of ions and a low deposition rate. To solve these problems, an expanding electromagnetic field is proposed to control the plasma transport in this work. The particle in cell/Monte Carlo collision (PIC/MCC) method and the plasma diffusion model are used to simulate the plasma transport in and out of the cylindrical cathode with different currents in the electromagnetic coils, respectively. The simulation results reveal that different electromagnetic fields can achieve different plasma density distributions, resulting in different accumulated positions and different diffusion paths. When the coil current is positive, the resistance to axial motion of electrons is small but the resistance to radial motion is large, so that the hollow cathode effect is weakened and the plasma beam tends to output uniformly. When the coil current is negative, the resistance to axial motion of electrons is large but the resistance to radial motion is small, so that the hollow cathode effect is enhanced and the plasma tends to gather on the central axis and then diffuses outward. To verify the simulation results, Ar/Cr HiPIMS discharge experiments are carried out with the cylindrical cathode in a homemade vacuum system. The experiment results indicate that the threshold voltage, the plasma flow shape, the optical emission spectrum (OES) intensity, and the deposition distribution are determined by the electromagnetic coil current. The variation tendency is in coincidence with the prediction of the simulation. Consequently, by adding an expanding electromagnetic field, the plasma discharge in the cylindrical cathode can be easily controlled and the deposition rate is greatly enhanced. This electromagnetic control strategy not only realizes the enhancement and effective control of plasma, but also improves the homogeneity and the deposition rate of the coatings, thus laying a foundation for the industrial application of HiPIMS.

-

Keywords:

- high-power impulse magnetron sputtering /

- cylindrical cathode /

- electromagnetic field /

- deposition rate

[1] Kouznetsov V, Macák K, Schneider J M, Helmersson U, Petrov I 1999 Surf. Coat. Technol. 122 290

Google Scholar

Google Scholar

[2] Bohlmark J, Alami J, Christou C, Ehiasarian A P, Helmersson U 2005 J. Vac. Sci. Technol., A 23 18

Google Scholar

Google Scholar

[3] 吴忠振, 田修波, 潘锋, 傅劲裕, 朱剑豪 2014 63 185207

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Phys. Sin. 63 185207

Google Scholar

Google Scholar

[4] Anders A 2011 Surf. Coat. Technol. 20 S1

Google Scholar

Google Scholar

[5] 吴忠振, 田修波, 潘锋, Ricky K Y Fu, 朱剑豪 2014 金属学报 10 1279

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Meta. Sin. 10 1279

Google Scholar

Google Scholar

[6] Samuelsson M, Lundin D, Jensen J, Raadu M A, Gudmundsson J T, Helmersson U 2010 Surf. Coat. Technol. 205 591

Google Scholar

Google Scholar

[7] Sarakinos K, Alami J, Konstantinidis S 2010 Surf. Coat. Technol. 204 1661

Google Scholar

Google Scholar

[8] Qin X, Ke P, Wang A, Kim K H 2013 Surf. Coat. Technol. 228 275

Google Scholar

Google Scholar

[9] Olejníček J, Hubička Z, Kment Š 2013 Surf. Coat. Technol. 232 376

Google Scholar

Google Scholar

[10] Holtzer N, Antonin O, Minea T, Marnieros S, Bouchier D 2014 Surf. Coat. Technol. 250 32

Google Scholar

Google Scholar

[11] Oliveira J C, Fernandes F, Ferreira F, Cavaleiro A 2015 Surf. Coat. Technol. 264 140

Google Scholar

Google Scholar

[12] Helmersson U 2011 Proceedings of 11th International Workshop on Plasma Based Ion Implantation & Deposition Harbin, October 8—12, 2011 p21

[13] Čapek J, Hála M, Zabeida O, Klemberg-Sapieha J E, Martinu L 2012 J. Appl. Phys. 111 023301

Google Scholar

Google Scholar

[14] Ehiasarian A P, New R, Münz W D, Hultman L, Helmersson U, Kouznetsov V 2002 Vacuum 65 147

Google Scholar

Google Scholar

[15] 段伟赞 2010 硕士学位论文 (哈尔滨: 哈尔滨工业大学)

Duan W Z 2010 M. S. Thesis (Harbin: Harbin Institute of Technology) (in Chinese)

[16] 肖舒, 吴忠振, 崔岁寒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 潘锋, 朱剑豪 2016 65 185202

Google Scholar

Google Scholar

Xiao S, Wu Z Z, Cui S H, Liu L L, Zheng B C, Lin H, Fu J Y, Tian X B, Pan F, Chu P K 2016 Acta Phys. Sin. 65 185202

Google Scholar

Google Scholar

[17] 崔岁寒, 吴忠振, 肖舒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 朱剑豪, 谭文长, 潘锋, 2017 66 095203

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Liu L L, Zheng B C, Lin H, Fu Ricky K Y, Tian X B, Chu P K, Tan W C, Pan F, 2017 Acta Phys. Sin. 66 095203

Google Scholar

Google Scholar

[18] 赖建军, 余建华, 黄建军, 王新兵, 丘军林 2001 50 1528

Google Scholar

Google Scholar

Lai J J, Yu J H, Huang J J, Wang X B, Qiu J L 2001 Acta Phys. Sin. 50 1528

Google Scholar

Google Scholar

[19] Cui S H, Wu Z Z, Lin H, Xiao S, Zheng B C, Liu L L, An X K, Fu Ricky K Y, Tian X B, Tan W C, Chu P K 2019 J. Appl. Phys. 125 063302

Google Scholar

Google Scholar

[20] Guillaumot A, Lapostolle F, Langlade C, Billard A, Oliveira J C, Cavaleiro A, Tixier D C 2010 IEEE Trans. Plasma Sci. 38 3040

Google Scholar

Google Scholar

[21] Ma Q S, Li L H, Xu Y, Gu J B, Wang L, Xu Y 2017 Appl. Surf. Sci. 392 826

Google Scholar

Google Scholar

[22] Li C W, Tian X B 2016 Rev. Sci. Instrum. 87 083507

Google Scholar

Google Scholar

[23] Gangopadhyay S, Acharya R, Chattopadhyay A K, Paul S 2010 Vacuum 84 843

Google Scholar

Google Scholar

[24] Wang P, Wang X, Chen Y, Zhang G, Liu W, Zhang J 2007 Appl. Surf. Sci. 253 3722

Google Scholar

Google Scholar

[25] Bohlmark J, Östbye M, Lattemann M, Ljungcrantz H, Rosell T, Helmersson U 2006 Thin Solid Films 515 1928

Google Scholar

Google Scholar

[26] Ganesan R, Akhavan B, Dong X, McKenzie D R, Bilek M M M 2018 Surf. Coat. Technol. 352 671

Google Scholar

Google Scholar

[27] Kelly P J, Arnell R D 2000 Vacuum 56 159

Google Scholar

Google Scholar

[28] Olaya J J, Rodil S E, Muhl S 2008 Thin Solid Films 516 8319

Google Scholar

Google Scholar

[29] Anders A, Brown J 2011 IEEE Trans. Plasma Sci. 39 2528

Google Scholar

Google Scholar

[30] Li C W, Tian X B, Gong C Z, Liu S X 2017 Vacuum 144 125

Google Scholar

Google Scholar

[31] Dawson J M 1983 Rev. Mod. Phys. 5 5

Google Scholar

Google Scholar

[32] Vahedi V, Surendra M 1995 Comput. Phys. Commun. 8 7

Google Scholar

Google Scholar

[33] 宮文英 2009 硕士学位论文 (成都: 电子科技大学)

Gong W Y 2009 M. S. Thesis (Chengdu: University of Electronic Science and Technology of China) (in Chinese)

[34] Liang M, He Y, Szott M M, McLain J T, Ruzic D N 2014 J. Appl. Phys. 115 223301

Google Scholar

Google Scholar

[35] Kozak T, Vlcek J, Kos S 2013 J. Phys. D 46 105203

Google Scholar

Google Scholar

[36] 关奎之, 李云奇 1986 真空 23 37

Guan K Z, Li Y Q 1986 Vaccum 23 37

[37] 王合英, 孙文博, 陈宜宝, 何元金 2008 物理实验 28 1

Google Scholar

Google Scholar

Wang H Y, Sun W B, Chen Y B, He Y J 2008 Phys. Exp. 28 1

Google Scholar

Google Scholar

-

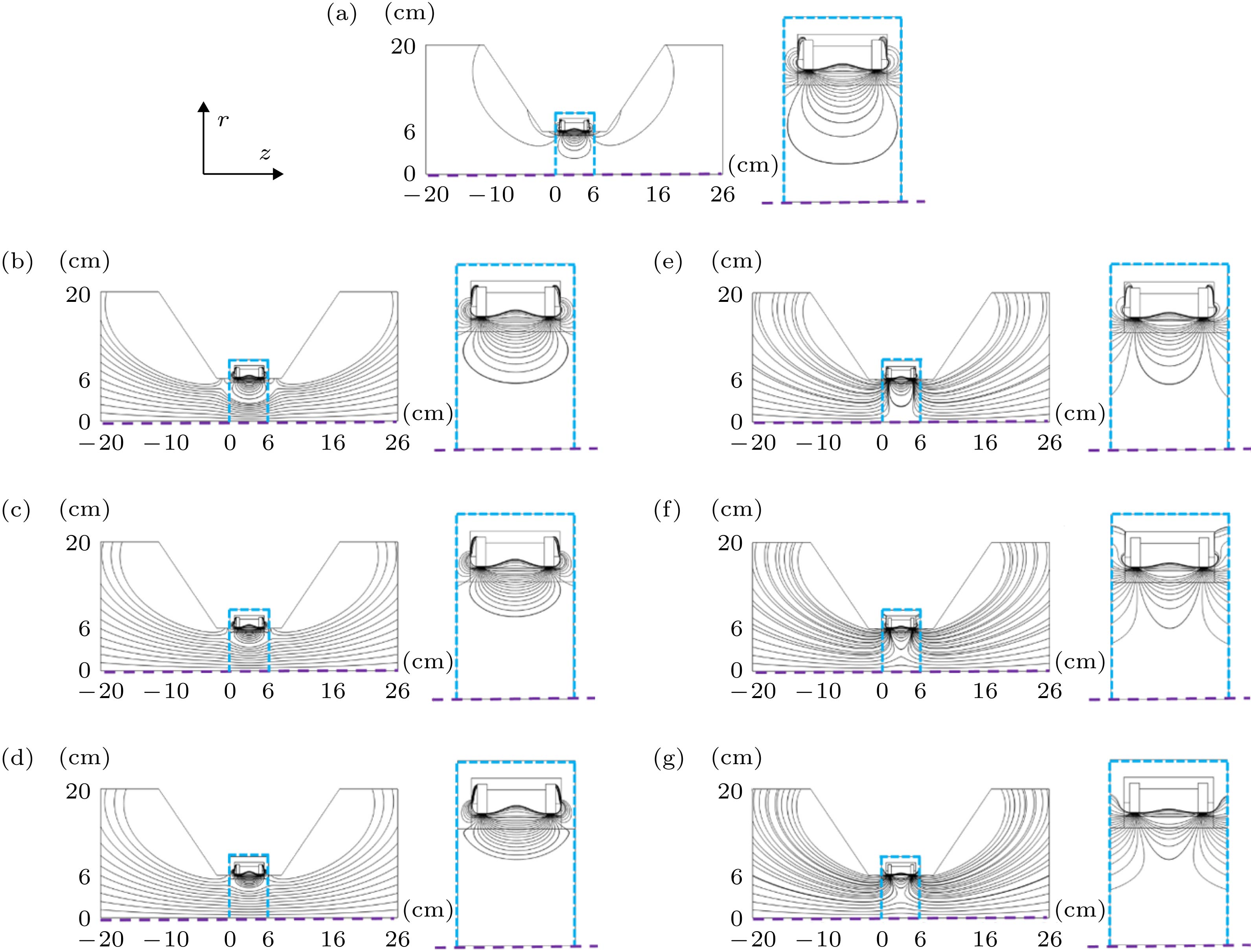

图 2 磁感线分布与电磁线圈电流的关系, 右侧为筒形阴极内的磁感线分布放大图 (a) 0 A; (b) 5 A; (c) 10 A; (d) 15 A; (e) –5 A; (f) –10 A; (g) –15 A. 图中紫色虚线为筒形阴极中央轴, 蓝色方框中的部分为筒形阴极的放大区域

Fig. 2. The distribution of the magnetic induction line vs. the current in electromagnetic coils: (a) 0 A; (b) 5 A; (c) 10 A; (d) 15 A; (e) –5 A; (f) –10 A and (g) –15 A. The purple dotted line is the center axis of the cylindrical cathode and the magnified area of the cylindrical cathode is marked by the blue square.

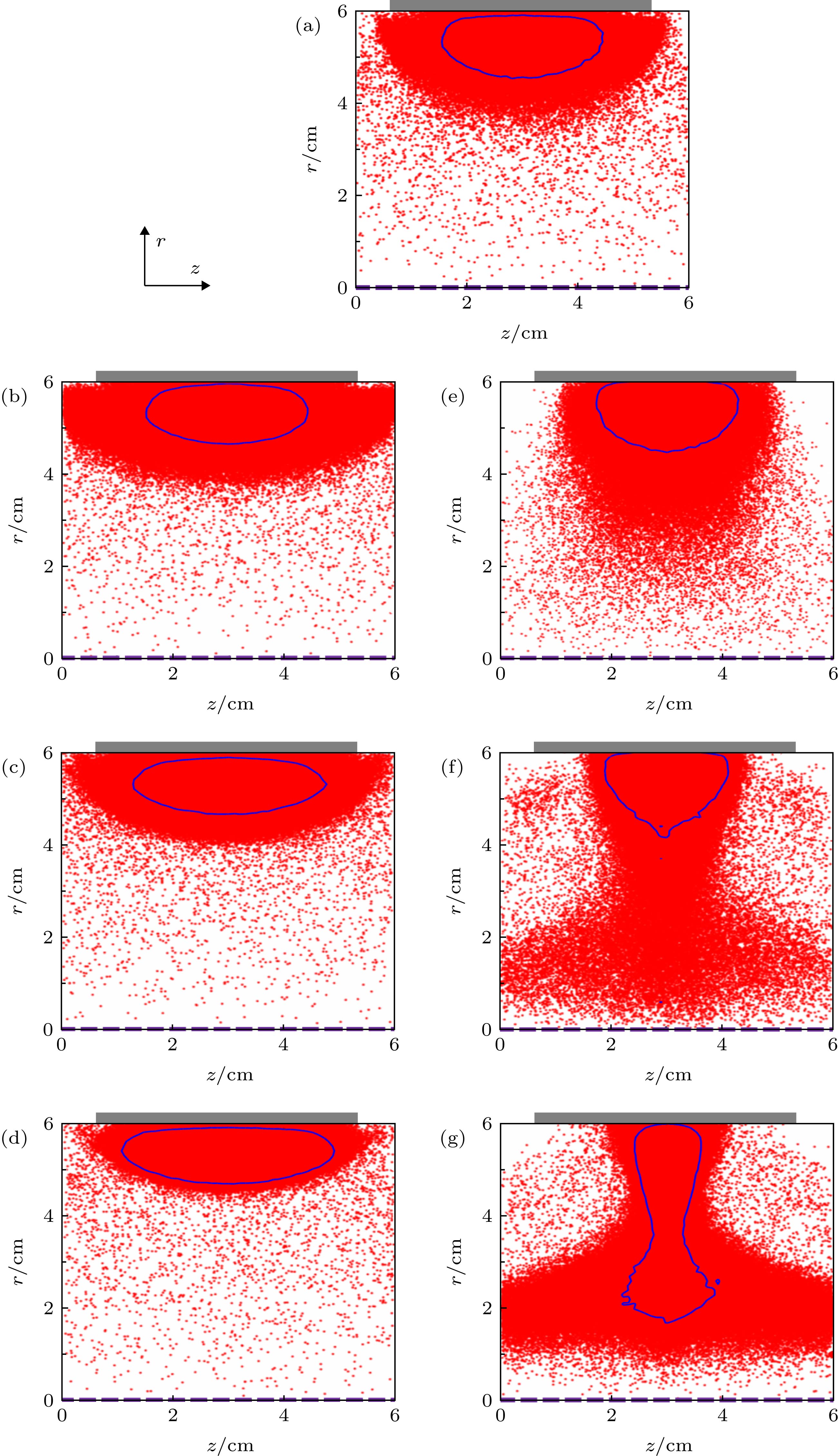

图 3 不同电磁线圈电流条件下筒形阴极内Ar+离子分布 (a) 0 A; (b) 5 A; (c) 10 A; (d) 15 A; (e) –5 A; (f) –10 A; (g) –15 A. 图中紫色虚线为中央旋转轴, 灰色区域为靶材, 蓝线为1×1017 m–3的密度等值线

Fig. 3. The Ar+ ion distribution in the cylindrical cathode vs. the current in electromagnetic coils: (a) 0 A; (b) 5 A; (c) 10 A; (d) 15 A; (e) –5 A; (f) –10 A and (g) –15 A. The purple dotted line is the center axis of the cylindrical cathode, the gray square is the target and the blue line is the contour line of 1×1017 m–3.

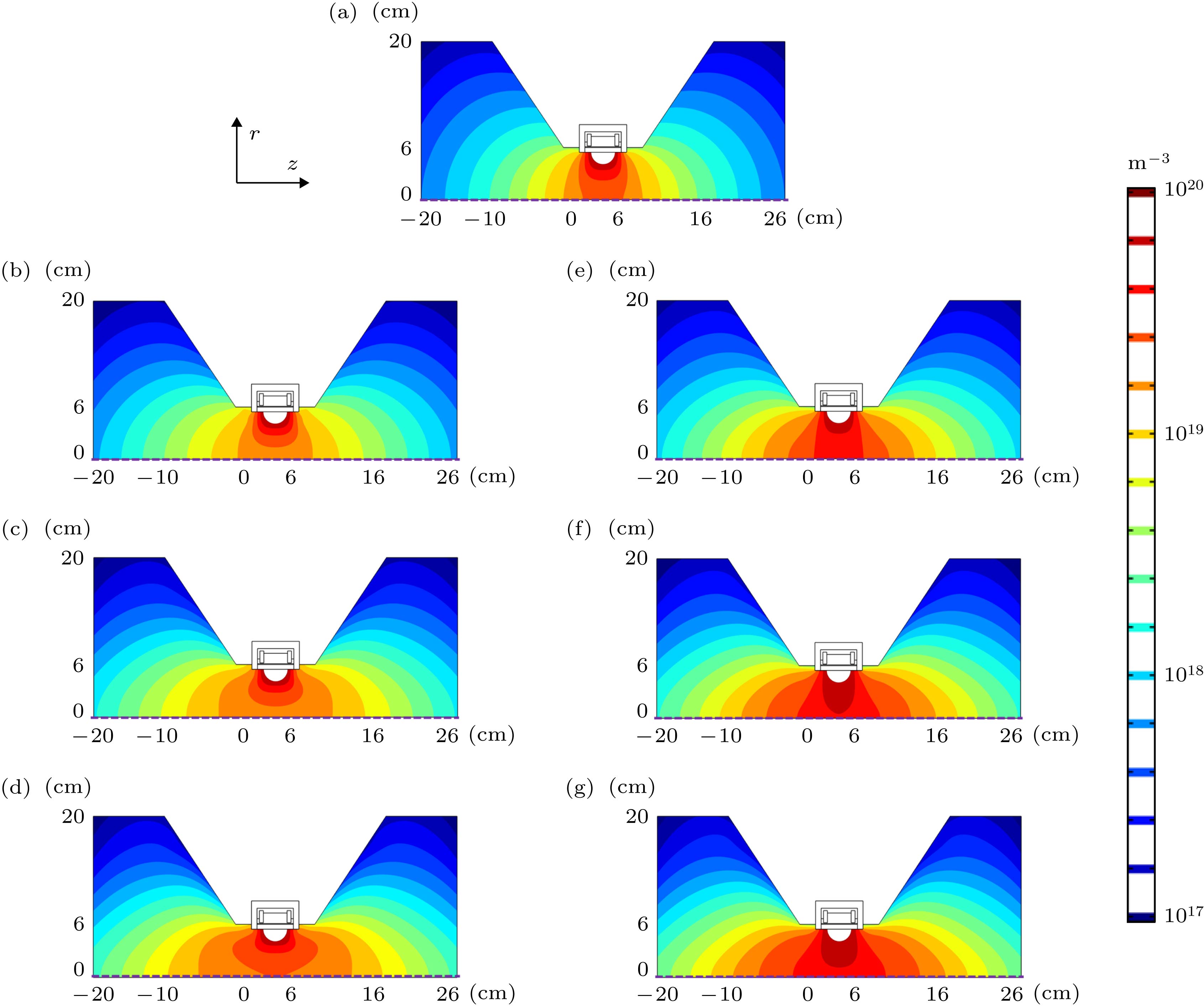

图 5 等离子体密度分布与电磁线圈电流的关系 (a) 0 A; (b) 5 A; (c) 10 A; (d) 15 A; (e) –5 A; (f) –10 A; (g) –15 A. 图中紫色虚线为中央旋转轴

Fig. 5. The plasma density distribution vs. the current in electromagnetic coils: (a) 0 A; (b) 5 A; (c) 10 A; (d) 15 A; (e) –5 A; (f) –10 A and (g) –15 A. The purple dotted line is the center axis of the cylindrical cathode.

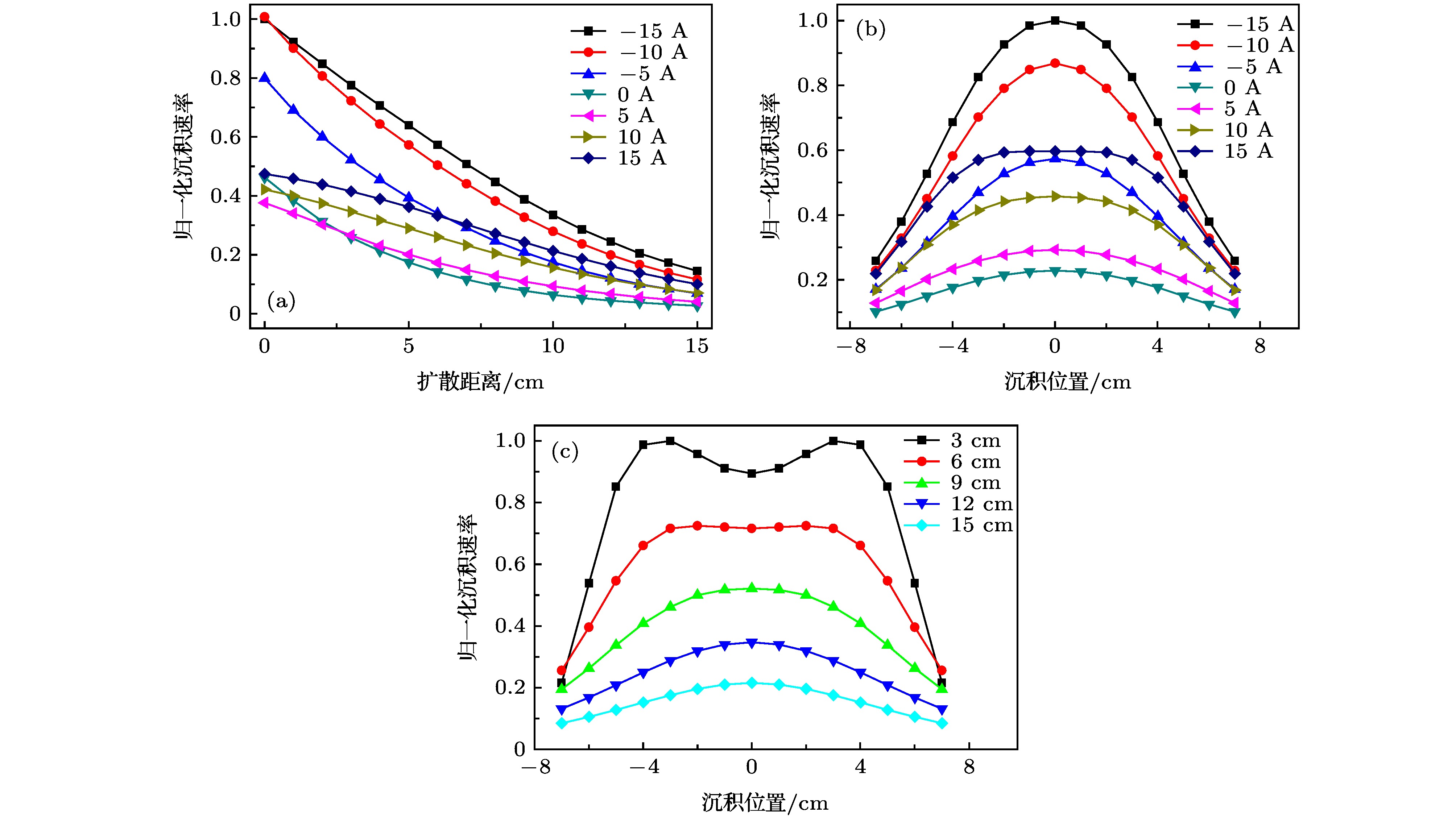

图 6 沉积速率的空间分布 (a) 不同线圈电流下中央轴沉积速率随扩散距离的变化; (b) 不同线圈电流下距筒形阴极8 cm处截面上的沉积速率分布; (c) 线圈电流15 A时不同距离的截面上的沉积速率分布

Fig. 6. Spatial distribution of the deposition rates: (a) Deposition rate on the central axis depends on the diffusion distance and the coil currents; (b) deposition rate at the distance of 8 cm from the cylindrical cathode at different coil currents; (c) deposition rate distribution at different distances from the cylindrical cathode when the coil current is 15 A.

表 1 Ar气放电的主要反应表

Table 1. The main reactions of simple Ar gas discharge.

序号 反应方程式 反应能量/eV 反应类型 1 $e + {\rm{Ar}} \to {\rm{A}}{{\rm{r}}^ + } + 2e$ 15.76 电离 2 $e + {\rm{Ar}} \to {\rm{A}}{{\rm{r}}^m} + e$ 11.56 激发 3 $e + {\rm{A}}{{\rm{r}}^m} \to {\rm{Ar}} + e$ –11.56 退激发 4 $e + {\rm{A}}{{\rm{r}}^m} \to {\rm{A}}{{\rm{r}}^ + } + 2e$ 4.2 电离 5 $e + {\rm{Ar}} \to {\rm{Ar}} + e$ —— 弹性 6 ${\rm{Ar}} + {\rm{A}}{{\rm{r}}^ + } \to {\rm{Ar}} + {\rm{A}}{{\rm{r}}^ + }$ —— 弹性 7 ${\rm{Ar}} + {\rm{A}}{{\rm{r}}^ + } \to {\rm{A}}{{\rm{r}}^+} + {\rm{Ar}}$ —— 电荷交换 表 2 靶面放电宽度和最大的等离子密度

Table 2. Target discharge width and maximum plasma density.

电磁线圈

电流/A靶面放电

宽度/cm最大等离子体

密度/m–315 4.2 4.63×1018 10 4.0 1.07×1019 5 3.6 2.93×1019 0 3.4 4.02×1019 -5 2.9 6.80×1019 -10 2.6 3.13×1019 -15 2.3 7.41×1018 -

[1] Kouznetsov V, Macák K, Schneider J M, Helmersson U, Petrov I 1999 Surf. Coat. Technol. 122 290

Google Scholar

Google Scholar

[2] Bohlmark J, Alami J, Christou C, Ehiasarian A P, Helmersson U 2005 J. Vac. Sci. Technol., A 23 18

Google Scholar

Google Scholar

[3] 吴忠振, 田修波, 潘锋, 傅劲裕, 朱剑豪 2014 63 185207

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Phys. Sin. 63 185207

Google Scholar

Google Scholar

[4] Anders A 2011 Surf. Coat. Technol. 20 S1

Google Scholar

Google Scholar

[5] 吴忠振, 田修波, 潘锋, Ricky K Y Fu, 朱剑豪 2014 金属学报 10 1279

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Meta. Sin. 10 1279

Google Scholar

Google Scholar

[6] Samuelsson M, Lundin D, Jensen J, Raadu M A, Gudmundsson J T, Helmersson U 2010 Surf. Coat. Technol. 205 591

Google Scholar

Google Scholar

[7] Sarakinos K, Alami J, Konstantinidis S 2010 Surf. Coat. Technol. 204 1661

Google Scholar

Google Scholar

[8] Qin X, Ke P, Wang A, Kim K H 2013 Surf. Coat. Technol. 228 275

Google Scholar

Google Scholar

[9] Olejníček J, Hubička Z, Kment Š 2013 Surf. Coat. Technol. 232 376

Google Scholar

Google Scholar

[10] Holtzer N, Antonin O, Minea T, Marnieros S, Bouchier D 2014 Surf. Coat. Technol. 250 32

Google Scholar

Google Scholar

[11] Oliveira J C, Fernandes F, Ferreira F, Cavaleiro A 2015 Surf. Coat. Technol. 264 140

Google Scholar

Google Scholar

[12] Helmersson U 2011 Proceedings of 11th International Workshop on Plasma Based Ion Implantation & Deposition Harbin, October 8—12, 2011 p21

[13] Čapek J, Hála M, Zabeida O, Klemberg-Sapieha J E, Martinu L 2012 J. Appl. Phys. 111 023301

Google Scholar

Google Scholar

[14] Ehiasarian A P, New R, Münz W D, Hultman L, Helmersson U, Kouznetsov V 2002 Vacuum 65 147

Google Scholar

Google Scholar

[15] 段伟赞 2010 硕士学位论文 (哈尔滨: 哈尔滨工业大学)

Duan W Z 2010 M. S. Thesis (Harbin: Harbin Institute of Technology) (in Chinese)

[16] 肖舒, 吴忠振, 崔岁寒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 潘锋, 朱剑豪 2016 65 185202

Google Scholar

Google Scholar

Xiao S, Wu Z Z, Cui S H, Liu L L, Zheng B C, Lin H, Fu J Y, Tian X B, Pan F, Chu P K 2016 Acta Phys. Sin. 65 185202

Google Scholar

Google Scholar

[17] 崔岁寒, 吴忠振, 肖舒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 朱剑豪, 谭文长, 潘锋, 2017 66 095203

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Liu L L, Zheng B C, Lin H, Fu Ricky K Y, Tian X B, Chu P K, Tan W C, Pan F, 2017 Acta Phys. Sin. 66 095203

Google Scholar

Google Scholar

[18] 赖建军, 余建华, 黄建军, 王新兵, 丘军林 2001 50 1528

Google Scholar

Google Scholar

Lai J J, Yu J H, Huang J J, Wang X B, Qiu J L 2001 Acta Phys. Sin. 50 1528

Google Scholar

Google Scholar

[19] Cui S H, Wu Z Z, Lin H, Xiao S, Zheng B C, Liu L L, An X K, Fu Ricky K Y, Tian X B, Tan W C, Chu P K 2019 J. Appl. Phys. 125 063302

Google Scholar

Google Scholar

[20] Guillaumot A, Lapostolle F, Langlade C, Billard A, Oliveira J C, Cavaleiro A, Tixier D C 2010 IEEE Trans. Plasma Sci. 38 3040

Google Scholar

Google Scholar

[21] Ma Q S, Li L H, Xu Y, Gu J B, Wang L, Xu Y 2017 Appl. Surf. Sci. 392 826

Google Scholar

Google Scholar

[22] Li C W, Tian X B 2016 Rev. Sci. Instrum. 87 083507

Google Scholar

Google Scholar

[23] Gangopadhyay S, Acharya R, Chattopadhyay A K, Paul S 2010 Vacuum 84 843

Google Scholar

Google Scholar

[24] Wang P, Wang X, Chen Y, Zhang G, Liu W, Zhang J 2007 Appl. Surf. Sci. 253 3722

Google Scholar

Google Scholar

[25] Bohlmark J, Östbye M, Lattemann M, Ljungcrantz H, Rosell T, Helmersson U 2006 Thin Solid Films 515 1928

Google Scholar

Google Scholar

[26] Ganesan R, Akhavan B, Dong X, McKenzie D R, Bilek M M M 2018 Surf. Coat. Technol. 352 671

Google Scholar

Google Scholar

[27] Kelly P J, Arnell R D 2000 Vacuum 56 159

Google Scholar

Google Scholar

[28] Olaya J J, Rodil S E, Muhl S 2008 Thin Solid Films 516 8319

Google Scholar

Google Scholar

[29] Anders A, Brown J 2011 IEEE Trans. Plasma Sci. 39 2528

Google Scholar

Google Scholar

[30] Li C W, Tian X B, Gong C Z, Liu S X 2017 Vacuum 144 125

Google Scholar

Google Scholar

[31] Dawson J M 1983 Rev. Mod. Phys. 5 5

Google Scholar

Google Scholar

[32] Vahedi V, Surendra M 1995 Comput. Phys. Commun. 8 7

Google Scholar

Google Scholar

[33] 宮文英 2009 硕士学位论文 (成都: 电子科技大学)

Gong W Y 2009 M. S. Thesis (Chengdu: University of Electronic Science and Technology of China) (in Chinese)

[34] Liang M, He Y, Szott M M, McLain J T, Ruzic D N 2014 J. Appl. Phys. 115 223301

Google Scholar

Google Scholar

[35] Kozak T, Vlcek J, Kos S 2013 J. Phys. D 46 105203

Google Scholar

Google Scholar

[36] 关奎之, 李云奇 1986 真空 23 37

Guan K Z, Li Y Q 1986 Vaccum 23 37

[37] 王合英, 孙文博, 陈宜宝, 何元金 2008 物理实验 28 1

Google Scholar

Google Scholar

Wang H Y, Sun W B, Chen Y B, He Y J 2008 Phys. Exp. 28 1

Google Scholar

Google Scholar

计量

- 文章访问数: 14853

- PDF下载量: 140

- 被引次数: 0

下载:

下载: