-

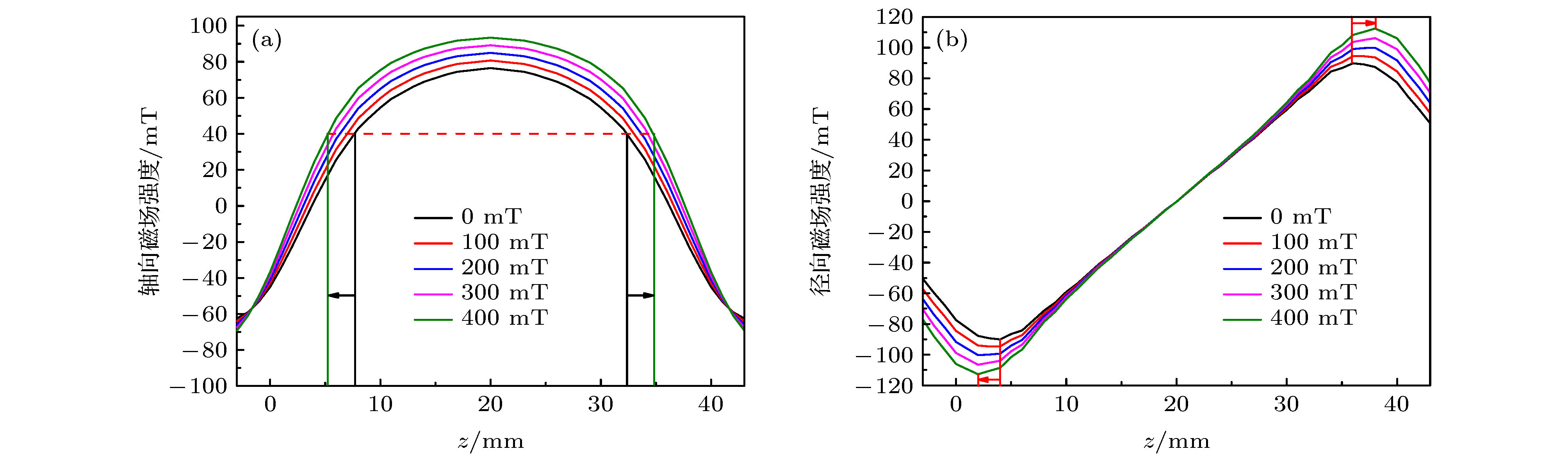

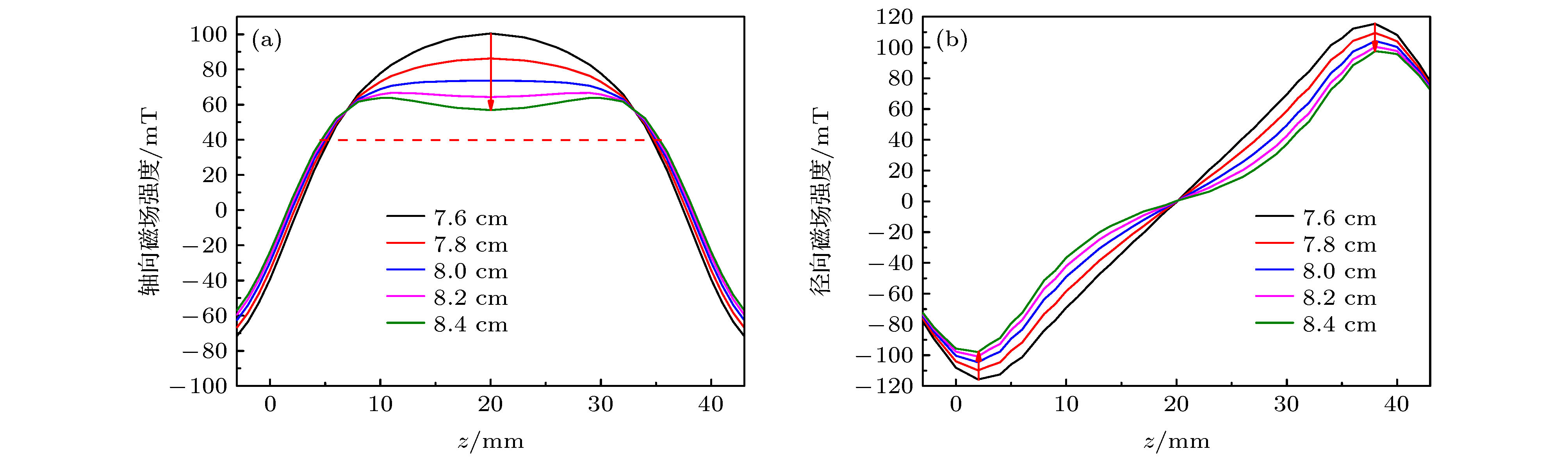

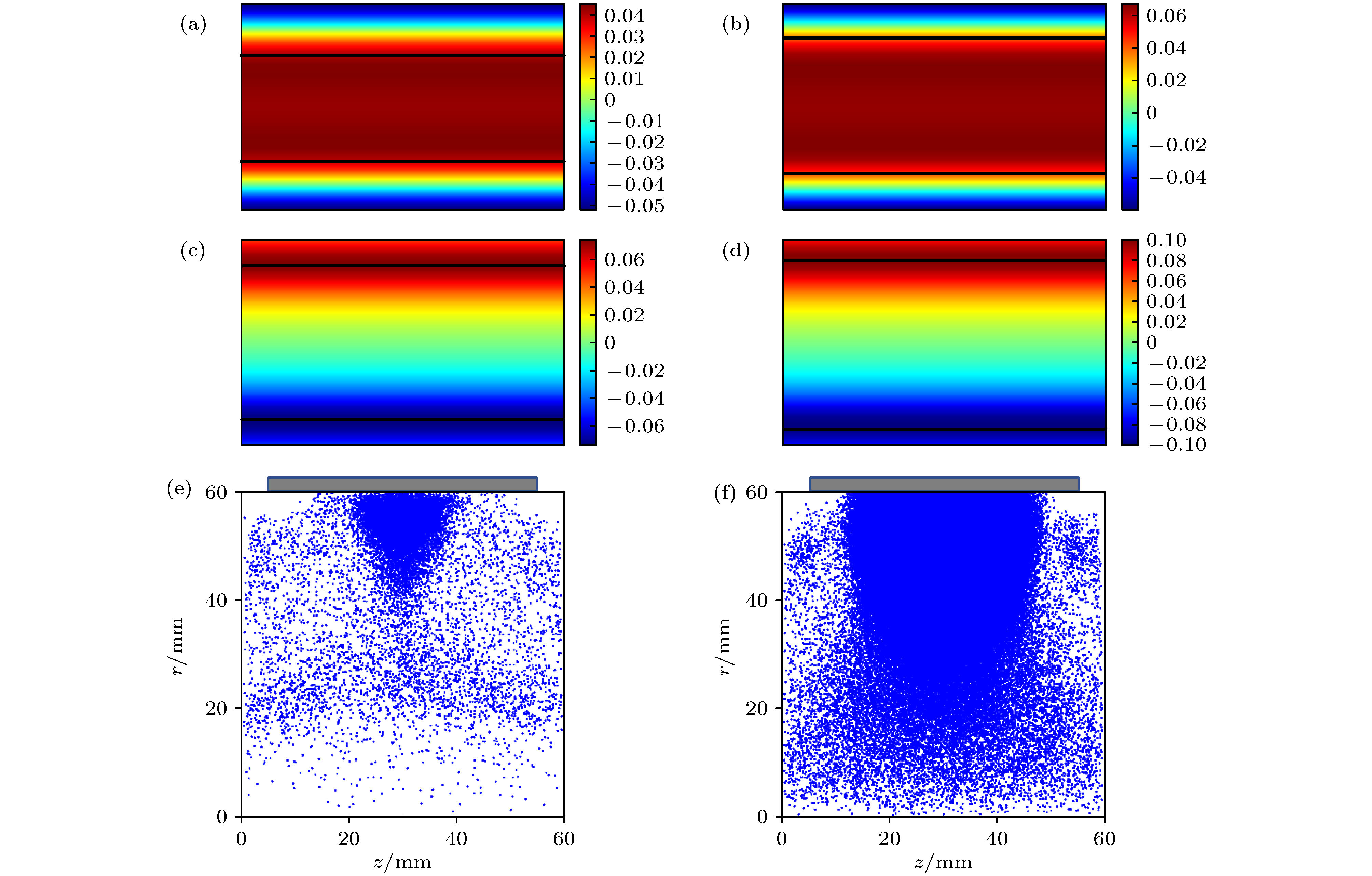

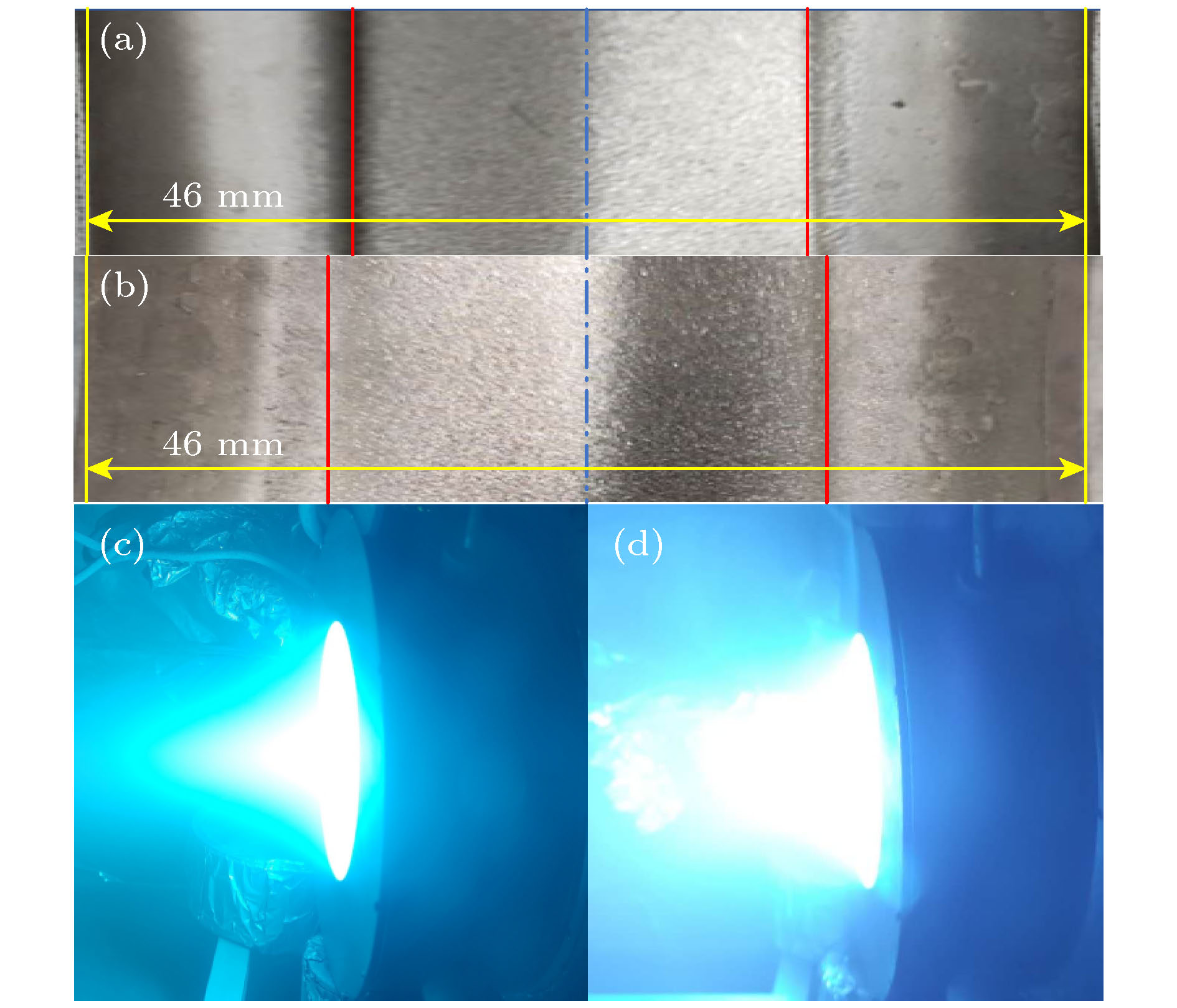

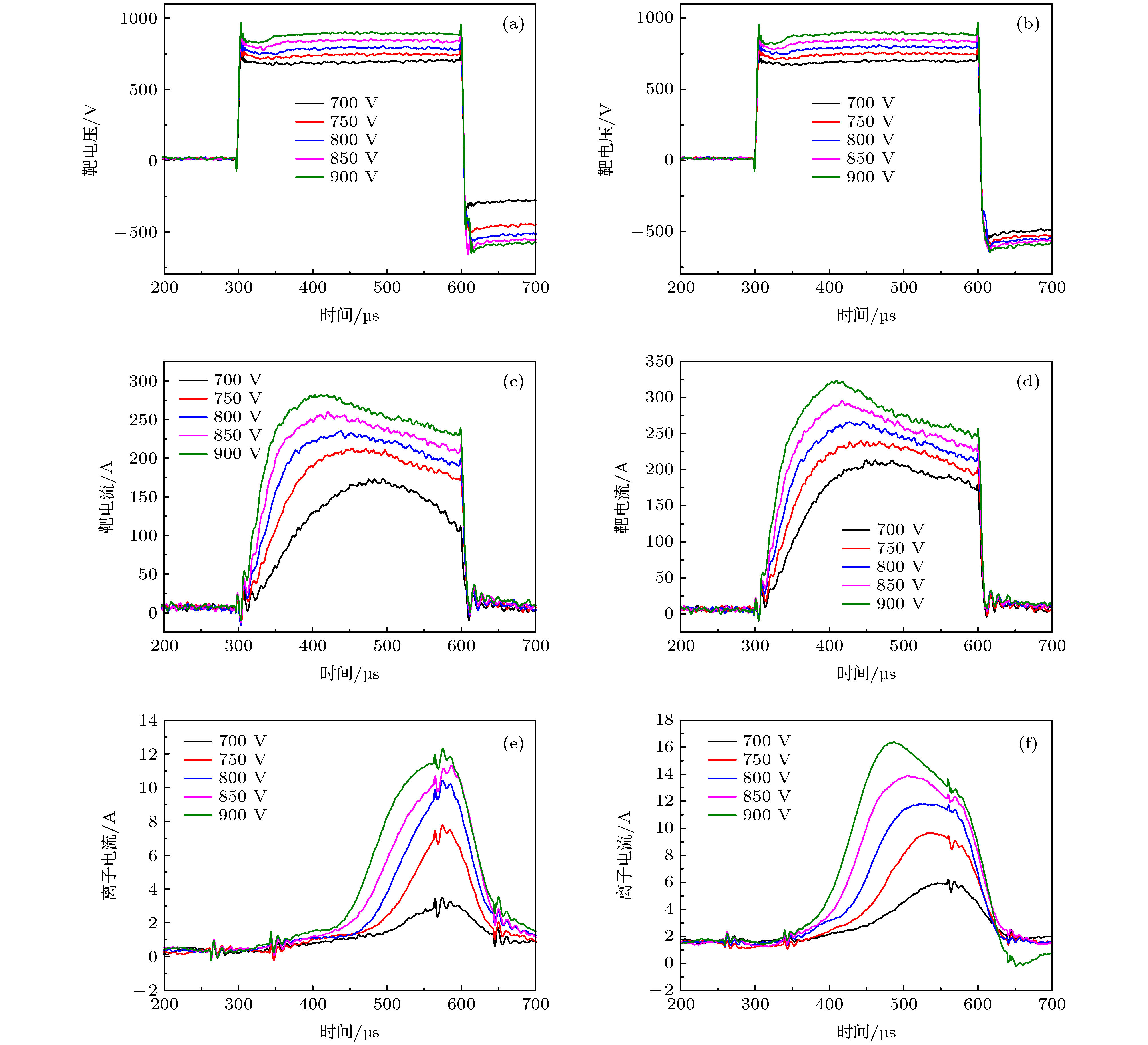

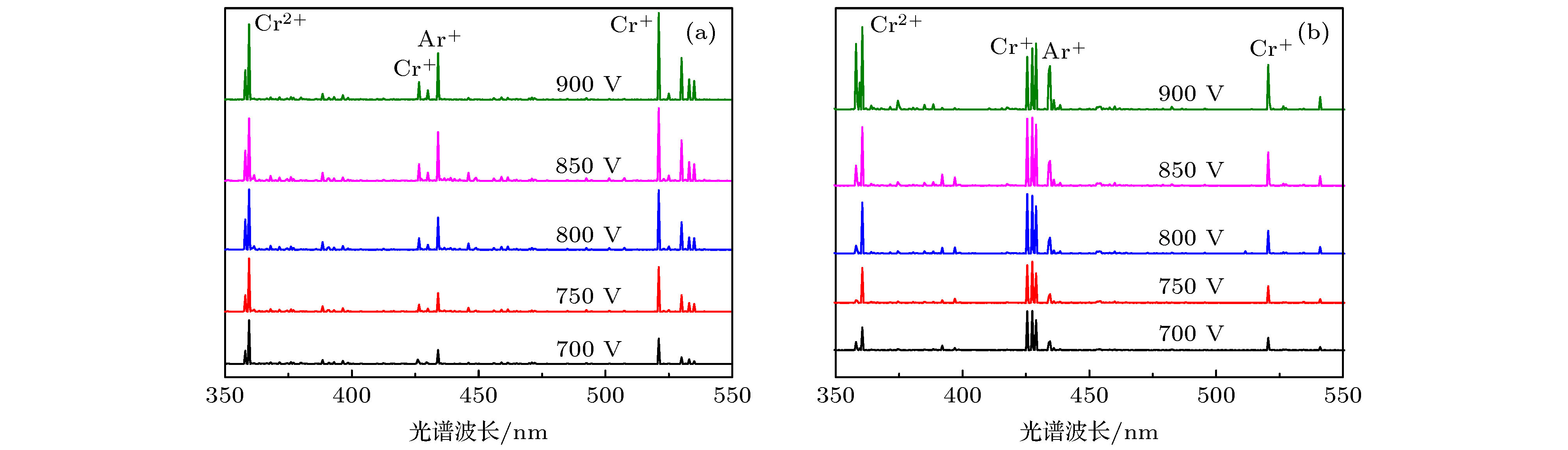

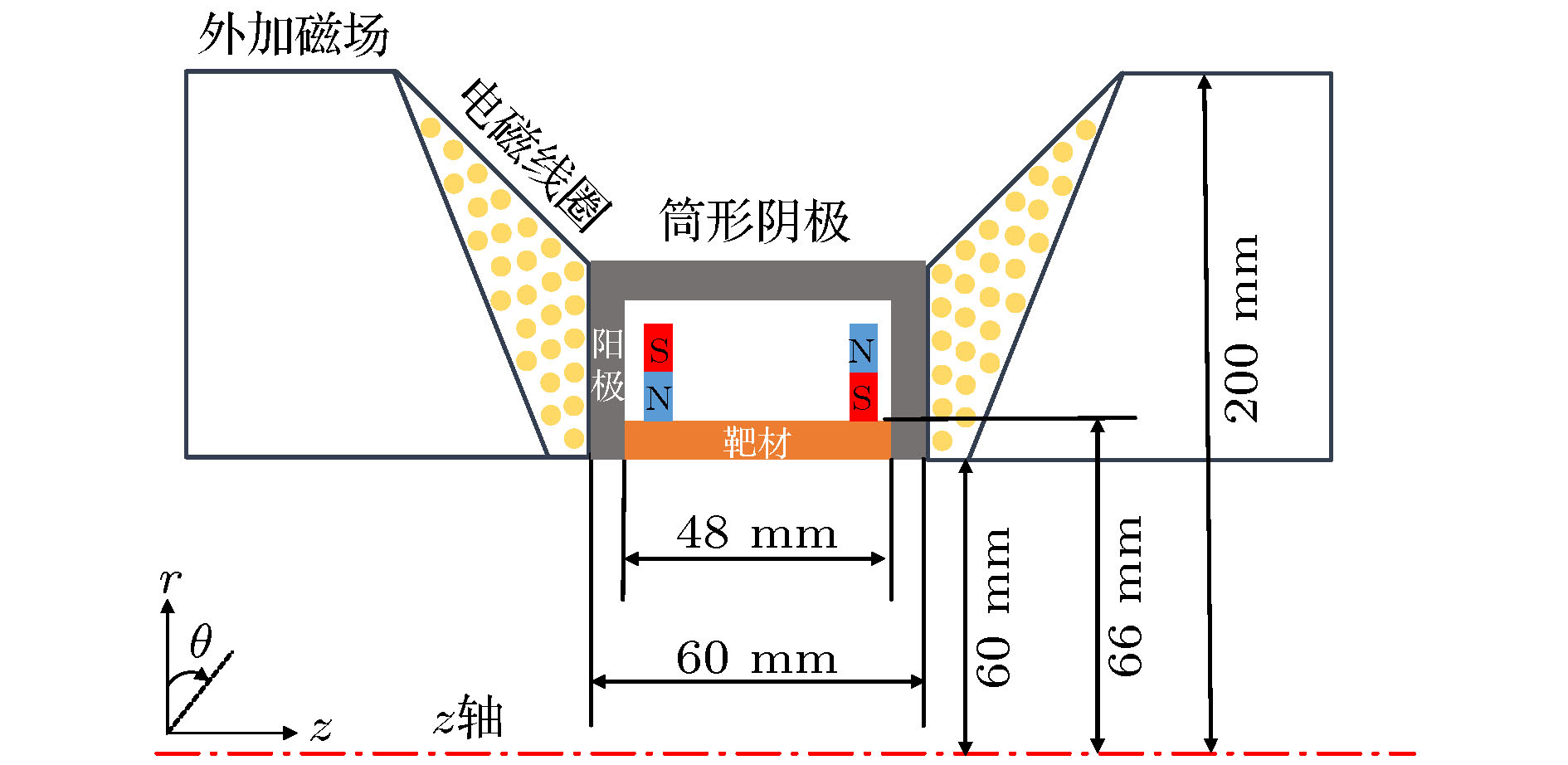

基于高功率脉冲磁控溅射(HiPIMS)技术开发的筒形溅射阴极, 配合电磁系统可有效地提升等离子体的输运效率. 然而电磁系统的引入反作用于筒内放电特性, 从而使靶面放电面积和放电强度无法同时维持. 鉴于此, 本文通过调整磁场布局, 研究了靶面切向(横向)磁场和法向(纵向)磁场对靶面放电的作用规律, 优化后靶面切向磁场分布更加均匀, 磁场强度高于40 mT的靶面区域占比由51%增至67%, 同时法向峰值强度外移, 强度由73 mT增至96 mT. 采用Ar/Cr体系放电发现:相同工艺条件下, 优化后的溅射阴极辉光变亮, 靶电流增大, 放电面积变宽, 放电特性得到显著提升. 利用等离子体整体模型仿真和发射光谱仪检测发现优化后离子电流和光谱强度得到明显提升, Cr粒子密度提高一倍, 增至2.6 × 1020 m–3, 且离化率上升至92.1%, 同时输出离子通量提高近一倍, 实现了靶面放电与离子输出的双促进.High-power pulsed magnetron sputtering (HiPIMS) can produce high density and high adhesion coatings due to the high ionization. However, industrial application of HiPIMS is limited because of the unstable discharge and small deposition rate. A cylindrical cathode, developed on the basis of hollow cathode effect, can improve the discharge stability. With the development of electromagnetic systems, the plasma transport is improved, and thus increasing the deposition rate significantly. However, the introduction of electromagnetic system leads the strong discharge and large etching area on the target to be incompatibly controlled. In this work, the distribution of the tangential and longitudinal magnetic field on the target surface are improved by adding external magnets, and their effects on the plasma discharge are studied. By optimizing the magnets, the tangential magnetic field on the target surface becomes stronger and more uniform. Meanwhile, the peak of the longitudinal magnetic field increases from 73 to 96 mT and the peak location expands to two-sides of the cathode. The simulation result shows that the target etching area described by the proportion of the target area with the tangential magnetic field intensity higher than 40 mT increases from 51% to 67%, and the HiPIMS discharge studied by the particle in cell/Monte Carlo collision (PIC/MCC) method and plasma global model shows that the ion current and spectral intensity are significantly enhanced, exhibiting a doubled Cr density of 2.6 × 1020 m–3 and an increased ionization from 90% to 92.1%. The practical Ar/Cr HiPIMS discharge is carried out separately with the original and optimized cylindrical cathode, and the results reveal that the brightness of plasma glow, the target current and the etching area all increase after the improvement. Furthermore, the ion current and the optical emission spectrum suggest that the flux of ions arriving at the substrate is approximately doubled, which means that an about doubled deposition rate of the optimized cathode is achievable.

-

Keywords:

- high power impulse magnetron sputtering /

- electromagnetic coordination /

- discharge enhancement /

- transport efficiency

[1] Bohlmark J, Alami J, Christou C, Ehiasarian A P, Helmersson U 2005 J. Vac. Sci. Technol. A23 18

Google Scholar

Google Scholar

[2] 吴忠振, 田修波, 潘锋, 傅劲裕, 朱剑豪 2014 63 185207

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Phys. Sin. 63 185207

Google Scholar

Google Scholar

[3] Fernandes F, Calderon V S, Ferreira P J, Cavaleiro A, Oliveira J C 2020 Surf. Coat. Technol. 397 125996

Google Scholar

Google Scholar

[4] Yang F C, Lin C Y, Tang J F, Chang C L 2020 Surf. Coat. Technol. 388 125579

Google Scholar

Google Scholar

[5] Liu L L, Tang W, Zhou L, Wu Z C, Ruan Q D, Li X Y, Qasim A M, Wu Z Z, Chu P K 2020 Ceram Int. 46 10814

Google Scholar

Google Scholar

[6] Anders A 2011 Surf. Coat. Technol. 205 S1

Google Scholar

Google Scholar

[7] Samuelsson M, Lundin D, Jensen J, Raadu M A, Gudmundsson J T, Helmersson U 2010 Surf. Coat. Technol. 205 591

Google Scholar

Google Scholar

[8] 肖舒, 吴忠振, 崔岁寒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 潘锋, 朱剑豪 2016 65 185202

Google Scholar

Google Scholar

Xiao S, Wu Z Z, Cui S H, Liu L L, Zheng B C, Lin H, Fu J Y, Tian X B, Pan F, Chu P K 2016 Acta Phys. Sin. 65 185202

Google Scholar

Google Scholar

[9] 崔岁寒, 吴忠振, 肖舒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 朱剑豪, 谭文长, 潘锋 2017 66 095203

Google Scholar

Google Scholar

Cui S H., Wu Z Z, Xiao S, Liu L L, Zheng B C, Lin H, Fu Ricky K Y, Tian X B, Chu P K, Tan W C, Pan F 2017 Acta Phys. Sin. 66 095203

Google Scholar

Google Scholar

[10] 崔岁寒, 吴忠振, 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Google Scholar

Google Scholar

Cui S H., Wu Z Z, Lin H, Xiao S, Chen L, Li T J, Liu L L, Fu R K Y, Tian X B, Chu P K, Tan W C 2019 Acta Phys. Sin. 68 195204

Google Scholar

Google Scholar

[11] 汪天龙, 邱清泉, 靖立伟, 张小波 2018 67 070703

Google Scholar

Google Scholar

Wang T L, Qiu Q Q, Jing L W, Zhang X B 2018 Acta Phys. Sin. 67 070703

Google Scholar

Google Scholar

[12] Mishra A, Kelly P J, Bradley J W 2010 Plasma Sources Sci. Technol. 19 045014

Google Scholar

Google Scholar

[13] Luo H, Gao F, Billard A 2019 Surf. Coat. Technol. 374 822

Google Scholar

Google Scholar

[14] Mischker F, Prenzel M, Benedikt J, et al. 2013 J. Phys. D: Appl. Phys. 46 495201

Google Scholar

Google Scholar

[15] Čapek J, Hála M, Zabeida O, Klemberg-Sapieha J E, Martinu L 2012 J. Appl. Phys. 111 023301

Google Scholar

Google Scholar

[16] Ganesan R, Akhavan B, Dong X, McKenzie D R, Bilek M M M 2018 Surf. Coat. Technol. 352 671

Google Scholar

Google Scholar

[17] 赖建军, 余建华, 黄建军, 王新兵, 丘军林 2001 50 1528

Google Scholar

Google Scholar

Lai J J, Yu J H, Huang J J, Wang X B, Qiu J L 2001 Acta Phys. Sin. 50 1528

Google Scholar

Google Scholar

[18] Cui S H, Wu Z Z, Lin H, Xiao S, Zheng B C, Chen L, Li T J, Fu R K Y, Chu P K, Tian X B, Tan W C, Fang D N, Pan F 2020 J. Appl. Phys. 127 23301

Google Scholar

Google Scholar

[19] Dawson J M 1983 Rev. Mod. Phys. 5 5

Google Scholar

Google Scholar

[20] Vahedi V, Surendra M 1995 Comput. Phys. Commun. 8 7

Google Scholar

Google Scholar

[21] Liebig B, Bradley J W 2013 Plasma Sources SCI. T. 22 045020

Google Scholar

Google Scholar

[22] Debel F, Cammarate F. 1998 J. Phys D:. Appl. Phys. 31 31

Google Scholar

Google Scholar

[23] Shidoji E, Masaharn N J. 1994 Jpn. J. Appl. Phys. 33 4281

Google Scholar

Google Scholar

[24] Qiu Q Q, Li Q F, Su J J 2008 Plasma Sources Sci. Technol. 10 694

Google Scholar

Google Scholar

[25] Bohlmark J, Gudmundsson J T, Alami J 2005 IEEE Trans. Plasma Sci. 33 346

Google Scholar

Google Scholar

[26] Qiu Q Q, Li Q F, Su J J 2008 IEEE Trans. Plasma Sci. 36 1899

Google Scholar

Google Scholar

[27] Wu Z Z, Xiao S, Ma Z Y, Cui S H Ji S P, Tian X B, Fu R K Y, Chu P K 2015 AIP Adv. 5 097178

Google Scholar

Google Scholar

[28] Anders A 2008 Appl. Phys. Lett. 92 201501

Google Scholar

Google Scholar

[29] Hecimovic A, Ehiasarian A P 2009 J. Phys D: Appl. 42 135209

Google Scholar

Google Scholar

[30] Konstantinidis S, Dauchot J P, Ganciu M 2006 Appl. Phys. Lett. 88 021501

Google Scholar

Google Scholar

[31] Duquenne C, Tessier P Y, Besland M P 2008 J. Appl. Phys. 104 063301

Google Scholar

Google Scholar

[32] Ogneva É Y, Raikhbaum Y D, Ognev B R 1972 J. Appl Spectrosc. 17 971

Google Scholar

Google Scholar

-

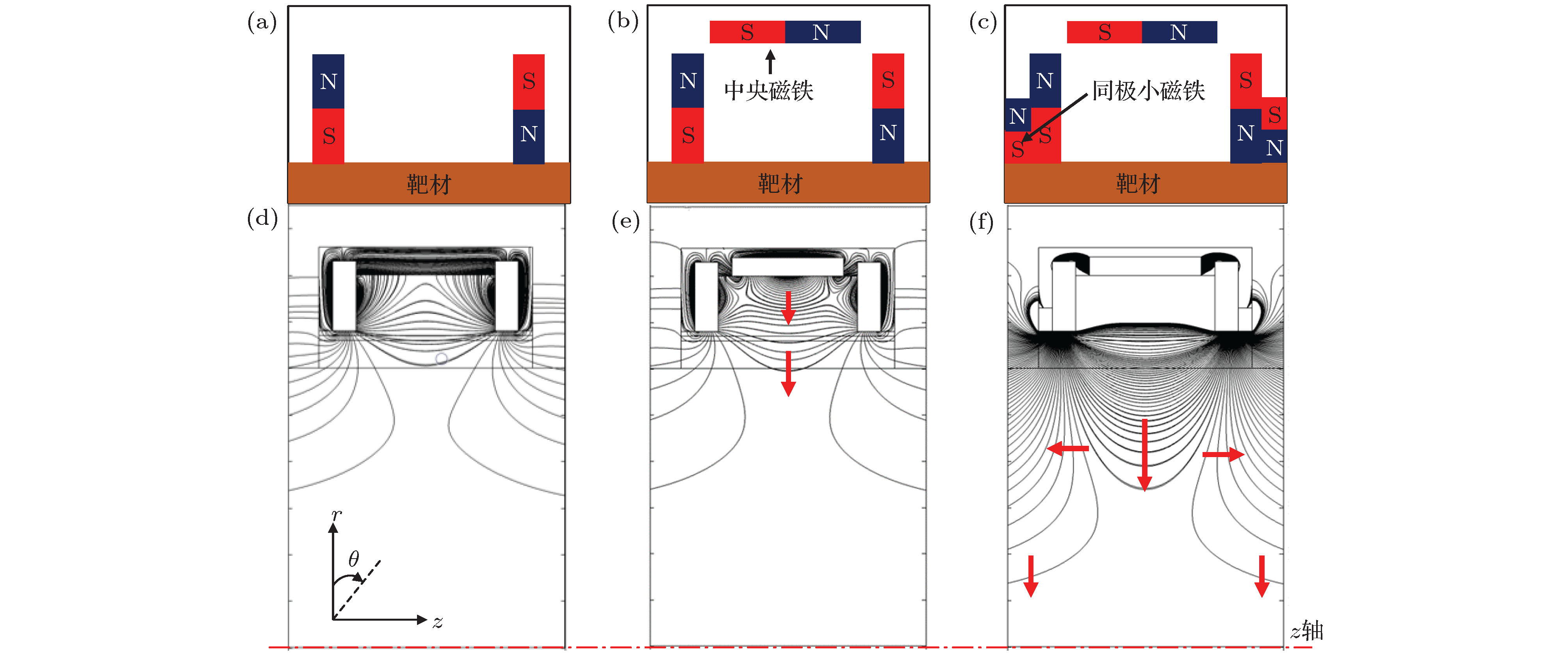

图 3 –15 A条件下筒形溅射阴极磁铁排布示意图及其内部磁感线分布 (a), (d)优化前; (b), (e) 增加中央磁铁; (c), (f)含有中央磁场和同极小磁铁

Fig. 3. Magnet arrangement and magnetic induction lines distributions in the cylindrical cathode under –15 A: (a), (d) Before improvement; (b), (e) with the central magnets; (c), (f) with the central magnets and dipole magnets.

图 7 优化前和优化后靶面磁场分布及放电预测 (a), (b) 切向磁场Bz分布; (c), (d) 法向磁场Br分布; (e), (f) 0.4 μs时放电Ar+离子密度分布

Fig. 7. The magnetic distribution of target surface and the discharge prediction before and after improvement: (a), (b) The tangential magnetic field strength Bz; (c), (d) the longitudinal magnetic field strength Br; (e), (f) the distributions of Ar+ ions at 0.4 μs.

表 1 Ar气放电的主要反应表

Table 1. The main reactions of simple Ar gas discharge.

反应方程式 反应能量/eV 反应类型 ${{{\rm e}}} + {{\rm Ar}} \to {{\rm Ar}} + {{{\rm e}}}$ — 弹性 ${{{\rm e}}} + {{\rm Ar}} \to {{\rm A}}{{{\rm r}}^ + } + 2{{{\rm e}}}$ 15.76 电离 ${{{\rm e}}} + {{\rm Ar}} \to {{\rm A}}{{{\rm r}}^m} + {{{\rm e}}}$ 11.56 激发 ${{{\rm e}}} + {\operatorname{Ar} ^m} \to {{\rm Ar}} + {{{\rm e}}}$ –11.56 退激发 ${{{\rm e}}} + {{\rm A}}{{{\rm r}}^m} \to {{\rm A}}{{{\rm r}}^ + } + 2{{{\rm e}}}$ 4.2 电离 ${{\rm A}}{{{\rm r}}^ + } + {{\rm Ar}} \to {{\rm A}}{{{\rm r}}^ + } + {{\rm Ar}}$ — 弹性 ${{\rm A}}{{{\rm r}}^ + } + {{\rm Ar}} \to {{\rm Ar}} + {{\rm A}}{{{\rm r}}^ + }$ — 电荷交换 -

[1] Bohlmark J, Alami J, Christou C, Ehiasarian A P, Helmersson U 2005 J. Vac. Sci. Technol. A23 18

Google Scholar

Google Scholar

[2] 吴忠振, 田修波, 潘锋, 傅劲裕, 朱剑豪 2014 63 185207

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Phys. Sin. 63 185207

Google Scholar

Google Scholar

[3] Fernandes F, Calderon V S, Ferreira P J, Cavaleiro A, Oliveira J C 2020 Surf. Coat. Technol. 397 125996

Google Scholar

Google Scholar

[4] Yang F C, Lin C Y, Tang J F, Chang C L 2020 Surf. Coat. Technol. 388 125579

Google Scholar

Google Scholar

[5] Liu L L, Tang W, Zhou L, Wu Z C, Ruan Q D, Li X Y, Qasim A M, Wu Z Z, Chu P K 2020 Ceram Int. 46 10814

Google Scholar

Google Scholar

[6] Anders A 2011 Surf. Coat. Technol. 205 S1

Google Scholar

Google Scholar

[7] Samuelsson M, Lundin D, Jensen J, Raadu M A, Gudmundsson J T, Helmersson U 2010 Surf. Coat. Technol. 205 591

Google Scholar

Google Scholar

[8] 肖舒, 吴忠振, 崔岁寒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 潘锋, 朱剑豪 2016 65 185202

Google Scholar

Google Scholar

Xiao S, Wu Z Z, Cui S H, Liu L L, Zheng B C, Lin H, Fu J Y, Tian X B, Pan F, Chu P K 2016 Acta Phys. Sin. 65 185202

Google Scholar

Google Scholar

[9] 崔岁寒, 吴忠振, 肖舒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 朱剑豪, 谭文长, 潘锋 2017 66 095203

Google Scholar

Google Scholar

Cui S H., Wu Z Z, Xiao S, Liu L L, Zheng B C, Lin H, Fu Ricky K Y, Tian X B, Chu P K, Tan W C, Pan F 2017 Acta Phys. Sin. 66 095203

Google Scholar

Google Scholar

[10] 崔岁寒, 吴忠振, 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Google Scholar

Google Scholar

Cui S H., Wu Z Z, Lin H, Xiao S, Chen L, Li T J, Liu L L, Fu R K Y, Tian X B, Chu P K, Tan W C 2019 Acta Phys. Sin. 68 195204

Google Scholar

Google Scholar

[11] 汪天龙, 邱清泉, 靖立伟, 张小波 2018 67 070703

Google Scholar

Google Scholar

Wang T L, Qiu Q Q, Jing L W, Zhang X B 2018 Acta Phys. Sin. 67 070703

Google Scholar

Google Scholar

[12] Mishra A, Kelly P J, Bradley J W 2010 Plasma Sources Sci. Technol. 19 045014

Google Scholar

Google Scholar

[13] Luo H, Gao F, Billard A 2019 Surf. Coat. Technol. 374 822

Google Scholar

Google Scholar

[14] Mischker F, Prenzel M, Benedikt J, et al. 2013 J. Phys. D: Appl. Phys. 46 495201

Google Scholar

Google Scholar

[15] Čapek J, Hála M, Zabeida O, Klemberg-Sapieha J E, Martinu L 2012 J. Appl. Phys. 111 023301

Google Scholar

Google Scholar

[16] Ganesan R, Akhavan B, Dong X, McKenzie D R, Bilek M M M 2018 Surf. Coat. Technol. 352 671

Google Scholar

Google Scholar

[17] 赖建军, 余建华, 黄建军, 王新兵, 丘军林 2001 50 1528

Google Scholar

Google Scholar

Lai J J, Yu J H, Huang J J, Wang X B, Qiu J L 2001 Acta Phys. Sin. 50 1528

Google Scholar

Google Scholar

[18] Cui S H, Wu Z Z, Lin H, Xiao S, Zheng B C, Chen L, Li T J, Fu R K Y, Chu P K, Tian X B, Tan W C, Fang D N, Pan F 2020 J. Appl. Phys. 127 23301

Google Scholar

Google Scholar

[19] Dawson J M 1983 Rev. Mod. Phys. 5 5

Google Scholar

Google Scholar

[20] Vahedi V, Surendra M 1995 Comput. Phys. Commun. 8 7

Google Scholar

Google Scholar

[21] Liebig B, Bradley J W 2013 Plasma Sources SCI. T. 22 045020

Google Scholar

Google Scholar

[22] Debel F, Cammarate F. 1998 J. Phys D:. Appl. Phys. 31 31

Google Scholar

Google Scholar

[23] Shidoji E, Masaharn N J. 1994 Jpn. J. Appl. Phys. 33 4281

Google Scholar

Google Scholar

[24] Qiu Q Q, Li Q F, Su J J 2008 Plasma Sources Sci. Technol. 10 694

Google Scholar

Google Scholar

[25] Bohlmark J, Gudmundsson J T, Alami J 2005 IEEE Trans. Plasma Sci. 33 346

Google Scholar

Google Scholar

[26] Qiu Q Q, Li Q F, Su J J 2008 IEEE Trans. Plasma Sci. 36 1899

Google Scholar

Google Scholar

[27] Wu Z Z, Xiao S, Ma Z Y, Cui S H Ji S P, Tian X B, Fu R K Y, Chu P K 2015 AIP Adv. 5 097178

Google Scholar

Google Scholar

[28] Anders A 2008 Appl. Phys. Lett. 92 201501

Google Scholar

Google Scholar

[29] Hecimovic A, Ehiasarian A P 2009 J. Phys D: Appl. 42 135209

Google Scholar

Google Scholar

[30] Konstantinidis S, Dauchot J P, Ganciu M 2006 Appl. Phys. Lett. 88 021501

Google Scholar

Google Scholar

[31] Duquenne C, Tessier P Y, Besland M P 2008 J. Appl. Phys. 104 063301

Google Scholar

Google Scholar

[32] Ogneva É Y, Raikhbaum Y D, Ognev B R 1972 J. Appl Spectrosc. 17 971

Google Scholar

Google Scholar

计量

- 文章访问数: 10812

- PDF下载量: 176

- 被引次数: 0

下载:

下载: