-

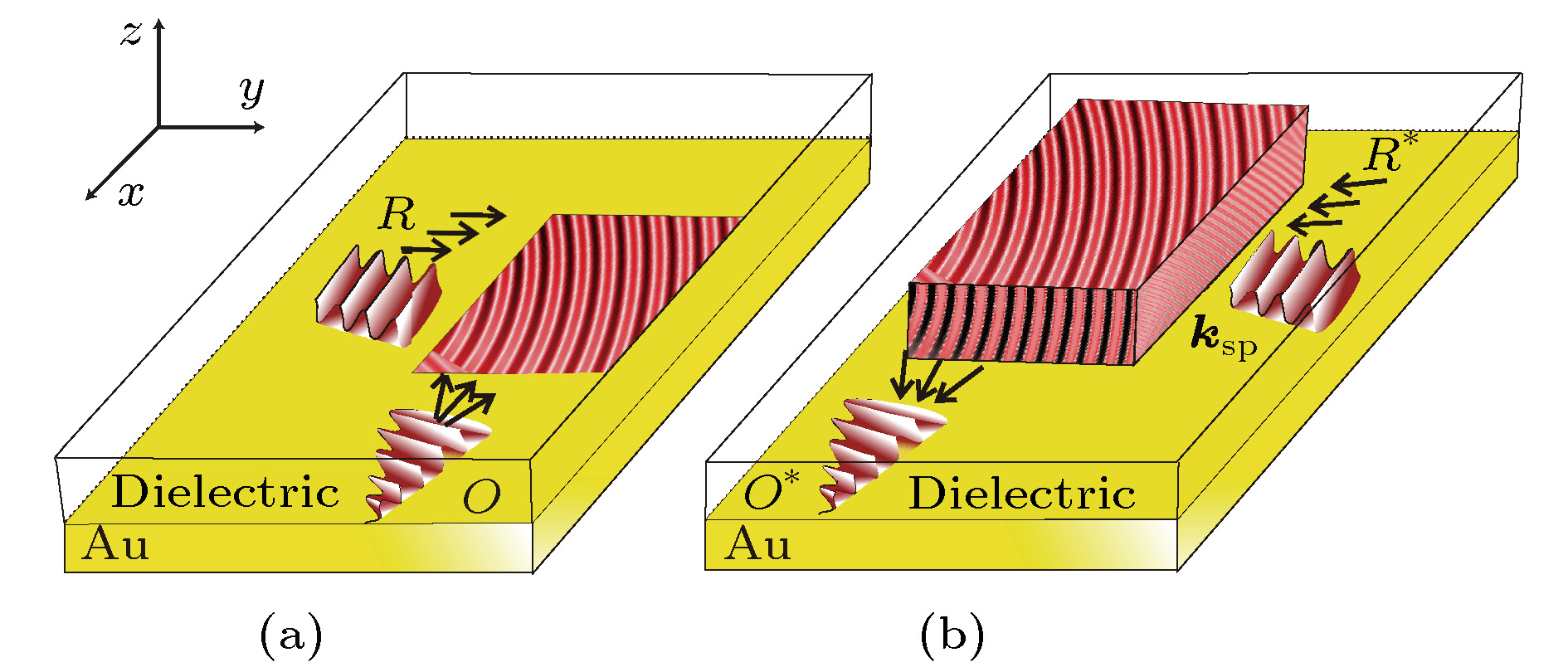

表面等离激元(surface plasmon polaritons, SPPs)控制具有重要意义. 表面电磁波全息法是在金属表面设计能有效控制SPP传输的凹槽阵列结构. 本文提出一种新的SPP传输的控制方法, 利用金属-光折变材料复合全息结构控制SPP传播. 在金属表面覆盖一层光折变材料, 两束SPP波在光折变材料内干涉生成全息结构, 利用此全息结构能够控制SPP的传播. 通过时域有限差分法模拟验证, 结果显示, 通过金属-光折变材料复合全息结构可以有效地控制SPP波束的传输, 实现SPP平面波束的单点聚焦、两点聚焦, 以及生成零阶和一阶高斯SPP波束. 经过优化发现, 光折变材料的最佳厚度为

$3.3\;{\text{μ}}{\rm{m}}$ , 最佳折射率调制度为0.06. 现有SPP控制器件主要是通过离子束刻蚀, 而金属-光折变材料复合全息结构不需要刻蚀, 从而扩展了SPP控制的器件的制作方法, 为SPPs的全光控制提供了新的思路, 使SPP全光控制成为可能, 进一步实现了SPP全光开关等功能.Control of surface plasmon polaritons’ (SPPs’) propagation is of great importance. The groove structure in metal surface, designed by the surface electromagnetic wave holography (SWH) method, can control the SPPs’ propagation effectively. In the SWH method, all designed groove structures are etched in metal surface. The fabrication method is confined to the etching method, such as the focused ion beam lithography and electron beam lithography. And the designed structures cannot implement the real-time control of SPP propagation. We propose a new method to control SPPs’ propagation through metal-photorefractive material composite holographical (MPRCH) structures. A photorefractive material film is coated on the metal surface, and the reference SPP wave interferes with the object SPP wave in the photorefractive material film. The interference intensity is recorded by the photorefractive material film, forming the MPRCH structure. The MPRCH structure is used to control the propagation of relatively weak SPP waves. The finite difference time domain method is used to verify the method. We simulate that a reconstructed SPP wave is incident into the structure region and interacts with the structure. The incident wave is reflected and scattered by the designed MPRCH structure. These reflected and scattered wave are propagated and superposed, forming the desired SPP wave on the metal surface. Simulation results show that the MPRCH structure can control SPPs’ propagation effectively and realize the functions such as SPP wave aside single-point focusing, two-point focusing, generating zero-order and first-order Gaussian SPP beams. It is found that the optimal thickness of the MPRCH film is$3.3\;{\text{μ}}{\rm{m}}$ and modulation amplitude of refractive index is 0.06. This method extends the SPP device fabrication methods, and gets rid of the etching method. Based on the investigation, the real-time controlling of SPP wave may be realized through the MPRCH structure. The study provides a new idea for realizing the all-optical control of SPP propagation, thus making it possible to implement the all-optical control of SPP and further switch.-

Keywords:

- surface plasmon polaritons /

- surface electromagnetic wave holography method /

- array structure design

[1] Wood R W 1902 Philos. Mag. 18 296

[2] Ebbesen T W, Lezec H J, Ghaemi H F, Thio T, Wolff P A 1998 Nature 391 667

Google Scholar

Google Scholar

[3] Homola J, Yee S S, Gauglitz G 1999 Sens. Actuators B 54 3

Google Scholar

Google Scholar

[4] 冯李航, 曾捷, 梁大开, 张为公 2013 62 124207

Google Scholar

Google Scholar

Feng L H, Zeng J, Liang D K, Zhang W G 2013 Acta Phys. Sin. 62 124207

Google Scholar

Google Scholar

[5] Bozhevolnyi S I, Volkov V S, Devaux E, Laluet J Y, Ebbesen T W 2006 Nature 440 508

Google Scholar

Google Scholar

[6] Csaki A, Garwe F, Steinbruck A, Maubach G, Festag G, Weise A 2007 Nano Lett. 7 247

Google Scholar

Google Scholar

[7] Oulton R F, Sorger V J, Zentgraf T, Ma R M, Gladden C, Dai L, Bartal G, Zhang X 2009 Nature 461 629

Google Scholar

Google Scholar

[8] Bergman D J, Stockman M I 2003 Phys. Rev. Lett. 90 027402

Google Scholar

Google Scholar

[9] Bozhevolnyi S I, Volkov V S, Devaux E, Ebbesen T W 2005 Phys. Rev. Lett. 95 046802

Google Scholar

Google Scholar

[10] 郭亚楠, 薛文瑞, 张文梅 2009 58 4168

Google Scholar

Google Scholar

Guo Y N, Xue Y N, Zhang W M 2009 Acta Phys. Sin. 58 4168

Google Scholar

Google Scholar

[11] Lu C C, Liu Y C, Hu X Y, Yang H, Gong Q H 2016 Sci. Rep. 6 27428

Google Scholar

Google Scholar

[12] Lezec H J, Degiron A, Devaux E, Linke R A, Martìn-Moreno L, Garcìa-Vidal F J, Ebbesen T W 2002 Science 297 820

Google Scholar

Google Scholar

[13] Yin L, Vlasko-Vlasov V K, Pearson J, Hiller J M, Hua J, Welp U, Brown D E, Kimball C W 2005 Nano Lett. 5 1399

Google Scholar

Google Scholar

[14] 张国浩, 陈跃刚 2015 光学学报 35 1113003

Zhang G H, Chen Y G 2015 Acta Opt. Sin. 35 1113003

[15] Li L, Li T, Wang S M, Zhang C, Zhu S N 2011 Phys. Rev. Lett. 107 126804

Google Scholar

Google Scholar

[16] Li L, Li T, Wang S M, Zhang C, Zhu S N 2013 Phys. Rev. Lett. 110 046807

Google Scholar

Google Scholar

[17] Li L, Li T, Tang X M, Wang S M, Wang Q J, Zhu S N 2015 Light: Sci. Appl. 4 e330

Google Scholar

Google Scholar

[18] Tanemura T, Balram K C, Ly-Gagnon D S, Wahl P, White J S, Brongersma M L, Miller D A 2011 Nano Lett. 11 2693

Google Scholar

Google Scholar

[19] Wang B, Wu X, Zhang Y 2013 Plasmonics 8 1535

Google Scholar

Google Scholar

[20] Drezet A, Koller D, Hohenau A, Leitner A, Aussenegg F R, Krenn J R 2007 Nano Lett. 7 1697

Google Scholar

Google Scholar

[21] Abbott S B, Daly K R, D'Alessandro G, Kaczmarek M, Smith D C 2012 J. Opt. Soc. Am. B 29 1947

Google Scholar

Google Scholar

[22] Stephen B A, Keith R. Daly, Giampaolo D'Alessandro, Kaczmarek M, Smith D C 2012 Opt. Lett. 37 2436

Google Scholar

Google Scholar

[23] Chen Y H, Fu J X, Li Z Y 2011 Opt. Express 19 23908

Google Scholar

Google Scholar

[24] Chen Y H, Zhang M Q, Gan L, Wu X Y, Sun L, Liu J, Wang J, Li Z Y 2013 Opt. Express 21 17558

Google Scholar

Google Scholar

[25] Chen Y H, Huang L, Gan L, Li Z Y 2012 Light: Sci. Appl. 1 e26

Google Scholar

Google Scholar

[26] Chen Y G, Chen Y H, Li Z Y 2014 Opt. Lett. 39 339

Google Scholar

Google Scholar

[27] Chen Y G, Yang F Y, Liu J, Li Z Y 2014 Opt. Express 22 14727

Google Scholar

Google Scholar

[28] Chen Y G, Wang Y, Li Z Y 2014 Plasmonics 9 1057

Google Scholar

Google Scholar

[29] Liu J, Chen Y G, Gan L, Xiao T H, Li Z Y 2016 Sci. Rep. 6 27565

Google Scholar

Google Scholar

[30] Chen Y G, Li Z Y 2015 Chin. Opt. lett. 13 020501

Google Scholar

Google Scholar

[31] Ashkin A, Boyd G D, Dziedzic J M 1966 Appl. Phys. Lett. 9 72

Google Scholar

Google Scholar

[32] Akella A, Sochava S L, Hesselink L 1997 Opt. Lett. 22 919

Google Scholar

Google Scholar

[33] 陶世荃, 江竹青, 万玉红, 王大勇, 王云新 2013 光学体全息技术及应用 (北京: 科学出版社) 第23页

Tao S Q, Jiang Z Q, Wan Y H, Wang D Y, Wang Y X 2013 Optical Volume Holography and its Applications (Beijing: Science Press) p23 (in Chinese)

-

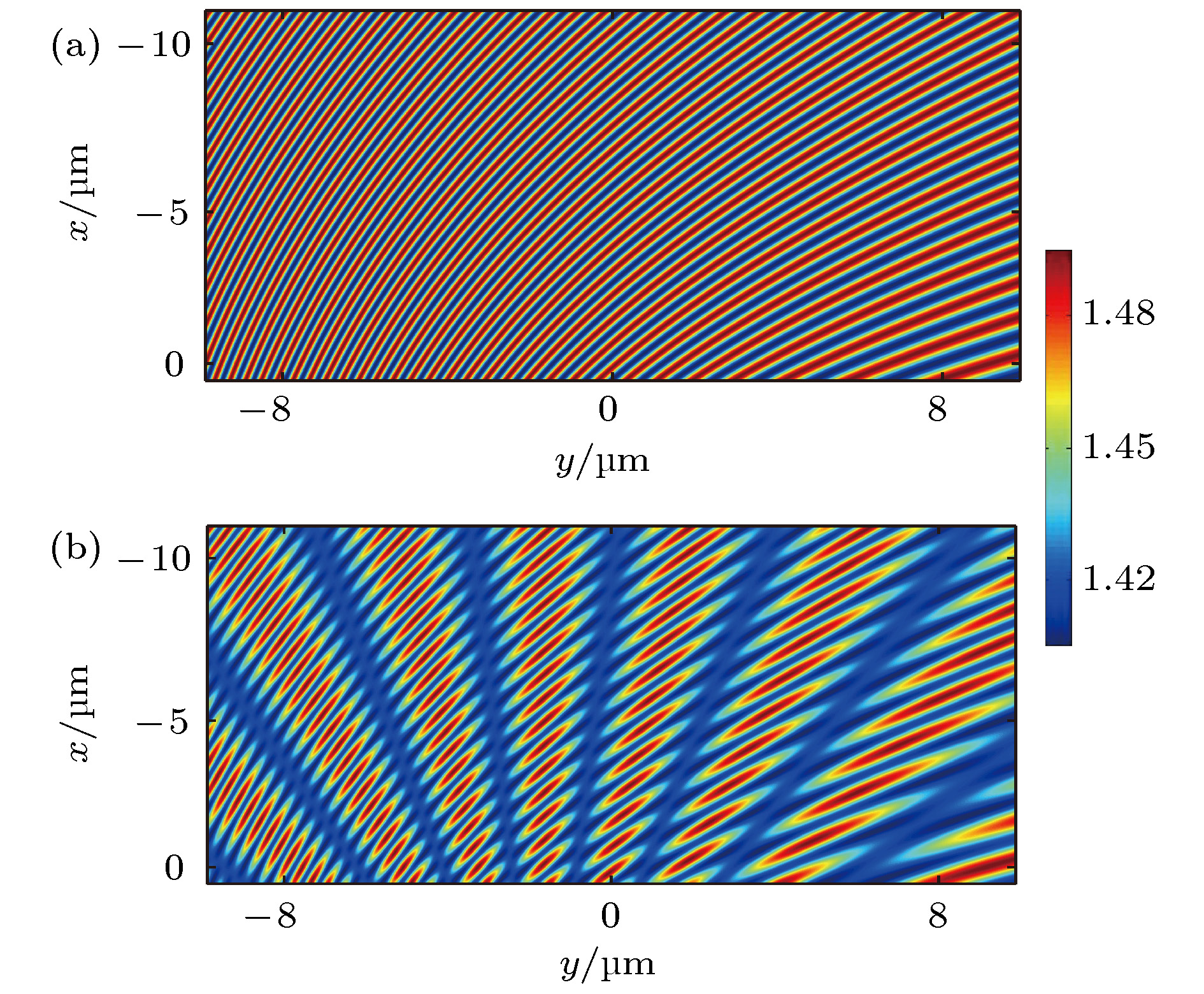

图 2 全息图设计 (a)汇聚SPP波于1个点

$O{\rm{(}}8\;{\text{μ}}{\rm{m}},0{\rm{)}}$ ; (b)汇聚SPP波于2个点${O_1}{\rm{(}}8\;{\text{μ}}{\rm{m}}, - 2\;{\text{μ}}{\rm{m}})$ 和${O_2}{\rm{(}}8\;{\text{μ}}{\rm{m}},$ $2\;{\text{μ}}{\rm{m}})$ Fig. 2. Designing the photorefractive holograms: (a) Focusing SPP at one point

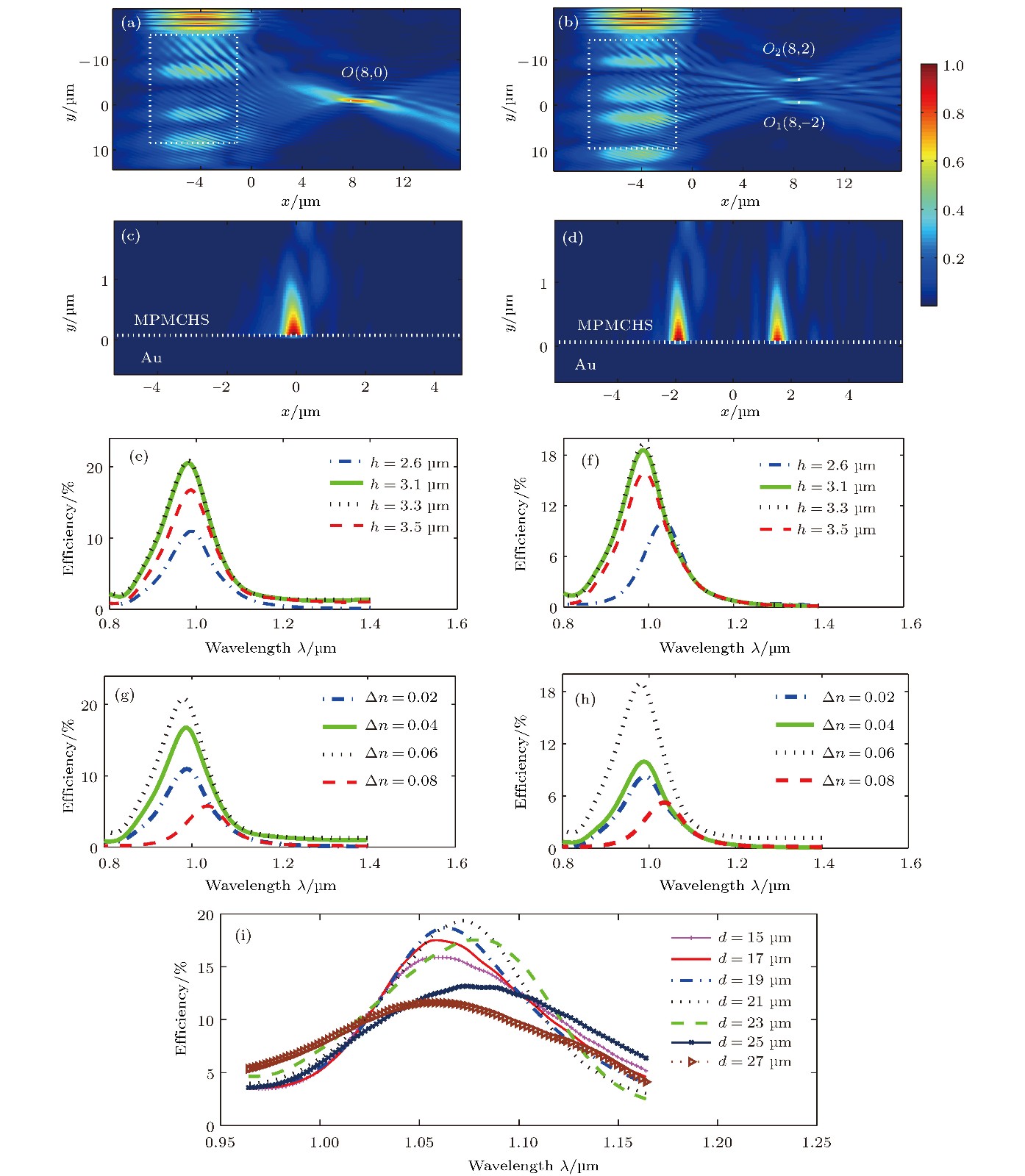

$O{\rm{(}}8\;{\text{μ}}{\rm{m}},0{\rm{)}}$ ; (b) focusing SPP at two points${O_1}{\rm{(8\;{\text{μ}}{\rm{m}}, -2\;{\text{μ}}{\rm{m}})}}$ and${O_2}{\rm{(8\;{\text{μ}}{\rm{m}},2\;{\text{μ}}{\rm{m}})}}$ 图 3 光折变材料汇聚平面SPP波到1个点和2个点的模拟结果 (a)汇聚到1个点时xy平面的光强分布; (b)汇聚到2个点时xy平面的光强分布; (c)汇聚到1个点时焦面yz平面的光强分布; (d)汇聚到2个点时焦面yz平面的光强分布; (e)材料厚度对1个点汇聚耦合效率的影响; (f)材料厚度对2个点汇聚耦合效率的影响; (g)折射率调制度对1个点汇聚耦合效率的影响; (h)折射率调制度对2个点汇聚耦合效率的影响; (i)全息图尺度对2个点汇聚耦合效率的影响

Fig. 3. Simulation results of coupling SPP wave to a point and two points by metal-photorefractive material complex holography structures: (a) Intensity distribution in the xy plane for focusing SPP to a point; (b) intensity distribution in the xy plane for focusing SPP to two points; (c) intensity distribution in the yz plane for focusing SPP to a point; (d) intensity distribution in the yz plane for focusing SPP to two points; (e) influence of material thickness on coupling efficiency for focusing SPP to a point; (f) influences of material thickness on coupling efficiency for focusing SPP to two points; (g) influence of refractive modulation on coupling efficiency for focusing SPP to a point; (h) influence of refractive modulation on coupling efficiency for focusing SPP to two points; (i) influence of hologram dimension on coupling efficiency for focusing SPP to two points

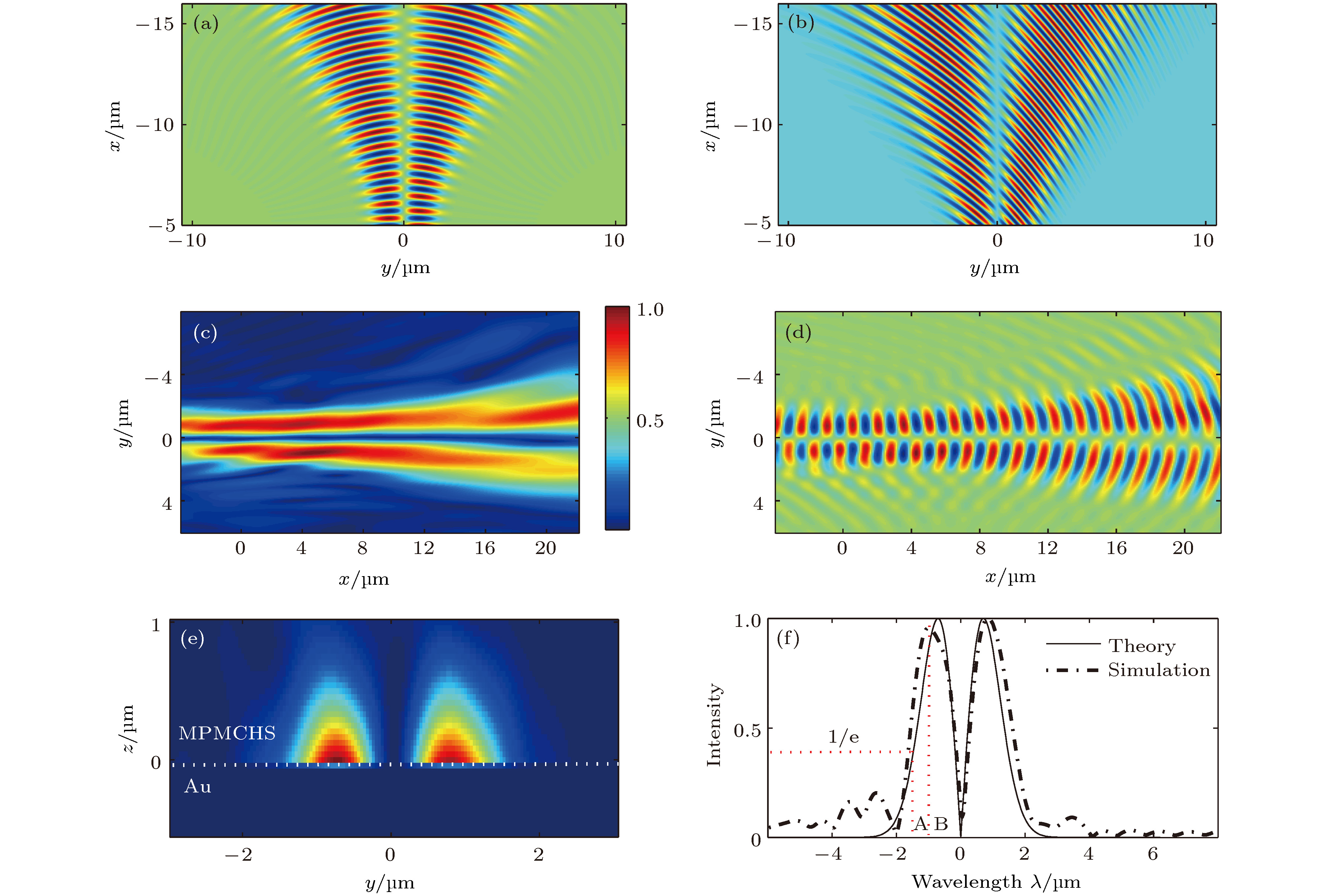

图 4 零阶高斯SPP波束的生成, 其中图(a)和(b)为物波波面分布、物波和参考光波干涉产生的光强分布; 全息图读出的模拟结果, 包括xy平面的(c)光强分布和(d)波阵面分布, (e) SPP高斯波束束腰处光强分布, (f)折射率调制度对耦合效率的影响

Fig. 4. Generation of Gaussian zero-order SPP beam in writing process: (a) Object SPP wavefront; (b) interference intensity distribution between object wave and reference wave. Simulation results of reading process: (c) intensity and (d) wavefront distribution in xy plane; (e) intensity distribution on waist for theory and simulation; (f) influence of refractive modulation on coupling efficiency

图 5 1阶高斯SPP波束的生成, 其中图(a)和(b)为物波波面分布、物波和参考光波干涉产生光强分布; 读出过程的模拟结果, 包括xy平面内(c)光强分布和(d)波阵面分布, (e) x = 0处yz截面内光强分布, (f)理论和模拟的1阶SPP高斯波束束腰处光强分布

Fig. 5. Generation of Gaussian first-order SPP beam in writing process: (a) Object SPP wavefront; (b) interference intensity distribution between object wave and reference wave. Simulation results of reading process: (c) intensity and (d) wavefront distribution in xy plane; (e) intensity distribution on yz plane with x = 0; (f) intensity distribution on waist for theory and simulation

-

[1] Wood R W 1902 Philos. Mag. 18 296

[2] Ebbesen T W, Lezec H J, Ghaemi H F, Thio T, Wolff P A 1998 Nature 391 667

Google Scholar

Google Scholar

[3] Homola J, Yee S S, Gauglitz G 1999 Sens. Actuators B 54 3

Google Scholar

Google Scholar

[4] 冯李航, 曾捷, 梁大开, 张为公 2013 62 124207

Google Scholar

Google Scholar

Feng L H, Zeng J, Liang D K, Zhang W G 2013 Acta Phys. Sin. 62 124207

Google Scholar

Google Scholar

[5] Bozhevolnyi S I, Volkov V S, Devaux E, Laluet J Y, Ebbesen T W 2006 Nature 440 508

Google Scholar

Google Scholar

[6] Csaki A, Garwe F, Steinbruck A, Maubach G, Festag G, Weise A 2007 Nano Lett. 7 247

Google Scholar

Google Scholar

[7] Oulton R F, Sorger V J, Zentgraf T, Ma R M, Gladden C, Dai L, Bartal G, Zhang X 2009 Nature 461 629

Google Scholar

Google Scholar

[8] Bergman D J, Stockman M I 2003 Phys. Rev. Lett. 90 027402

Google Scholar

Google Scholar

[9] Bozhevolnyi S I, Volkov V S, Devaux E, Ebbesen T W 2005 Phys. Rev. Lett. 95 046802

Google Scholar

Google Scholar

[10] 郭亚楠, 薛文瑞, 张文梅 2009 58 4168

Google Scholar

Google Scholar

Guo Y N, Xue Y N, Zhang W M 2009 Acta Phys. Sin. 58 4168

Google Scholar

Google Scholar

[11] Lu C C, Liu Y C, Hu X Y, Yang H, Gong Q H 2016 Sci. Rep. 6 27428

Google Scholar

Google Scholar

[12] Lezec H J, Degiron A, Devaux E, Linke R A, Martìn-Moreno L, Garcìa-Vidal F J, Ebbesen T W 2002 Science 297 820

Google Scholar

Google Scholar

[13] Yin L, Vlasko-Vlasov V K, Pearson J, Hiller J M, Hua J, Welp U, Brown D E, Kimball C W 2005 Nano Lett. 5 1399

Google Scholar

Google Scholar

[14] 张国浩, 陈跃刚 2015 光学学报 35 1113003

Zhang G H, Chen Y G 2015 Acta Opt. Sin. 35 1113003

[15] Li L, Li T, Wang S M, Zhang C, Zhu S N 2011 Phys. Rev. Lett. 107 126804

Google Scholar

Google Scholar

[16] Li L, Li T, Wang S M, Zhang C, Zhu S N 2013 Phys. Rev. Lett. 110 046807

Google Scholar

Google Scholar

[17] Li L, Li T, Tang X M, Wang S M, Wang Q J, Zhu S N 2015 Light: Sci. Appl. 4 e330

Google Scholar

Google Scholar

[18] Tanemura T, Balram K C, Ly-Gagnon D S, Wahl P, White J S, Brongersma M L, Miller D A 2011 Nano Lett. 11 2693

Google Scholar

Google Scholar

[19] Wang B, Wu X, Zhang Y 2013 Plasmonics 8 1535

Google Scholar

Google Scholar

[20] Drezet A, Koller D, Hohenau A, Leitner A, Aussenegg F R, Krenn J R 2007 Nano Lett. 7 1697

Google Scholar

Google Scholar

[21] Abbott S B, Daly K R, D'Alessandro G, Kaczmarek M, Smith D C 2012 J. Opt. Soc. Am. B 29 1947

Google Scholar

Google Scholar

[22] Stephen B A, Keith R. Daly, Giampaolo D'Alessandro, Kaczmarek M, Smith D C 2012 Opt. Lett. 37 2436

Google Scholar

Google Scholar

[23] Chen Y H, Fu J X, Li Z Y 2011 Opt. Express 19 23908

Google Scholar

Google Scholar

[24] Chen Y H, Zhang M Q, Gan L, Wu X Y, Sun L, Liu J, Wang J, Li Z Y 2013 Opt. Express 21 17558

Google Scholar

Google Scholar

[25] Chen Y H, Huang L, Gan L, Li Z Y 2012 Light: Sci. Appl. 1 e26

Google Scholar

Google Scholar

[26] Chen Y G, Chen Y H, Li Z Y 2014 Opt. Lett. 39 339

Google Scholar

Google Scholar

[27] Chen Y G, Yang F Y, Liu J, Li Z Y 2014 Opt. Express 22 14727

Google Scholar

Google Scholar

[28] Chen Y G, Wang Y, Li Z Y 2014 Plasmonics 9 1057

Google Scholar

Google Scholar

[29] Liu J, Chen Y G, Gan L, Xiao T H, Li Z Y 2016 Sci. Rep. 6 27565

Google Scholar

Google Scholar

[30] Chen Y G, Li Z Y 2015 Chin. Opt. lett. 13 020501

Google Scholar

Google Scholar

[31] Ashkin A, Boyd G D, Dziedzic J M 1966 Appl. Phys. Lett. 9 72

Google Scholar

Google Scholar

[32] Akella A, Sochava S L, Hesselink L 1997 Opt. Lett. 22 919

Google Scholar

Google Scholar

[33] 陶世荃, 江竹青, 万玉红, 王大勇, 王云新 2013 光学体全息技术及应用 (北京: 科学出版社) 第23页

Tao S Q, Jiang Z Q, Wan Y H, Wang D Y, Wang Y X 2013 Optical Volume Holography and its Applications (Beijing: Science Press) p23 (in Chinese)

计量

- 文章访问数: 9374

- PDF下载量: 105

- 被引次数: 0

下载:

下载: