-

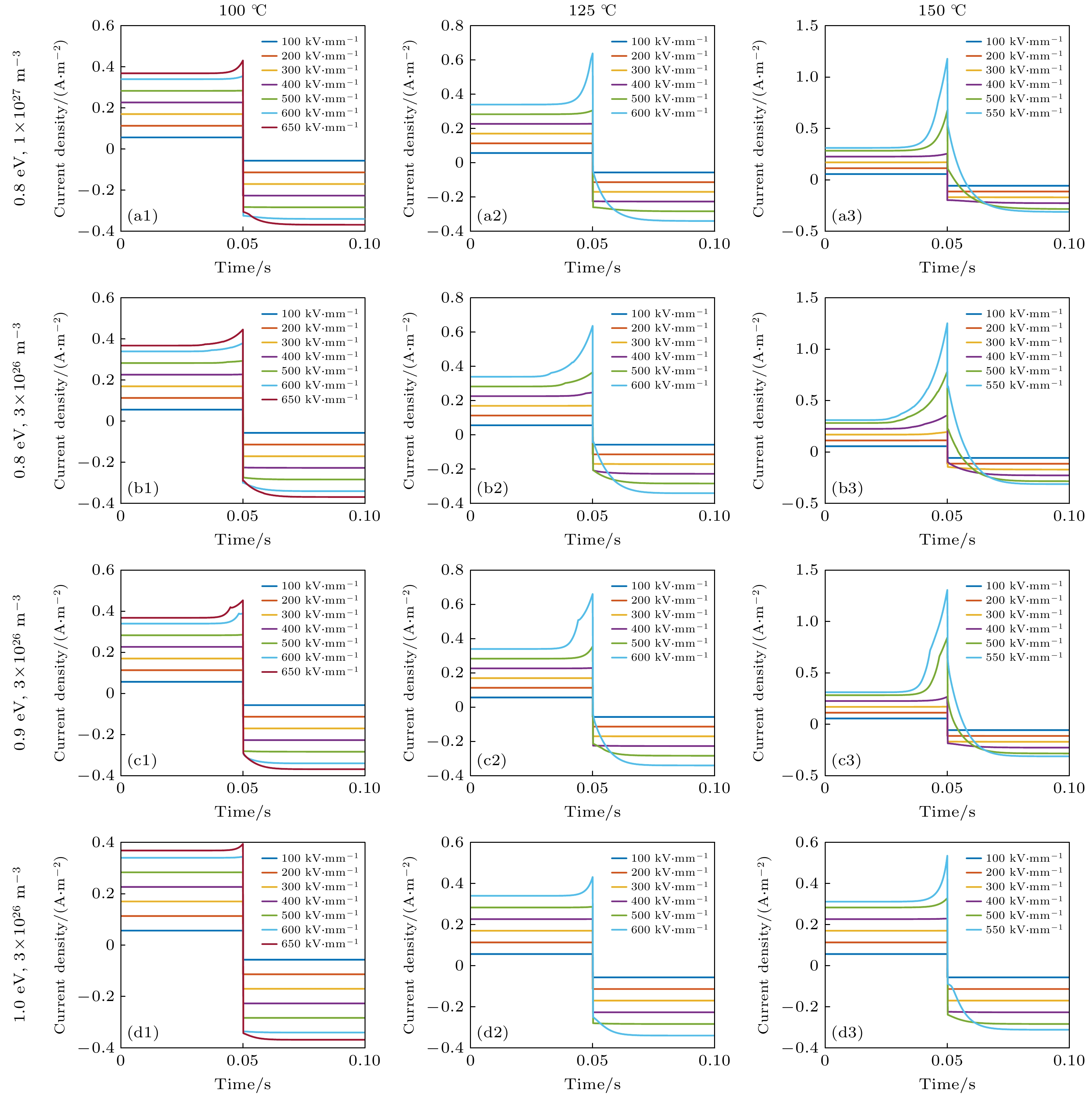

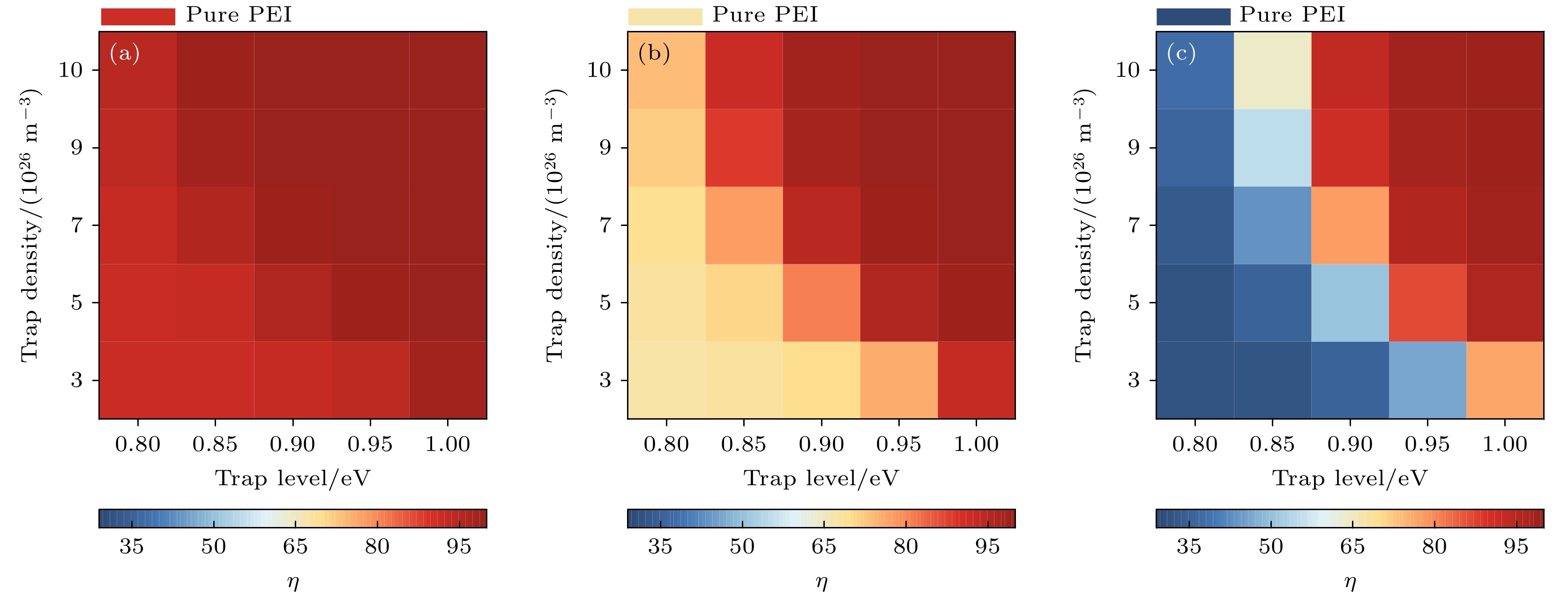

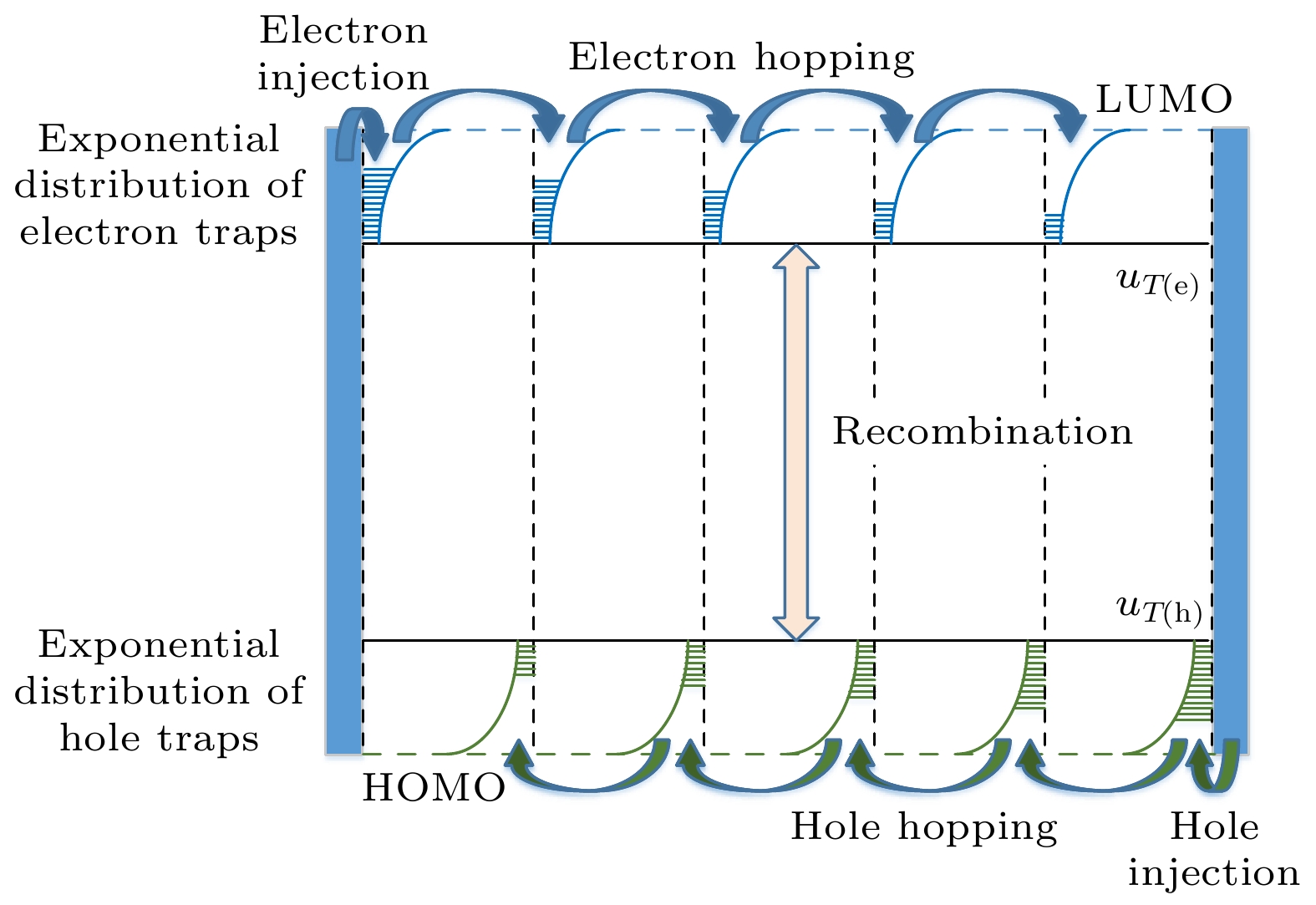

目前常见聚合物电介质电容器的储能性能在高温下会急剧劣化, 难以满足航空航天和能源等领域的需求. 为提高介质高温储能性能, 常掺杂纳米填料对电介质改性, 通过改变电介质内部陷阱参数来调控电荷输运过程, 但其内部陷阱的能级和密度与储能性能间的定量关系仍需进一步研究. 本文构建线性聚合物纳米复合电介质中指数分布陷阱电荷跳跃输运的储能与释能模型并进行了仿真. 纯聚醚酰亚胺在150 ℃的体积电阻率和电位移矢量-电场强度回线的仿真结果与实验符合, 证明了模型的有效性. 不同陷阱参数纳米复合电介质的仿真结果表明, 增大总陷阱密度和最深陷阱能级, 会降低载流子迁移率、电流密度和电导损耗, 提升放电能量密度和充放电效率. 在150 ℃和550 kV/mm外施场强下, 1.0 eV最深陷阱能级和1×1027 m–3总陷阱密度的纳米复合电介质放电能量密度和充放电效率分别为4.26 J/cm3和98.93%, 相比纯聚醚酰亚胺提升率分别为91.09%和227.58%, 显著提升了高温储能性能. 本研究为耐高温高储能性能电容器的研发提供了理论和模型支撑.With the development of science and technology, polymer dielectric capacitors are widely used in energy, electronics, transportation, aerospace, and many other areas. For polymer dielectric energy storage capacitors to remain effective in practical applications, excellent charge and discharge performance is essential. However, the performance of the common polymer dielectric capacitors will deteriorate rapidly at high temperature, which makes them fail to work efficiently under worse working conditions. Dielectric trap energy levels and trap densities increase when nanoparticles are incorporated into the dielectric. The change in trap parameters will affect carrier transport. Therefore, the high temperature energy storage performance of polymer nanocomposite dielectric can be improved by changing the trap parameters to regulate the carrier transport process. However, the quantitative relationship between trap energy level and trap density and the energy storage properties of nanocomposite dielectric need further studying. In this paper, the energy storage and release model for exponentially distributed trapped charge jump transport in linear polymer nanocomposite dielectrics is constructed and simulated. The volume resistivity and electric displacement-electric field loops of pure polyetherimide are simulated at 150 ℃, and the simulation results match the experimental results, which demonstrates the validity of the model. Following that, under different temperatures and electric fields, the current density, electric displacement-electric field loops, discharge energy density and charge-discharge efficiency of polyetherimide nanocomposite dielectric are simulated by using different trap parameters. The results show that increasing the maximum trap energy level and the total trap density can effectively reduce the carrier mobility, current density and conductivity loss, and enhance the discharge energy density and the charge-discharge efficiency of the nanocomposite dielectric. On condition that temperature is 150 ℃ and applied electric field is 550 kV/mm, the polyetherimide nanocomposite dielectric with a maximum trap energy level of 1.0 eV and a total trap density of 1×1027 m–3, has 4.26 J·cm–3 of discharge energy density and 98.93% of energy efficiency. Compared with pure polyetherimide, the rate of improvement is 91.09% and 227.58%, respectively. The energy storage performance under high temperature and high electric field is obviously improved. It provides theoretical and model support for the research and development of capacitors with high temperature resistance and energy storage performance.

-

Keywords:

- trap energy level and density /

- energy storage density /

- charge and discharge efficiency /

- nanocomposites dielectric

[1] Miao W J, Chen H X, Pan Z B, Pei X L, Li L, Li P, Liu J J, Zhai J W, Pan H 2021 Compos. Sci. Technol. 201 108501

Google Scholar

Google Scholar

[2] Zhou Y, Yuan C, Wang S J, Zhu Y J, Cheng S, Yang X, Yang Y, Hu J, He J L, Li Q 2020 Energy Stor. Mater. 28 255

Google Scholar

Google Scholar

[3] Ren W B, Pan J Y, Dan Z K, Zhang T, Jiang J Y, Fan M Z, Hu P H, Li M, Lin Y H, Nan C W, Shen Y 2021 Chem. Eng. J. 420 127614

Google Scholar

Google Scholar

[4] Li H, Ai D , Ren L L , Yao B, Han Z B, Shen Z H, Wang J J , Chen L Q , Wang Q 2019 Adv. Mater. 31 1900875

[5] 李琦, 李曼茜 2021 高电压技术 47 3105

Google Scholar

Google Scholar

LI Q, LI M Q 2021 High Volt. Eng. 47 3105

Google Scholar

Google Scholar

[6] Li Z Z, Treich G M, Tefferi M, Wu C, Nasreen S, Scheirey S K, Ramprasad R, Sotzing G A, Cao Y 2019 J. Mater. Chem. A 7 15026

Google Scholar

Google Scholar

[7] Li H, Liu F H, Fan B Y, Ai D, Peng Z R, Wang Q 2018 Small Methods 2 1700399

Google Scholar

Google Scholar

[8] 查俊伟, 黄文杰, 杨兴, 万宝全, 郑明胜 2023 高电压技术 49 1055

Google Scholar

Google Scholar

Zha J W, Huang W J, Yang X, Wan B Q, Zheng M S 2023 High volt. Eng. 49 1055

Google Scholar

Google Scholar

[9] Chi Q G, Zhou Y H, Feng Y, Cui Y, Zhang Y, Zhang T D, Chen Q G 2020 Mater. Today Energy 18 100516

Google Scholar

Google Scholar

[10] Yuan C, Zhou Y, Zhu Y J, Liang J J, Wang S J, Peng S M, Li Y S, Cheng S, Yang M C, Hu J, Zhang B, Zeng R, He J L, Li Q 2020 Nat. Commun. 11 3919

Google Scholar

Google Scholar

[11] Ren L L, Qiao J Q, Wang C, Zheng W Y, Li H, Zhao X T, Yang L J, Liao R J 2022 Mater. Today Energy 30 101161

Google Scholar

Google Scholar

[12] Fan Z H, Zhang Y Y, Jiang Y, Luo Z M, He Y B, Zhang Q F 2022 J. Mater. Res. Technol. 18 4367

Google Scholar

Google Scholar

[13] Chen H X, Pan Z B, Wang W L, Chen Y Y, Xing S, Cheng Y, Ding X P, Liu J J, Zhai J W, Yu J H 2021 Compos. Part A Appl. Sci. Manuf. 142 106266

Google Scholar

Google Scholar

[14] Min D M, Ji M Z, Li P X, Gao Z W, Liu W F, Li S T, Liu J 2021 IEEE Trans. Dielectr. Electr. Insul. 28 2011

Google Scholar

Google Scholar

[15] Kuik M, Koster L J, Wetzelaer G A, Blom P W 2011 Phys. Rev. Lett. 107 256805

Google Scholar

Google Scholar

[16] Sun B Z, Hu P H, Ji X M, Fan M Z, Zhou L, Guo M F, He S, Shen Y 2022 Small 18 e2202421

Google Scholar

Google Scholar

[17] Ding X P, Pan Z B, Cheng Y, Chen H X, Li Z C, Fan X, Liu J J, Yu J H, Zhai J W 2023 Chem. Eng. J. 453 139917

Google Scholar

Google Scholar

[18] Hoang A T, Serdyuk Y V, Gubanski S M 2016 Polymers 8 103

Google Scholar

Google Scholar

[19] Kao K C 2004 Dielectric Phenomena in Solids (San Diego: Elsevier Academic Press

[20] Jakobs A, Kehr K W 1993 Phys. Rev. B 48 8780

Google Scholar

Google Scholar

[21] 金维芳 1997 电介质物理学 (北京: 机械工业出版社)

Jin W F 1997 Dielectric Physics (Beijing: China Machine Press

[22] Li Q, Chen L, Gadinski M R, Zhang S H, Zhang G Z, Li H U, Iagodkine E, Haque A, Chen L Q, Jackson N T, Wang Q 2015 Nature 523 576

Google Scholar

Google Scholar

[23] Lewis T J 1994 IEEE Trans. Dielectr. Electr. Insul. 1 812

Google Scholar

Google Scholar

[24] Yang M Z, Ren W B, Guo M F, Shen Y 2022 Small 18 e2205247

Google Scholar

Google Scholar

[25] Li H, Ren L L, Ai D, Han Z B, Liu Y, Yao B, Wang Q 2019 InfoMat 2 389

Google Scholar

Google Scholar

[26] Akram S, Yang Y, Zhong X, Bhutta S, Wu G N, Castellon J, Zhou K 2018 IEEE Trans. Dielectr. Electr. Insul. 25 1461

Google Scholar

Google Scholar

[27] 马超, 闵道敏, 李盛涛, 郑旭, 李西育, 闵超, 湛海涯 2017 66 067701

Google Scholar

Google Scholar

Ma C, Min D M, Li S T, Zheng X, Li X Y, Min C, Zhan H X 2017 Acta Phys. Sin. 66 067701

Google Scholar

Google Scholar

[28] 查俊伟, 查磊军, 郑明胜 2023 72 018401

Google Scholar

Google Scholar

Zha J W, Zha L J, Zheng M S 2023 Acta Phys. Sin. 72 018401

Google Scholar

Google Scholar

[29] Ding X P, Pan Z B, Zhang Y, Shi S H, Cheng Y, Chen H X, Li Z C, Fan X, Liu J J, Yu J H, Zhai J W 2022 Adv. Mater. Interfaces 9 2201100

Google Scholar

Google Scholar

[30] Ren L L, Yang L J, Zhang S Y, Li H, Zhou Y, Ai D, Xie Z L, Zhao X T, Peng Z R, Liao R J, Wang Q 2021 Compos. Sci. Technol. 201 108528

Google Scholar

Google Scholar

[31] Boufayed F, Teyssèdre G, Laurent C, Le Roy S, Dissado L A, Ségur P, Montanari G C 2006 J. Appl. Phys. 100 104105

Google Scholar

Google Scholar

[32] Yan J J, Wang J, Zeng J Y, Shen Z H, Li B W, Zhang X, Zhang S J 2022 J. Mater. Chem. C 10 13157

Google Scholar

Google Scholar

-

图 3 (a)纯PEI薄膜的实验测量[10,22]与仿真计算的体积电阻率; (b)仿真计算出纯PEI薄膜在不同电场下的电位移矢量-电场强度回线; (c)最大电位移和残余电位移仿真结果与实验结果[10,22]对比

Fig. 3. (a) Comparison of experimental volume resistivities[10,22] and simulation results of pure PEI film; (b) simulation results of the D-E loops of pure PEI film under different electric fields; (c) comparison of simulation results of Dmax and Dr and experiments[10,22].

图 4 (a)在150 ℃, 总陷阱密度为3×1026 m–3、具有不同最深陷阱能级PEI纳米复合电介质下的Dr随外施电场变化关系; (b)在550 kV/mm, 最深陷阱能级为0.8 eV、具有不同总陷阱密度PEI纳米复合电介质的Dr随温度变化关系

Fig. 4. (a) Dependence between Dr and applied electric fields in PEI nanocomposite dielectrics with different deepest trap levels at the total trap density of 3×1026 m–3 and 150 ℃; (b) dependence between Dr and temperatures in PEI nanocomposite dielectrics with different total trap densities at the deepest trap level of 0.8 eV and 500 kV/mm.

表 1 指数分布陷阱电荷跳跃输运的PEI纳米复合电介质储能与释能模型参数设置

Table 1. Parameter setting of energy storage and release model for PEI nanocomposite dielectric with exponentially distributed trap jump transport.

参数 值 温度/℃ 100—150 总陷阱密度/m–3 3×1026—1×1027 最深陷阱能级/eV 0.8—1.0 指数分布形状参数/K 1200 外施电场强度/(kV·mm–1) 100—650 (100 ℃)

100—600 (125 ℃)

100—550 (150 ℃) -

[1] Miao W J, Chen H X, Pan Z B, Pei X L, Li L, Li P, Liu J J, Zhai J W, Pan H 2021 Compos. Sci. Technol. 201 108501

Google Scholar

Google Scholar

[2] Zhou Y, Yuan C, Wang S J, Zhu Y J, Cheng S, Yang X, Yang Y, Hu J, He J L, Li Q 2020 Energy Stor. Mater. 28 255

Google Scholar

Google Scholar

[3] Ren W B, Pan J Y, Dan Z K, Zhang T, Jiang J Y, Fan M Z, Hu P H, Li M, Lin Y H, Nan C W, Shen Y 2021 Chem. Eng. J. 420 127614

Google Scholar

Google Scholar

[4] Li H, Ai D , Ren L L , Yao B, Han Z B, Shen Z H, Wang J J , Chen L Q , Wang Q 2019 Adv. Mater. 31 1900875

[5] 李琦, 李曼茜 2021 高电压技术 47 3105

Google Scholar

Google Scholar

LI Q, LI M Q 2021 High Volt. Eng. 47 3105

Google Scholar

Google Scholar

[6] Li Z Z, Treich G M, Tefferi M, Wu C, Nasreen S, Scheirey S K, Ramprasad R, Sotzing G A, Cao Y 2019 J. Mater. Chem. A 7 15026

Google Scholar

Google Scholar

[7] Li H, Liu F H, Fan B Y, Ai D, Peng Z R, Wang Q 2018 Small Methods 2 1700399

Google Scholar

Google Scholar

[8] 查俊伟, 黄文杰, 杨兴, 万宝全, 郑明胜 2023 高电压技术 49 1055

Google Scholar

Google Scholar

Zha J W, Huang W J, Yang X, Wan B Q, Zheng M S 2023 High volt. Eng. 49 1055

Google Scholar

Google Scholar

[9] Chi Q G, Zhou Y H, Feng Y, Cui Y, Zhang Y, Zhang T D, Chen Q G 2020 Mater. Today Energy 18 100516

Google Scholar

Google Scholar

[10] Yuan C, Zhou Y, Zhu Y J, Liang J J, Wang S J, Peng S M, Li Y S, Cheng S, Yang M C, Hu J, Zhang B, Zeng R, He J L, Li Q 2020 Nat. Commun. 11 3919

Google Scholar

Google Scholar

[11] Ren L L, Qiao J Q, Wang C, Zheng W Y, Li H, Zhao X T, Yang L J, Liao R J 2022 Mater. Today Energy 30 101161

Google Scholar

Google Scholar

[12] Fan Z H, Zhang Y Y, Jiang Y, Luo Z M, He Y B, Zhang Q F 2022 J. Mater. Res. Technol. 18 4367

Google Scholar

Google Scholar

[13] Chen H X, Pan Z B, Wang W L, Chen Y Y, Xing S, Cheng Y, Ding X P, Liu J J, Zhai J W, Yu J H 2021 Compos. Part A Appl. Sci. Manuf. 142 106266

Google Scholar

Google Scholar

[14] Min D M, Ji M Z, Li P X, Gao Z W, Liu W F, Li S T, Liu J 2021 IEEE Trans. Dielectr. Electr. Insul. 28 2011

Google Scholar

Google Scholar

[15] Kuik M, Koster L J, Wetzelaer G A, Blom P W 2011 Phys. Rev. Lett. 107 256805

Google Scholar

Google Scholar

[16] Sun B Z, Hu P H, Ji X M, Fan M Z, Zhou L, Guo M F, He S, Shen Y 2022 Small 18 e2202421

Google Scholar

Google Scholar

[17] Ding X P, Pan Z B, Cheng Y, Chen H X, Li Z C, Fan X, Liu J J, Yu J H, Zhai J W 2023 Chem. Eng. J. 453 139917

Google Scholar

Google Scholar

[18] Hoang A T, Serdyuk Y V, Gubanski S M 2016 Polymers 8 103

Google Scholar

Google Scholar

[19] Kao K C 2004 Dielectric Phenomena in Solids (San Diego: Elsevier Academic Press

[20] Jakobs A, Kehr K W 1993 Phys. Rev. B 48 8780

Google Scholar

Google Scholar

[21] 金维芳 1997 电介质物理学 (北京: 机械工业出版社)

Jin W F 1997 Dielectric Physics (Beijing: China Machine Press

[22] Li Q, Chen L, Gadinski M R, Zhang S H, Zhang G Z, Li H U, Iagodkine E, Haque A, Chen L Q, Jackson N T, Wang Q 2015 Nature 523 576

Google Scholar

Google Scholar

[23] Lewis T J 1994 IEEE Trans. Dielectr. Electr. Insul. 1 812

Google Scholar

Google Scholar

[24] Yang M Z, Ren W B, Guo M F, Shen Y 2022 Small 18 e2205247

Google Scholar

Google Scholar

[25] Li H, Ren L L, Ai D, Han Z B, Liu Y, Yao B, Wang Q 2019 InfoMat 2 389

Google Scholar

Google Scholar

[26] Akram S, Yang Y, Zhong X, Bhutta S, Wu G N, Castellon J, Zhou K 2018 IEEE Trans. Dielectr. Electr. Insul. 25 1461

Google Scholar

Google Scholar

[27] 马超, 闵道敏, 李盛涛, 郑旭, 李西育, 闵超, 湛海涯 2017 66 067701

Google Scholar

Google Scholar

Ma C, Min D M, Li S T, Zheng X, Li X Y, Min C, Zhan H X 2017 Acta Phys. Sin. 66 067701

Google Scholar

Google Scholar

[28] 查俊伟, 查磊军, 郑明胜 2023 72 018401

Google Scholar

Google Scholar

Zha J W, Zha L J, Zheng M S 2023 Acta Phys. Sin. 72 018401

Google Scholar

Google Scholar

[29] Ding X P, Pan Z B, Zhang Y, Shi S H, Cheng Y, Chen H X, Li Z C, Fan X, Liu J J, Yu J H, Zhai J W 2022 Adv. Mater. Interfaces 9 2201100

Google Scholar

Google Scholar

[30] Ren L L, Yang L J, Zhang S Y, Li H, Zhou Y, Ai D, Xie Z L, Zhao X T, Peng Z R, Liao R J, Wang Q 2021 Compos. Sci. Technol. 201 108528

Google Scholar

Google Scholar

[31] Boufayed F, Teyssèdre G, Laurent C, Le Roy S, Dissado L A, Ségur P, Montanari G C 2006 J. Appl. Phys. 100 104105

Google Scholar

Google Scholar

[32] Yan J J, Wang J, Zeng J Y, Shen Z H, Li B W, Zhang X, Zhang S J 2022 J. Mater. Chem. C 10 13157

Google Scholar

Google Scholar

计量

- 文章访问数: 6277

- PDF下载量: 175

- 被引次数: 0

下载:

下载: