-

二维铁电材料因具有自发极化特性, 在铁电场效应晶体管、非易失性存储器和传感器中具有广泛的技术和器件应用. 特别是第Ⅳ主族单硫属化合物具有最高的理论预测热电特性和本征的面内铁电极化特性, 适合作为探索二维铁电极化特性的模型材料. 然而, 由于相对大的解理能, 目前不容易获得高质量和大尺寸单层第Ⅳ主族单硫属化合物, 严重阻碍了这些材料应用到快速发展的二维材料及其异质结研究中. 本文采用分子束外延方法在Cu(111)衬底上成功制备单层GeS. 通过高分辨扫描隧道显微镜, 原位X射线光电子能谱和角分辨光电子能谱以及密度泛函理论计算, 对单层GeS原子晶格和电子能带结构进行了系统表征. 研究结果表明: 单层GeS具有正交晶格结构和近似平带的电子能带结构. 单层GeS的成功制备和表征使得制备高质量和大尺寸单层第Ⅳ主族单硫属化合物成为可能, 有利于该主族材料应用到快速发展的二维铁电材料以及异质结研究中.

-

关键词:

- 二维铁电 /

- 过渡金属单硫属化合物 /

- 硫化锗 /

- 扫描隧道显微镜 /

- X射线光电子能谱

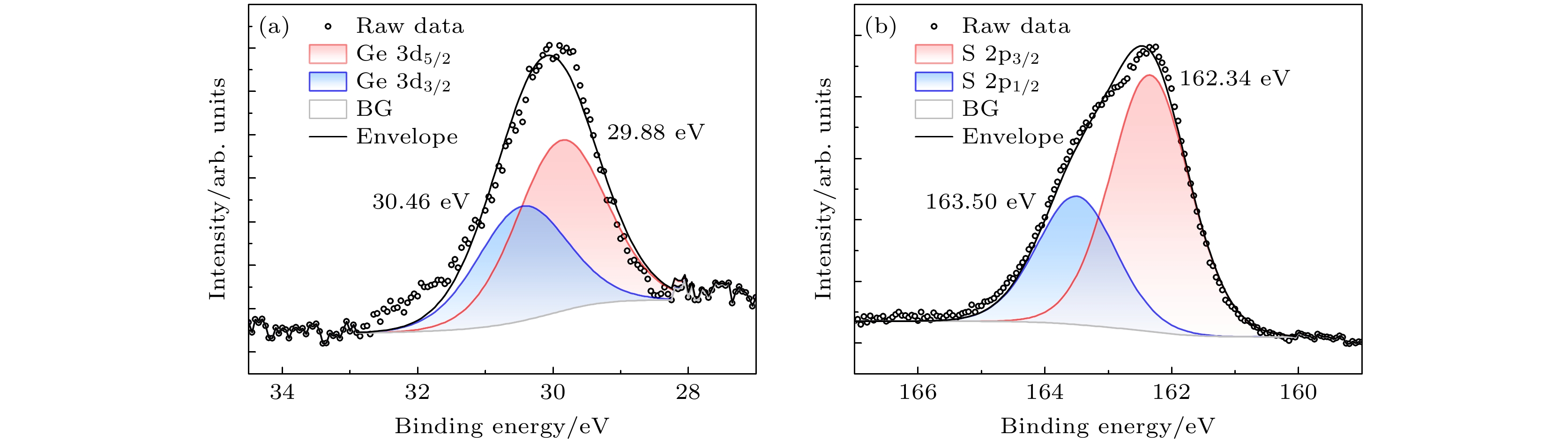

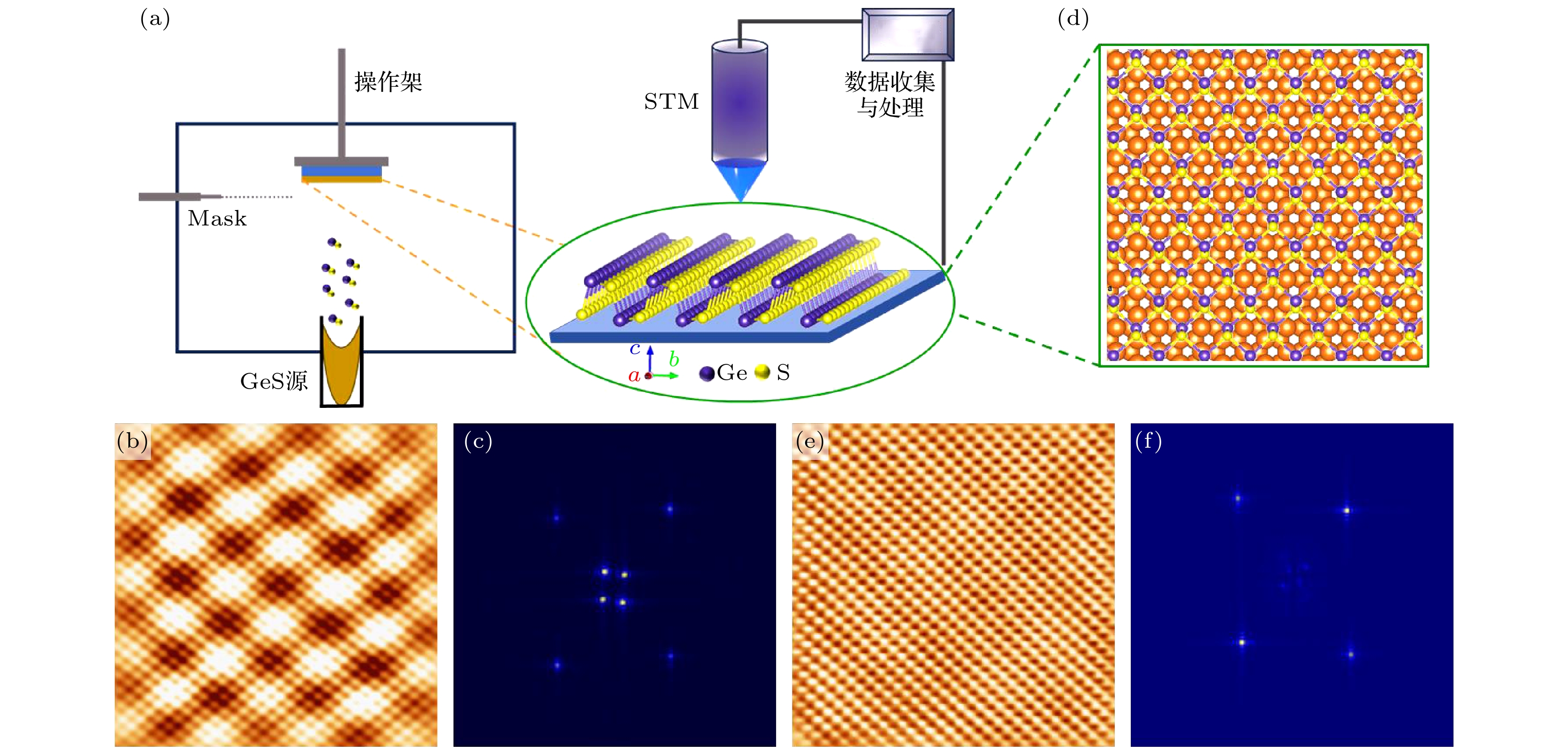

Two-dimensional (2D) ferroelectric materials are important materials for both fundamental properties and potential applications. Especially, group Ⅳ monochalcogenide possesses highest thermoelectric performance and intrinsic ferroelectric polarization properties and can sever as a model to explore ferroelectric polarization properties. However, due to the relatively large exfoliation energy, the creation of high-quality and large-size monolayer group Ⅳ monochalcogenide is not so easy, which seriously hinders the integration of these materials into the fast-developing field of 2D materials and their heterostructures. Herein, monolayer GeS is successfully fabricated on Cu(111) substrate by molecular beam epitaxy method, and the lattice structure and the electronic band structure of monolayer GeS are systematically characterized by high-resolution scanning tunneling microscopy, low-energy electron diffraction, in-situ X-ray photoelectron spectroscopy, Raman spectra, and angle-resolved photoelectron spectroscopy, and density functional theory calculations. All atomically resolved STM images reveal that the obtained monolayer GeS has an orthogonal lattice structure, which consists with theoretical prediction. Meanwhile, the distinct moiré pattern formed between monolayer GeS and Cu(111) substrate also confirms the orthogonal lattice structure. In order to examine the chemical composition and valence state of as-prepared monolayer GeS, in-situ XPS is utilized without being exposed to air. The measured spectra of XPS core levels suggest that the valence states of Ge and S elements are identified to be +2 and –2, respectively and the atomic ratio of Ge/S is 1∶1.5, which is extremely close to the stoichiometric ratio of 1∶1 for GeS. To further corroborate the quality and lattice structure of the monolayer GeS film, ex-situ Raman measurements are also performed for monolayer GeS on highly oriented pyrolytic graphene (HOPG) and multilayer graphene substrate. Three well-defined typical characteristic Raman peaks of GeS are observed. Finally, in-situ ARPES measurement are conducted to determine the electronic band structure of monolayer GeS on Cu(111). The results demonstrate that the monolayer GeS has a nearly flat band electronic band structure, consistent with our density functional theory calculation. The realization and investigation of the monolayer GeS extend the scope of 2D ferroelectric materials and make it possible to prepare high quality and large size monolayer group Ⅳ monochalcogenides, which is beneficial to the application of this main group material to the rapidly developing 2D ferroelectric materials and heterojunction research.-

Keywords:

- 2D ferroelectrics /

- transition metal monochalcogenides /

- germanium sulfide /

- scanning tunneling microscopy /

- X-ray photoemission spectroscopy

[1] Khan A I, Keshavarzi A, Datta S 2020 Nat. Electron. 3 588

Google Scholar

Google Scholar

[2] Wang S, Liu L, Gan L, Chen H, Hou X, Ding Y, Ma S, Zhang D W, Zhou P 2021 Nat. Commun. 12 53

Google Scholar

Google Scholar

[3] John R A, Demirağ Y, Shynkarenko Y, Berezovska Y, Ohannessian N, Payvand M, Zeng P, Bodnarchuk M I, Krumeich F, Kara G, Shorubalko I, Nair M V, Cooke G A, Lippert T, Indiveri G, Kovalenko M V 2022 Nat. Commun. 13 2074

Google Scholar

Google Scholar

[4] Wang J, Wang F, Wang Z, Huang W, Yao Y, Wang Y, Yang J, Li N, Yin L, Cheng R, Zhan X, Shan C, He J 2021 Sci. Bull. 66 2288

Google Scholar

Google Scholar

[5] Junquera J, Ghosez P 2003 Nature 422 506

Google Scholar

Google Scholar

[6] Lee D, Lu H, Gu Y, Choi S Y, Li S D, Ryu S, Paudel T R, Song K, Mikheev E, Lee S, Stemmer S, Tenne D A, Oh S H, Tsymbal E Y, Wu X, Chen L Q, Gruverman A, Eom C B 2015 Science 349 1314

Google Scholar

Google Scholar

[7] 胡婷, 阚二军 2018 67 157701

Google Scholar

Google Scholar

Hu T, Kan E J 2018 Acta Phys. Sin. 67 157701

Google Scholar

Google Scholar

[8] Yang Q, Xiong W, Zhu L, Gao G, Wu M 2017 J. Am. Chem. Soc. 139 11506

Google Scholar

Google Scholar

[9] Wu M, Dong S, Yao K, Liu J, Zeng X C 2016 Nano Lett. 16 7309

Google Scholar

Google Scholar

[10] Voiry D, Goswami A, Kappera R, et al. 2015 Nat. Chem. 7 45

Google Scholar

Google Scholar

[11] Chang K, Liu J, Lin H, Wang N, Zhao K, Zhang A, Jin F, Zhong Y, Hu X, Duan W, Zhang Q, Fu L, Xue Q K, Chen X, Ji S H 2016 Science 353 274

Google Scholar

Google Scholar

[12] Liu F, You L, Seyler K L, Li X, Yu P, Lin J, Wang X, Zhou J, Wang H, He H, Pantelides S T, Zhou W, Sharma P, Xu X, Ajayan P M, Wang J, Liu Z 2016 Nat. Commun. 7 12357

Google Scholar

Google Scholar

[13] Ding W, Zhu J, Wang Z, Gao Y, Xiao D, Gu Y, Zhang Z, Zhu W 2017 Nat. Commun. 8 14956

Google Scholar

Google Scholar

[14] Bao Y, Song P, Liu Y, Chen Z, Zhu M, Abdelwahab I, Su J, Fu W, Chi X, Yu W, Liu W, Zhao X, Xu Q H, Yang M, Loh K P 2019 Nano Lett. 19 5109

Google Scholar

Google Scholar

[15] Sui F, Jin M, Zhang Y, Qi R, Wu Y N, Huang R, Yue F, Chu J 2023 Nat. Commun. 14 36

Google Scholar

Google Scholar

[16] Yang Q, Wu M, Li J 2018 J. Phys. Chem. Lett. 9 7160

Google Scholar

Google Scholar

[17] Meng P, Wu Y, Bian R, Pan E, Dong B, Zhao X, Chen J, Wu L, Sun Y, Fu Q, Liu Q, Shi D, Zhang Q, Zhang Y W, Liu Z, Liu F 2022 Nat. Commun. 13 7696

Google Scholar

Google Scholar

[18] 孟雨欣, 赵漪凡, 李绍春 2021 70 148101

Google Scholar

Google Scholar

Meng Y X, Zhao Y F, Li S C 2021 Acta Phys. Sin. 70 148101

Google Scholar

Google Scholar

[19] 叶倩, 沈阳, 袁野, 赵祎峰, 段纯刚 2020 69 217710

Google Scholar

Google Scholar

Ye Q, Shen Y, Yuan Y, Zhao Y F, Duan C G 2020 Acta Phys. Sin. 69 217710

Google Scholar

Google Scholar

[20] Chowdhury T, Taneja C, Vasdev A, Ghosh P, Sheet G, Kumar G V P, Rahman A 2022 Adv. Electron. Mater. 8 2101158

Google Scholar

Google Scholar

[21] Sutter E, Zhang B, Sun M, Sutter P 2019 ACS Nano 13 9352

Google Scholar

Google Scholar

[22] Guan Z, Zhao Y, Wang X, Zhong N, Deng X, Zheng Y, Wang J, Xu D, Ma R, Yue F, Cheng Y, Huang R, Xiang P, Wei Z, Chu J, Duan C 2022 ACS Nano 16 1308

Google Scholar

Google Scholar

[23] Yu H, Gao D, Wang X, Du X, Lin X, Guo W, Zou R, Jin C, Li K, Chen Y 2018 NPG Asia Mater. 10 882

Google Scholar

Google Scholar

[24] Zhu M, Zhong M, Guo X, Wang Y, Chen Z, Huang H, He J, Su C, Loh K P 2021 Adv. Opt. Mater. 9 2101200

Google Scholar

Google Scholar

[25] Sutter P, Komsa H P, Lu H, Gruverman A, Sutter E 2021 Nano Today 37 101082

Google Scholar

Google Scholar

[26] Du R, Wang Y, Cheng M, Wang P, Li H, Feng W, Song L, Shi J, He J 2022 Nat. Commun. 13 6130

Google Scholar

Google Scholar

[27] Higashitarumizu N, Kawamoto H, Lee C J, Lin B H, Chu F H, Yonemori I, Nishimura T, Wakabayashi K, Chang W H, Nagashio K 2020 Nat. Commun. 11 2428

Google Scholar

Google Scholar

[28] Khan H, Mahmood N, Zavabeti A, Elbourne A, Rahman Md A, Zhang B Y, Krishnamurthi V, Atkin P, Ghasemian M B, Yang J, Zheng G, Ravindran A R, Walia S, Wang L, Russo S P, Daeneke T, Li Y, Kalantar-Zadeh K 2020 Nat. Commun. 11 3449

Google Scholar

Google Scholar

[29] Chang K, Küster F, Miller B J, Ji J R, Zhang J L, Sessi P, Barraza-Lopez S, Parkin S S P 2020 Nano Lett. 20 6590

Google Scholar

Google Scholar

[30] Chiu M H, Ji X, Zhang T, Mao N, Luo Y, Shi C, Zheng X, Liu H, Han Y, Wilson W L, Luo Z, Tung V, Kong J 2023 Adv. Electron. Mater. 9 2201031

Google Scholar

Google Scholar

[31] Sarkar A S, Konidakis I, Gagaoudakis E, Maragkakis G M, Psilodimitrakopoulos S, Katerinopoulou D, Sygellou L, Deligeorgis G, Binas V, Oikonomou I M, Komninou P, Kiriakidis G, Kioseoglou G, Stratakis E 2023 Adv. Sci. 10 2201842

Google Scholar

Google Scholar

[32] Zhou B, Gong S J, Jiang K, Xu L, Shang L, Zhang J, Hu Z, Chu J 2020 J. Mater. Chem. C 8 89

Google Scholar

Google Scholar

[33] Yan Y, Deng Q, Li S, Guo T, Li X, Jiang Y, Song X, Huang W, Yang J, Xia C 2021 Nanoscale 13 16122

Google Scholar

Google Scholar

[34] Pan J, Jing S, Chen W, Bian B, Liao B, Wan G 2022 Appl. Phys. A 128 141

Google Scholar

Google Scholar

[35] Sharma D, Kumar R, Pal A, Sakhuja N, Bhat N 2023 ACS Appl. Electron. Mater. 5 3162

Google Scholar

Google Scholar

[36] Xia F, Wang H, Hwang J C M, Neto A H C, Yang L 2019 Nat. Rev. Phys. 1 306

Google Scholar

Google Scholar

[37] Wu S, Chen Y, Wang X, Jiao H, Zhao Q, Huang X, Tai X, Zhou Y, Chen H, Wang X, Huang S, Yan H, Lin T, Shen H, Hu W, Meng X, Chu J, Wang J 2022 Nat. Commun. 13 3198

Google Scholar

Google Scholar

[38] Guan S, Liu C, Lu Y, Yao Y, Yang S A 2018 Phys. Rev. B 97 144104

Google Scholar

Google Scholar

[39] Xu Y, Zhang H, Shao H, Ni G, Li J, Lu H, Zhang R, Peng B, Zhu Y, Zhu H 2017 Phys. Rev. B 96 245421

Google Scholar

Google Scholar

[40] Li Z, Gu Y, He C, Zou X 2022 Phys. Rev. B 106 035426

Google Scholar

Google Scholar

[41] Von Rohr F O, Ji H, Cevallos F A, Gao T, Ong N P, Cava R J 2017 J. Am. Chem. Soc. 139 2771

Google Scholar

Google Scholar

[42] Luo N, Wang C, Jiang Z, Xu Y, Zou X, Duan W 2018 Adv. Funct. Mater. 28 1804581

Google Scholar

Google Scholar

[43] Nguyen L T, Makov G 2022 Cryst. Growth Des. 22 4956

Google Scholar

Google Scholar

[44] Zhang S, Xie M, Li F, Yan Z, Li Y, Kan E, Liu W, Chen Z, Zeng H 2016 Angew. Chem. Int. Ed. 128 1698

Google Scholar

Google Scholar

[45] Jia S, Li H, Gotoh T, Longeaud C, Zhang B, Lü J, Lü S, Zhu M, Song Z, Liu Q, Robertson J, Liu M 2020 Nat. Commun. 11 4636

Google Scholar

Google Scholar

[46] Feng M, Liu S C, Hu L, Wu J, Liu X, Xue D J, Hu J S, Wan L J 2021 J. Am. Chem. Soc. 143 9664

Google Scholar

Google Scholar

[47] Chen H, Keiser C, Du S, Gao H J, Sutter P, Sutter E 2017 Phys. Chem. Chem. Phys. 19 32473

Google Scholar

Google Scholar

[48] Ribeiro H B, Ramos S, Seixas L, De Matos C J S, Pimenta M A 2019 Phys. Rev. B 100 094301

Google Scholar

Google Scholar

[49] Ul Haq B, AlFaify S, Laref A 2019 J. Phys. Chem. C 123 18124

Google Scholar

Google Scholar

[50] Zhou Y, Wu D, Zhu Y, Cho Y, He Q, Yang X, Herrera K, Chu Z, Han Y, Downer M C, Peng H, Lai K 2017 Nano Lett. 17 5508

Google Scholar

Google Scholar

[51] 王慧, 徐萌, 郑仁奎 2020 69 017301

Google Scholar

Google Scholar

Wang H, Xu M, Zheng R K 2020 Acta Phys. Sin. 69 017301

Google Scholar

Google Scholar

-

图 1 单层GeS原子分辨STM测量 (a) MBE生长腔结构(左)与STM测量和单层GeS晶体结构(右); (b), (c) 单层GeS在Cu(111)衬底表面形成的摩尔条纹及其快速傅里叶变换, 图像大小为14 nm×14 nm; (d) Cu(111)上单层GeS生长顶示意图; (e), (f) 单层GeS原子分辨STM图像及其快速傅里叶变换, 样品偏压1.2 V和隧穿电流0.60 nA, 图像大小为14 nm×14 nm

Fig. 1. Atomically resolved STM measurements of monolayer GeS: (a) Schematic of MBE growth chamber (left) and STM set-up and crystal structure of monolayer GeS (right); (b), (c) moiré pattern formed betweem monolayer GeS and Cu(111) substrate and its fast Fourier transform with the image size of 14 nm × 14 nm; (d) schematic of the monolayer GeS grown on Cu(111); (e), (f) atomically resolved STM images of monolayer GeS and its fast Fourier transform with sample bias voltage of 1.2 V and tunneling current of 0.60 nA, and image size of 14 nm × 14 nm.

图 3 Γ→Χ和Γ→Y高对称方向的能带结构 (a), (b) 单层GeS理论计算能带结构; (c), (d) Cu(111)衬底能带结构; (e), (f)单层GeS/Cu(111)异质结理论计算的能带结构(上)与APRES测量的能带结构(下)

Fig. 3. Electronic band structures along Γ→Χ and Γ→Y high symmetry directions: (a), (b) Theoretically calculated electronic band structure of monolayer GeS; (c), (d) elelctronic band structure of Cu(111) substrate; (e), (f) theoretically calculated electronic band structure of monolayer GeS/Cu(111) heterojunction (top) and electronic band structure measured by APRES (bottom).

-

[1] Khan A I, Keshavarzi A, Datta S 2020 Nat. Electron. 3 588

Google Scholar

Google Scholar

[2] Wang S, Liu L, Gan L, Chen H, Hou X, Ding Y, Ma S, Zhang D W, Zhou P 2021 Nat. Commun. 12 53

Google Scholar

Google Scholar

[3] John R A, Demirağ Y, Shynkarenko Y, Berezovska Y, Ohannessian N, Payvand M, Zeng P, Bodnarchuk M I, Krumeich F, Kara G, Shorubalko I, Nair M V, Cooke G A, Lippert T, Indiveri G, Kovalenko M V 2022 Nat. Commun. 13 2074

Google Scholar

Google Scholar

[4] Wang J, Wang F, Wang Z, Huang W, Yao Y, Wang Y, Yang J, Li N, Yin L, Cheng R, Zhan X, Shan C, He J 2021 Sci. Bull. 66 2288

Google Scholar

Google Scholar

[5] Junquera J, Ghosez P 2003 Nature 422 506

Google Scholar

Google Scholar

[6] Lee D, Lu H, Gu Y, Choi S Y, Li S D, Ryu S, Paudel T R, Song K, Mikheev E, Lee S, Stemmer S, Tenne D A, Oh S H, Tsymbal E Y, Wu X, Chen L Q, Gruverman A, Eom C B 2015 Science 349 1314

Google Scholar

Google Scholar

[7] 胡婷, 阚二军 2018 67 157701

Google Scholar

Google Scholar

Hu T, Kan E J 2018 Acta Phys. Sin. 67 157701

Google Scholar

Google Scholar

[8] Yang Q, Xiong W, Zhu L, Gao G, Wu M 2017 J. Am. Chem. Soc. 139 11506

Google Scholar

Google Scholar

[9] Wu M, Dong S, Yao K, Liu J, Zeng X C 2016 Nano Lett. 16 7309

Google Scholar

Google Scholar

[10] Voiry D, Goswami A, Kappera R, et al. 2015 Nat. Chem. 7 45

Google Scholar

Google Scholar

[11] Chang K, Liu J, Lin H, Wang N, Zhao K, Zhang A, Jin F, Zhong Y, Hu X, Duan W, Zhang Q, Fu L, Xue Q K, Chen X, Ji S H 2016 Science 353 274

Google Scholar

Google Scholar

[12] Liu F, You L, Seyler K L, Li X, Yu P, Lin J, Wang X, Zhou J, Wang H, He H, Pantelides S T, Zhou W, Sharma P, Xu X, Ajayan P M, Wang J, Liu Z 2016 Nat. Commun. 7 12357

Google Scholar

Google Scholar

[13] Ding W, Zhu J, Wang Z, Gao Y, Xiao D, Gu Y, Zhang Z, Zhu W 2017 Nat. Commun. 8 14956

Google Scholar

Google Scholar

[14] Bao Y, Song P, Liu Y, Chen Z, Zhu M, Abdelwahab I, Su J, Fu W, Chi X, Yu W, Liu W, Zhao X, Xu Q H, Yang M, Loh K P 2019 Nano Lett. 19 5109

Google Scholar

Google Scholar

[15] Sui F, Jin M, Zhang Y, Qi R, Wu Y N, Huang R, Yue F, Chu J 2023 Nat. Commun. 14 36

Google Scholar

Google Scholar

[16] Yang Q, Wu M, Li J 2018 J. Phys. Chem. Lett. 9 7160

Google Scholar

Google Scholar

[17] Meng P, Wu Y, Bian R, Pan E, Dong B, Zhao X, Chen J, Wu L, Sun Y, Fu Q, Liu Q, Shi D, Zhang Q, Zhang Y W, Liu Z, Liu F 2022 Nat. Commun. 13 7696

Google Scholar

Google Scholar

[18] 孟雨欣, 赵漪凡, 李绍春 2021 70 148101

Google Scholar

Google Scholar

Meng Y X, Zhao Y F, Li S C 2021 Acta Phys. Sin. 70 148101

Google Scholar

Google Scholar

[19] 叶倩, 沈阳, 袁野, 赵祎峰, 段纯刚 2020 69 217710

Google Scholar

Google Scholar

Ye Q, Shen Y, Yuan Y, Zhao Y F, Duan C G 2020 Acta Phys. Sin. 69 217710

Google Scholar

Google Scholar

[20] Chowdhury T, Taneja C, Vasdev A, Ghosh P, Sheet G, Kumar G V P, Rahman A 2022 Adv. Electron. Mater. 8 2101158

Google Scholar

Google Scholar

[21] Sutter E, Zhang B, Sun M, Sutter P 2019 ACS Nano 13 9352

Google Scholar

Google Scholar

[22] Guan Z, Zhao Y, Wang X, Zhong N, Deng X, Zheng Y, Wang J, Xu D, Ma R, Yue F, Cheng Y, Huang R, Xiang P, Wei Z, Chu J, Duan C 2022 ACS Nano 16 1308

Google Scholar

Google Scholar

[23] Yu H, Gao D, Wang X, Du X, Lin X, Guo W, Zou R, Jin C, Li K, Chen Y 2018 NPG Asia Mater. 10 882

Google Scholar

Google Scholar

[24] Zhu M, Zhong M, Guo X, Wang Y, Chen Z, Huang H, He J, Su C, Loh K P 2021 Adv. Opt. Mater. 9 2101200

Google Scholar

Google Scholar

[25] Sutter P, Komsa H P, Lu H, Gruverman A, Sutter E 2021 Nano Today 37 101082

Google Scholar

Google Scholar

[26] Du R, Wang Y, Cheng M, Wang P, Li H, Feng W, Song L, Shi J, He J 2022 Nat. Commun. 13 6130

Google Scholar

Google Scholar

[27] Higashitarumizu N, Kawamoto H, Lee C J, Lin B H, Chu F H, Yonemori I, Nishimura T, Wakabayashi K, Chang W H, Nagashio K 2020 Nat. Commun. 11 2428

Google Scholar

Google Scholar

[28] Khan H, Mahmood N, Zavabeti A, Elbourne A, Rahman Md A, Zhang B Y, Krishnamurthi V, Atkin P, Ghasemian M B, Yang J, Zheng G, Ravindran A R, Walia S, Wang L, Russo S P, Daeneke T, Li Y, Kalantar-Zadeh K 2020 Nat. Commun. 11 3449

Google Scholar

Google Scholar

[29] Chang K, Küster F, Miller B J, Ji J R, Zhang J L, Sessi P, Barraza-Lopez S, Parkin S S P 2020 Nano Lett. 20 6590

Google Scholar

Google Scholar

[30] Chiu M H, Ji X, Zhang T, Mao N, Luo Y, Shi C, Zheng X, Liu H, Han Y, Wilson W L, Luo Z, Tung V, Kong J 2023 Adv. Electron. Mater. 9 2201031

Google Scholar

Google Scholar

[31] Sarkar A S, Konidakis I, Gagaoudakis E, Maragkakis G M, Psilodimitrakopoulos S, Katerinopoulou D, Sygellou L, Deligeorgis G, Binas V, Oikonomou I M, Komninou P, Kiriakidis G, Kioseoglou G, Stratakis E 2023 Adv. Sci. 10 2201842

Google Scholar

Google Scholar

[32] Zhou B, Gong S J, Jiang K, Xu L, Shang L, Zhang J, Hu Z, Chu J 2020 J. Mater. Chem. C 8 89

Google Scholar

Google Scholar

[33] Yan Y, Deng Q, Li S, Guo T, Li X, Jiang Y, Song X, Huang W, Yang J, Xia C 2021 Nanoscale 13 16122

Google Scholar

Google Scholar

[34] Pan J, Jing S, Chen W, Bian B, Liao B, Wan G 2022 Appl. Phys. A 128 141

Google Scholar

Google Scholar

[35] Sharma D, Kumar R, Pal A, Sakhuja N, Bhat N 2023 ACS Appl. Electron. Mater. 5 3162

Google Scholar

Google Scholar

[36] Xia F, Wang H, Hwang J C M, Neto A H C, Yang L 2019 Nat. Rev. Phys. 1 306

Google Scholar

Google Scholar

[37] Wu S, Chen Y, Wang X, Jiao H, Zhao Q, Huang X, Tai X, Zhou Y, Chen H, Wang X, Huang S, Yan H, Lin T, Shen H, Hu W, Meng X, Chu J, Wang J 2022 Nat. Commun. 13 3198

Google Scholar

Google Scholar

[38] Guan S, Liu C, Lu Y, Yao Y, Yang S A 2018 Phys. Rev. B 97 144104

Google Scholar

Google Scholar

[39] Xu Y, Zhang H, Shao H, Ni G, Li J, Lu H, Zhang R, Peng B, Zhu Y, Zhu H 2017 Phys. Rev. B 96 245421

Google Scholar

Google Scholar

[40] Li Z, Gu Y, He C, Zou X 2022 Phys. Rev. B 106 035426

Google Scholar

Google Scholar

[41] Von Rohr F O, Ji H, Cevallos F A, Gao T, Ong N P, Cava R J 2017 J. Am. Chem. Soc. 139 2771

Google Scholar

Google Scholar

[42] Luo N, Wang C, Jiang Z, Xu Y, Zou X, Duan W 2018 Adv. Funct. Mater. 28 1804581

Google Scholar

Google Scholar

[43] Nguyen L T, Makov G 2022 Cryst. Growth Des. 22 4956

Google Scholar

Google Scholar

[44] Zhang S, Xie M, Li F, Yan Z, Li Y, Kan E, Liu W, Chen Z, Zeng H 2016 Angew. Chem. Int. Ed. 128 1698

Google Scholar

Google Scholar

[45] Jia S, Li H, Gotoh T, Longeaud C, Zhang B, Lü J, Lü S, Zhu M, Song Z, Liu Q, Robertson J, Liu M 2020 Nat. Commun. 11 4636

Google Scholar

Google Scholar

[46] Feng M, Liu S C, Hu L, Wu J, Liu X, Xue D J, Hu J S, Wan L J 2021 J. Am. Chem. Soc. 143 9664

Google Scholar

Google Scholar

[47] Chen H, Keiser C, Du S, Gao H J, Sutter P, Sutter E 2017 Phys. Chem. Chem. Phys. 19 32473

Google Scholar

Google Scholar

[48] Ribeiro H B, Ramos S, Seixas L, De Matos C J S, Pimenta M A 2019 Phys. Rev. B 100 094301

Google Scholar

Google Scholar

[49] Ul Haq B, AlFaify S, Laref A 2019 J. Phys. Chem. C 123 18124

Google Scholar

Google Scholar

[50] Zhou Y, Wu D, Zhu Y, Cho Y, He Q, Yang X, Herrera K, Chu Z, Han Y, Downer M C, Peng H, Lai K 2017 Nano Lett. 17 5508

Google Scholar

Google Scholar

[51] 王慧, 徐萌, 郑仁奎 2020 69 017301

Google Scholar

Google Scholar

Wang H, Xu M, Zheng R K 2020 Acta Phys. Sin. 69 017301

Google Scholar

Google Scholar

计量

- 文章访问数: 5131

- PDF下载量: 253

- 被引次数: 0

下载:

下载: