-

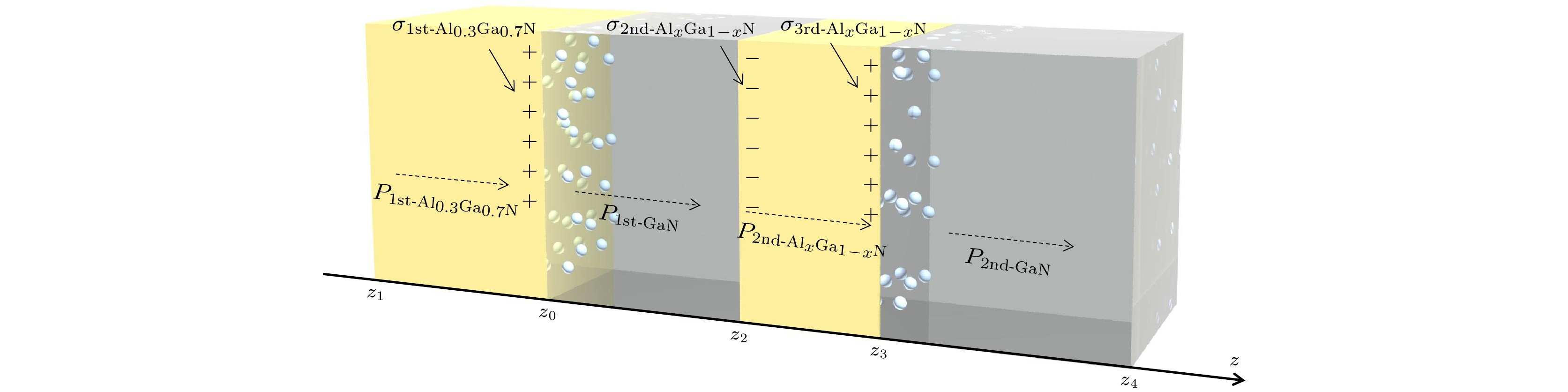

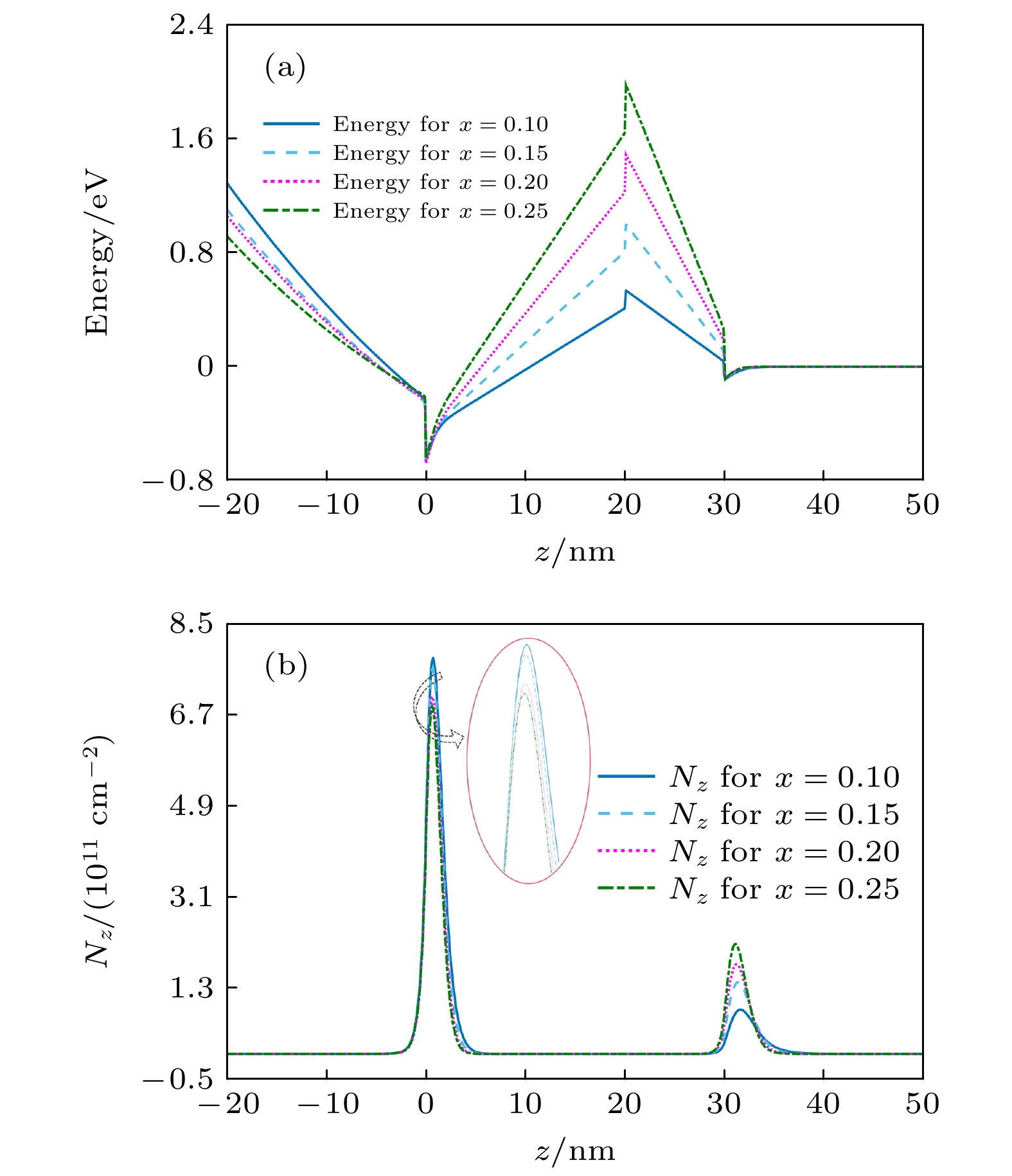

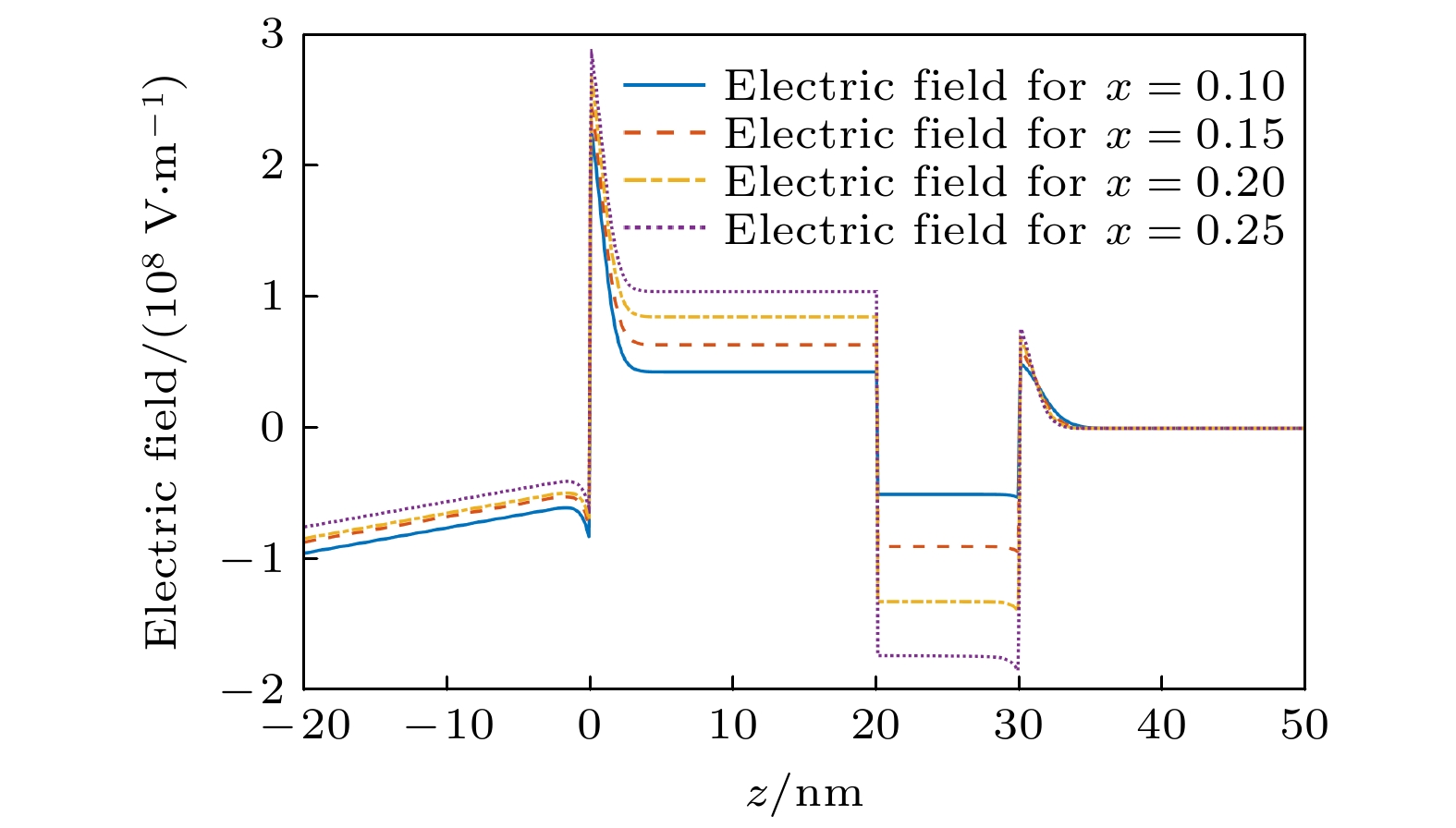

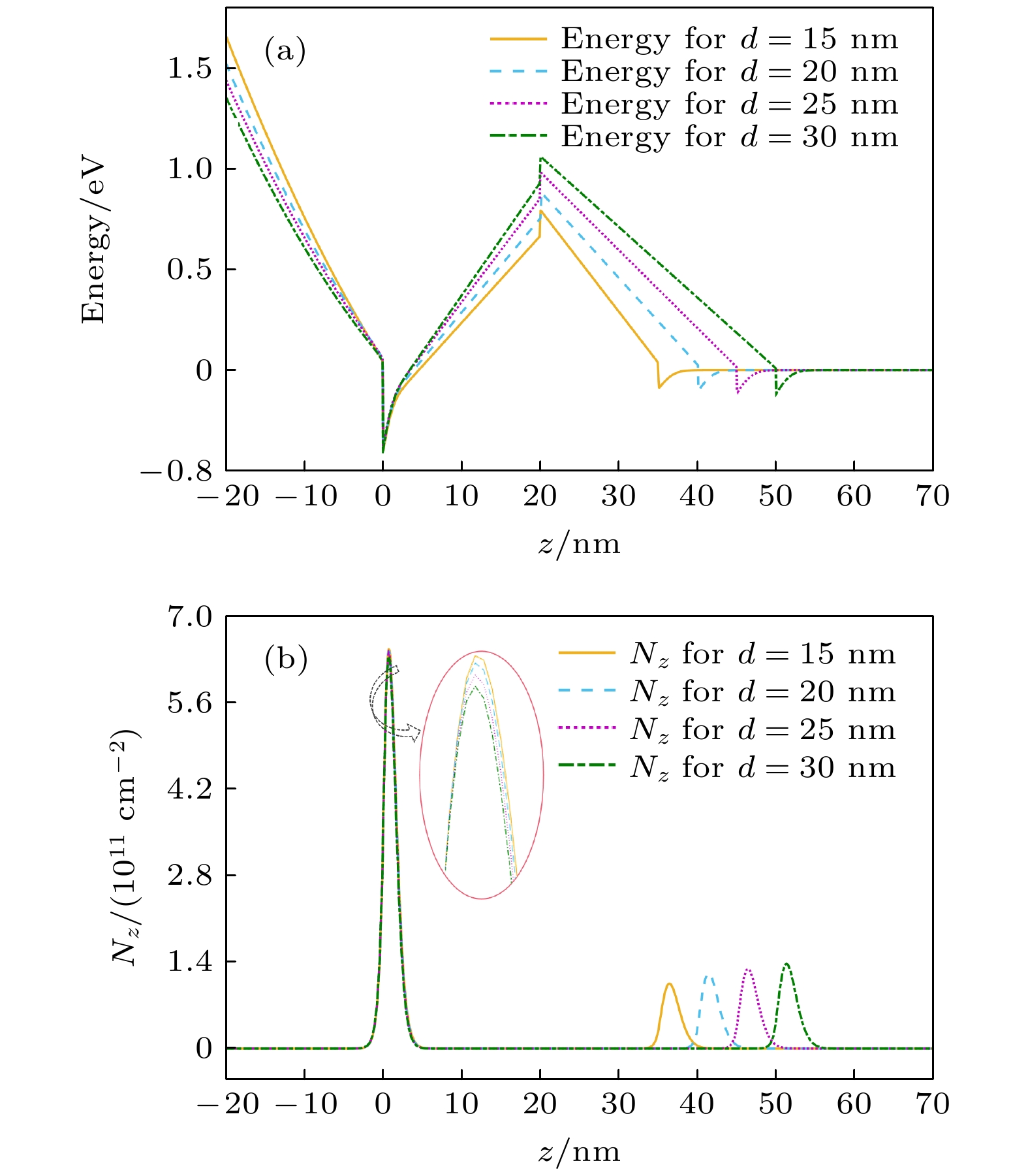

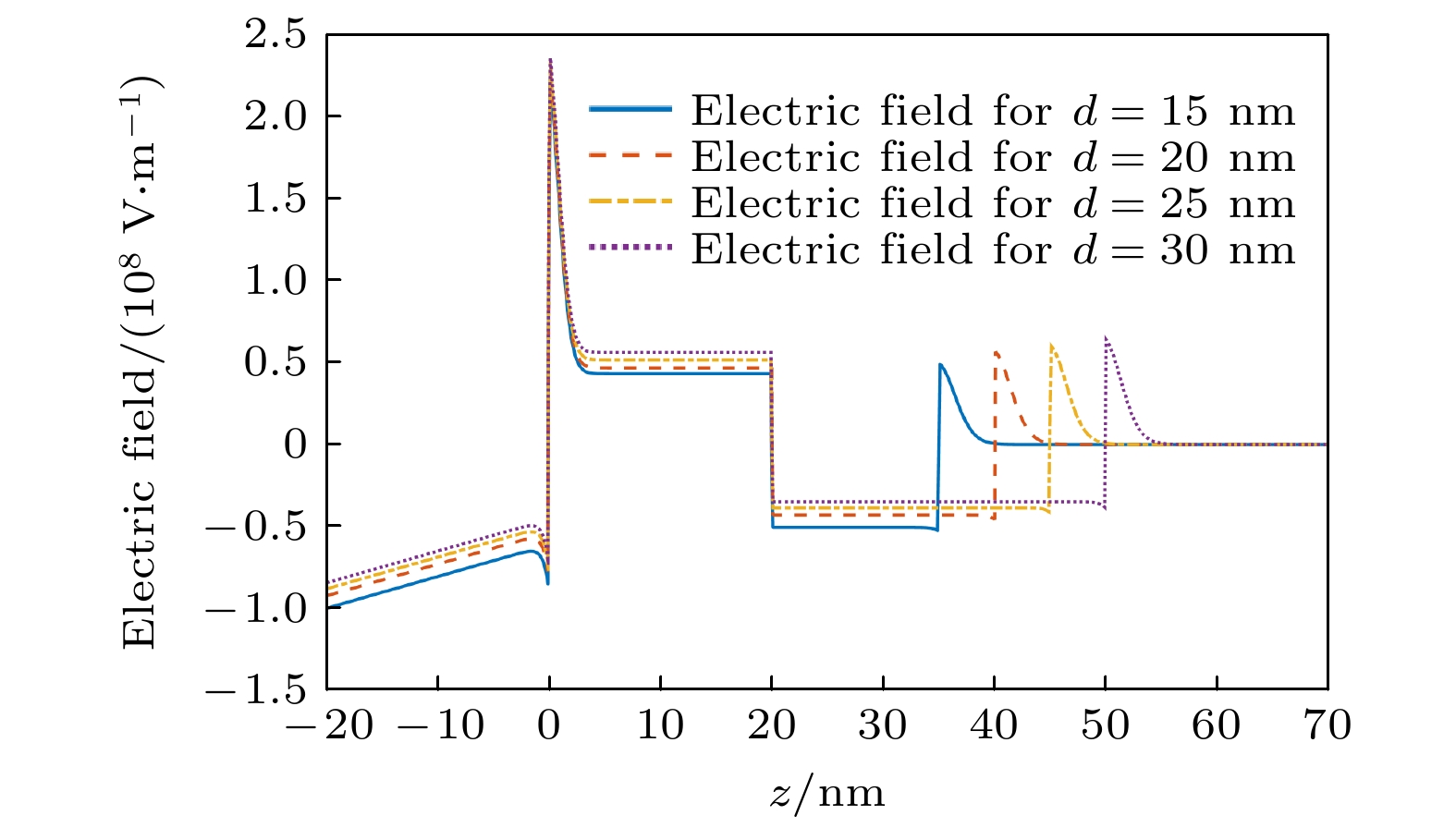

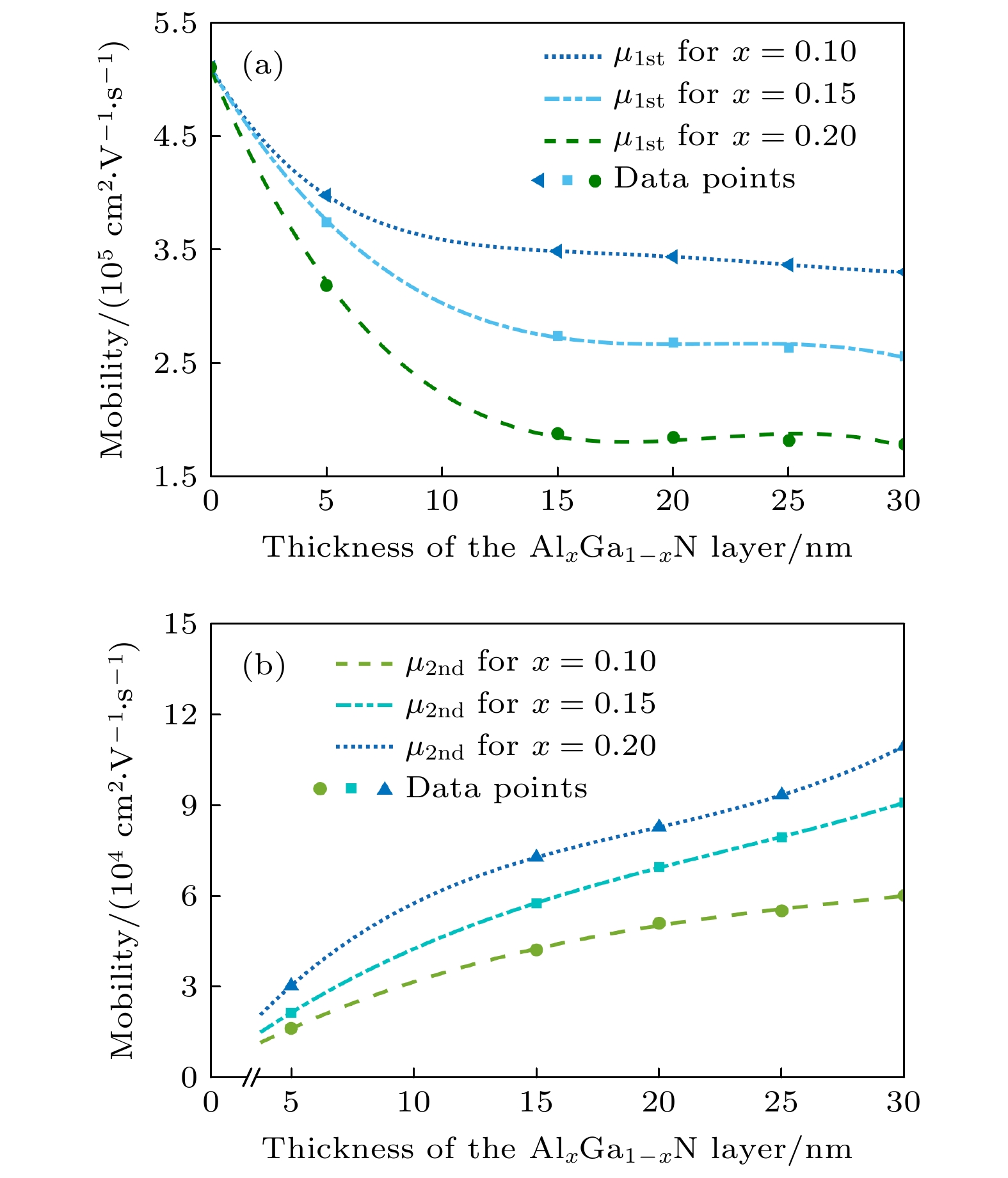

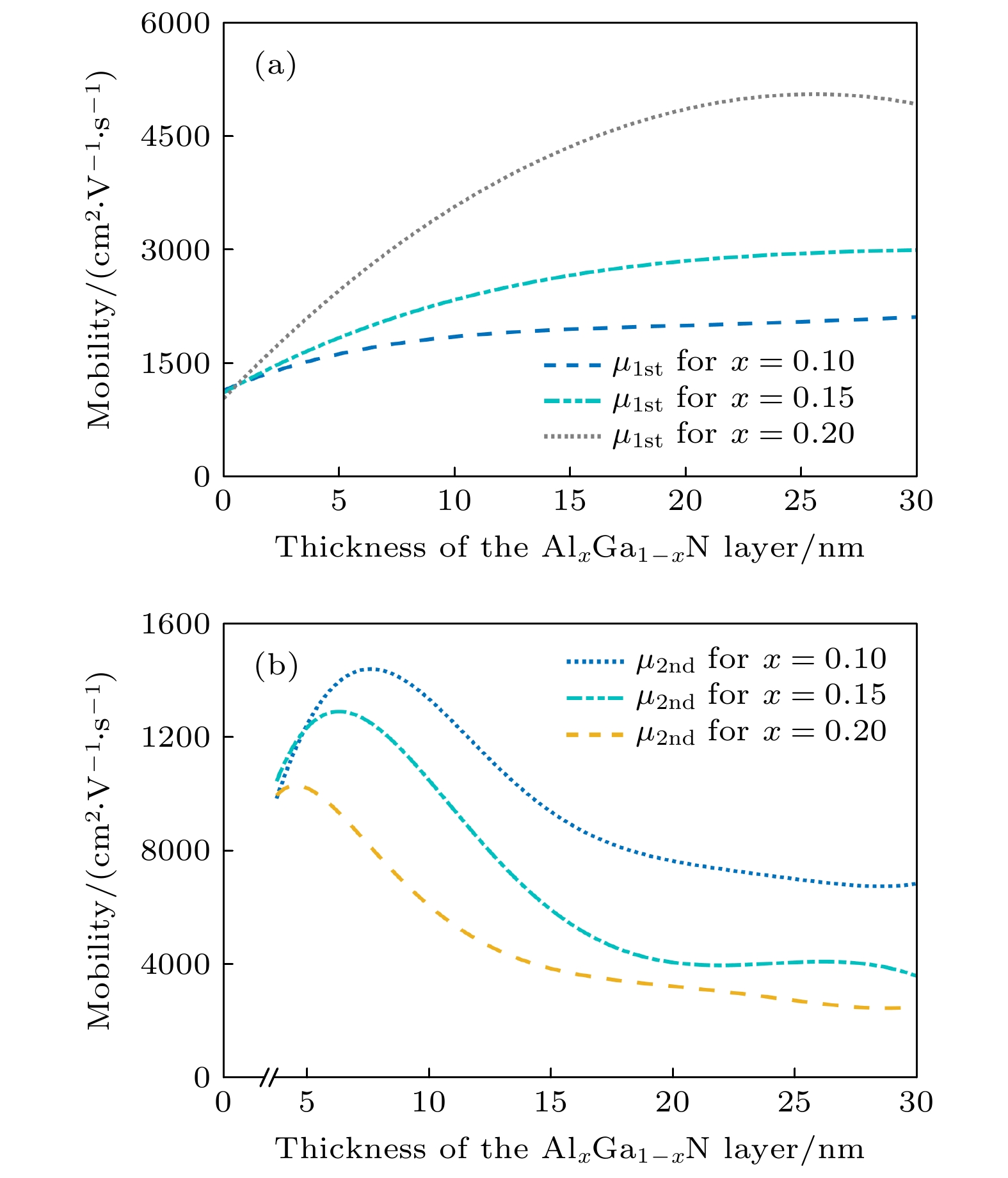

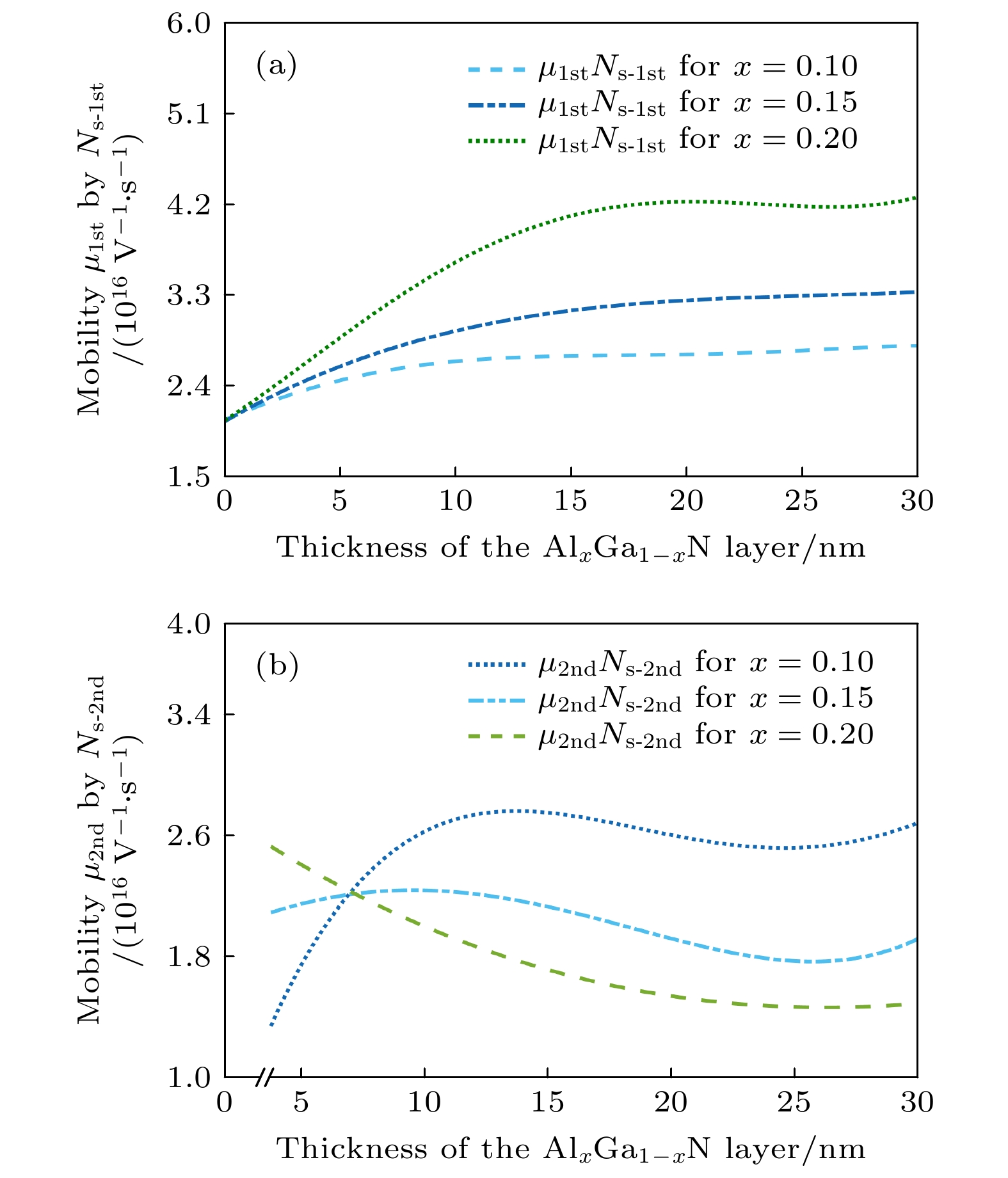

双沟道AlGaN/GaN HEMT器件在电子限域性、电流运输等方面优于单沟道结构, 且能更好地缓解电流崩塌, 提高设备的运行能力, 在高功率应用中具有重要意义. 本文对n-Al0.3Ga0.7N/GaN/i-AlxGa1–xN/GaN结构中的电荷状态以及运输性质进行研究. 通过求解一维薛定谔方程和泊松方程, 获得其电势、电场和电子分布, 分析了双沟道中二维电子气状态与合金无序散射、位错散射的关系. 结果表明, 在第一沟道中, 当AlxGa1–xN的Al组分和厚度提升时, 二维电子气密度逐渐减小, 合金无序散射的减弱使迁移率增大, 位错散射增强致迁移率变小, 总迁移率主要由合金无序散射决定. 在第二沟道中, 当AlxGa1–xN的Al组分和厚度提升时, 二维电子气密度随之增大, 由于较低的势垒高度以及高渗透电子的作用, 第二沟道中的合金无序散射影响更大, 合金无序散射迁移率随AlxGa1–xN层的Al组分和厚度的增加而减少且变化趋势逐渐趋于平缓, 位错散射作用的减弱导致迁移率的提升. 总体上, 第一沟道势阱中受到的位错散射低于第二沟道势阱. 随着背势垒厚度的增加, 第二沟道中主导的散射机制逐渐从位错散射转为合金无序散射.

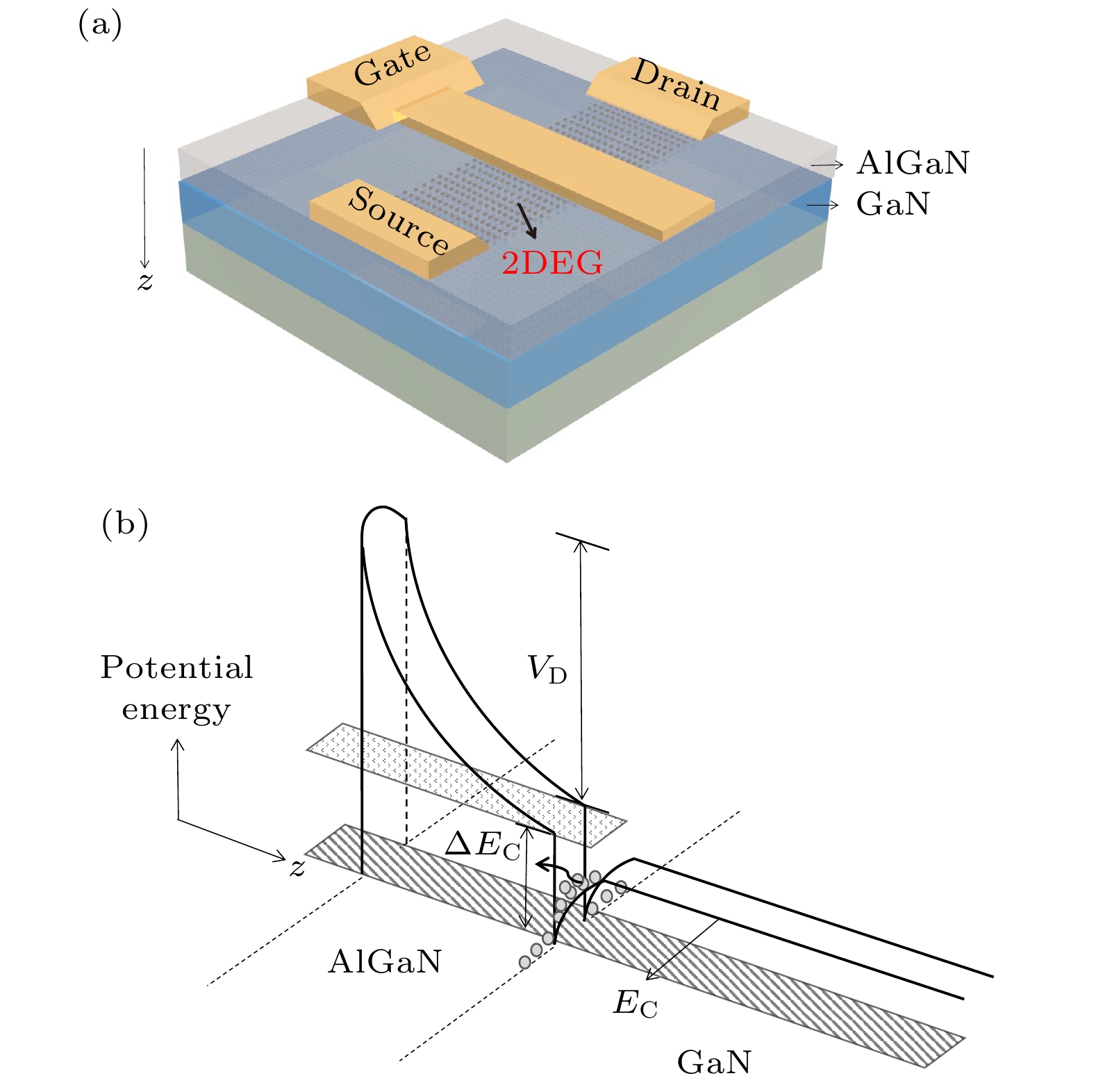

With the demand for high-temperature, high-frequency, and high-power microwave applications increasing, AlGaN/GaN high electron mobility transistors (HEMT) have attracted much attention in recent years. Two-dimensional electron gas (2DEG) induced by spontaneous polarization and piezoelectric polarization caused by the uneven charge distribution on Ga-N bond and the large tensile strain guarantees the high performance of AlGaN/GaN HEMT. Compared with single-channel devices, dual-channel AlGaN/GaN HEMT has great application prospects in enhancing the electronic confinement, current drive and alleviating the current collapse. In order to study the physical characteristics, the carrier state and transportation characterization of n-Al0.3Ga0.7N/GaN/i-AlxGa1–xN/GaN multilayer structure are investigated. By calculating the one-dimensional self-consistent Poisson-Schrödinger, the energy band diagram, electric field and charge distribution in the devices are obtained. The 2DEG, alloy disorder and dislocation scattering mechanism in the device are also analyzed by analytical models in which the wave function in finite barriers and Fermi’s rule are used. With AlxGa1–xN layer thickness increasing from 0 nm to 30 nm and Al content rising from 0.1 to 0.2, the concentration of 2DEG localized in the heterointerface is diminished in the first channel. Simultaneously, mobility limited by alloy disorder scattering increases monotonically with the r composition occupation number and the AlxGa1–xN thickness proportion increasing. Besides, dislocation scattering on carriers is strengthened in the same quantum well, resulting in the lower mobility. In the second channel, 2DEG density gets growing when the variables mentioned above is enlarged. The mobility restricted by alloy disorder scattering shows a reverse trend with the variation of the AlxGa1–xN thickness and Al fraction, which more greatly affect the carriers in the parasitic channel due to the lower barrier height and high permeable carriers. Furthermore, the effect of dislocation scattering on channel electrons is gradually weakened, resulting in an increasing mobility. In general, The dislocation scattering effect in the second channel is intenser than that in the first channel. -

Keywords:

- double-channel /

- two-dimensional electron gas /

- mobility

[1] Mishra U K, Parikh P, Wu Y F 2002 Proc. IEEE 90 1022

Google Scholar

Google Scholar

[2] Mohammad S N, Salvador A A, Morkoc H 1995 Proc. IEEE 83 1306

Google Scholar

Google Scholar

[3] Ibbetson J P, Fini P T, Ness K D, DenBaars S P, Speck J S, Mishrab U K 2000 Appl. Phys. Lett. 77 250

Google Scholar

Google Scholar

[4] 王现彬, 赵正平, 冯志红 2014 63 080202

Google Scholar

Google Scholar

Wang X B, Zhao Z P, Feng Z H 2014 Acta Phys. Sin. 63 080202

Google Scholar

Google Scholar

[5] 张雪冰, 刘乃漳, 姚若河 2020 69 157303

Google Scholar

Google Scholar

Zhang X B, Liu N Z, Yao R H 2020 Acta Phys. Sin. 69 157303

Google Scholar

Google Scholar

[6] Kranti A, Haldar S, Gupta R S 2002 Solid-State Electron. 46 621

Google Scholar

Google Scholar

[7] Kwon H K, Eiting C J, Lambert D J H, Shelton B S, Wong M M, Zhu T G, Dupuisa R D 1999 Appl. Phys. Lett. 75 2788

Google Scholar

Google Scholar

[8] Chu R M, Zhou Y G, Zheng Y D, Han P, Shen B, Gu S 2001 Appl. Phys. Lett. 79 2270

Google Scholar

Google Scholar

[9] Fan Z F, Lu C Z, Botchkarev A E, Tang H, Salvador A, Aktas O, Kim W, Morkog H 1997 Electron. Lett. 33 814

Google Scholar

Google Scholar

[10] Gaska R, Shur M S, Fjeldly T A 1999 J. Appl. Phys. 85 3009

Google Scholar

Google Scholar

[11] Chu R, Zhou Y, Jie L, Wang D, Chen K J, Lau K M 2005 IEEE Trans. Electron Devices 52 438

Google Scholar

Google Scholar

[12] Quan S, Hao Y, Ma X, Zheng P, Xie Y 2010 J. Semicond. 31 044003

Google Scholar

Google Scholar

[13] Zhang Y., Li Y., Wang J, Shen Y, Hao Y 2020 Nanoscale Res. Lett. 15 1

Google Scholar

Google Scholar

[14] 王冲, 赵梦荻, 裴九清 2016 65 038501

Google Scholar

Google Scholar

Wang C, Zhao M D, Pei J Q 2016 Acta Phys. Sin. 65 038501

Google Scholar

Google Scholar

[15] Lee Y J, Yao Y C, Huang C Y, Lin T Y, Cheng L L, Liu C Y, Wang M T Hwang J M 2014 Nanoscale Res. Lett. 9 433

Google Scholar

Google Scholar

[16] Chakraborty A, Ghosh S, Mukhopadhyay P, Jana S K, Dinara S M, Bag A, Mahata M K, Kumar R, Das S, Das P, Biswas D 2016 Electron. Mater. Lett. 12 232

Google Scholar

Google Scholar

[17] Chen C Q, Zhang J P 2003 Appl. Phys. Lett. 82 4593

Google Scholar

Google Scholar

[18] Visalli D, Hove M V, Derluyn J, Cheng K, Degroote S, Leys M, Germain M, Borghs G 2009 Phys. Status Solidi C 6 S988

[19] Yu H B, Lisesivdin S B, Bolukbas B, Kelekci O, Ozturk M K, Ozcelik S, Caliskan D, Ozturk M, Cakmak H, Demirel P, Ozbay E 2010 Phys. Status Solidi A 207 2593

Google Scholar

Google Scholar

[20] Martins J L, Zunger A 1984 Phys. Rev. B 30 6217

Google Scholar

Google Scholar

[21] Fang F F, Howard W E 1966 Phys. Rev. Lett. 16 797

Google Scholar

Google Scholar

[22] Shur M S, Bykhovski A D, Gaska R 2000 Solid-State Electron. 44 205

Google Scholar

Google Scholar

[23] Walukiewicz W, Ruda H E 1984 Phys. Rev. B 30 4571

Google Scholar

Google Scholar

[24] Jena D, Gossard A C, Mishra U K 2000 Appl. Phys. Lett. 76 1707

Google Scholar

Google Scholar

[25] Miyoshi M, Egawa T, Ishikawa H 2015 J. Vac. Sci. Technol. , B 23 1527

[26] Leung K, Wright A F, Stechel E B 1999 Appl. Phys. Lett. 74 2495

Google Scholar

Google Scholar

-

表 1 AlN, GaN和AlxGa1–xN的各项结构参数(300 K)

Table 1. The key parameters of AlN, GaN and AlxGa1 – xN at temperature 300 K.

参数 AlN GaN AlxGa1–xN A/(10–10 nm) 3.112 3.189 C13/GPa 108 103 C33/GPa 373 405 xPAlN + (1 – x) PGaN e31/(C·m–2) –0.6 –0.49 e33/(C·m–2) 1.46 0.73 PSP/(C·m–2) –0.081 –0.029 表 2 沟道中2DEG在基态上的占比

Table 2. The proportion of 2DEG at the ground-state energy in channel 1 & channel 2.

x = 0.1 x = 0.15 x = 0.2 x = 0.25 Nz–1 st在基态E0上的占比 0.9451 0.9669 0.9872 0.9909 Nz–2 nd在基态E0上的占比 0.9651 0.9748 0.9850 0.9908 -

[1] Mishra U K, Parikh P, Wu Y F 2002 Proc. IEEE 90 1022

Google Scholar

Google Scholar

[2] Mohammad S N, Salvador A A, Morkoc H 1995 Proc. IEEE 83 1306

Google Scholar

Google Scholar

[3] Ibbetson J P, Fini P T, Ness K D, DenBaars S P, Speck J S, Mishrab U K 2000 Appl. Phys. Lett. 77 250

Google Scholar

Google Scholar

[4] 王现彬, 赵正平, 冯志红 2014 63 080202

Google Scholar

Google Scholar

Wang X B, Zhao Z P, Feng Z H 2014 Acta Phys. Sin. 63 080202

Google Scholar

Google Scholar

[5] 张雪冰, 刘乃漳, 姚若河 2020 69 157303

Google Scholar

Google Scholar

Zhang X B, Liu N Z, Yao R H 2020 Acta Phys. Sin. 69 157303

Google Scholar

Google Scholar

[6] Kranti A, Haldar S, Gupta R S 2002 Solid-State Electron. 46 621

Google Scholar

Google Scholar

[7] Kwon H K, Eiting C J, Lambert D J H, Shelton B S, Wong M M, Zhu T G, Dupuisa R D 1999 Appl. Phys. Lett. 75 2788

Google Scholar

Google Scholar

[8] Chu R M, Zhou Y G, Zheng Y D, Han P, Shen B, Gu S 2001 Appl. Phys. Lett. 79 2270

Google Scholar

Google Scholar

[9] Fan Z F, Lu C Z, Botchkarev A E, Tang H, Salvador A, Aktas O, Kim W, Morkog H 1997 Electron. Lett. 33 814

Google Scholar

Google Scholar

[10] Gaska R, Shur M S, Fjeldly T A 1999 J. Appl. Phys. 85 3009

Google Scholar

Google Scholar

[11] Chu R, Zhou Y, Jie L, Wang D, Chen K J, Lau K M 2005 IEEE Trans. Electron Devices 52 438

Google Scholar

Google Scholar

[12] Quan S, Hao Y, Ma X, Zheng P, Xie Y 2010 J. Semicond. 31 044003

Google Scholar

Google Scholar

[13] Zhang Y., Li Y., Wang J, Shen Y, Hao Y 2020 Nanoscale Res. Lett. 15 1

Google Scholar

Google Scholar

[14] 王冲, 赵梦荻, 裴九清 2016 65 038501

Google Scholar

Google Scholar

Wang C, Zhao M D, Pei J Q 2016 Acta Phys. Sin. 65 038501

Google Scholar

Google Scholar

[15] Lee Y J, Yao Y C, Huang C Y, Lin T Y, Cheng L L, Liu C Y, Wang M T Hwang J M 2014 Nanoscale Res. Lett. 9 433

Google Scholar

Google Scholar

[16] Chakraborty A, Ghosh S, Mukhopadhyay P, Jana S K, Dinara S M, Bag A, Mahata M K, Kumar R, Das S, Das P, Biswas D 2016 Electron. Mater. Lett. 12 232

Google Scholar

Google Scholar

[17] Chen C Q, Zhang J P 2003 Appl. Phys. Lett. 82 4593

Google Scholar

Google Scholar

[18] Visalli D, Hove M V, Derluyn J, Cheng K, Degroote S, Leys M, Germain M, Borghs G 2009 Phys. Status Solidi C 6 S988

[19] Yu H B, Lisesivdin S B, Bolukbas B, Kelekci O, Ozturk M K, Ozcelik S, Caliskan D, Ozturk M, Cakmak H, Demirel P, Ozbay E 2010 Phys. Status Solidi A 207 2593

Google Scholar

Google Scholar

[20] Martins J L, Zunger A 1984 Phys. Rev. B 30 6217

Google Scholar

Google Scholar

[21] Fang F F, Howard W E 1966 Phys. Rev. Lett. 16 797

Google Scholar

Google Scholar

[22] Shur M S, Bykhovski A D, Gaska R 2000 Solid-State Electron. 44 205

Google Scholar

Google Scholar

[23] Walukiewicz W, Ruda H E 1984 Phys. Rev. B 30 4571

Google Scholar

Google Scholar

[24] Jena D, Gossard A C, Mishra U K 2000 Appl. Phys. Lett. 76 1707

Google Scholar

Google Scholar

[25] Miyoshi M, Egawa T, Ishikawa H 2015 J. Vac. Sci. Technol. , B 23 1527

[26] Leung K, Wright A F, Stechel E B 1999 Appl. Phys. Lett. 74 2495

Google Scholar

Google Scholar

计量

- 文章访问数: 5948

- PDF下载量: 147

- 被引次数: 0

下载:

下载: