-

本文研究了300 V绝缘体上硅横向双扩散金属氧化物半导体场效应管在电离辐射总剂量效应下的线性电流退化机理, 提出了一种具有超薄屏蔽层的抗辐射结构实现线性电流加固. 超薄屏蔽层位于器件场氧化层的下方, 旨在阻止P型掺杂层表面发生反型, 从而截断表面电流路径, 有效抑制线性电流的退化. 对于横向双扩散金属氧化物半导体场效应管, 漂移区上的场氧化层中引入的空穴对线性电流的退化起着主导作用. 本文基于器件工艺仿真软件, 研究器件在辐照前后的电学特性, 对超薄屏蔽层的长度、注入能量、横向间距进行优化, 给出相应的剂量窗口, 在电离辐射总剂量为0—500 krad(Si)的条件下, 将最大线性电流增量从传统结构的447%缩减至10%以内, 且辐照前后击穿电压均维持在300 V以上.

-

关键词:

- 总剂量效应 /

- 横向双扩散金属氧化物半导体场效应管 /

- 超薄屏蔽层 /

- 线性电流加固 /

- 绝缘体上硅

In this work, the linear current degradation mechanism of 300 V silicon-on-insulator laterally double-diffused metal-oxide-semiconductor field effect transistor under total ionizing effect is studied, and a method in radiation-hardness for linear current by introducing an ultra-thin shielding layer is proposed. This new structure is realized with P-type ultra-thin shielding layer implantation under field oxide, in order to prevent the P-type layer from complete surface inversion, thereby truncating the surface current route and mitigating the current degradation effectively. For a laterally double-diffused metal-oxide-semiconductor field effect transistor, linear current degradation can be attributed mainly to holes introduced in the field oxide. In this work, the influence of introduced holes on electrical properties in the transistor oxides under harsh environment is simulated based on device and process simulation software, with optimized layer length, implantation energy, lateral distance and dose window, and the goal of linear current hardness (linear current increment decreasing from 447% in conventional structure to less than 10% in proposed structure) is achieved while maintaining pre-rad and post-rad breakdown voltages above 300 V under total dose of 0–500 krad(Si).-

Keywords:

- total ionizing dose effect /

- laterally double-diffused metal-oxide-semiconductor field effect transistor /

- ultra-thin shielding layer /

- linear current hardness /

- silicon-on-insulator

[1] Winokur P S, Lum G K, Shaneyfelt M R, Sexton F W, Hash G L, Scott L 1999 IEEE Trans. Nucl. Sci. 46 1494

Google Scholar

Google Scholar

[2] Barth J L, Dyer C S, Stassinopoulos E G 2003 IEEE Trans. Nucl. Sci. 50 466

Google Scholar

Google Scholar

[3] Pease R L 1996 IEEE Trans. Nucl. Sci. 43 442

Google Scholar

Google Scholar

[4] Oldham T R, Mclean B 2003 IEEE Trans. Nucl. Sci. 50 483

Google Scholar

Google Scholar

[5] Barnaby H J 2006 IEEE Trans. Nucl. Sci. 53 3103

Google Scholar

Google Scholar

[6] Normand E 1996 IEEE Trans. Nucl. Sci. 43 461

Google Scholar

Google Scholar

[7] Titus J L 2013 IEEE Trans. Nucl. Sci. 60 1912

Google Scholar

Google Scholar

[8] Srour J R, Palko J W 2013 IEEE Trans. Nucl. Sci. 60 1740

Google Scholar

Google Scholar

[9] Jiang J Z, Shu W, Chong K S, Lin T, Zwa Lwin N K, Chang J S, Liu J Y 2016 IEEE International Symposium on Circuits and Systems Montreal, Canada May 22–25, 2016 p5

[10] Xie X D, Yang Z Z, Deng M X, Chen K B, Li W 2019 IEEE Trans. Device Mater. Reliab. 19 242

Google Scholar

Google Scholar

[11] 范雪, 李威, 李平, 张斌, 谢小东, 王刚, 胡滨, 翟亚红 2012 61 016106

Google Scholar

Google Scholar

Fan X, Li W, Li P, Zhang B, Xie X D, Wang G, Hu B, Zhai Y H 2012 Acta Phys. Sin. 61 016106

Google Scholar

Google Scholar

[12] Dodd P E, Shaneyfelt M R, Schwank J R, Felix J A 2010 IEEE Trans. Nucl. Sci. 57 1747

Google Scholar

Google Scholar

[13] Hughes H L, Benedetto J M 2003 IEEE Trans. Nucl. Sci. 50 500

Google Scholar

Google Scholar

[14] 刘张李, 胡志远, 张正选, 邵华, 宁冰旭, 毕大炜, 陈明, 邹世昌 2011 60 116103

Google Scholar

Google Scholar

Liu Z L, Hu Z Y, Zhang Z X, Shao H, Ning B X, Bi D W, Chen M, Zou S C 2011 Acta Phys. Sin. 60 116103

Google Scholar

Google Scholar

[15] Wu M, Zhang C C, Peng W, Xu J, Jin H, Zeng Y, Chen Z J 2020 IEEE Trans. Nucl. Sci. 67 708

Google Scholar

Google Scholar

[16] Sorge R, Schmidt J, Reimer F, Wipf C, Korndoerfer F, Pliquett R, Barth R 2019 Nucl. Instr. and Meth. in Phys. Res. 924 166

Google Scholar

Google Scholar

[17] Ali K B, Gammon P M, Chan C W, Li F, Pathirana V, Trajkovic T, Gity F, Flandre D, Kilchytska V 2017 47 th European Solid State Device Research Conference Leuven, Belgium, September 11–14, 2017 p236

[18] Liu M X, Han Z S, Bi J S, Fan X M, Liu G, Du H 2009 J. Semicond. 30 014004

Google Scholar

Google Scholar

[19] Qiao F Y, Pan L Y, Wu D, Liu L F, Xu J 2014 J. Semicond. 35 024003

Google Scholar

Google Scholar

[20] Liu M X, Han Z S, Bi J S, Fan X M, Liu G, Du H, Song L M 2008 J. Semicond. 29 2158

[21] Li Y F, Zhu S L, Wu J W, Hong G S, Xu Z 2019 J. Semicond. 40 052401

Google Scholar

Google Scholar

[22] Asano M, Sekigawa D, Hara K, Aoyagi W, Honda S, Tobita N, Arai Y, Miyoshi T, Kurachi I, Tsuboyama T, Yamada M 2016 Nucl. Instr. and Meth. in Phys. Res. 831 315

Google Scholar

Google Scholar

[23] Schwank J R, Ferlet- Cavrois V, Shaneyfelt M R, Paillet P, Dodd P E 2003 IEEE Trans. Nucl. Sci. 50 522

Google Scholar

Google Scholar

[24] Huang Y, Li B H, Zhao X, Zheng Z S, Gao J T, Zhang G, Li B, Zhang G H, Tang K, Han Z S, Luo J J 2018 IEEE Trans. Nucl. Sci. 65 1532

Google Scholar

Google Scholar

[25] Yuan Z Y A, Qiao M, Li X J, Hou D C, Zhang S H, Zhou X, Li Z J, Zhang B 2021 IEEE Trans. Electron Devices 68 2064

Google Scholar

Google Scholar

[26] Huang Y S, Baliga B J 1991 3rd International Symposium on Power Semiconductor Devices and ICs, Baltimore, USA April 22-24, 1991 27

[27] Imam M, Hossain Z, Quddus M, Adams J, Hoggatt C, Ishiguro T, Nair R 2003 IEEE Trans. Electron Devices 50 1697

Google Scholar

Google Scholar

[28] Ludikhuize A W 2000 12 th International Symposium on Power Semiconductor Devices and ICs, Toulouse, France May 22–25, 2000 11

-

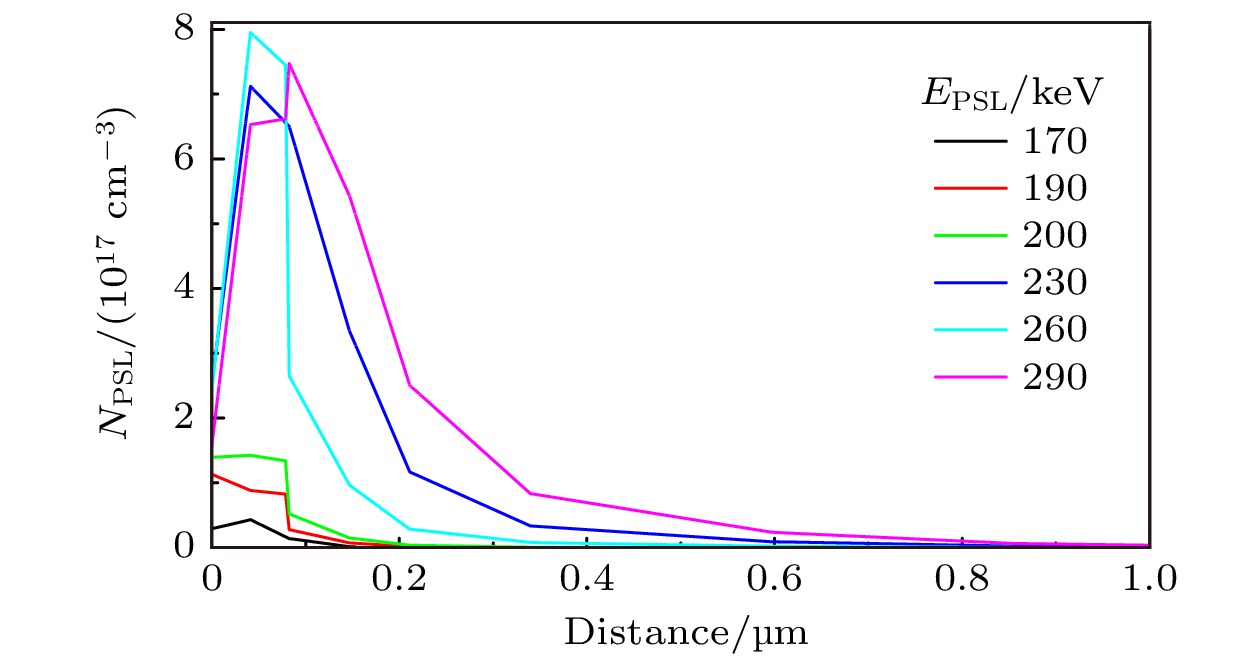

图 2 传统结构中, (a) DPTOP对辐照前后VB, Idlin的影响; (b) DPTOP =

$ 5\times {10}^{11} $ cm–2, 辐照前后线性电流密度分布, 其中横坐标表示距PTOP表面的纵向距离Fig. 2. In the conventional structure, (a) impact of DPTOP on pre-rad and post-rad VB and Idlin; (b) distribution of pre-rad and post-rad linear current density when DPTOP =

$ 5\times {10}^{11} $ cm–2, wherein X axis represents vertical distance to PTOP surface.图 4 d = 8

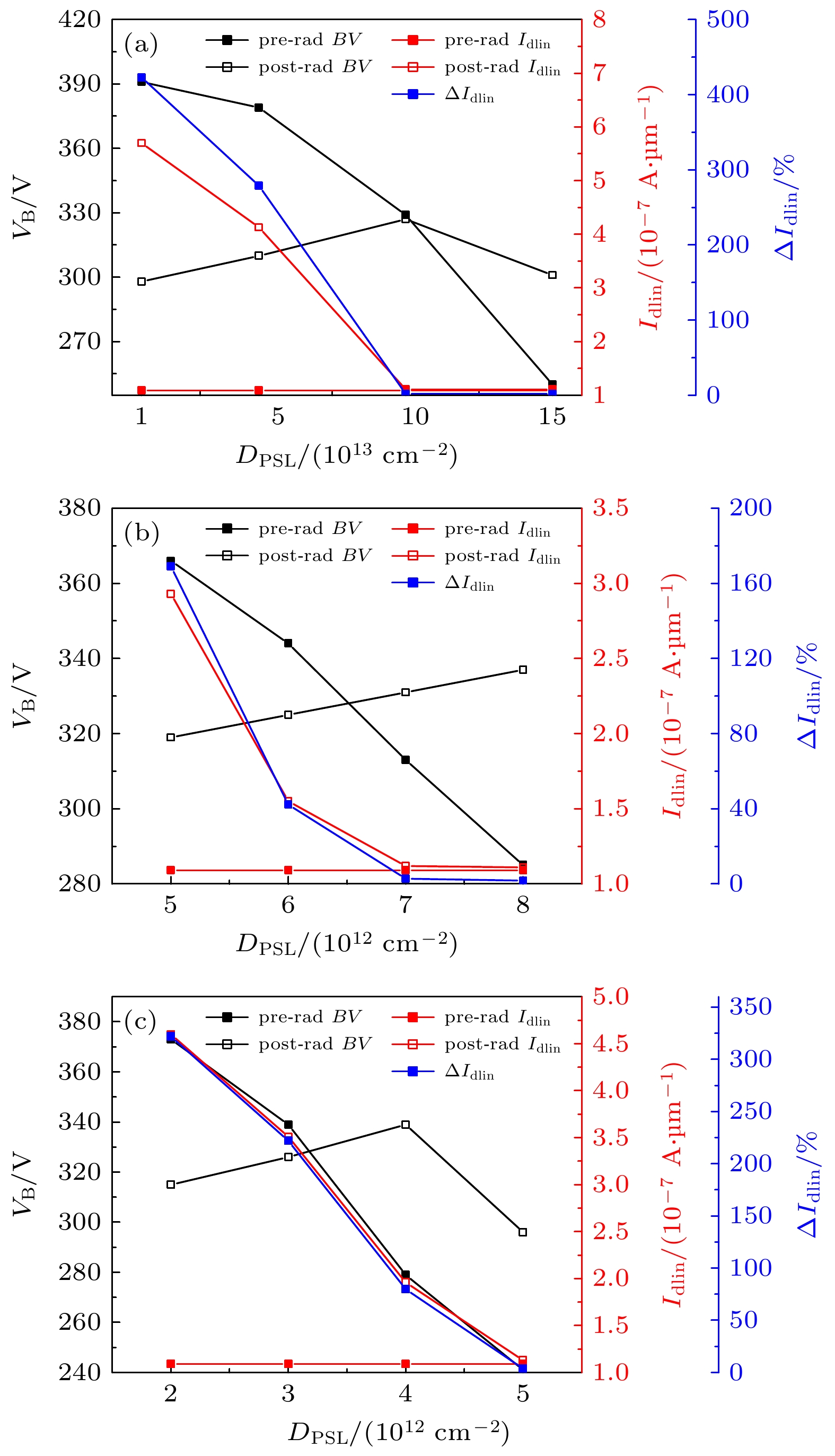

$ \mathrm{\mu }\mathrm{m} $ , LPSL = 3$ \mathrm{\mu }\mathrm{m} $ , DPTOP =$ 5\times {10}^{11} $ cm–2条件下, DPSL在不同注入能量下对辐照前后VB、Idlin的影响 (a) EPSL = 170 keV; (b) EPSL = 200 keV; (c) EPSL = 230 keVFig. 4. d = 8

$ \mathrm{\mu }\mathrm{m} $ , LPSL = 3$ \mathrm{\mu }\mathrm{m} $ , DPTOP =$ 5\times {10}^{11} $ cm–2, impact of DPSL on pre-rad and post-rad VB and Idlin for (a) EPSL = 170 keV; (b) EPSL = 200 keV; (c) EPSL = 230 keV.图 5 d = 8

$ \mathrm{\mu }\mathrm{m} $ , LPSL = 3$ \mathrm{\mu }\mathrm{m} $ , EPSL = 190 keV, 不同DPSL对辐照前后VB, Idlin的影响: (a) DPTOP =$ 5\times {10}^{11} $ cm–2; (b) DPTOP =$ 6\times {10}^{11} $ cm–2; (c) DPTOP =$ 7\times {10}^{11} $ cm–2; (d) DPTOP =$ 8\times {10}^{11} $ cm–2Fig. 5. Impact of DPSL on pre-rad and post-rad VB and Idlin for (a) DPTOP =

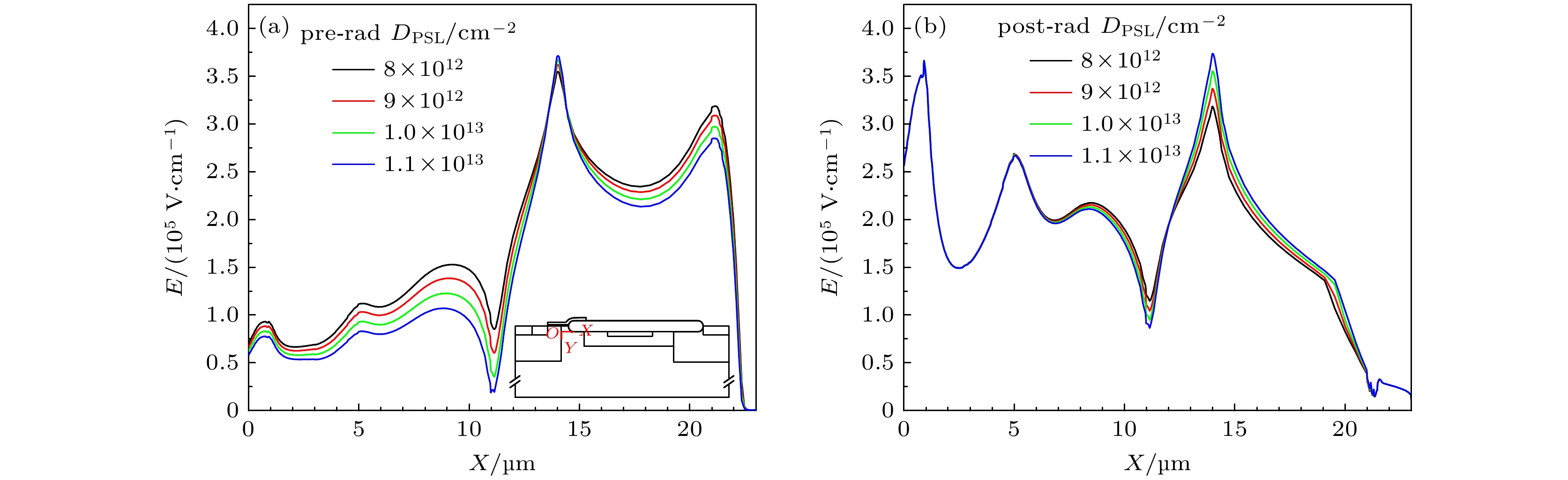

$ 5\times {10}^{11} $ cm–2; (b) DPTOP =$ 6\times {10}^{11} $ cm–2; (c) DPTOP =$ 7\times {10}^{11} $ cm–2; (d) DPTOP =$ 8\times {10}^{11} $ cm–2 when d = 8$ \mathrm{\mu }\mathrm{m} $ , LPSL = 3$ \mathrm{\mu }\mathrm{m} $ , EPSL = 190 keV.图 6 d = 8

$ \mathrm{\mu }\mathrm{m} $ , LPSL = 3$ \mathrm{\mu }\mathrm{m} $ , EPSL = 190 keV, DPTOP =$ 7\times {10}^{11} $ cm–2, 不同DPSL对应的漂移区硅表面电场分布 (a) 辐照前; (b) 辐照后. 图(a)中内插图标明坐标原点O与X方向Fig. 6. Silicon surface electric field distribution in drift region under various DPSL for (a) pre-rad and (b) post-rad conditions when d = 8

$ \mathrm{\mu }\mathrm{m} $ , LPSL = 3$ \mathrm{\mu }\mathrm{m} $ , EPSL = 190 keV, DPTOP =$ 7\times {10}^{11} $ cm–2. Inset indicates origin of the coordinate and X direction图 7 LPSL = 3

$ \mathrm{\mu }\mathrm{m} $ , EPSL = 190 keV, d对辐照前后VB和Idlin的影响: (a) DPTOP =$ 5\times {10}^{11} $ cm–2, DPSL =$ 1\times {10}^{13} $ cm–2; (b) DPTOP =$ 6\times {10}^{11} $ cm–2, DPSL =$ 1\times {10}^{13} $ cm–2Fig. 7. Impact of d on pre-rad and post-rad VB and Idlin when LPSL = 3

$ \mathrm{\mu }\mathrm{m} $ , EPSL = 190 keV for (a) DPTOP =$ 5\times {10}^{11} $ cm–2, DPSL =$ 1\times {10}^{13} $ cm–2; (b) DPTOP =$ 6\times {10}^{11} $ cm–2, DPSL =$ 1\times {10}^{13} $ cm–2.图 8 DPTOP =

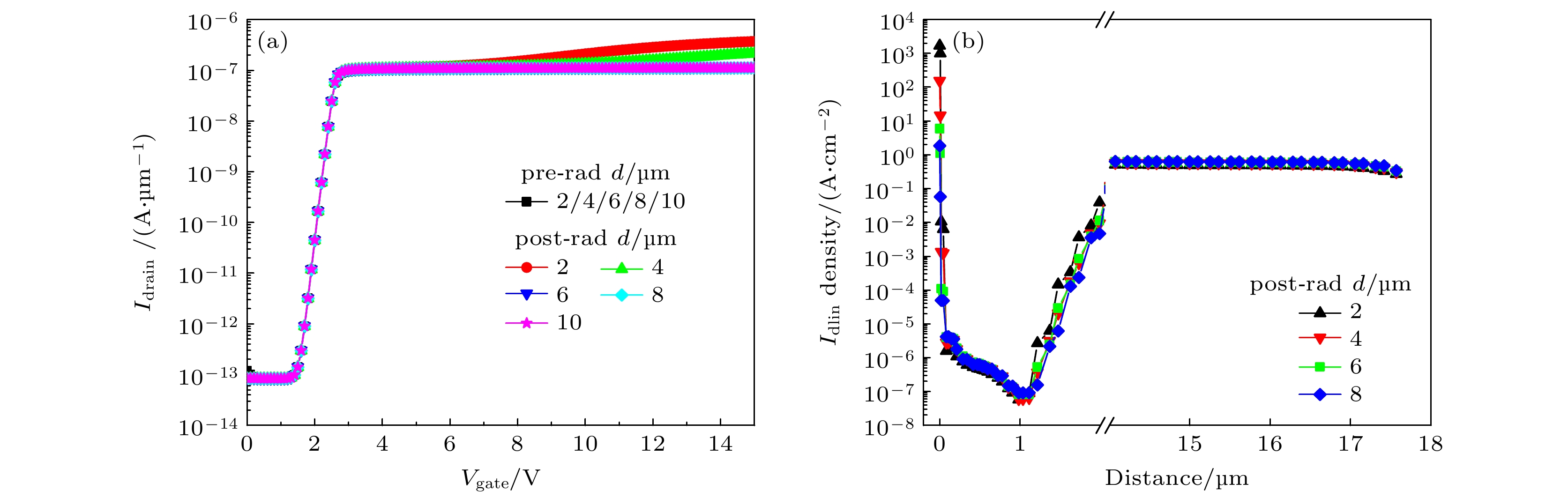

$ 5\times {10}^{11} $ cm–2, DPSL =$ 1\times {10}^{13} $ cm–2, EPSL = 190 keV, LPSL = 3$ \mathrm{\mu }\mathrm{m} $ , (a)不同d值下, 器件的辐照前与辐照后转移特性曲线; (b) d = 2, 4, 6, 8$ \mathrm{\mu }\mathrm{m} $ , 辐照后线性电流密度分布, 其中横坐标表示距PTOP表面的纵向距离Fig. 8. DPTOP =

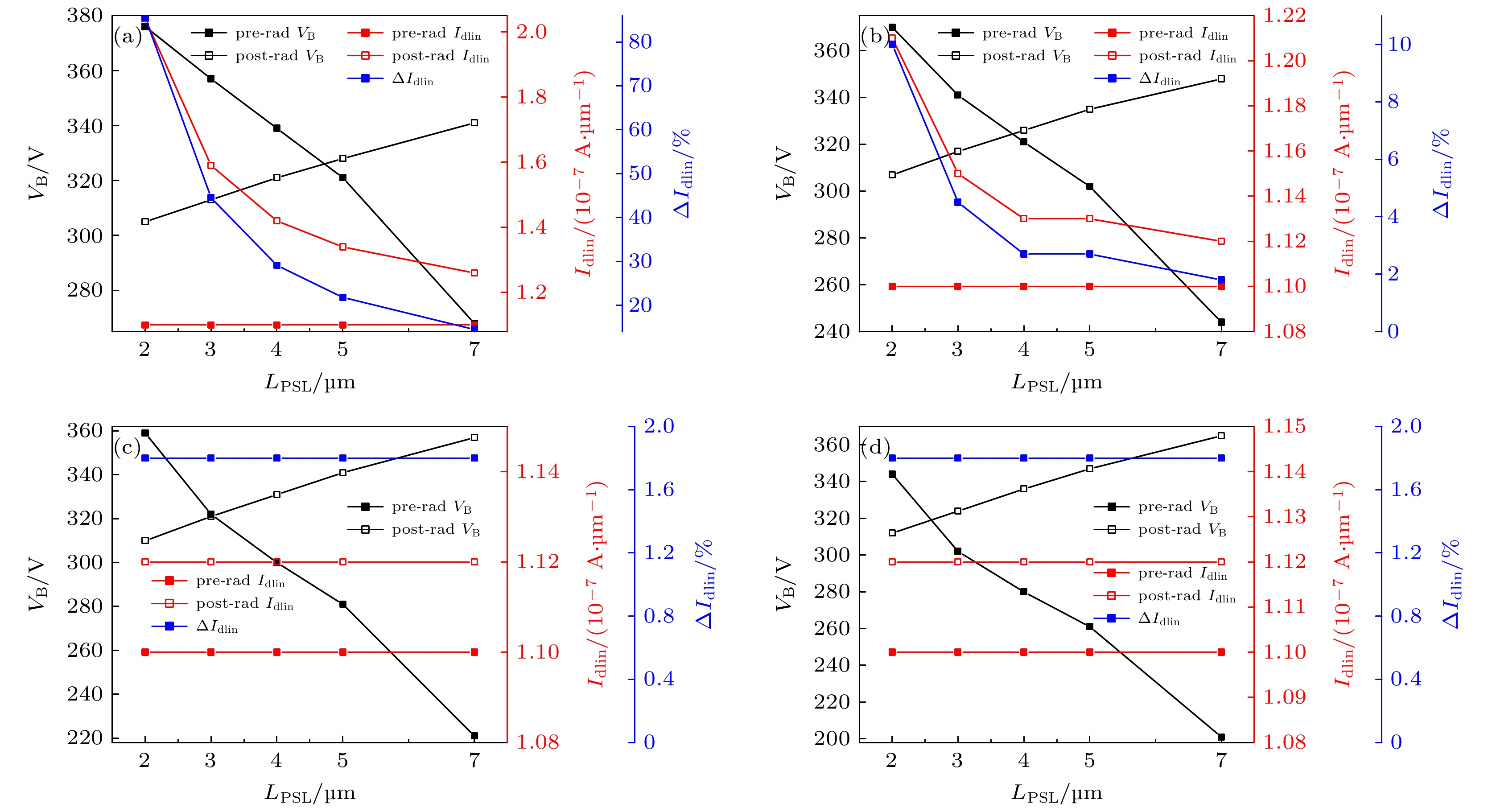

$ 5\times {10}^{11} $ cm–2, DPSL =$ 1\times {10}^{13} $ cm–2, EPSL = 190 keV, LPSL = 3$ \mathrm{\mu }\mathrm{m} $ , (a) Pre-rad and post-rad transfer curves under various d; (b) distribution of post-rad linear current density when d = 2, 4, 6, 8$ \mathrm{\mu }\mathrm{m} $ , wherein X axis represents vertical distance to PTOP surface.图 9 DPTOP =

$ 5\times {10}^{11} $ cm–2, d = 8$ \mathrm{\mu }\mathrm{m} $ , EPSL = 190 keV, 不同LPSL对辐照前后VB, Idlin的影响: (a) DPSL =$ 8\times {10}^{12} $ cm–2; (b) DPSL =$ 9\times {10}^{12} $ cm–2; (c) DPSL =$ 1\times {10}^{13} $ cm–2; (d) DPSL =$ 1.1\times {10}^{13} $ cm–2Fig. 9. Impact of LPSL on pre-rad and post-rad VB and Idlin for (a) DPSL =

$ 8\times {10}^{12} $ cm–2; (b) DPSL =$ 9\times {10}^{12} $ cm–2; (c) DPSL =$ 1\times {10}^{13} $ cm–2; (d) DPSL =$ 1.1\times {10}^{13} $ cm–2 when DPTOP=$ 5\times {10}^{11} $ cm–2, d = 8$ \mathrm{\mu }\mathrm{m} $ , EPSL = 190 keV. -

[1] Winokur P S, Lum G K, Shaneyfelt M R, Sexton F W, Hash G L, Scott L 1999 IEEE Trans. Nucl. Sci. 46 1494

Google Scholar

Google Scholar

[2] Barth J L, Dyer C S, Stassinopoulos E G 2003 IEEE Trans. Nucl. Sci. 50 466

Google Scholar

Google Scholar

[3] Pease R L 1996 IEEE Trans. Nucl. Sci. 43 442

Google Scholar

Google Scholar

[4] Oldham T R, Mclean B 2003 IEEE Trans. Nucl. Sci. 50 483

Google Scholar

Google Scholar

[5] Barnaby H J 2006 IEEE Trans. Nucl. Sci. 53 3103

Google Scholar

Google Scholar

[6] Normand E 1996 IEEE Trans. Nucl. Sci. 43 461

Google Scholar

Google Scholar

[7] Titus J L 2013 IEEE Trans. Nucl. Sci. 60 1912

Google Scholar

Google Scholar

[8] Srour J R, Palko J W 2013 IEEE Trans. Nucl. Sci. 60 1740

Google Scholar

Google Scholar

[9] Jiang J Z, Shu W, Chong K S, Lin T, Zwa Lwin N K, Chang J S, Liu J Y 2016 IEEE International Symposium on Circuits and Systems Montreal, Canada May 22–25, 2016 p5

[10] Xie X D, Yang Z Z, Deng M X, Chen K B, Li W 2019 IEEE Trans. Device Mater. Reliab. 19 242

Google Scholar

Google Scholar

[11] 范雪, 李威, 李平, 张斌, 谢小东, 王刚, 胡滨, 翟亚红 2012 61 016106

Google Scholar

Google Scholar

Fan X, Li W, Li P, Zhang B, Xie X D, Wang G, Hu B, Zhai Y H 2012 Acta Phys. Sin. 61 016106

Google Scholar

Google Scholar

[12] Dodd P E, Shaneyfelt M R, Schwank J R, Felix J A 2010 IEEE Trans. Nucl. Sci. 57 1747

Google Scholar

Google Scholar

[13] Hughes H L, Benedetto J M 2003 IEEE Trans. Nucl. Sci. 50 500

Google Scholar

Google Scholar

[14] 刘张李, 胡志远, 张正选, 邵华, 宁冰旭, 毕大炜, 陈明, 邹世昌 2011 60 116103

Google Scholar

Google Scholar

Liu Z L, Hu Z Y, Zhang Z X, Shao H, Ning B X, Bi D W, Chen M, Zou S C 2011 Acta Phys. Sin. 60 116103

Google Scholar

Google Scholar

[15] Wu M, Zhang C C, Peng W, Xu J, Jin H, Zeng Y, Chen Z J 2020 IEEE Trans. Nucl. Sci. 67 708

Google Scholar

Google Scholar

[16] Sorge R, Schmidt J, Reimer F, Wipf C, Korndoerfer F, Pliquett R, Barth R 2019 Nucl. Instr. and Meth. in Phys. Res. 924 166

Google Scholar

Google Scholar

[17] Ali K B, Gammon P M, Chan C W, Li F, Pathirana V, Trajkovic T, Gity F, Flandre D, Kilchytska V 2017 47 th European Solid State Device Research Conference Leuven, Belgium, September 11–14, 2017 p236

[18] Liu M X, Han Z S, Bi J S, Fan X M, Liu G, Du H 2009 J. Semicond. 30 014004

Google Scholar

Google Scholar

[19] Qiao F Y, Pan L Y, Wu D, Liu L F, Xu J 2014 J. Semicond. 35 024003

Google Scholar

Google Scholar

[20] Liu M X, Han Z S, Bi J S, Fan X M, Liu G, Du H, Song L M 2008 J. Semicond. 29 2158

[21] Li Y F, Zhu S L, Wu J W, Hong G S, Xu Z 2019 J. Semicond. 40 052401

Google Scholar

Google Scholar

[22] Asano M, Sekigawa D, Hara K, Aoyagi W, Honda S, Tobita N, Arai Y, Miyoshi T, Kurachi I, Tsuboyama T, Yamada M 2016 Nucl. Instr. and Meth. in Phys. Res. 831 315

Google Scholar

Google Scholar

[23] Schwank J R, Ferlet- Cavrois V, Shaneyfelt M R, Paillet P, Dodd P E 2003 IEEE Trans. Nucl. Sci. 50 522

Google Scholar

Google Scholar

[24] Huang Y, Li B H, Zhao X, Zheng Z S, Gao J T, Zhang G, Li B, Zhang G H, Tang K, Han Z S, Luo J J 2018 IEEE Trans. Nucl. Sci. 65 1532

Google Scholar

Google Scholar

[25] Yuan Z Y A, Qiao M, Li X J, Hou D C, Zhang S H, Zhou X, Li Z J, Zhang B 2021 IEEE Trans. Electron Devices 68 2064

Google Scholar

Google Scholar

[26] Huang Y S, Baliga B J 1991 3rd International Symposium on Power Semiconductor Devices and ICs, Baltimore, USA April 22-24, 1991 27

[27] Imam M, Hossain Z, Quddus M, Adams J, Hoggatt C, Ishiguro T, Nair R 2003 IEEE Trans. Electron Devices 50 1697

Google Scholar

Google Scholar

[28] Ludikhuize A W 2000 12 th International Symposium on Power Semiconductor Devices and ICs, Toulouse, France May 22–25, 2000 11

计量

- 文章访问数: 6426

- PDF下载量: 106

- 被引次数: 0

下载:

下载: