-

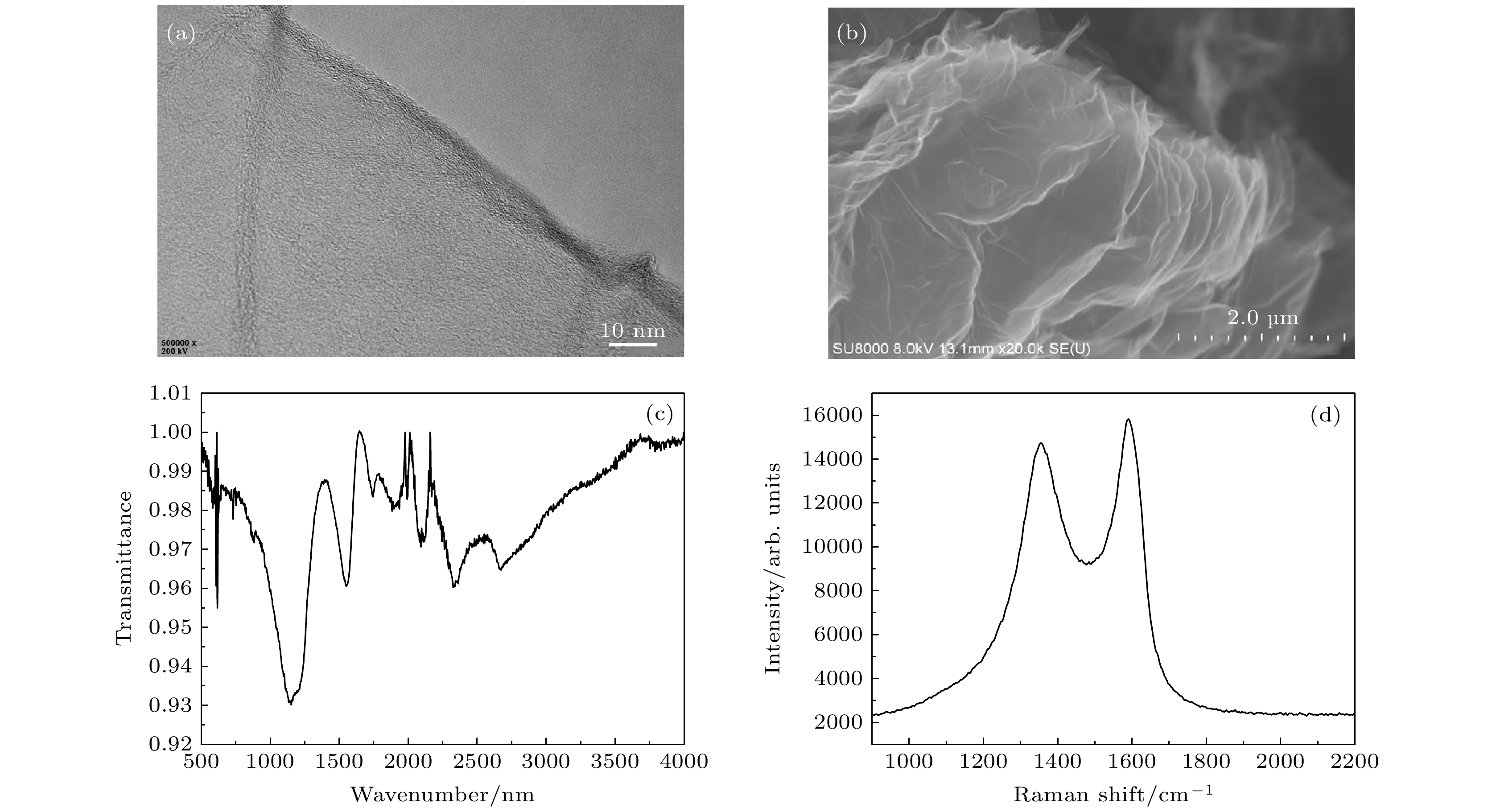

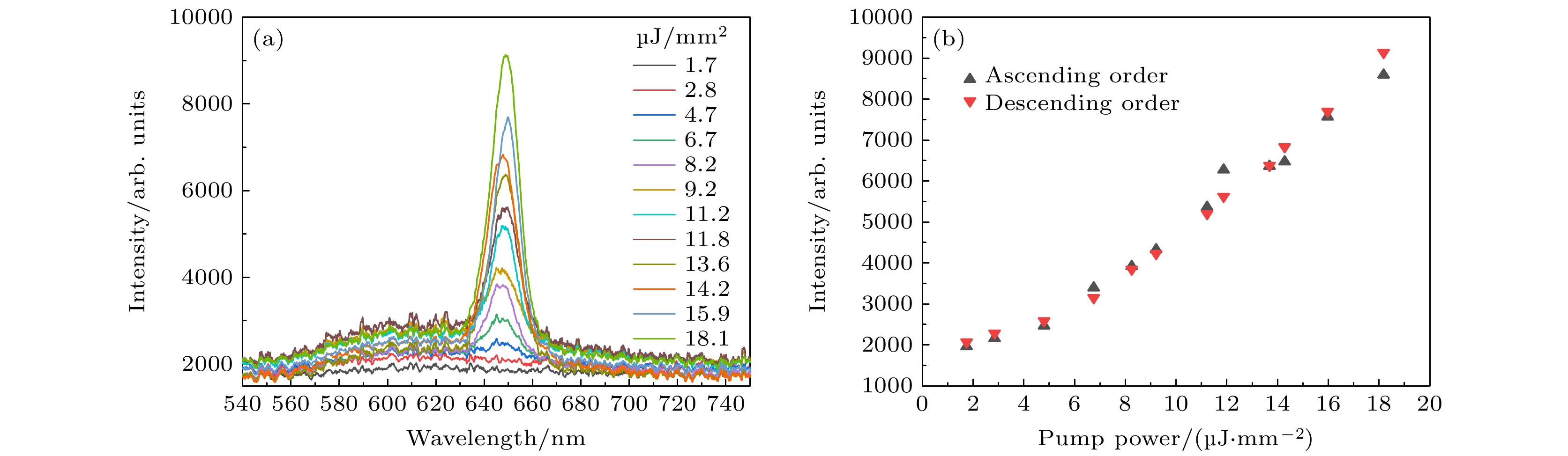

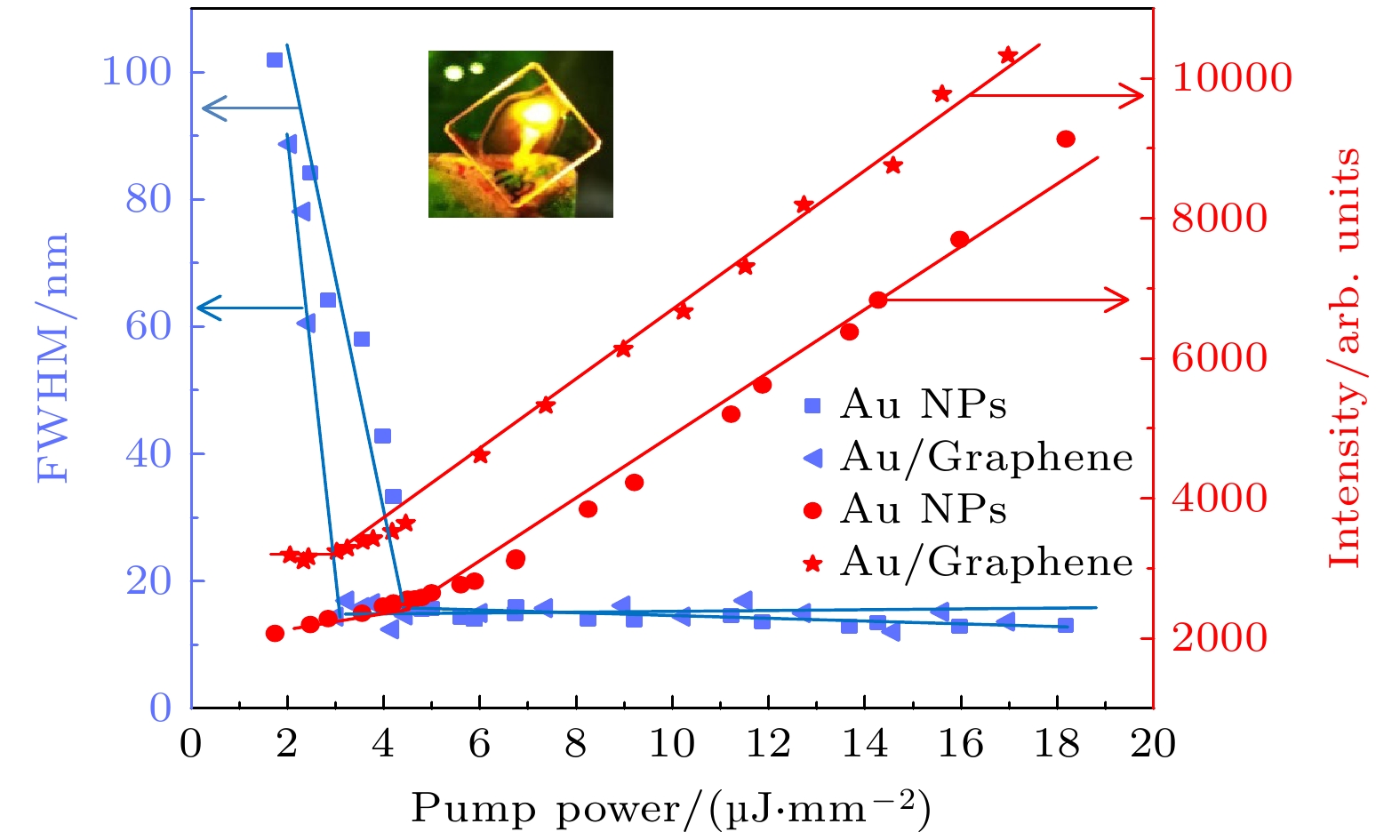

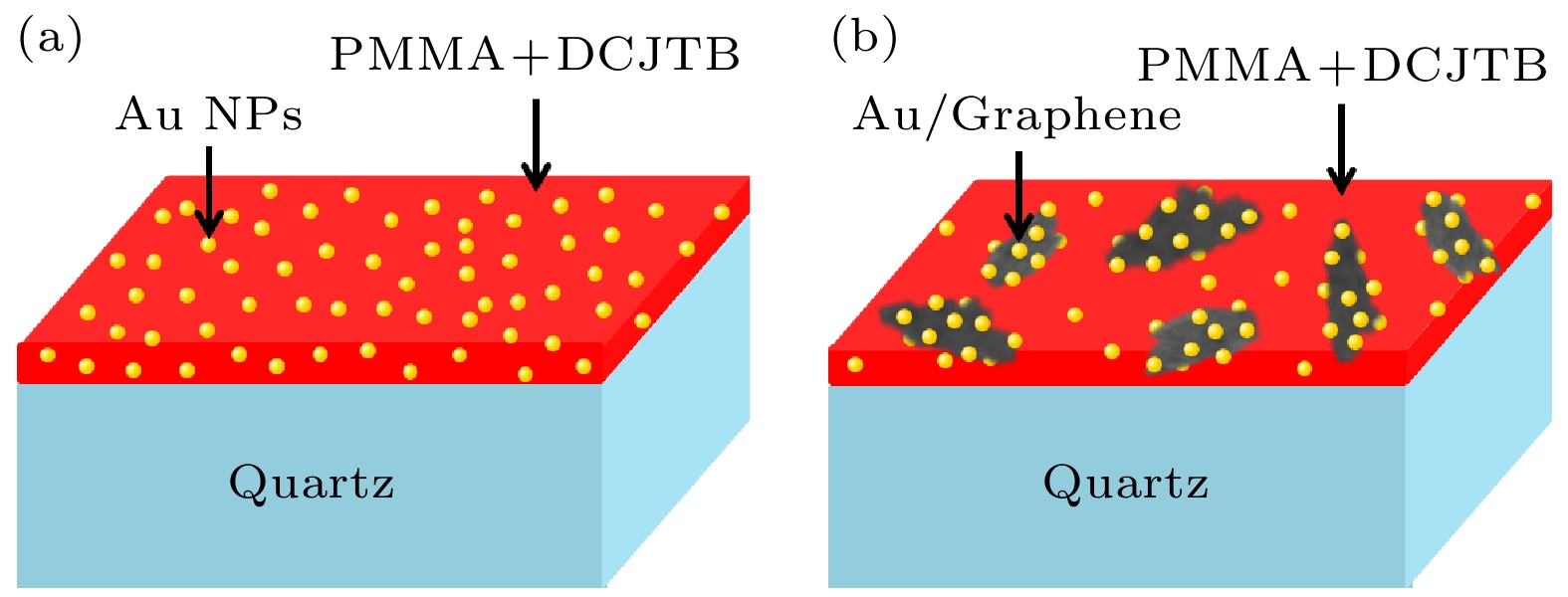

石墨烯和纳米颗粒的复合材料具有新颖的光学和电学特性, 被广泛应用于信息传感、光电转换、医学诊断等领域, 具有十分广阔的发展前景. 虽然石墨烯拥有优异的光电性能, 可以实现对随机激光性质的调控, 但目前实现特殊结构的石墨烯与金属纳米结构的复合过程复杂繁琐, 利用石墨烯有效降低随机激光阈值仍存在挑战. 本文利用便捷的化学还原及吸附法制备Au/石墨烯结构, 以染料DCJTB为增益介质, 使用旋涂法制备了均匀的薄膜样品; 研究对比Au纳米颗粒和Au/石墨烯结构随机激光特性, 分析了石墨烯的作用机理. 研究结果表明, Au/石墨烯复合材料透射峰与增益介质的光致发光光谱峰最为接近, 对于染料分子的能级迁跃起到了促进作用. 在相同的增益介质中, 石墨烯的加入不仅使得光子在无序介质中散射频次增加, 促进了增益效果, 而且增强了Au纳米颗粒表面的等离子体共振效应. 二者相互协同, 展现出了优异的随机激光特性, 阈值降低至2.8 μJ/mm2; 对样品重复测量可得样品的激射重复性较强、品质较高. 本研究对促进随机激光应用、实现高性能的光电器件起到了一定的推动作用.The graphene and nanoparticles composites have novel optical and electrical properties. They are widely used in the fields of information sensing, photoelectric conversion and medical diagnosis. Graphene has excellent photoelectric properties and can regulate the random laser properties, but the current composite process of graphene with special structures and metal nanostructures is complicated. Thus, there is still a challenge to effectively reducing the threshold of random laser by using graphene. In this work, the Au/graphene structure is prepared by convenient chemical reduction and adsorption method, and the dye DCJTB is used as the gain medium to form the film by spin coating. The random laser properties of Au nanoparticles and Au/graphene structure are studied, and the mechanism of graphene is analyzed. The results show that the transmission peak of Au/graphene composite is near the photoluminescence peak of gain medium, which promotes the energy level transition of dye molecules. With the addition of graphene into the same gain medium, the scattering frequency of photons in the disordered medium increases, resulting in the enhancement of surface plasmon resonance. The scattering effect and the surface plasmon resonance effect cooperate with each other, showing good random laser threshold, which is reduced from 3.4 μJ/mm2 to 2.8 μJ/mm2. Repeatability and high quality of maser are obtained by repetitively measuring the same sample, showing that the lasing sample has good repeatability and high quality. This study plays a certain role in promoting the application of random laser and realizing the high-performance optoelectronic devices.

-

Keywords:

- random laser /

- surface plasmon resonance /

- graphene /

- Au nanoparticles

[1] Soest G V, Lagendijk A 2002 Phys. Rev. E 65 047601

Google Scholar

Google Scholar

[2] Soest G V, Poelwijk F J, Lagendijk A 2002 Phys. Rev. E 65 046603

Google Scholar

Google Scholar

[3] Wang Y, Duan Z J, Qiu Z, Zhang P, Wu J W, Zhang D K, Xiang T X 2017 Sci. Rep. 7 8385

Google Scholar

Google Scholar

[4] Chen H, Gao S H, Zhang M J, Zhang J Z, Qiao L J, Wang T, Gao F, Hu X X, Li S C, Zhu Y C 2020 Sensors 20 6122

Google Scholar

Google Scholar

[5] Wiersma, Diederik S 2008 Nat. Phys. 4 359

Google Scholar

Google Scholar

[6] Rashidi M, Haggren T, Su Z, Jagadish C, Tan H H 2021 Nano. Lett. 21 3901

Google Scholar

Google Scholar

[7] Siva G V, Nair R V, Krishnan S R, Vijayan C 2017 Opt. Lett. 42 5002

Google Scholar

Google Scholar

[8] Haddaw S F, Humud H R, Hamidi S M 2020 Optik 207 164482

Google Scholar

Google Scholar

[9] Xia J Y, He J J, Xie K, Zhang X J, Hu L, Li Y, Chen X X, Ma J J, Wen J X, Chen J J, Pan Q S, Zhang J X, Vatnik I D, Churkin D, Hu Z J 2019 Annalen der Physik 531 1900066

Google Scholar

Google Scholar

[10] Li Y X, Xie K, Zhang X J, Hu Z J, Ma J J, Chen X X, Zhang J X, Liu Z M, Chen D 2020 Photonic. Sens. 10 254

Google Scholar

Google Scholar

[11] Chen Z X, Zhang Y J, Chu S, Sun R, Wang J, Chen J P, Wei B, Zhang X, Zhou W H, Shi Y M 2020 ACS Appl. Mater. Interfaces 12 23323

Google Scholar

Google Scholar

[12] Yuan F L, Xi Z F, Shi X Y, Li Y C, Li X H, Wang Z N, Fa L Z, Yang S H 2019 Adv. Opt. Mater. 7 1801202

Google Scholar

Google Scholar

[13] Gayathri R, Monika K, Murukeshan V M, Vijayan C 2021 Opt. Laser. Technol. 139 106959

Google Scholar

Google Scholar

[14] Shi X Y, Bian Y X, Tong J H, Liu D H, Zhou J, Wang Z N 2020 Opt. Express 28 13576

Google Scholar

Google Scholar

[15] Wan Y, Deng L G 2019 Opt. Express 27 27103

Google Scholar

Google Scholar

[16] Shi X Y, Chang Q, Bian Y X, Cui H B, Wang Z N 2019 ACS Photonics 6 2245

Google Scholar

Google Scholar

[17] Wan Y, An Y, Deng L G 2017 Sci. Rep. 7 16185

Google Scholar

Google Scholar

[18] Zhang R, Knitter S, Liew S F, Omenetto F G, Reinhard B M, Cao H, Negro D L 2016 Appl. Phys. Lett. 108 011103

Google Scholar

Google Scholar

[19] Long L, He D, Bao W, Feng M, Chen S 2017 J. Alloys. Compd. 693 876

Google Scholar

Google Scholar

[20] Zhai T, Zhang X, Pang Z, Su X, Liu H, Feng S, Wang L 2011 Nano. Lett. 11 4295

Google Scholar

Google Scholar

[21] Zhang N M, Ning S Y, Dai K, Zhang Y F, Wu Y, Yuan F, Zhang F H 2020 Opt. Mater. Express 10 1204

Google Scholar

Google Scholar

[22] Marini A, Garcia D A F J 2016 Phys. Rev. Lett. 116 217401

Google Scholar

Google Scholar

[23] Pradip K R, Golam H, Lin H, Liao Y M, Lu C H, Chen K H, Chen L H, Shi W H, Liang C T, Chen Y F 2018 Adv. Opt. Mater. 6 1800382

Google Scholar

Google Scholar

[24] Lee J, Kim J, Ahmed S R, Zhou H 2014 ACS Appl. Mater. Interfaces 6 21380

Google Scholar

Google Scholar

[25] Shi J Y, Chan C Y, Pang Y T, Ye W W, Tian F, Jing L Y, Zhang Y, Yang M 2015 Biosens. Bioelectron. 67 595

Google Scholar

Google Scholar

[26] Lü H, Lan Y Y, Zhao Q L, Wang X, Zhang S Y, Teng L H, Tam W Y 2018 Appl. Phys. B 124 227

Google Scholar

Google Scholar

[27] Ma H R, Lü H, Wang X 2020 Optik 223 165567

Google Scholar

Google Scholar

[28] Bae S, Kim H, Lee Y, Xu X, Park J S, Zheng Y, Balakrishnan J, Lei T, Kim R T, Song Y 2010 Nat. Nanotechnol. 5 574

Google Scholar

Google Scholar

[29] Shen T, Li Z, Jiang Y, Luo Z G 2019 Funct. Mater. Lett. 12 1950028

Google Scholar

Google Scholar

[30] Ning S, Dong H, Zhang N, Zhao J, Ding L 2016 Opt. Mater. Express 6 3725

Google Scholar

Google Scholar

[31] Tao A, Sinsermsuksakul P, Yang P D 2007 Nat. Nanotechnol. 2 435

Google Scholar

Google Scholar

[32] Zhang Z Y, Liu L H, Wang W, Cao Z J, Martinelli A, Wang E G, Cao Y, Chen J N, Yurgens A, Sun J 2016 Adv. Opt. Mater. 4 2021

Google Scholar

Google Scholar

-

-

[1] Soest G V, Lagendijk A 2002 Phys. Rev. E 65 047601

Google Scholar

Google Scholar

[2] Soest G V, Poelwijk F J, Lagendijk A 2002 Phys. Rev. E 65 046603

Google Scholar

Google Scholar

[3] Wang Y, Duan Z J, Qiu Z, Zhang P, Wu J W, Zhang D K, Xiang T X 2017 Sci. Rep. 7 8385

Google Scholar

Google Scholar

[4] Chen H, Gao S H, Zhang M J, Zhang J Z, Qiao L J, Wang T, Gao F, Hu X X, Li S C, Zhu Y C 2020 Sensors 20 6122

Google Scholar

Google Scholar

[5] Wiersma, Diederik S 2008 Nat. Phys. 4 359

Google Scholar

Google Scholar

[6] Rashidi M, Haggren T, Su Z, Jagadish C, Tan H H 2021 Nano. Lett. 21 3901

Google Scholar

Google Scholar

[7] Siva G V, Nair R V, Krishnan S R, Vijayan C 2017 Opt. Lett. 42 5002

Google Scholar

Google Scholar

[8] Haddaw S F, Humud H R, Hamidi S M 2020 Optik 207 164482

Google Scholar

Google Scholar

[9] Xia J Y, He J J, Xie K, Zhang X J, Hu L, Li Y, Chen X X, Ma J J, Wen J X, Chen J J, Pan Q S, Zhang J X, Vatnik I D, Churkin D, Hu Z J 2019 Annalen der Physik 531 1900066

Google Scholar

Google Scholar

[10] Li Y X, Xie K, Zhang X J, Hu Z J, Ma J J, Chen X X, Zhang J X, Liu Z M, Chen D 2020 Photonic. Sens. 10 254

Google Scholar

Google Scholar

[11] Chen Z X, Zhang Y J, Chu S, Sun R, Wang J, Chen J P, Wei B, Zhang X, Zhou W H, Shi Y M 2020 ACS Appl. Mater. Interfaces 12 23323

Google Scholar

Google Scholar

[12] Yuan F L, Xi Z F, Shi X Y, Li Y C, Li X H, Wang Z N, Fa L Z, Yang S H 2019 Adv. Opt. Mater. 7 1801202

Google Scholar

Google Scholar

[13] Gayathri R, Monika K, Murukeshan V M, Vijayan C 2021 Opt. Laser. Technol. 139 106959

Google Scholar

Google Scholar

[14] Shi X Y, Bian Y X, Tong J H, Liu D H, Zhou J, Wang Z N 2020 Opt. Express 28 13576

Google Scholar

Google Scholar

[15] Wan Y, Deng L G 2019 Opt. Express 27 27103

Google Scholar

Google Scholar

[16] Shi X Y, Chang Q, Bian Y X, Cui H B, Wang Z N 2019 ACS Photonics 6 2245

Google Scholar

Google Scholar

[17] Wan Y, An Y, Deng L G 2017 Sci. Rep. 7 16185

Google Scholar

Google Scholar

[18] Zhang R, Knitter S, Liew S F, Omenetto F G, Reinhard B M, Cao H, Negro D L 2016 Appl. Phys. Lett. 108 011103

Google Scholar

Google Scholar

[19] Long L, He D, Bao W, Feng M, Chen S 2017 J. Alloys. Compd. 693 876

Google Scholar

Google Scholar

[20] Zhai T, Zhang X, Pang Z, Su X, Liu H, Feng S, Wang L 2011 Nano. Lett. 11 4295

Google Scholar

Google Scholar

[21] Zhang N M, Ning S Y, Dai K, Zhang Y F, Wu Y, Yuan F, Zhang F H 2020 Opt. Mater. Express 10 1204

Google Scholar

Google Scholar

[22] Marini A, Garcia D A F J 2016 Phys. Rev. Lett. 116 217401

Google Scholar

Google Scholar

[23] Pradip K R, Golam H, Lin H, Liao Y M, Lu C H, Chen K H, Chen L H, Shi W H, Liang C T, Chen Y F 2018 Adv. Opt. Mater. 6 1800382

Google Scholar

Google Scholar

[24] Lee J, Kim J, Ahmed S R, Zhou H 2014 ACS Appl. Mater. Interfaces 6 21380

Google Scholar

Google Scholar

[25] Shi J Y, Chan C Y, Pang Y T, Ye W W, Tian F, Jing L Y, Zhang Y, Yang M 2015 Biosens. Bioelectron. 67 595

Google Scholar

Google Scholar

[26] Lü H, Lan Y Y, Zhao Q L, Wang X, Zhang S Y, Teng L H, Tam W Y 2018 Appl. Phys. B 124 227

Google Scholar

Google Scholar

[27] Ma H R, Lü H, Wang X 2020 Optik 223 165567

Google Scholar

Google Scholar

[28] Bae S, Kim H, Lee Y, Xu X, Park J S, Zheng Y, Balakrishnan J, Lei T, Kim R T, Song Y 2010 Nat. Nanotechnol. 5 574

Google Scholar

Google Scholar

[29] Shen T, Li Z, Jiang Y, Luo Z G 2019 Funct. Mater. Lett. 12 1950028

Google Scholar

Google Scholar

[30] Ning S, Dong H, Zhang N, Zhao J, Ding L 2016 Opt. Mater. Express 6 3725

Google Scholar

Google Scholar

[31] Tao A, Sinsermsuksakul P, Yang P D 2007 Nat. Nanotechnol. 2 435

Google Scholar

Google Scholar

[32] Zhang Z Y, Liu L H, Wang W, Cao Z J, Martinelli A, Wang E G, Cao Y, Chen J N, Yurgens A, Sun J 2016 Adv. Opt. Mater. 4 2021

Google Scholar

Google Scholar

计量

- 文章访问数: 10174

- PDF下载量: 118

- 被引次数: 0

下载:

下载: