-

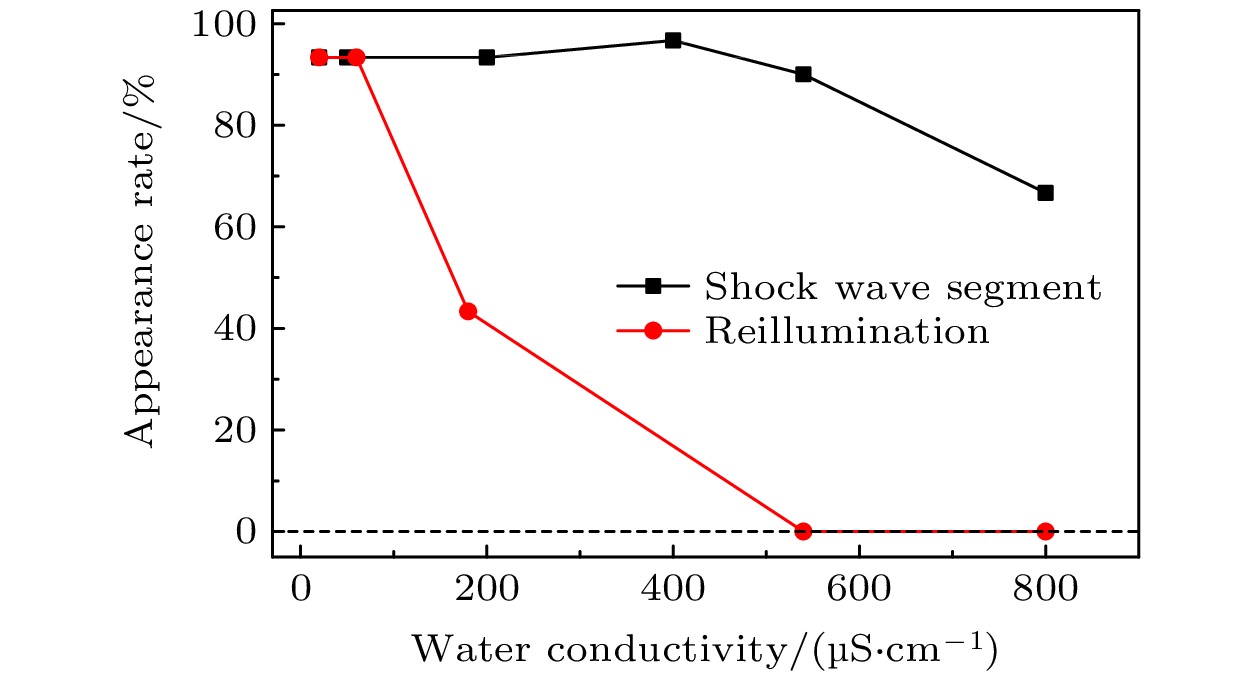

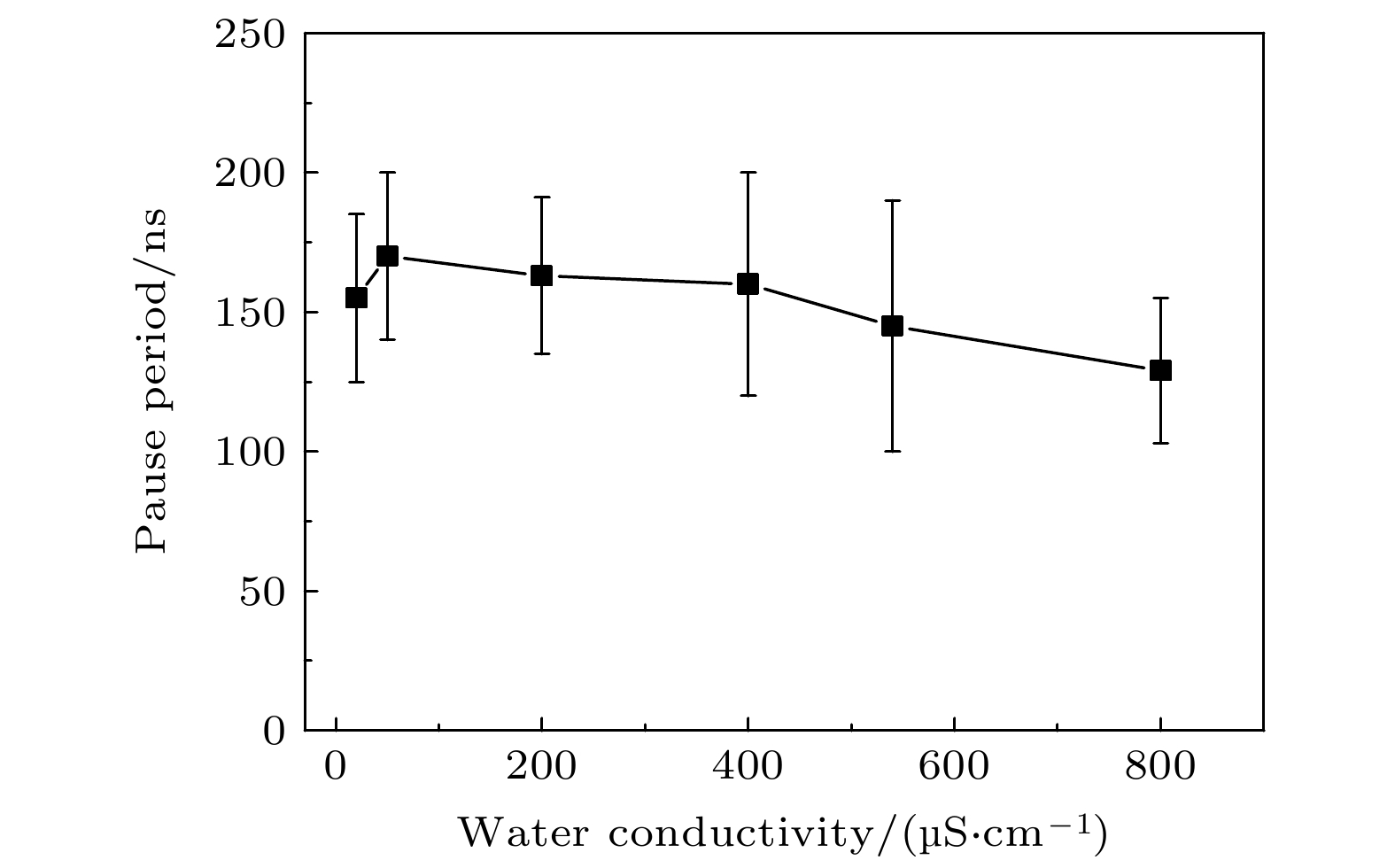

水中流光放电是研究水中放电基本物理、化学过程的主要研究对象. 本文利用四分幅超高速相机、采用针-板电极结构、在20—800 μS/cm水电导率范围内研究了水中微秒脉冲流光放电流光丝的再发光和暂停行为, 探讨了高水电导率下观测不到流光丝的再发光的原因. 结果发现: 再发光在不同的流光丝之间交替发生并存在两种模式: 一种为整根丝熄灭后再发光; 一种为只有先端部分发光熄灭随后恢复发光. 随着水电导率的增大, 观测到流光丝的再发光现象的频度急剧减小, 540 μS/cm水电导率时降到零; 在20—800 μS/cm水电导率条件下都可观测到流光丝伴生冲击波串分段现象, 冲击波串分段现象的出现频度在65%以上, 表明在20—800 μS/cm水电导率条件下流光丝的暂停是一种普遍行为. 通过测量两段冲击波的半径差得到流光的暂停时间平均为157 ns, 几乎不受水电导率的影响; 随着水电导率的增大, 流光丝的发光强度显著增大, 水电导率大于350 μS/cm时, 流光丝暂停期间内流光丝的光强度无法衰减到相机分辨水平以下, 在相机获得的发光图像上看上去是持续发光的, 难以分辨出流光丝“熄灭-再发光”过程.The streamer discharge in water is a main object for studying the basic physical and chemical processes of an electric discharge in water. In this paper, the re-illuminations and the pause behaviors of a streamer filament of the microsecond pulsed streamer discharge in water with different conductivities (20 to 800 µS/cm) are studied by adopting a needle-plate electrode system and an ultra-high-speed camera system. The cause why the re-illumination of the streamer filament is difficult to detect by using the camera system as the water conductivity gets higher is discussed. It is found that the re-illumination alternately occurs among different streamer filaments, and two modes of the re-illumination are identified: one is that the whole filament quenches and then illuminates again; the other is that only the tip part of the filament quenches and then resumes the illumination. The appearance rate of the re-illumination of the streamer filament decreases rapidly as the water conductivity increases, and then drops to zero as the water conductivity exceeds 540 µS/cm. Within a water conductivity range of 20–800 µS/cm, the appearance rate of segmentation in shockwave pattern of the streamer filament is larger than 65%, indicating that the pause is a common behavior of the streamer filament. By measuring the difference in radius between two adjacent shockwave segments, the average pause period of the streamer filament is estimated at 157 ns, which is almost not affected by the water conductivity. As the water conductivity increases, the light intensity of the streamer filament increases rapidly. The light intensity of the streamer filament cannot decay to the noise level of the camera system during the pause period of the streamer filament as the water conductivity exceeds 350 µS/cm. The streamer filament produces glow on the light emission image, which makes it difficult to distinguish the “extinction and illumination” process by the camera system.

-

Keywords:

- streamer discharge in water /

- re-illumination of a streamer filament /

- pause of a streamer filament

[1] Fridman G, Friedman G, Gutsol A, Shekhter A B, Vasilets V N, Fridman A 2008 Plasma Processes Polym. 5 503

Google Scholar

Google Scholar

[2] Locke B R, Thagard S M 2012 Plasma Chem. Plasma Process. 32 875

Google Scholar

Google Scholar

[3] Chen Q, Li J S, Li Y F 2015 J. Phys. D: Appl. Phys. 48 424005

Google Scholar

Google Scholar

[4] Sivachandiran L, Khacef A 2017 RSC Adv. 7 1822

Google Scholar

Google Scholar

[5] Saito N, Bratescu M A, Hashimi K 2018 Jpn. J. Appl. Phys. 57 0102A4

Google Scholar

Google Scholar

[6] Bruggeman P J, Kushner M J, Locke B R, Gardeniers J G E, Graham W G, Graves D B, Hofman-Caris R C H M, Maric D, Reid J P, Ceriani E, Fernandez Rivas D, Foster J E, Garrick S C, Gorbanev Y, Hamaguchi S, Iza F, Jablonowski H, Klimova E, Kolb J, Krcma F, Lukes P, Machala Z, Marinov I, Mariotti D, Mededovic Thagard S, Minakata D, Neyts E C, Pawlat J, Lj Petrovic Z, Pflieger R, Reuter S, Schram D C, Schröter S, Shiraiwa M, Tarabová B, Tsai P A, Verlet J R R, von Woedtke T, Wilson K R, Yasui K, Zvereva G 2016 Plasma Sources Sci. Technol. 25 053002

Google Scholar

Google Scholar

[7] Adamovich I, Baalrud S D, Bogaerts A, Bruggeman P J, Cappelli M, Colombo V, Czarnetzki U, Ebert U, Eden J G, Favia P, Graves D B, Hamaguchi S, Hieftje G, Hori M, Kaganovich I D, Kortshagen U, Kushner M J, Mason N J, Mazouffre S, Mededovic Thagard S, Metelmann H R, Mizuno A, Moreau E, Murphy A B, Niemira B A, Oehrlein G S, Petrovic Z L, Pitchford L C, Pu Y K, Rauf S, Sakai O, Samukawa S, Starikovskaia S, Tennyson J, Terashima K, Turner M M, van de Sanden M C M, Vardelle A 2017 J. Phys. D: Appl. Phys. 50 323001

Google Scholar

Google Scholar

[8] Vanraes P, Bogaerts A 2018 Appl. Phys. Rev. 5 031103

Google Scholar

Google Scholar

[9] Joshi R P, Thagard S M 2013 Plasma Chem. Plasma Process. 33 1

Google Scholar

Google Scholar

[10] Sun A, Huo C, Zhuang J 2016 High Voltage 1 74

Google Scholar

Google Scholar

[11] Lesaint O 2016 J. Phys. D: Appl. Phys. 49 144001

Google Scholar

Google Scholar

[12] Salazar J N, Bonifaci N, Denat A, Lesaint O 2005 IEEE International Conference on Dielectric Liquids Coimbra, Portugal, 26 June–1 July, 2005 p91

[13] Ceccato P H, Guaitella O, Gloahec Le M R, Rousseau A 2010 J. Phys. D: Appl. Phys. 43 175202

Google Scholar

Google Scholar

[14] An W, Baumung K, Bluhm H 2007 J. Appl. Phys. 101 053302

Google Scholar

Google Scholar

[15] Katsuki S, Tanaka K, Fudamoto T, Namihira T, Akiyama H, Bluhm H 2006 Jpn. J. Appl. Phys. 45 239

Google Scholar

Google Scholar

[16] Wen X Q, Xue X D 2019 AIP Adv. 9 075310

Google Scholar

Google Scholar

[17] Wen X Q, Xue X D, Liu X H, Li J S, Zhou Y B 2019 J. Appl. Phys. 125 133302

Google Scholar

Google Scholar

[18] Šimek M, Člupek M, Babický V, Lukeš P, Šunka P 2012 Plasma Sources Sci. Technol. 21 055031

Google Scholar

Google Scholar

[19] Bruggeman P, Schram D, Gonzalez M A, Rego R, Kong M G, Leys C 2009 Plasma Sources Sci. Technol. 18 025017

Google Scholar

Google Scholar

[20] https://www.nist.gov/[2021-6-21]

-

图 3 水下流光放电时间演化图像 (a)水电导率20 μS/cm, 相邻两幅图像的时间间隔为40 ns; (b)水电导率60 μS/cm, 相邻两幅图像的时间间隔为40 ns; (c)水电导率180 μS/cm, 相邻两幅图像的时间间隔为60 ns. (a)—(c)中CH1图像的曝光时间为100 ns, CH2-CH4图像的曝光时间为20 ns, 图中所标的时间是相对高压脉冲起始点的时间

Fig. 3. Light emission images of underwater streamer discharge: (a) 20 μS/cm, 40 ns interval; (b) 60 μS/cm, 40 ns interval; (c) 180 μS/cm, 60 ns interval. The exposure time of the CH1 image in Figure (a)–(c) is 100 ns, and the exposure time of the CH2-CH4 image is 20 ns. The time marked in the Figure 3 is the time to the start of the high-voltage pulse.

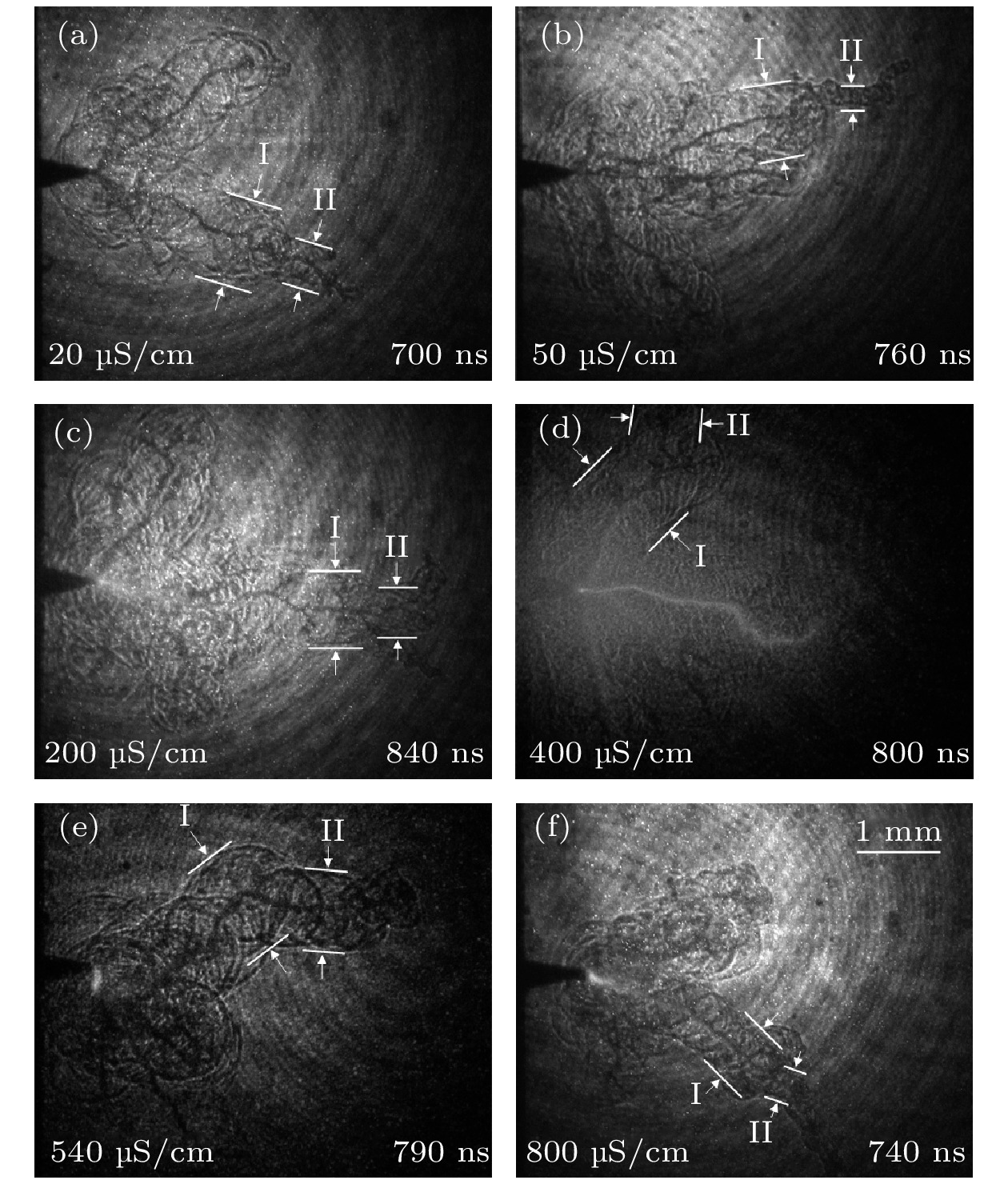

图 4 流光伴生冲击波的分段现象 (a) 20 μS/cm; (b) 50 μS/cm; (c) 200 μS/cm; (d) 400 μS/cm; (e) 540 μS/cm; (f) 800 μS/cm. 图中所标的时间是相对高压脉冲起始点的时间

Fig. 4. The segmentation of shock wave chain: (a) 20 μS/cm; (b) 50 μS/cm; (c) 200 μS/cm; (d) 400 μS/cm; (e) 540 μS/cm; (f) 800 μS/cm. The time marked in the figure is the time to the start of the high-voltage pulse.

-

[1] Fridman G, Friedman G, Gutsol A, Shekhter A B, Vasilets V N, Fridman A 2008 Plasma Processes Polym. 5 503

Google Scholar

Google Scholar

[2] Locke B R, Thagard S M 2012 Plasma Chem. Plasma Process. 32 875

Google Scholar

Google Scholar

[3] Chen Q, Li J S, Li Y F 2015 J. Phys. D: Appl. Phys. 48 424005

Google Scholar

Google Scholar

[4] Sivachandiran L, Khacef A 2017 RSC Adv. 7 1822

Google Scholar

Google Scholar

[5] Saito N, Bratescu M A, Hashimi K 2018 Jpn. J. Appl. Phys. 57 0102A4

Google Scholar

Google Scholar

[6] Bruggeman P J, Kushner M J, Locke B R, Gardeniers J G E, Graham W G, Graves D B, Hofman-Caris R C H M, Maric D, Reid J P, Ceriani E, Fernandez Rivas D, Foster J E, Garrick S C, Gorbanev Y, Hamaguchi S, Iza F, Jablonowski H, Klimova E, Kolb J, Krcma F, Lukes P, Machala Z, Marinov I, Mariotti D, Mededovic Thagard S, Minakata D, Neyts E C, Pawlat J, Lj Petrovic Z, Pflieger R, Reuter S, Schram D C, Schröter S, Shiraiwa M, Tarabová B, Tsai P A, Verlet J R R, von Woedtke T, Wilson K R, Yasui K, Zvereva G 2016 Plasma Sources Sci. Technol. 25 053002

Google Scholar

Google Scholar

[7] Adamovich I, Baalrud S D, Bogaerts A, Bruggeman P J, Cappelli M, Colombo V, Czarnetzki U, Ebert U, Eden J G, Favia P, Graves D B, Hamaguchi S, Hieftje G, Hori M, Kaganovich I D, Kortshagen U, Kushner M J, Mason N J, Mazouffre S, Mededovic Thagard S, Metelmann H R, Mizuno A, Moreau E, Murphy A B, Niemira B A, Oehrlein G S, Petrovic Z L, Pitchford L C, Pu Y K, Rauf S, Sakai O, Samukawa S, Starikovskaia S, Tennyson J, Terashima K, Turner M M, van de Sanden M C M, Vardelle A 2017 J. Phys. D: Appl. Phys. 50 323001

Google Scholar

Google Scholar

[8] Vanraes P, Bogaerts A 2018 Appl. Phys. Rev. 5 031103

Google Scholar

Google Scholar

[9] Joshi R P, Thagard S M 2013 Plasma Chem. Plasma Process. 33 1

Google Scholar

Google Scholar

[10] Sun A, Huo C, Zhuang J 2016 High Voltage 1 74

Google Scholar

Google Scholar

[11] Lesaint O 2016 J. Phys. D: Appl. Phys. 49 144001

Google Scholar

Google Scholar

[12] Salazar J N, Bonifaci N, Denat A, Lesaint O 2005 IEEE International Conference on Dielectric Liquids Coimbra, Portugal, 26 June–1 July, 2005 p91

[13] Ceccato P H, Guaitella O, Gloahec Le M R, Rousseau A 2010 J. Phys. D: Appl. Phys. 43 175202

Google Scholar

Google Scholar

[14] An W, Baumung K, Bluhm H 2007 J. Appl. Phys. 101 053302

Google Scholar

Google Scholar

[15] Katsuki S, Tanaka K, Fudamoto T, Namihira T, Akiyama H, Bluhm H 2006 Jpn. J. Appl. Phys. 45 239

Google Scholar

Google Scholar

[16] Wen X Q, Xue X D 2019 AIP Adv. 9 075310

Google Scholar

Google Scholar

[17] Wen X Q, Xue X D, Liu X H, Li J S, Zhou Y B 2019 J. Appl. Phys. 125 133302

Google Scholar

Google Scholar

[18] Šimek M, Člupek M, Babický V, Lukeš P, Šunka P 2012 Plasma Sources Sci. Technol. 21 055031

Google Scholar

Google Scholar

[19] Bruggeman P, Schram D, Gonzalez M A, Rego R, Kong M G, Leys C 2009 Plasma Sources Sci. Technol. 18 025017

Google Scholar

Google Scholar

[20] https://www.nist.gov/[2021-6-21]

计量

- 文章访问数: 5518

- PDF下载量: 72

- 被引次数: 0

下载:

下载: