-

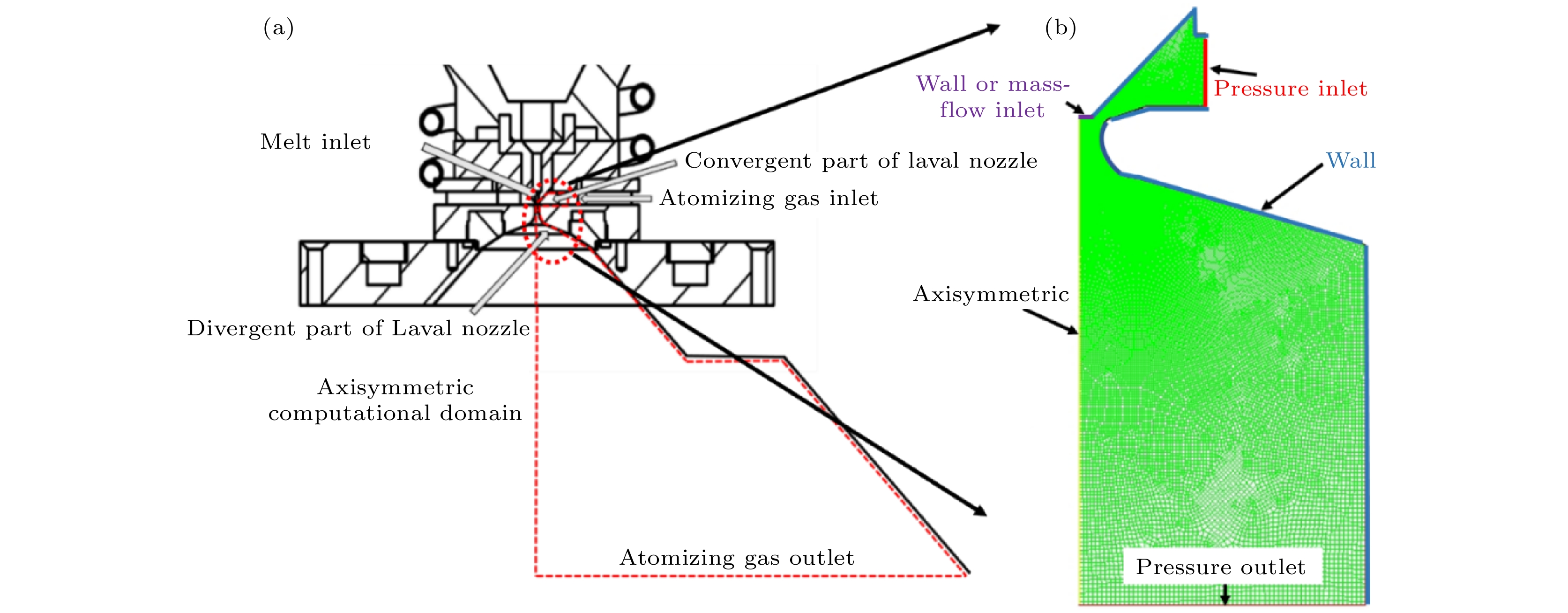

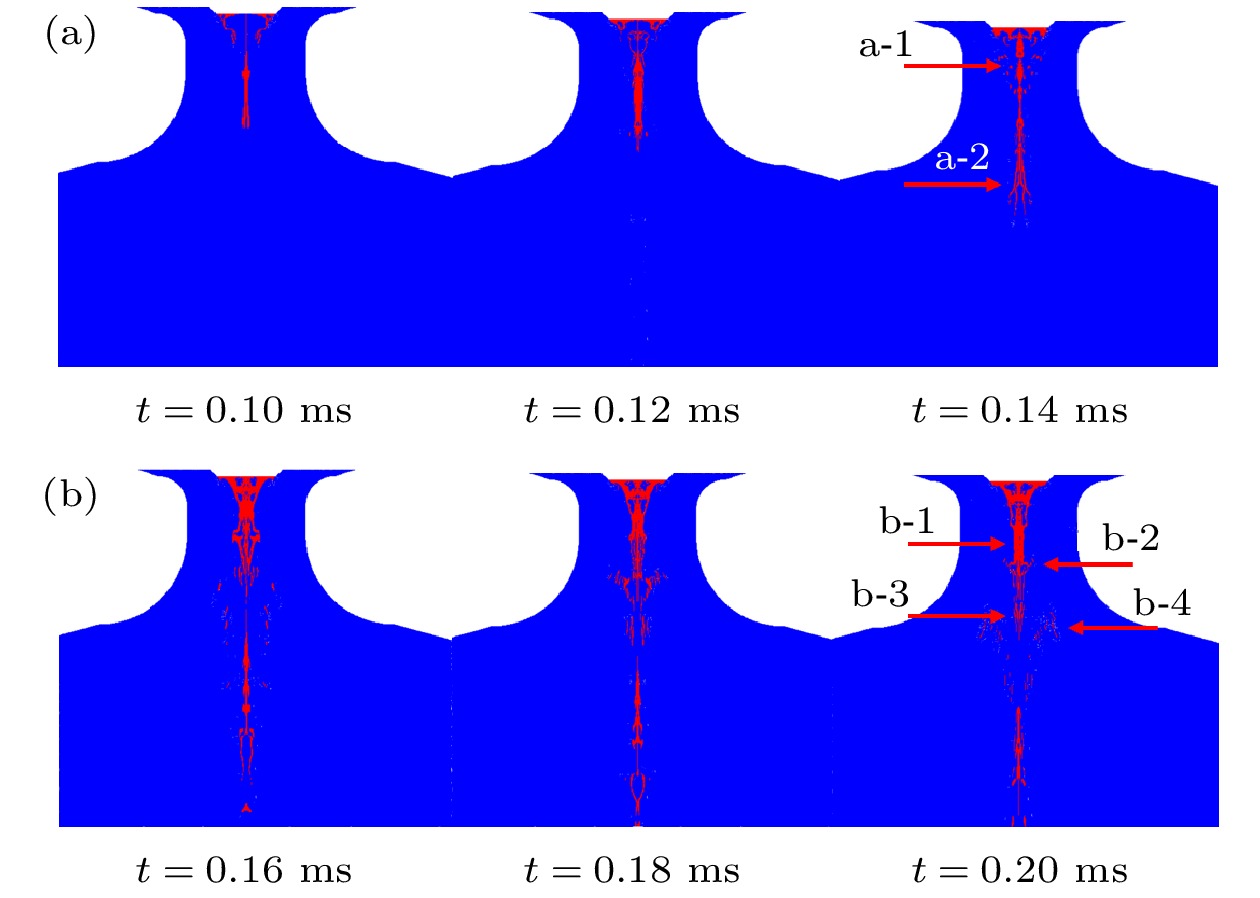

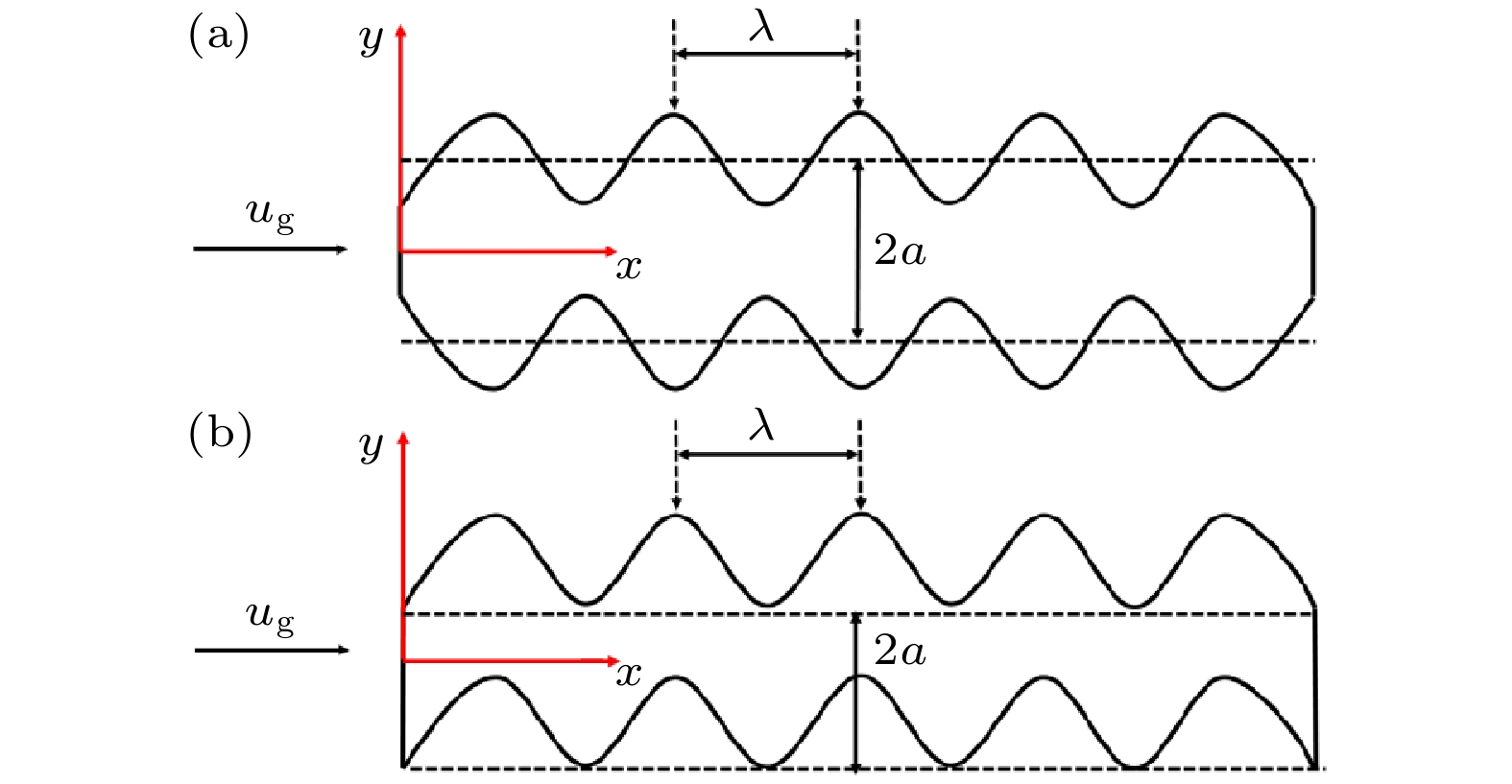

层流气体雾化制备的金属粉末具有粒径较小且粒度分布窄的优点, 目前对层流气体雾化的研究主要集中在工艺参数对雾化效果和粉末特性的影响, 其雾化机理仍不完全清楚. 本文通过数值模拟和实验分析, 系统地研究了层流气体雾化过程中的雾化气体流场、一次雾化和二次雾化机理以及最终的粉末颗粒形态. 采用标准k-ε湍流模型, 研究了基于De Laval喷嘴的层流雾化单相气体流场, 流场呈“项链”状结构, 并伴有斜激波的膨胀波团. 采用耦合水平集-体积分数法研究了一次雾化和二次雾化机理, 并通过雾化实验得到了凝固碎片和粉末, 验证了该模型的有效性, 数值模拟结果也为层流气雾化制粉技术的实际应用和具体工艺提供了重要参考. 研究表明, 液柱周围的熔体主要以细丝或韧带的形式剥离, 这显示出了增压低维度雾化的特点. 二次雾化过程中球形液滴主要基于Rayleigh-Taylor不稳定变形和Sheet-Thinning破碎模式分解破碎, 丝状熔体则主要以曲张波表面发生扰动从而引起波谷处破裂的方式进行破碎.

-

关键词:

- 层流气体雾化 /

- 一次雾化和二次雾化 /

- 耦合水平集-体积分数法 /

- 雾化机理

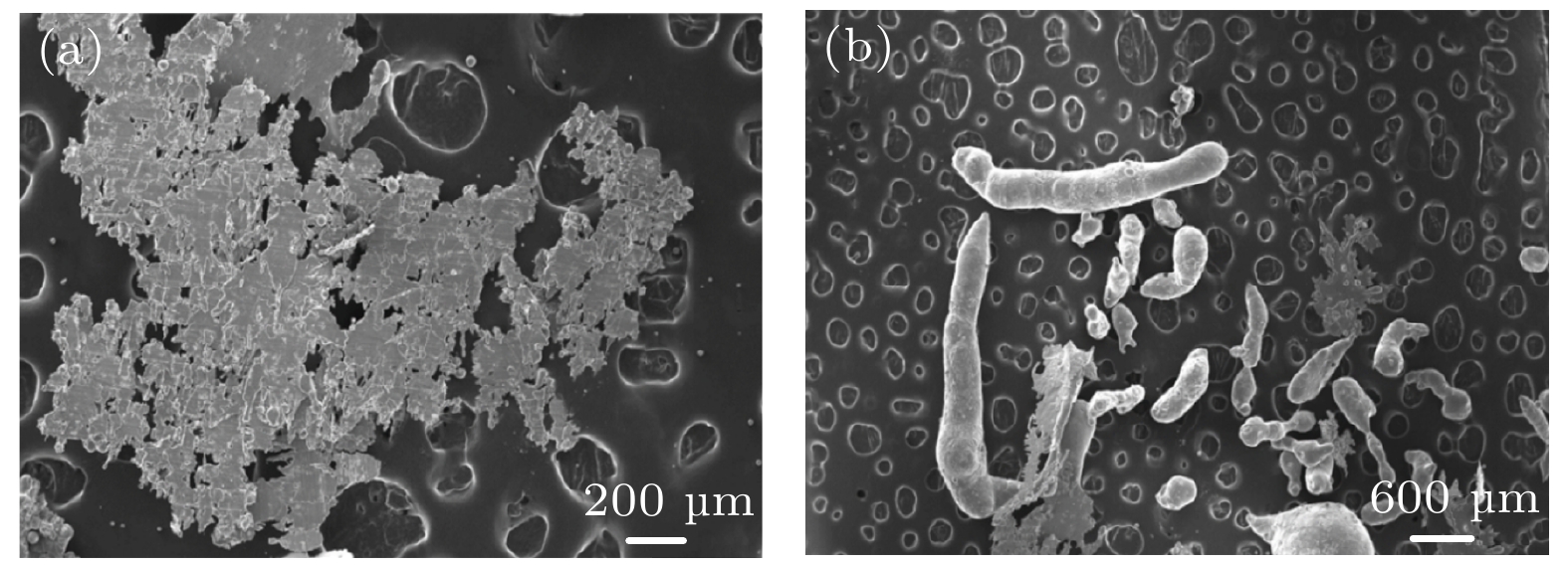

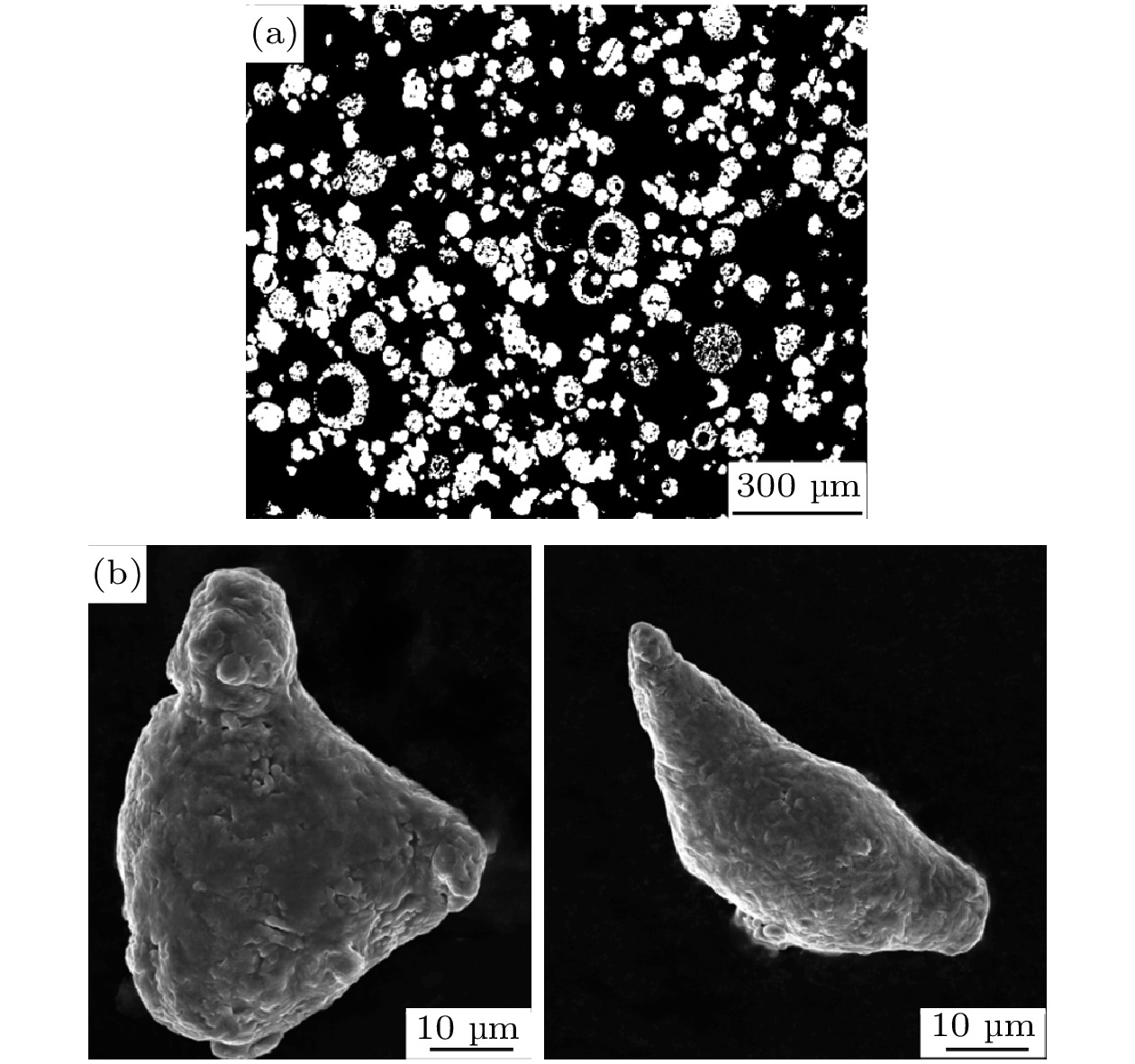

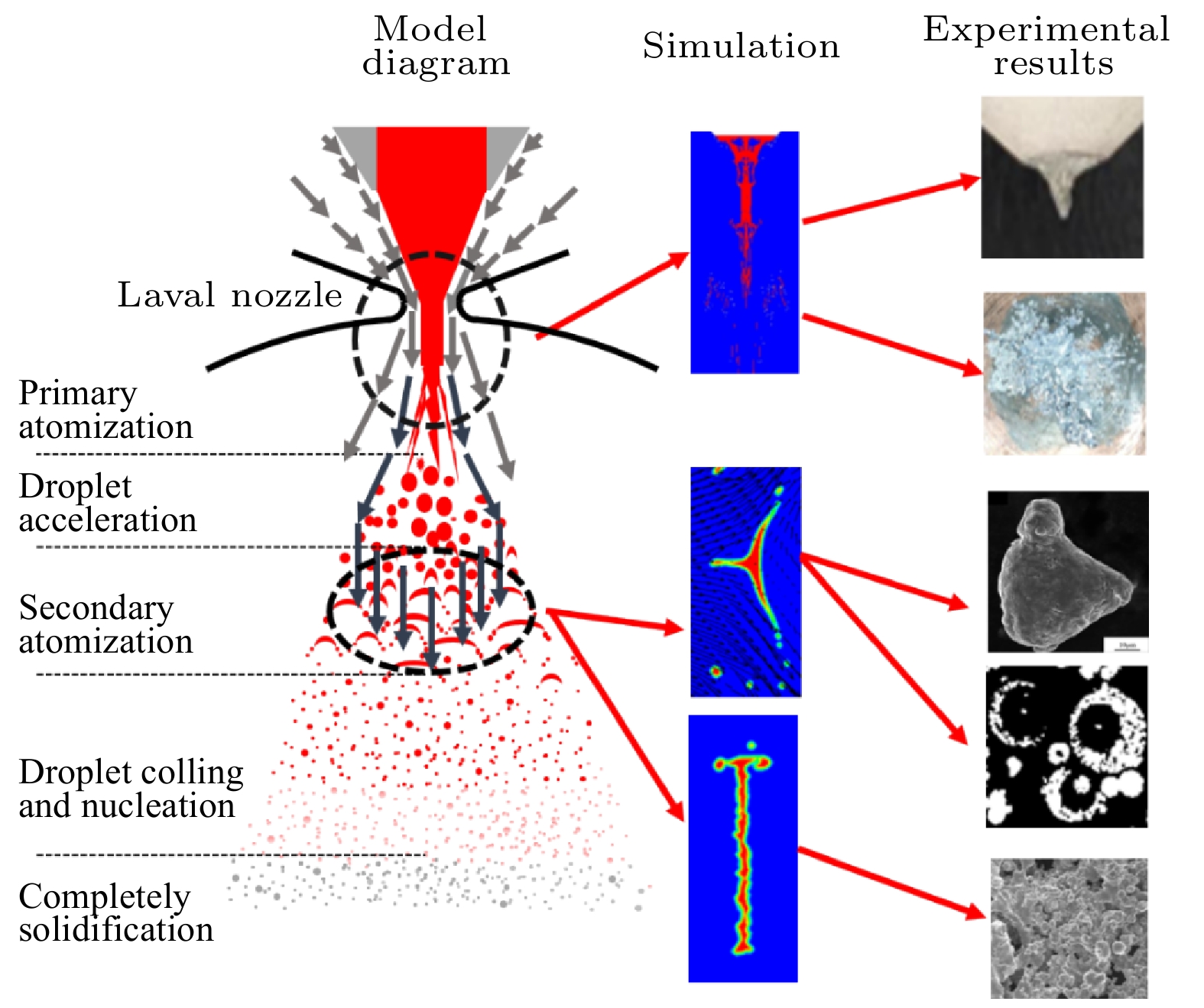

Metal powders prepared by laminar flow gas atomization have the advantages of small particle size and narrow particle size distribution. At present, the research on laminar flow gas atomization mainly focuses on the influence of process parameters on atomization and powder characteristics, but the atomization mechanism of laminar flow gas atomization is still not clear. In this work, the atomization gas flow, primary and secondary breakup mechanism, and particle morphology of the laminar flow gas atomization process are systematically investigated through numerical simulation and experimental analysis. The characteristics of single-phase atomization gas flow through the De Laval nozzle are studied using the standard k-ε turbulence model. The flow field structure shows a “necklace”-like structure with an expansion wave cluster of oblique shock. The primary and secondary atomization mechanism are investigated using the coupled level-set and volume-of-fluid model, which is validated by solidified fragments and powders after the atomization experiment, and results of the numerical simulation also provide some important advices for the application and specific process of laminar gas atomization technology. The studies indicate that the melts at the periphery of the liquid column are mainly peeled off by filaments or ligaments, which exhibits the small dimension and pressurized melt atomization characteristics. The secondary atomization is mainly based on the disintegration of spherical droplets in the mode of Rayleigh-Taylor instability deformation and sheet-thinning breakup. The simulation results also show that increasing the gas pressure and melt superheat can effectively reduce the probability of irregular powders to occur. The AlSi10Mg powders are obtained under a pressure of 2.0 MPa in the experiment on gas atomization, and the properties of the powders are analyzed. The results show that the powders have good sphericity and flowability, and the proportion of hollow powders is very low. In addition, the mean particle size of the AlSi10Mg powders is 54.3 μm, and the yield of fine powders reaches 48.7%, which is greatly improved compared with the traditional gas atomization processes. Moreover, about 90% of the powders have particle sizes in a range of 30–100 μm, which indicates that a narrow particle size distribution can be obtained by the laminar gas atomization technology.-

Keywords:

- laminar flow gas atomization /

- primary and secondary atomization /

- coupled level-set and volume-of-fluid model /

- atomization mechanism

[1] Chen C Y, Xie Y C, Yan X C, Yin S, Fukanuma H, Huang R Z, Zhao R X, Wang J, Ren Z M, Liu M, Liao H L 2019 Addit. Manuf. 27 595

Google Scholar

Google Scholar

[2] Frazier W E 2014 J. Mater. Eng. Perform. 23 1917

Google Scholar

Google Scholar

[3] Gu D D, Meiners W, Wissenbach K, Poprawe R 2012 Int. Mater. Rev. 57 133

Google Scholar

Google Scholar

[4] Jia W M, Chen S Y, Wei M W, Liang J, Liu C S, Li J G 2019 Powder Metall. 62 30

Google Scholar

Google Scholar

[5] Gerling R, Schimansky F P, Wegmann G 2010 Adv. Eng. Mater. 3 387

Google Scholar

Google Scholar

[6] Liu M J, Zhang K J, Zhang Q, Zhang M, Yang G J, Li C X, Li C J 2019 Appl. Surf. Sci. 471 950

Google Scholar

Google Scholar

[7] Balbaa M A, Ghasemi A, Fereiduni E, Elbestawi M A, Jadhav S D, Kruth J P 2020 Addit. Manuf. 10163

Google Scholar

Google Scholar

[8] Baitimerov R, Lykov P, Zherebtsov D, Radionova L, Shultc A, Prashanth K G 2018 Materials (Basel) 11 742

Google Scholar

Google Scholar

[9] Maskery I, Aboulkhair N T, Corfield M R, Tuck C, Clare A T, Leach R K, Wildman R D, Ashcroft I A, Hague R J M 2016 Mater. Charact. 111 193

Google Scholar

Google Scholar

[10] Henein H, Uhlenwinkel V, Fritsching U 2017 Metal Sprays and Spray Deposition (Cham: Springer)pp 49−70

[11] Wei M W, Chen S Y, Sun M, Liang J, Liu C S, Wang M 2020 Powder Technol. 367 724

Google Scholar

Google Scholar

[12] Wei M W, Chen S Y, Liang J, Liu C S 2017 Vacuum 143 185

[13] Park J M, Na T W, Park H K, Yang S M, Kang J W, Lee T W 2019 Mater. Lett. 243 5

Google Scholar

Google Scholar

[14] Li X G, Fritsching U 2017 J. Mater. Process. Technol. 239 1

Google Scholar

Google Scholar

[15] Thompson J S, Hassan O, Rolland S A, Sienz J 2016 Powder Technol. 291 75

Google Scholar

Google Scholar

[16] Planche M P, Khatim O, Dembinski L, Bailly Y, Coddet C 2013 Mater. Chem. Phys. 137 681

Google Scholar

Google Scholar

[17] Schulz G 1996 Met. Powder Rep. 51 30

Google Scholar

Google Scholar

[18] Stobik M 2000 Adv. Eng. Mater. 2 547

[19] Ahmed M, Pasha M, Nan W G, Ghadiri M 2020 Powder Technol. 367 671

Google Scholar

Google Scholar

[20] Yu S S, Zhang P C, Qiu K H, Zhang W T, Li J F, Yao S, Zhou D Y, Yao N N, Li J C 2018 Ferroelectrics 530 25

Google Scholar

Google Scholar

[21] Allimant A, Planche M P, Bailly Y, Dembinski L, Coddet C 2009 Powder Technol. 190 79

Google Scholar

Google Scholar

[22] Khatim O, Planche M P, Dembinski L, Bailly Y, Coddet C 2010 Surf. Coat. Technol. 205 1171

Google Scholar

Google Scholar

[23] Kaiser R, Li C G, Yang S S, Lee D G 2018 Adv. Powder Technol. 29 623

Google Scholar

Google Scholar

[24] Mi J, Figliola R S, Anderson I E 1997 Metall. Mater. Trans. B 28 935

Google Scholar

Google Scholar

[25] Ting J, Anderson I E 2004 Mater. Sci. Eng. A 379 264

Google Scholar

Google Scholar

[26] Xiao F, Dianat M, McGuirk J J 2014 Atomization Sprays 24 281

Google Scholar

Google Scholar

[27] 夏敏, 汪鹏, 张晓虎, 葛昌纯 2018 67 170201

Google Scholar

Google Scholar

Xia M, Wang P, Zhang X H, Ge C C 2018 Acta Phys. Sin. 67 170201

Google Scholar

Google Scholar

[28] 戴剑锋, 樊学萍, 蒙波, 刘骥飞 2015 64 094704

Google Scholar

Google Scholar

Dai J F, Fan X P, Meng B, Liu J F 2015 Acta Phys. Sin. 64 094704

Google Scholar

Google Scholar

[29] Shao C X, Luo K, Yang J S, Chen S, Fan J R 2015 Chin. J. Chem. Eng. 23 597

Google Scholar

Google Scholar

[30] Rabin B H, Swank W D, Wright R N 2013 Nucl. Eng. Des. 262 72

Google Scholar

Google Scholar

[31] Beale J C, Reitz R D 1999 Atomization Sprays 9 623

Google Scholar

Google Scholar

[32] Yang Q, Liu Y T, Liu J, Wang L, Chen Z, Wang M L, Zhong S Y, Wu Y, Wang H W 2019 Mater. Des. 182 108045

Google Scholar

Google Scholar

[33] Sarkar S, Sivaprasad P V, Bakshi S 2016 Atomization Sprays 26 23

Google Scholar

Google Scholar

[34] Markus S, Fritsching U 2006 Int. J. Powder Metall. 42 23

[35] Strotos G, Malgarinos I, Nikolopoulos N, Gavaises M 2016 Int. J. Multiphase Flow 85 96

Google Scholar

Google Scholar

[36] Su Y H, Tsao C Y A 1997 Metall. Mater. Trans. B 28 1249

Google Scholar

Google Scholar

[37] Guildenbecher D R, Lopez R C, Sojka P E 2009 Exp. Fluids 46 371

Google Scholar

Google Scholar

[38] Guildenbecher D R, Lopez R C, Sojka P E 2011 Handbook of Atomization and Sprays: Theory and Applications (Boston: Springer US) pp145−156

[39] Pilch M, Erdman C A 1987 Int. J. Multiphase Flow 13 741

Google Scholar

Google Scholar

[40] Ashgriz N, Li X, Sarchami A 2011 Handbook of Atomization and Sprays: Instability of Liquid Sheets (Boston: Springer US) pp75−95

[41] Chuech S G 2006 Int. J. Numer. Methods Fluids 50 1461

Google Scholar

Google Scholar

[42] Dai Z, Faeth G M 2001 Int. J. Multiphase Flow 27 217

Google Scholar

Google Scholar

[43] Yang W, Jia M, Sun K, Wang T Y 2016 Fuel 174 25

Google Scholar

Google Scholar

[44] 舒适 2018 硕士学位论文 (北京: 有色金属研究总院)

Shu S 2018 M. S. Thesis (Beijing: General Research Institute for Nonferrous Metals) (in Chinese)

-

表 1 单相流模型的模拟参数

Table 1. Simulation parameters of the single-phase flow model.

参数 数值 入口压力/MPa 1.0 1.5 2.0 2.5 3.0 出口压力/MPa 0.1 表 2 数值模拟中使用的AlSi10Mg合金和氩气的特性参数[30]

Table 2. Properties of AlSi10Mg alloy and argon used for numerical simulation[30].

材料 参数 数值 AlSi10Mg 比热容/(J·kg–1·K–1) 871 密度/(kg·m–3) 2719 黏度/(kg·m–1·s–1) 0.0135 导热系数/(W·m–1·K–1) 202.4 表面张力/(N·m–1) 0.854 Ar 比热容/(J·kg–1·K–1) 520.64 导热系数/(W·m–1·K–1) 0.0158 黏度/(kg·m–1·s–1) 2.125 × 10–5 表 3 一次雾化模拟参数

Table 3. Simulation parameters of primary atomization.

参数 数值 入口压力/MPa 2.0 出口压力/MPa 0.1 质量流量/(g·s–1) 20 熔体初始温度/K 1073 表 4 二次雾化的数值模拟参数

Table 4. Parameters for numerical simulation of the secondary breakup.

参数 数值 入口速度/(m·s–1) 400 液滴直径/μm 1000 丝状熔体尺寸/μm φ50 × 500 表 A1 文中所用参数

Table A1. Parameters in the article.

${{\rho } }_{\rm{g} }$ 气体密度 t 时间 ${{u} }_{{i} }$ $ {x}_{i} $方向上的速度分量 ${{u} }_{{j} }$ $ {x}_{j} $方向上的速度分量 ${{\mu } }$ 动力黏度 ${{\tau } }_{{ij} }$ 雷诺应力张量 ${{S} }_{{i} }$ 动量守恒方程的广义源项 ${{S} }_{\rm{T} }$ 粘性耗散函数 T 温度 K 热导率 k 湍流动能 ${{\varepsilon } }$ 湍流动能耗散率 ${{G} }_{{k} }$ 平均速度梯度引起的湍流动能k ${{G} }_{\rm{b} }$ 浮力产生湍流动能k ${{Y} }_{\rm{M} }$ 可压缩湍流中脉动膨胀 ${\mu }_{{t} }$ 湍流黏度 ${{S} }_{{k} }$, ${{S} }_{{\varepsilon } }$ 源项 v 速度矢量 P 压力 ${{\tau } }$ 粘性应力张量 ${{\sigma } }$ 表面张力 $ \alpha $ 体积相分数 g 重力加速度 ${{F} }_{\sigma }$ 体积表面张力 ${{F} }_{\rm{D} }$ 阻力 ${{A} }_{\rm{d} }$ 液滴最大截面积 ${{p} }_{\rm{dg} }$ 气体作用在液滴上的压力 ${{u} }_{\rm{g} }$ 气流速度 ${{u} }_{\rm{d} }$ 液滴速度 ${{\mu } }_{\rm{g} }$ 气体黏性系数 ${{C} }_{\rm{D} }$ 阻力系数 d 特征长度 ${{\rho } }_{\rm{d} }$ 液滴密度 ${{V} }_{\rm{d} }$ 液滴体积 ${{Re} }$ 雷诺数 u 特征速度 ${{We} }$ 韦伯数 -

[1] Chen C Y, Xie Y C, Yan X C, Yin S, Fukanuma H, Huang R Z, Zhao R X, Wang J, Ren Z M, Liu M, Liao H L 2019 Addit. Manuf. 27 595

Google Scholar

Google Scholar

[2] Frazier W E 2014 J. Mater. Eng. Perform. 23 1917

Google Scholar

Google Scholar

[3] Gu D D, Meiners W, Wissenbach K, Poprawe R 2012 Int. Mater. Rev. 57 133

Google Scholar

Google Scholar

[4] Jia W M, Chen S Y, Wei M W, Liang J, Liu C S, Li J G 2019 Powder Metall. 62 30

Google Scholar

Google Scholar

[5] Gerling R, Schimansky F P, Wegmann G 2010 Adv. Eng. Mater. 3 387

Google Scholar

Google Scholar

[6] Liu M J, Zhang K J, Zhang Q, Zhang M, Yang G J, Li C X, Li C J 2019 Appl. Surf. Sci. 471 950

Google Scholar

Google Scholar

[7] Balbaa M A, Ghasemi A, Fereiduni E, Elbestawi M A, Jadhav S D, Kruth J P 2020 Addit. Manuf. 10163

Google Scholar

Google Scholar

[8] Baitimerov R, Lykov P, Zherebtsov D, Radionova L, Shultc A, Prashanth K G 2018 Materials (Basel) 11 742

Google Scholar

Google Scholar

[9] Maskery I, Aboulkhair N T, Corfield M R, Tuck C, Clare A T, Leach R K, Wildman R D, Ashcroft I A, Hague R J M 2016 Mater. Charact. 111 193

Google Scholar

Google Scholar

[10] Henein H, Uhlenwinkel V, Fritsching U 2017 Metal Sprays and Spray Deposition (Cham: Springer)pp 49−70

[11] Wei M W, Chen S Y, Sun M, Liang J, Liu C S, Wang M 2020 Powder Technol. 367 724

Google Scholar

Google Scholar

[12] Wei M W, Chen S Y, Liang J, Liu C S 2017 Vacuum 143 185

[13] Park J M, Na T W, Park H K, Yang S M, Kang J W, Lee T W 2019 Mater. Lett. 243 5

Google Scholar

Google Scholar

[14] Li X G, Fritsching U 2017 J. Mater. Process. Technol. 239 1

Google Scholar

Google Scholar

[15] Thompson J S, Hassan O, Rolland S A, Sienz J 2016 Powder Technol. 291 75

Google Scholar

Google Scholar

[16] Planche M P, Khatim O, Dembinski L, Bailly Y, Coddet C 2013 Mater. Chem. Phys. 137 681

Google Scholar

Google Scholar

[17] Schulz G 1996 Met. Powder Rep. 51 30

Google Scholar

Google Scholar

[18] Stobik M 2000 Adv. Eng. Mater. 2 547

[19] Ahmed M, Pasha M, Nan W G, Ghadiri M 2020 Powder Technol. 367 671

Google Scholar

Google Scholar

[20] Yu S S, Zhang P C, Qiu K H, Zhang W T, Li J F, Yao S, Zhou D Y, Yao N N, Li J C 2018 Ferroelectrics 530 25

Google Scholar

Google Scholar

[21] Allimant A, Planche M P, Bailly Y, Dembinski L, Coddet C 2009 Powder Technol. 190 79

Google Scholar

Google Scholar

[22] Khatim O, Planche M P, Dembinski L, Bailly Y, Coddet C 2010 Surf. Coat. Technol. 205 1171

Google Scholar

Google Scholar

[23] Kaiser R, Li C G, Yang S S, Lee D G 2018 Adv. Powder Technol. 29 623

Google Scholar

Google Scholar

[24] Mi J, Figliola R S, Anderson I E 1997 Metall. Mater. Trans. B 28 935

Google Scholar

Google Scholar

[25] Ting J, Anderson I E 2004 Mater. Sci. Eng. A 379 264

Google Scholar

Google Scholar

[26] Xiao F, Dianat M, McGuirk J J 2014 Atomization Sprays 24 281

Google Scholar

Google Scholar

[27] 夏敏, 汪鹏, 张晓虎, 葛昌纯 2018 67 170201

Google Scholar

Google Scholar

Xia M, Wang P, Zhang X H, Ge C C 2018 Acta Phys. Sin. 67 170201

Google Scholar

Google Scholar

[28] 戴剑锋, 樊学萍, 蒙波, 刘骥飞 2015 64 094704

Google Scholar

Google Scholar

Dai J F, Fan X P, Meng B, Liu J F 2015 Acta Phys. Sin. 64 094704

Google Scholar

Google Scholar

[29] Shao C X, Luo K, Yang J S, Chen S, Fan J R 2015 Chin. J. Chem. Eng. 23 597

Google Scholar

Google Scholar

[30] Rabin B H, Swank W D, Wright R N 2013 Nucl. Eng. Des. 262 72

Google Scholar

Google Scholar

[31] Beale J C, Reitz R D 1999 Atomization Sprays 9 623

Google Scholar

Google Scholar

[32] Yang Q, Liu Y T, Liu J, Wang L, Chen Z, Wang M L, Zhong S Y, Wu Y, Wang H W 2019 Mater. Des. 182 108045

Google Scholar

Google Scholar

[33] Sarkar S, Sivaprasad P V, Bakshi S 2016 Atomization Sprays 26 23

Google Scholar

Google Scholar

[34] Markus S, Fritsching U 2006 Int. J. Powder Metall. 42 23

[35] Strotos G, Malgarinos I, Nikolopoulos N, Gavaises M 2016 Int. J. Multiphase Flow 85 96

Google Scholar

Google Scholar

[36] Su Y H, Tsao C Y A 1997 Metall. Mater. Trans. B 28 1249

Google Scholar

Google Scholar

[37] Guildenbecher D R, Lopez R C, Sojka P E 2009 Exp. Fluids 46 371

Google Scholar

Google Scholar

[38] Guildenbecher D R, Lopez R C, Sojka P E 2011 Handbook of Atomization and Sprays: Theory and Applications (Boston: Springer US) pp145−156

[39] Pilch M, Erdman C A 1987 Int. J. Multiphase Flow 13 741

Google Scholar

Google Scholar

[40] Ashgriz N, Li X, Sarchami A 2011 Handbook of Atomization and Sprays: Instability of Liquid Sheets (Boston: Springer US) pp75−95

[41] Chuech S G 2006 Int. J. Numer. Methods Fluids 50 1461

Google Scholar

Google Scholar

[42] Dai Z, Faeth G M 2001 Int. J. Multiphase Flow 27 217

Google Scholar

Google Scholar

[43] Yang W, Jia M, Sun K, Wang T Y 2016 Fuel 174 25

Google Scholar

Google Scholar

[44] 舒适 2018 硕士学位论文 (北京: 有色金属研究总院)

Shu S 2018 M. S. Thesis (Beijing: General Research Institute for Nonferrous Metals) (in Chinese)

计量

- 文章访问数: 11788

- PDF下载量: 272

- 被引次数: 0

下载:

下载: