-

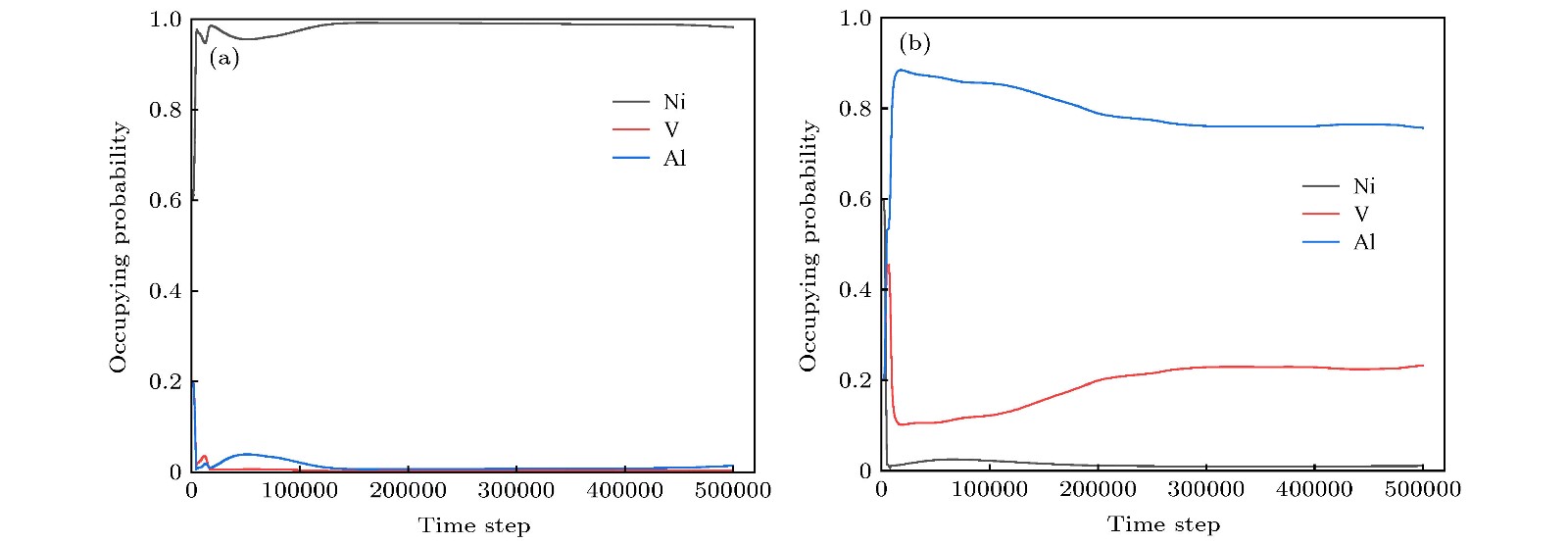

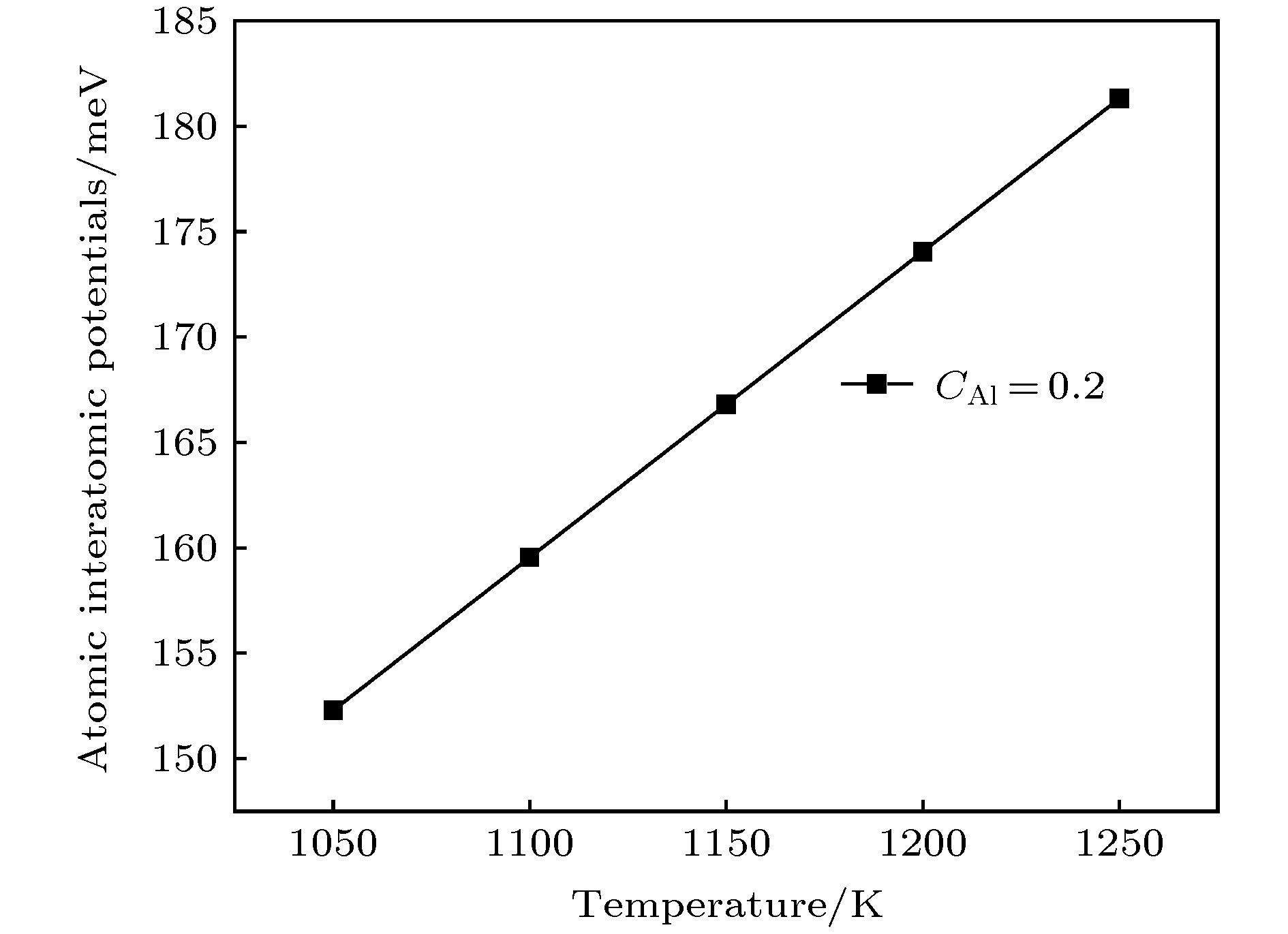

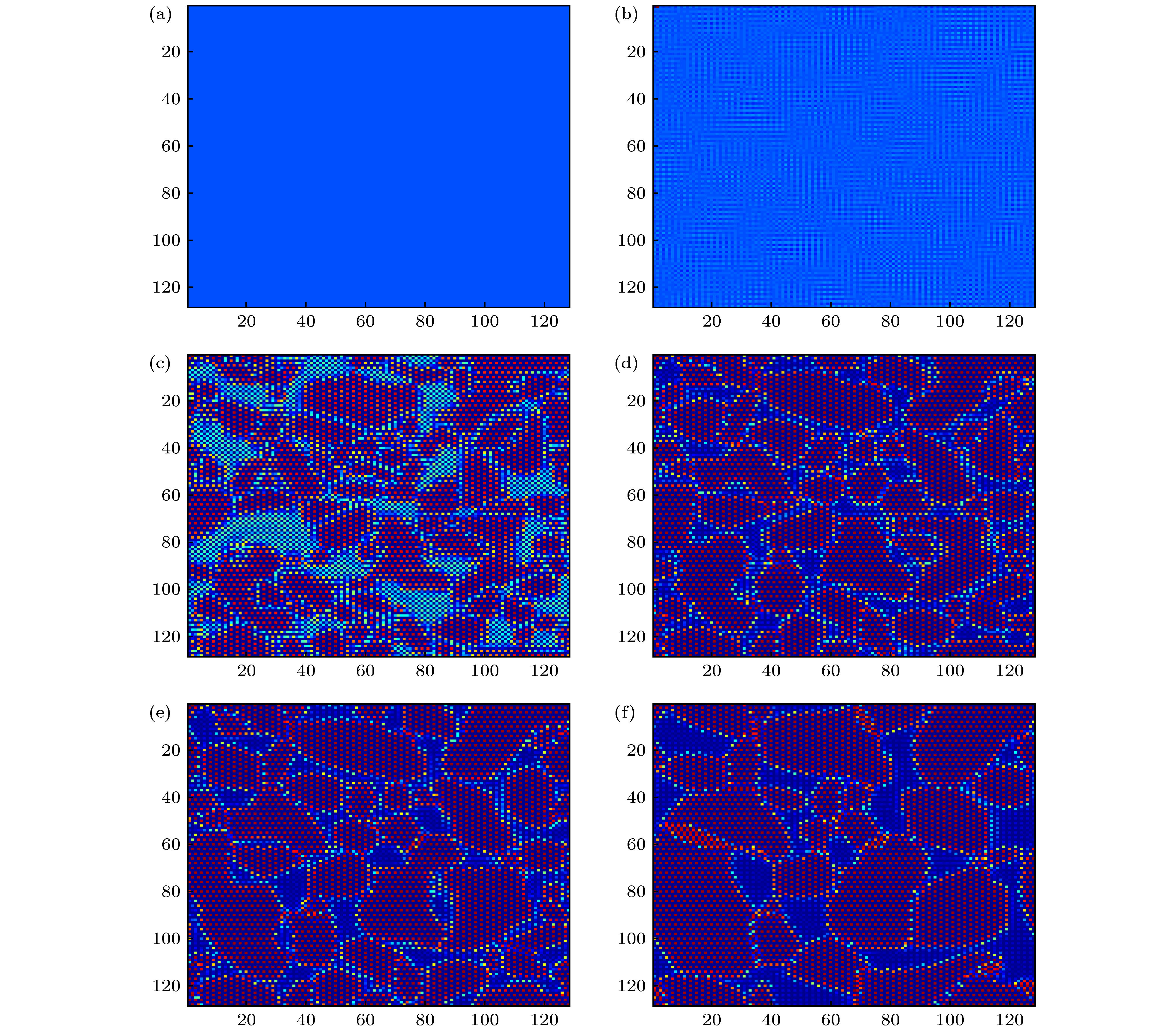

纳米级L12结构的γ′有序相形态、析出过程和原子排布等对镍基中熵合金强化具有重要作用. 本文采用微扩散相场动力学模型探究Ni60Al20V20中熵合金沉淀过程微观机理, 以原子占据晶格位置的几率为场变量描述微结构变化, 结合反演算法, 通过分析γ′相和θ相原子图像演化, 序参数变化, 体积分数变化等, 探讨了γ′(Ni3Al)和θ(DO22)有序相的沉淀机制. 研究结果表明: Ni60Al20V20中熵合金无序相有序化动力学过程中, L10相和DO22相同时析出, L10相逐渐转变为L12-γ′相, 而传统Ni75Al7.5V17.5合金沉淀序列是先析出L10相, L10转变为L12相后, DO22相在L12相的反相畴界处析出. L10向L12转变时, 面心立方晶格α位被Ni原子占据, β位被Al原子和V共同占据. 原子等成分有序化形成DO22结构θ单相有序畴, 随后失稳分解; L10结构非经典形核, 逐渐转化为L12-γ′相并失稳分解. Ni-Al第一近邻原子间相互作用势随温度线性升高, 随长程序参数增加逐渐增加; Ni60Al20V20中熵合金孕育期随温度升高而时间变长. 本文研究适用于Ni-Al-V中熵合金设计.

-

关键词:

- 微扩散相场法 /

- Ni60Al20V20中熵合金 /

- 有序相沉淀机制 /

- 第一近邻原子作用势

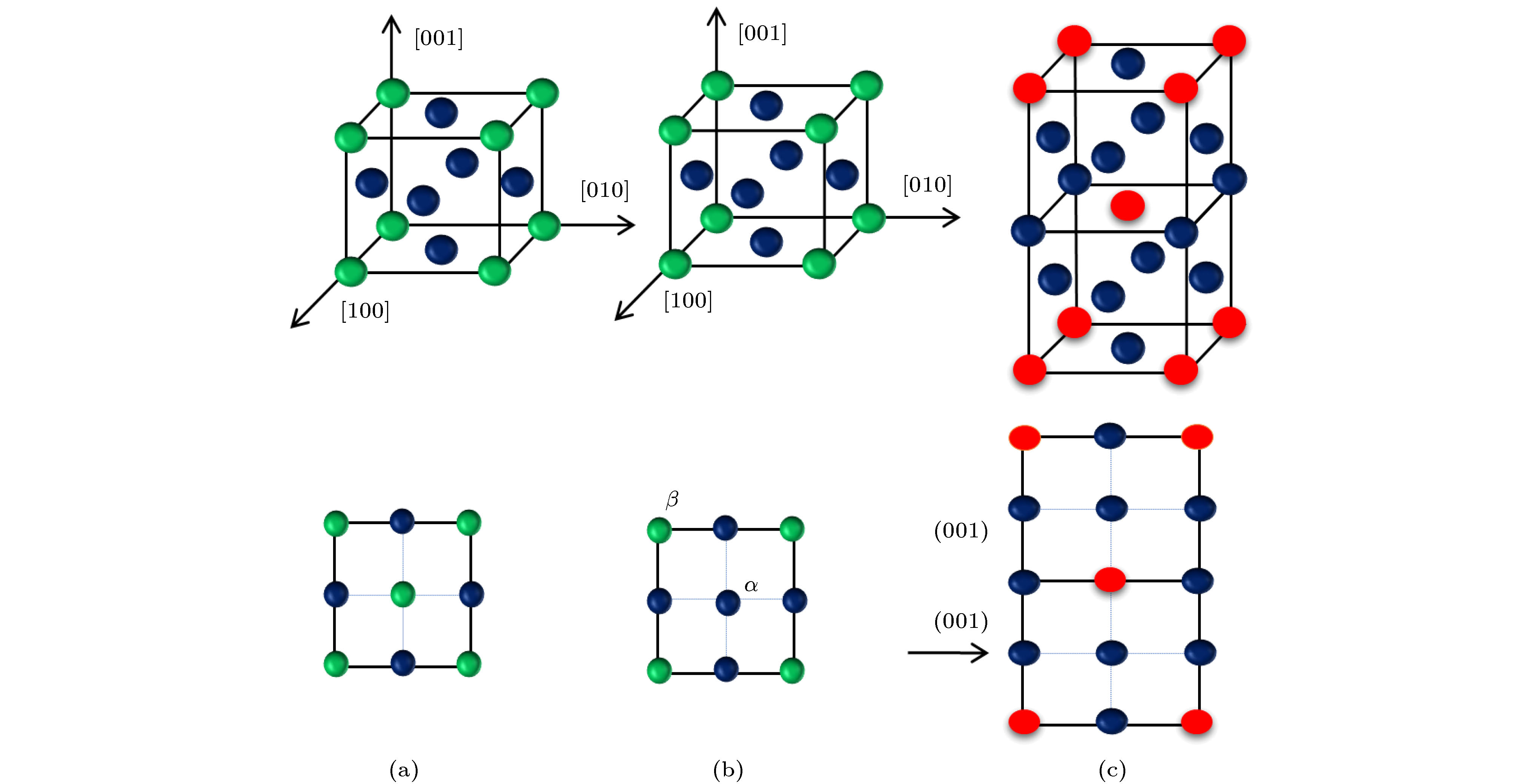

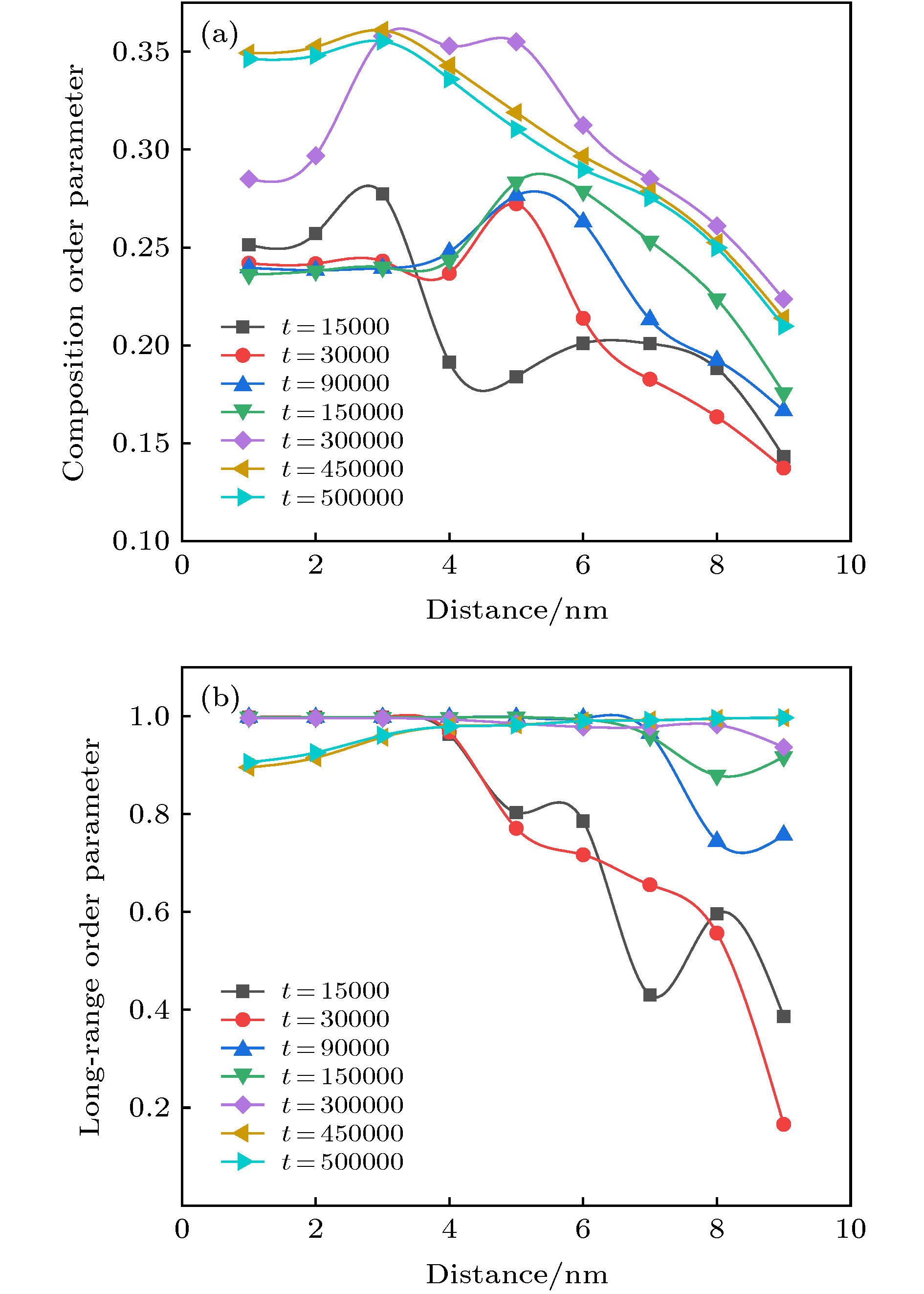

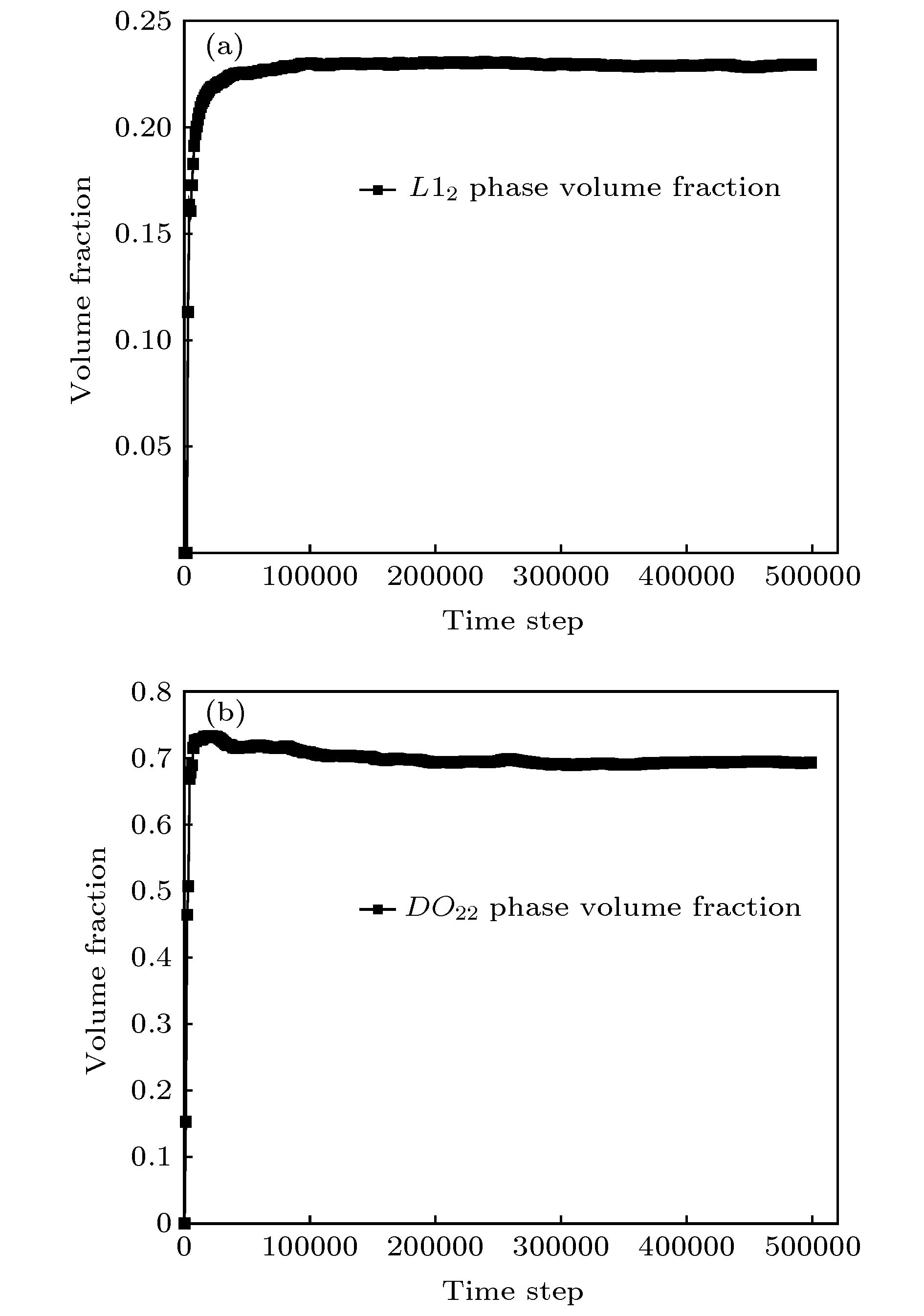

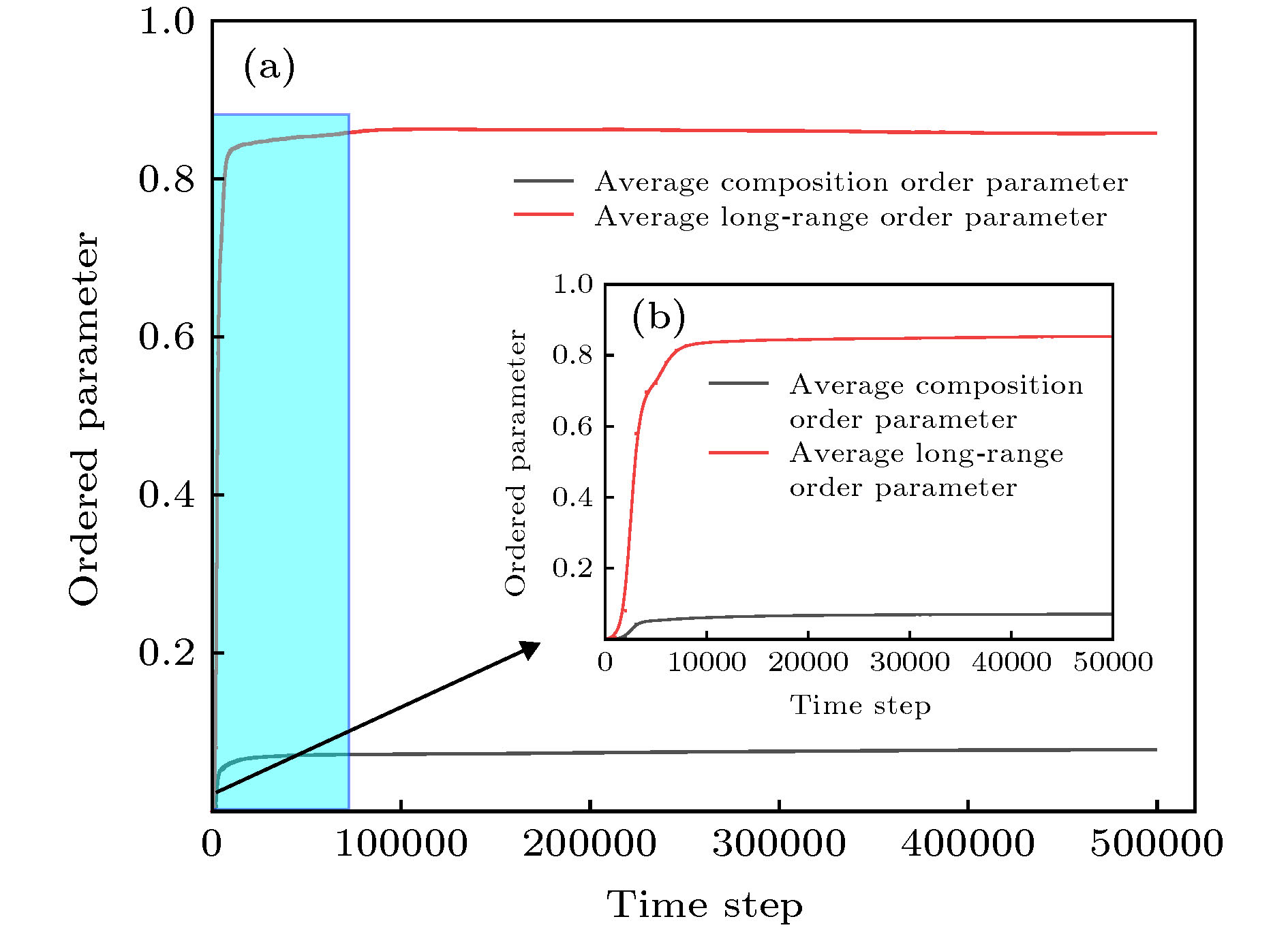

Medium entropy alloys have attracted much attention because of their excellent physical and chemical properties. Nano-scaled L12 structure ordered phase plays an important role in strengthening the mechanical properties of medium entropy alloys, and its local atomic arrangement plays a decisive role in yield strength of medium entropy alloys. In this paper, the microscopic mechanism of the precipitation process of Ni60Al20V20 medium entropy alloy is studied by using the micro diffusion phase field dynamics model, in which the probability of atoms to occupy the lattice position is taken as a field variable to describe the configuration of atoms and the morphology of precipitates. In this model, the shape and concentration of precipitate phase, the position and appearance of new phase cannot be set in advance. Combined with the inversion algorithm, the precipitation mechanism of ordered phases of γ' (L12-Ni3Al) and θ (DO22-Ni3V) is discussed by analyzing the evolution of atomic images, the change of order parameters and volume fraction. The result shows that two kinds of ordered phases are precipitated in the kinetical process of disordered phase ordering into Ni60Al20V20 medium entropy alloys, which are of$ {\gamma }' $ phase with L12 structure and of$ \theta $ phase with DO22 structure.The two ordered phases constitute a pseudo binary system. The L10 phase precipitates at the same time as DO22, and the L10 phase gradually transforms into the L12-γ′ phase, while the traditional Ni75Al7.5V17.5 alloy first precipitates L10 phase, and then the DO22 phase precipitates at the boundary of anti-phase domain of L12 phase. In the transition from L10 to L12, α position of fcc lattice is occupied by Ni atom, and the β position is occupied by Al atom and V atom. The congruent ordering of atoms results in the formation of θ single-phase ordered domain of DO22 structure, followed by spinodal decomposition; the non-classical nucleation of L10 structure gradually transforms into L12-γ′ phase and spinodal decomposition. The interaction potential between the first-nearest-neighbor atoms of Ni-Al increases linearly with temperature, and increases gradually with the increase of long range order parameters. The incubation period of Ni60Al20V20 medium entropy alloy lengthens with temperature increasing. This study can be applied to the design of Ni-Al-V medium entropy alloy.-

Keywords:

- microscopic phase-field model /

- Ni60Al20V20 medium entropy alloy /

- ordered phase precipitation mechanism /

- first neighbor interatomic potential

[1] Pickering E J, Jones N G 2016 Int. Mater. Rev. 61 183

Google Scholar

Google Scholar

[2] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[3] Yeh J W, Chang S Y, Hong Y D, Chen S K, Lin S J 2007 Mater. Chem. Phys. 103 41

Google Scholar

Google Scholar

[4] Gludovatz B, Hohenwarter A, Thurston K V, Bei H B, Wu Z G, George E P, Ritchie R O 2016 Nat. Commun. 7 10602

Google Scholar

Google Scholar

[5] Zhao Y H, Wang S, Zhang B, Yuan Y, Guo Q W, Hou H 2019 J. Solid State Chem. 276 232

Google Scholar

Google Scholar

[6] Chen J, Zhou X Y, Wang W L, Liu B, Lv Y K, Yang W, Xu D P, Liu Y 2018 J. Alloys Compd. 760 15

Google Scholar

Google Scholar

[7] Agustuaningum M P, Ondicho I, Jodi D E, Park N, Lee U 2019 Mater. Sci. Eng., A 759 633

Google Scholar

Google Scholar

[8] Jodi D E, Park J, Park N 2019 Mater. Charact. 157 109888

Google Scholar

Google Scholar

[9] Agustuaningum M P, Yoshid S, Tsuji N, Park N 2019 J. Alloys Compd. 781 866

Google Scholar

Google Scholar

[10] Zhao Y L, Yang T, Tong Y, Wang J, Luan J H, Jiao Z B, Chen D, Yang Y, Hu A, Liu C T, Kai J J 2017 Acta. Mater. 138 72

Google Scholar

Google Scholar

[11] Yang K, Wang Y X, Dong W Q, Chen Z, Zhang M Y 2011 Rare Met. Mater. Eng. 40 1605

[12] 吴静, 刘永长, 李冲, 伍宇婷, 夏兴川, 李会军 2020 金属学报 56 21

Google Scholar

Google Scholar

Wu J, Liu Y C, Li C, Wu Y T, Xia X C, Li H J 2020 Acta Metall. Sin. 56 21

Google Scholar

Google Scholar

[13] Sun Y Y, Zhao Y H, Zhao B J, Yang W K, Li X L, Hou H 2019 J. Mater. Sci. 54 11263

Google Scholar

Google Scholar

[14] Kuang W W, Wang H F, Li X, Zhang J B, Zhou Q, Zhao Y H 2018 Acta. Mater. 159 16

Google Scholar

Google Scholar

[15] Zhang J B, Wang H F, Kuang W W, Zhang Y C, Li S, Zhao Y H, Herlach D M 2018 Acta. Mater. 148 86

Google Scholar

Google Scholar

[16] Zhao Y H, Zhang B, Hou H, Chen W P, Wang M 2019 J. mater. Sci. Technol. 35 1044

Google Scholar

Google Scholar

[17] Mushongera L T, Amos P G K, School E, Kumar P 2020 J. Mater. Sci. 55 5280

Google Scholar

Google Scholar

[18] Xia B H, Mei C L, Yu Q, Li Y B 2020 Comput. Method. Appl. Mech. Eng. 363 112795

Google Scholar

Google Scholar

[19] Guo H J, Zhao Y H, Sun Y Y, Tian J Z, Hou H, Qi K W, Tian X L 2019 Superlattices Microstruct. 129 163

Google Scholar

Google Scholar

[20] Chen L Q 2002 Annu. Rev. Mater. Res. 32 113

Google Scholar

Google Scholar

[21] Zhao Y H, Tian X L, Zhao B J, Sun Y Y, Guo H J, Dong M, Liu H, Wang X, Guo Z, Umar A, Hou H 2018 Sci. Adv. Mater. 1012 1793

Google Scholar

Google Scholar

[22] Vogel F, Wanderka N, Balogh Z, Ibrahim M, Stender P, Schmitz G, Banhart J 2015 Ultramicroscopy 159 278

Google Scholar

Google Scholar

[23] Vogel F, Wanderka N, Balogh Z, Ibrahim M, Stender P, Schmitz G, Banhart J 2013 Nat. Commun. 4 2955

Google Scholar

Google Scholar

[24] Hou H, Zhao Y H, Zhao Y H 2009 Mat. Sci. Eng. A. 499 204

Google Scholar

Google Scholar

[25] Wang K, Wang Y X 2020 J. Alloys Compd 824 153923

Google Scholar

Google Scholar

[26] 赵宇宏, 侯华, 任娟娜 2012 中南大学学报 8 81

Zhao Y H, Hou H, Ren J N 2012 J. Cent. South Univ. 8 81

[27] 田晓林, 赵宇宏, 田晋忠, 侯华 2018 67 230201

Google Scholar

Google Scholar

Tian X L, Zhao Y H, Tian J Z, Hou H 2018 Acta Phys. Sin. 67 230201

Google Scholar

Google Scholar

[28] 马庆爽, 靳玉春, 赵宇宏, 侯华, 王欣然, 王锟 2015 中国有色金属学报 25 1450

Google Scholar

Google Scholar

Ma Q S, Jin Y C, Zhao Y H, Hou H, Wang X R, Wang K 2015 Chin. J. Nonferrous Met. 25 1450

Google Scholar

Google Scholar

[29] Zhang M Y, Liu F, Chen Z, Guo H J, Yue G Q, Yang K 2012 T. Nonferr. Metal. Soc. 22 2439

Google Scholar

Google Scholar

[30] 张静, 陈铮, 王永欣, 童立甲 2015 中国科技论文 10 189

Zhang J, Chen Z, Wang Y X, Tong L J 2015 China Sciencepaper 10 189

[31] 杨坤, 吉楠, 沙婷, 杨放, 王海涛, 陈铮 2017 稀有金属材料与工程 07 125

Yang K, Ji N, Sha T, Yang F, Wang H T, Chen Z 2017 Rare Metal Mat. Eng. 07 125

[32] Cahn J W, Hilliard J E 1958 Acta Mater. 6 772

Google Scholar

Google Scholar

[33] Cahn J W, Hilliard J E 1959 Acta Mater. 7 219

Google Scholar

Google Scholar

[34] Khachaturyan A G 1983 Theory of Structural Trans-formations in Solids (New York: Wiley) pp131–156

[35] Chen L Q, Khachaturyan A G 1991 Scr. Metall. Mater. 25 67

Google Scholar

Google Scholar

[36] Poduri R, Chen L Q 1998 Acta Mater. 44 4253

Google Scholar

Google Scholar

[37] Zhao Y, Zhou Y J, Lin J P, Chen G L, Liaw P K 2008 Adv. Eng. Mater. 10 534

Google Scholar

Google Scholar

[38] Wendt H, Haasen P 1983 Acta Metall. 31 1649

Google Scholar

Google Scholar

[39] Jackson M P, Starink M J, Reed R C 1999 Mater. Sci. Eng., A 264 26

Google Scholar

Google Scholar

[40] Onaka S, Kobayashi N, Fujii T, Kato M 2002 Int. J. Plast. 10 343

Google Scholar

Google Scholar

[41] Zhang Y, Chen Z, Cao D D, Zhang J Y, Zhang P, Tao Q, Yang X Q 2019 J. Mater. Res. Technol. 8 726

Google Scholar

Google Scholar

[42] Wang Y W, Shang S L, Wang Y, Han F B, Darling K A, Wu Y D, Xie X, Senkov O N, Li J S, Hui X D, Dahmen K A, Liaw P K, Kecskes L J, Liu Z K 2017 Npj. Comput. Mater. 3 23

Google Scholar

Google Scholar

[43] Jodi A E, Park N 2019 Mater. Lett. 255 126528

Google Scholar

Google Scholar

-

图 1 1050 K时Ni60Al20V20中熵合金沉淀过程中的原子演化形貌 (a) t = 1000; (b) t = 3000; (c) t = 9000; (d) t = 40000; (e) t = 80000; (f) t = 500000

Fig. 1. Atomic evolution morphology of Ni60Al20V20 middle entropy alloy during precipitation at 1050 K: (a) t = 1000; (b) t = 3000; (c) t = 9000; (d) t = 40000; (e) t = 80000; (f) t = 500000

-

[1] Pickering E J, Jones N G 2016 Int. Mater. Rev. 61 183

Google Scholar

Google Scholar

[2] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[3] Yeh J W, Chang S Y, Hong Y D, Chen S K, Lin S J 2007 Mater. Chem. Phys. 103 41

Google Scholar

Google Scholar

[4] Gludovatz B, Hohenwarter A, Thurston K V, Bei H B, Wu Z G, George E P, Ritchie R O 2016 Nat. Commun. 7 10602

Google Scholar

Google Scholar

[5] Zhao Y H, Wang S, Zhang B, Yuan Y, Guo Q W, Hou H 2019 J. Solid State Chem. 276 232

Google Scholar

Google Scholar

[6] Chen J, Zhou X Y, Wang W L, Liu B, Lv Y K, Yang W, Xu D P, Liu Y 2018 J. Alloys Compd. 760 15

Google Scholar

Google Scholar

[7] Agustuaningum M P, Ondicho I, Jodi D E, Park N, Lee U 2019 Mater. Sci. Eng., A 759 633

Google Scholar

Google Scholar

[8] Jodi D E, Park J, Park N 2019 Mater. Charact. 157 109888

Google Scholar

Google Scholar

[9] Agustuaningum M P, Yoshid S, Tsuji N, Park N 2019 J. Alloys Compd. 781 866

Google Scholar

Google Scholar

[10] Zhao Y L, Yang T, Tong Y, Wang J, Luan J H, Jiao Z B, Chen D, Yang Y, Hu A, Liu C T, Kai J J 2017 Acta. Mater. 138 72

Google Scholar

Google Scholar

[11] Yang K, Wang Y X, Dong W Q, Chen Z, Zhang M Y 2011 Rare Met. Mater. Eng. 40 1605

[12] 吴静, 刘永长, 李冲, 伍宇婷, 夏兴川, 李会军 2020 金属学报 56 21

Google Scholar

Google Scholar

Wu J, Liu Y C, Li C, Wu Y T, Xia X C, Li H J 2020 Acta Metall. Sin. 56 21

Google Scholar

Google Scholar

[13] Sun Y Y, Zhao Y H, Zhao B J, Yang W K, Li X L, Hou H 2019 J. Mater. Sci. 54 11263

Google Scholar

Google Scholar

[14] Kuang W W, Wang H F, Li X, Zhang J B, Zhou Q, Zhao Y H 2018 Acta. Mater. 159 16

Google Scholar

Google Scholar

[15] Zhang J B, Wang H F, Kuang W W, Zhang Y C, Li S, Zhao Y H, Herlach D M 2018 Acta. Mater. 148 86

Google Scholar

Google Scholar

[16] Zhao Y H, Zhang B, Hou H, Chen W P, Wang M 2019 J. mater. Sci. Technol. 35 1044

Google Scholar

Google Scholar

[17] Mushongera L T, Amos P G K, School E, Kumar P 2020 J. Mater. Sci. 55 5280

Google Scholar

Google Scholar

[18] Xia B H, Mei C L, Yu Q, Li Y B 2020 Comput. Method. Appl. Mech. Eng. 363 112795

Google Scholar

Google Scholar

[19] Guo H J, Zhao Y H, Sun Y Y, Tian J Z, Hou H, Qi K W, Tian X L 2019 Superlattices Microstruct. 129 163

Google Scholar

Google Scholar

[20] Chen L Q 2002 Annu. Rev. Mater. Res. 32 113

Google Scholar

Google Scholar

[21] Zhao Y H, Tian X L, Zhao B J, Sun Y Y, Guo H J, Dong M, Liu H, Wang X, Guo Z, Umar A, Hou H 2018 Sci. Adv. Mater. 1012 1793

Google Scholar

Google Scholar

[22] Vogel F, Wanderka N, Balogh Z, Ibrahim M, Stender P, Schmitz G, Banhart J 2015 Ultramicroscopy 159 278

Google Scholar

Google Scholar

[23] Vogel F, Wanderka N, Balogh Z, Ibrahim M, Stender P, Schmitz G, Banhart J 2013 Nat. Commun. 4 2955

Google Scholar

Google Scholar

[24] Hou H, Zhao Y H, Zhao Y H 2009 Mat. Sci. Eng. A. 499 204

Google Scholar

Google Scholar

[25] Wang K, Wang Y X 2020 J. Alloys Compd 824 153923

Google Scholar

Google Scholar

[26] 赵宇宏, 侯华, 任娟娜 2012 中南大学学报 8 81

Zhao Y H, Hou H, Ren J N 2012 J. Cent. South Univ. 8 81

[27] 田晓林, 赵宇宏, 田晋忠, 侯华 2018 67 230201

Google Scholar

Google Scholar

Tian X L, Zhao Y H, Tian J Z, Hou H 2018 Acta Phys. Sin. 67 230201

Google Scholar

Google Scholar

[28] 马庆爽, 靳玉春, 赵宇宏, 侯华, 王欣然, 王锟 2015 中国有色金属学报 25 1450

Google Scholar

Google Scholar

Ma Q S, Jin Y C, Zhao Y H, Hou H, Wang X R, Wang K 2015 Chin. J. Nonferrous Met. 25 1450

Google Scholar

Google Scholar

[29] Zhang M Y, Liu F, Chen Z, Guo H J, Yue G Q, Yang K 2012 T. Nonferr. Metal. Soc. 22 2439

Google Scholar

Google Scholar

[30] 张静, 陈铮, 王永欣, 童立甲 2015 中国科技论文 10 189

Zhang J, Chen Z, Wang Y X, Tong L J 2015 China Sciencepaper 10 189

[31] 杨坤, 吉楠, 沙婷, 杨放, 王海涛, 陈铮 2017 稀有金属材料与工程 07 125

Yang K, Ji N, Sha T, Yang F, Wang H T, Chen Z 2017 Rare Metal Mat. Eng. 07 125

[32] Cahn J W, Hilliard J E 1958 Acta Mater. 6 772

Google Scholar

Google Scholar

[33] Cahn J W, Hilliard J E 1959 Acta Mater. 7 219

Google Scholar

Google Scholar

[34] Khachaturyan A G 1983 Theory of Structural Trans-formations in Solids (New York: Wiley) pp131–156

[35] Chen L Q, Khachaturyan A G 1991 Scr. Metall. Mater. 25 67

Google Scholar

Google Scholar

[36] Poduri R, Chen L Q 1998 Acta Mater. 44 4253

Google Scholar

Google Scholar

[37] Zhao Y, Zhou Y J, Lin J P, Chen G L, Liaw P K 2008 Adv. Eng. Mater. 10 534

Google Scholar

Google Scholar

[38] Wendt H, Haasen P 1983 Acta Metall. 31 1649

Google Scholar

Google Scholar

[39] Jackson M P, Starink M J, Reed R C 1999 Mater. Sci. Eng., A 264 26

Google Scholar

Google Scholar

[40] Onaka S, Kobayashi N, Fujii T, Kato M 2002 Int. J. Plast. 10 343

Google Scholar

Google Scholar

[41] Zhang Y, Chen Z, Cao D D, Zhang J Y, Zhang P, Tao Q, Yang X Q 2019 J. Mater. Res. Technol. 8 726

Google Scholar

Google Scholar

[42] Wang Y W, Shang S L, Wang Y, Han F B, Darling K A, Wu Y D, Xie X, Senkov O N, Li J S, Hui X D, Dahmen K A, Liaw P K, Kecskes L J, Liu Z K 2017 Npj. Comput. Mater. 3 23

Google Scholar

Google Scholar

[43] Jodi A E, Park N 2019 Mater. Lett. 255 126528

Google Scholar

Google Scholar

计量

- 文章访问数: 9802

- PDF下载量: 113

- 被引次数: 0

下载:

下载: