-

基于阳极氧化铝模板, 采用真空蒸镀技术, 制备了高度有序的周期性银纳米球阵列. 阵列几何结构参数调控实验发现, 通过控制蒸镀厚度, 可实现对阵列中银纳米球尺寸(直径)和间距的有效调控, 进而有效实现对紫外-可见-近红外各波段吸收峰位和峰宽的调制. 吸收光谱测试显示, 该纳米阵列在紫外、可见和近红外波段都具有明显的电磁波吸收特性. 时域有限差分理论模拟结合实验分析不同波段光吸收特性的物理机制, 紫外超窄强吸收为银、铝介电环境非对称诱发的法诺共振, 可见波段吸收源自于银纳米粒子局域表面等离子体共振, 近红外波段强吸收为银纳米球阵列表面晶格共振所激发.

-

关键词:

- 局域表面等离子体激元 /

- 纳米阵列 /

- 阳极氧化铝 /

- 吸收峰位

In this paper, the highly ordered periodic silver nanosphere arrays are fabricated by vacuum evaporation based on anodic aluminum oxide (AAO) template. The diameter and spacing of silver nanosphere in the arrays are adjusted just by controlling the thickness of evaporation. Furthermore, this can effectively modulate the absorption peaks and bandwidths in ultraviolet-visible-near-infrared regions. The measurement results of absorption spectra show that the nano-arrays have obvious electromagnetic wave absorption characteristics in the ultraviolet, visible and near-infrared bands. The finite-difference time-domain theoretical simulation combined with experiments is used to analyze the physical mechanism of light absorption characteristics in different wavebands. The ultraviolet strong absorption is due to the Fano resonance induced by asymmetric dielectric environment of silver and aluminum; the visible absorption originates from local surface plasmon resonance of silver nanoparticles; the near-infrared strong absorption is attributed to the surface lattice resonance of silver nanosphere arrays.-

Keywords:

- localized surface plasmon /

- nano arrays /

- anodic aluminum oxide /

- absorption peak-position

[1] Wang S Q, Xu L P, Wen Y Q, Du H W, Wang S T, Zhang X J 2013 Nanoscale 5 4284

Google Scholar

Google Scholar

[2] Shipway A N, Katz E, Willner I 2000 ChemPhysChem 1 18

Google Scholar

Google Scholar

[3] Prakash J, Harris R A, Swart H C 2016 Int. Rev. Phys. Chem. 35 353

Google Scholar

Google Scholar

[4] Fuku K, Hayashi R, Takakura S, Kamegawa T, Mori K, Yamashita H 2013 Angew. Chem. Int. Ed. 52 7446

Google Scholar

Google Scholar

[5] Yan B, Yang X X, Fang J Y, Huang Y D, Qin H, Qin S Q 2015 Chin. Phys. B 24 15203

Google Scholar

Google Scholar

[6] 张喆, 柳倩, 祁志美 2013 62 060703

Google Scholar

Google Scholar

Zhang Z, Liu Q, Qi Z M 2013 Acta Phys. Sin. 62 060703

Google Scholar

Google Scholar

[7] Offermans P, Schaafsma M C, Rodriguez S R K, Zhang Y C, Crego-Calama M, Brongersma S H, Rivas J G 2015 ACS Nano 5 5151

[8] Ren K, Yin P, Zhou Y, Cao X, Dong C, Cui L, Liu H, Du X 2017 Small 13 1700867

Google Scholar

Google Scholar

[9] Mi Y, Wen L Y, Xu R, Wang Z J, Cao D W, Fang Y G, Lei Y 2016 Adv. Energy Mater. 6 1501496

Google Scholar

Google Scholar

[10] 叶松, 王向贤, 侯宜栋, 张志友, 杜惊雷 2014 65 087802

Google Scholar

Google Scholar

Ye S, Wang X, Hou Y D, Zhang Z Y, Du J L 2014 Acta Phys. Sin. 65 087802

Google Scholar

Google Scholar

[11] Zhang J, Dong L, Yu S H 2015 Sci. Bull. 60 785

Google Scholar

Google Scholar

[12] Khan Y, Li A R, Chang L, Li L D 2018 Sens. Actuator, B 255 1298

Google Scholar

Google Scholar

[13] Xiong B, Zhou R, Hao J R, Jia Y H, He Y, Yeung E S 2013 Nat. Commun. 4 1708

Google Scholar

Google Scholar

[14] Jung H Y, Yeo I S, Kim T U, Ki H C, Gu H B 2018 Appl. Surf. Sci. 432 266

Google Scholar

Google Scholar

[15] Wu K, Li T, Schmidt M S, Rindzevicius T, Boisen A, Ndoni S 2018 Adv. Funct. Mater. 28 1704818

Google Scholar

Google Scholar

[16] Zhan Z B, Xu R, Mi Y, Zhao H P, Lei Y 2015 ACS Nano 9 4583

Google Scholar

Google Scholar

[17] Ji N, Ruan W D, Li Z S, Wang C X, Yang Z, Zhao B 2013 J. Raman Spectrosc. 44 1

Google Scholar

Google Scholar

[18] King N S, Liu L F, Yang X, Cerjan B, Everitt H O, Nordlander P, Halas N J 2015 ACS Nano 9 10628

Google Scholar

Google Scholar

[19] Zhan Z B, Xu R, Zheng X Z, Fu Q, Wu M H, Lei Y 2016 Nanotechnol. 27 445301

Google Scholar

Google Scholar

[20] Minamimoto H, Oikawa S, Hayashi T, Shibazaki A, Li X W, Murakoshi K 2018 J. Phys. Chem. C 122 14162

Google Scholar

Google Scholar

[21] Zhang C, Wu K, Ling B, Li X F 2016 J. Photonics Energy 6 042502

Google Scholar

Google Scholar

[22] González-Rubio G, Díaz-Núñez P, Rivera A, Prada A, Tardajos G, González-Izquierdo J, Bañares L, Llombart P, Macdowell L G, Palafox M A, Liz-Marzán L M, Peña-Rodríguez O, Guerrero-Martínez A 2017 Science 358 640

Google Scholar

Google Scholar

[23] Wang L C, Liu Z Q, Yi X Y, Zhang Y Y, Li H J, Li G M, Wang G H 2016 J. Appl. Phys. 119 1685

Google Scholar

Google Scholar

[24] Gromov D G, Pavlova L M, Savitsky A I, Trifonov A Y 2015 Appl. Phys. A 118 1297

Google Scholar

Google Scholar

[25] Liu Z H, Ye J 2016 Nanoscale 8 17665

Google Scholar

Google Scholar

[26] Marimuthu A, Zhang J W, Linic S 2013 Science 339 1590

Google Scholar

Google Scholar

[27] Ji N, Ruan W D, Wang C X, Lu C, Zhao B 2009 Langmuir 25 11869

Google Scholar

Google Scholar

[28] Zhang S P, Bao K, Halas N J, Xu H X, Nordlander P 2011 Nano Lett. 11 1657

Google Scholar

Google Scholar

[29] 屈炜, 李静 2017 新技术新工艺 5 15

Google Scholar

Google Scholar

Qu W, Li J 2017 New Technol. New Process 5 15

Google Scholar

Google Scholar

[30] Zhan Y H, Lei D Y, Li X F, Maier S A 2014 Nanoscale 6 4705

Google Scholar

Google Scholar

[31] 张佳, 牧凯军, 王俊俏, 范春珍, 梁二军 2017 光散射学报 29 1007

Google Scholar

Google Scholar

Zhang J, Mu K J, Wang J X, Fan C Z, Liang E J 2017 J. Light Scatt. 29 1007

Google Scholar

Google Scholar

[32] Knight M W, Wu Y P, Lassiter J B, Nordlander P, Halas N J 2009 Nano Lett. 9 2188

Google Scholar

Google Scholar

[33] Wu Y P, Nordlander P 2010 J. Phys. Chem. C 114 7302

Google Scholar

Google Scholar

[34] Benjamin G, Olivier Martin J F 2011 ACS Nano 5 8999

Google Scholar

Google Scholar

[35] Wang M S, Krasnok A, Zhang T Y, Scarabelli L, Liu H, Wu Z L, Luis M, Marzán L, Terrones M, Alù A, Zheng Y B 2018 Adv. Mater. 3 1705779

Google Scholar

Google Scholar

[36] Sherry L J, Chang S H, Schatz G C, Van Duyne R P, Wiley B J, Xia Y 2005 Nano Lett. 5 2034

Google Scholar

Google Scholar

[37] Yin J, Zang Y S, Xu B B, Li S P, Kang J Y, Fang Y Y, Wu Z H, Li J 2014 Nanoscale 6 3934

Google Scholar

Google Scholar

[38] Catchpole K R, Polman A 2008 Opt. Express 16 21793

Google Scholar

Google Scholar

[39] 黄昕乾, 姚若河 2018 真空科学与技术学报 38 791

Google Scholar

Google Scholar

Huang X Q, Yao R H 2018 Chin. J. Vacuum Sci. Technol. 38 791

Google Scholar

Google Scholar

[40] Cristiano M, Christoph H, Luis G P J, Judith L, Agustín M, Luis M, Liz M 2018 ACS Nano 12 8531

Google Scholar

Google Scholar

-

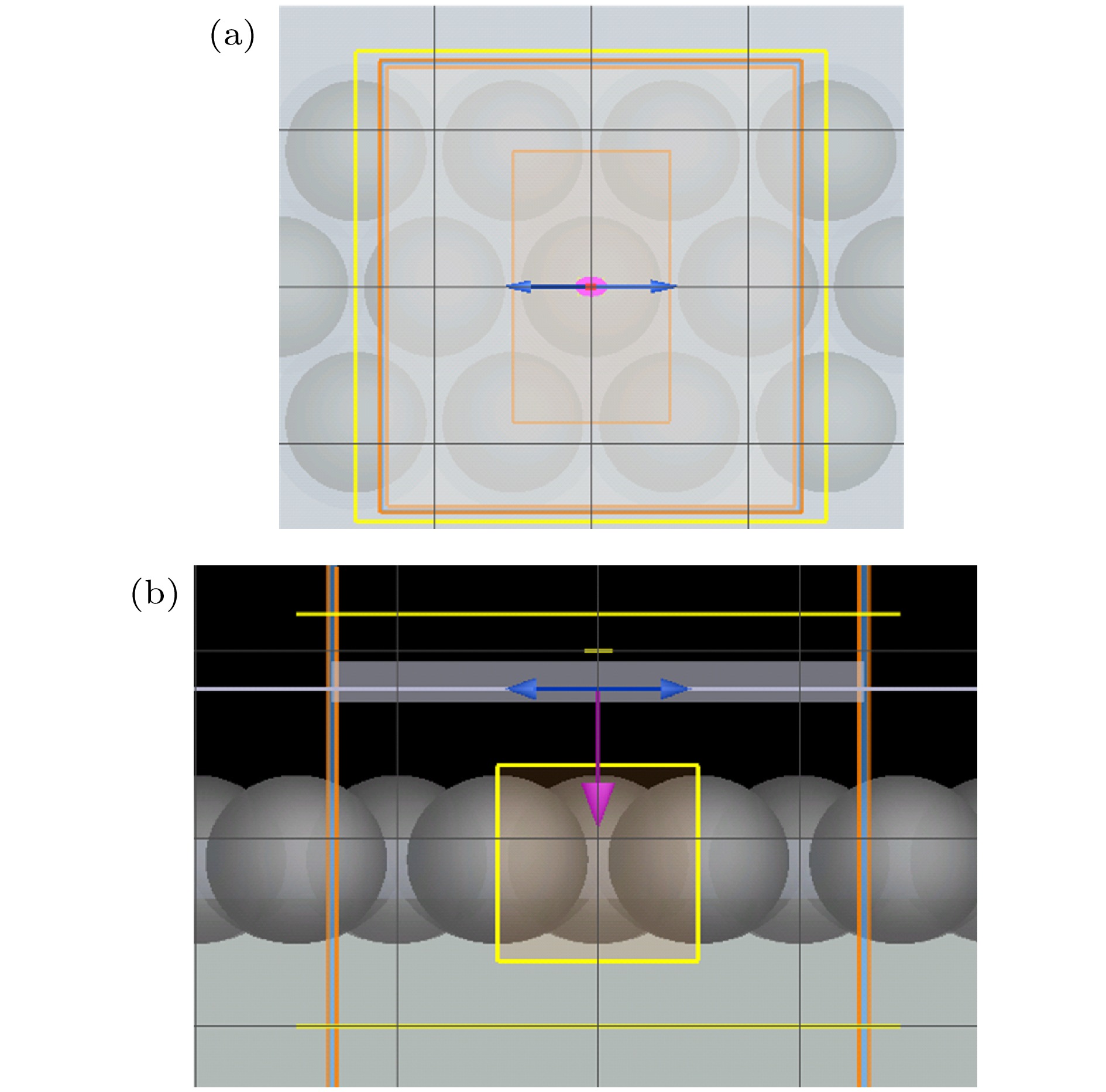

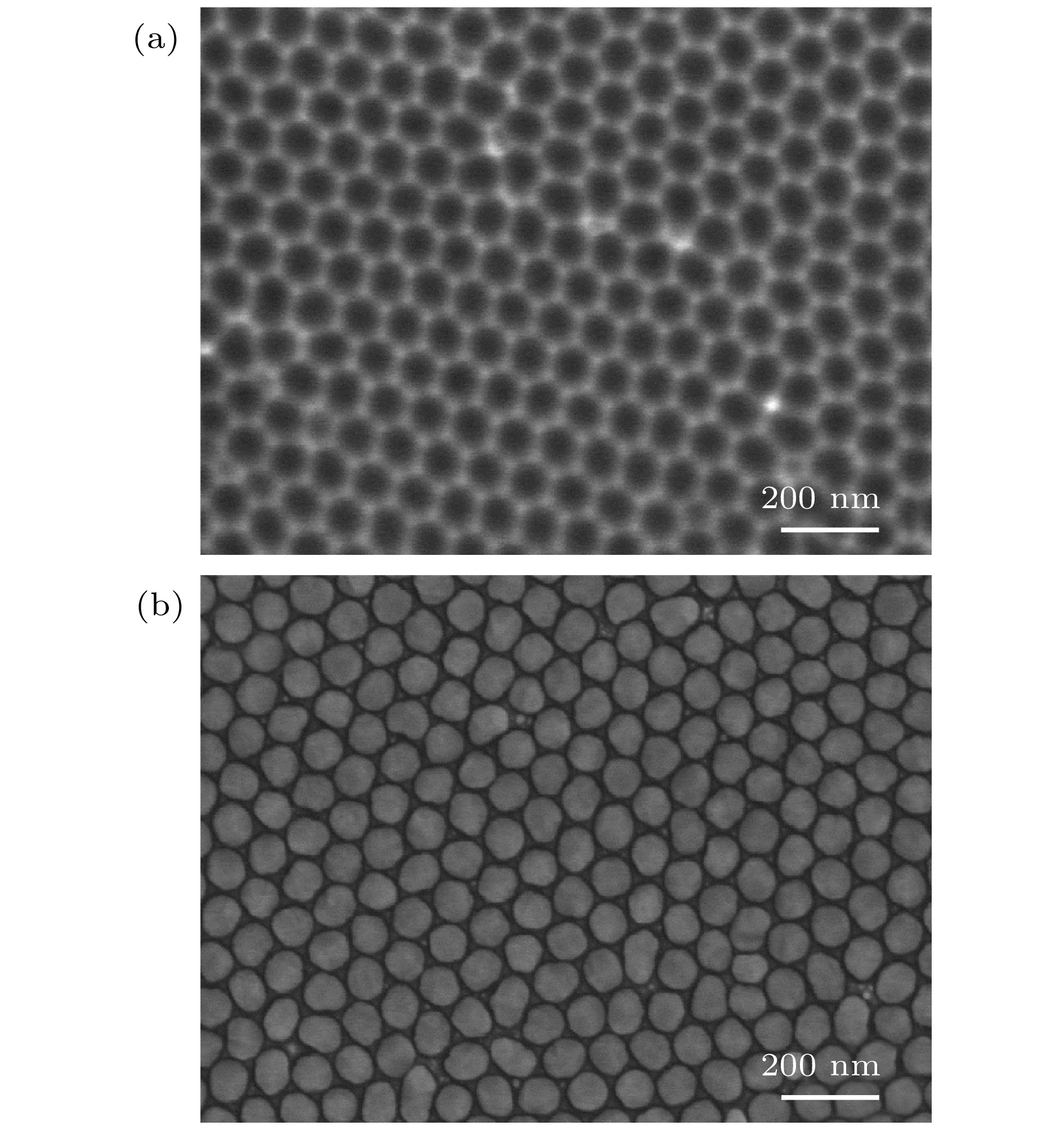

图 1 AAO纳米碗阵列和Ag纳米球阵列制备过程示意图 (a) 高纯铝片; (b) AAO纳米管阵列; (c) AAO纳米碗阵列; (d) Ag纳米颗粒; (e) Ag纳米球阵列

Fig. 1. Schematic diagram of the preparation procedure for fabricating patterned aluminum templates and Ag nanosphere arrays: (a) Purity aluminum; (b) AAO nanotube arrays after the first anodization; (c) AAO nanobowl arrays after the removal of the porous alumina layer; (d) Ag nanoparticles; (e) Ag nanosphere arrays.

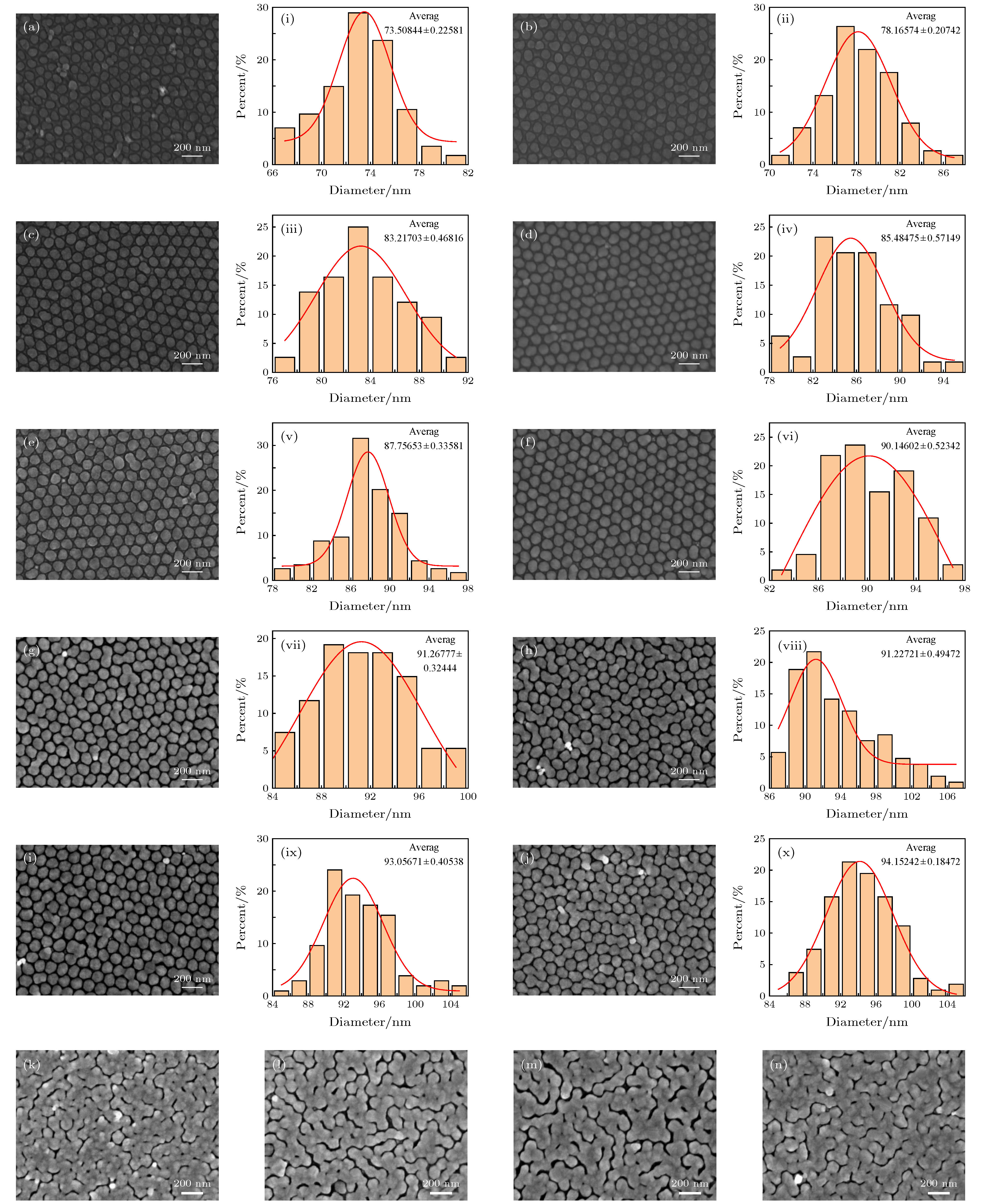

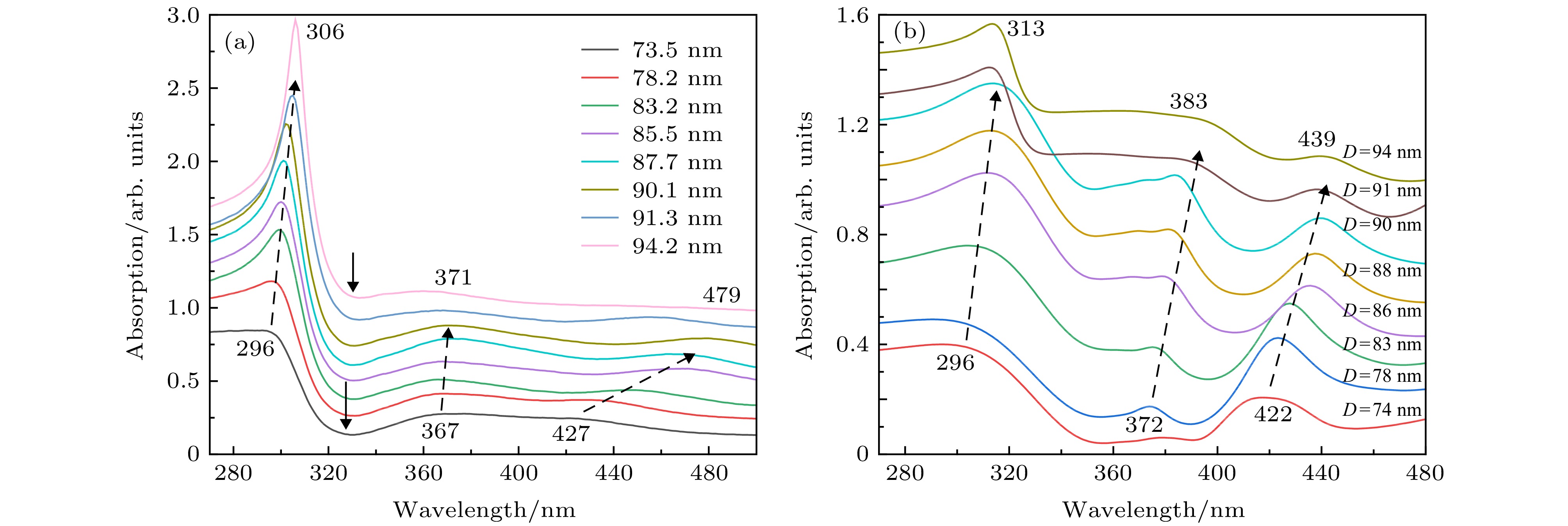

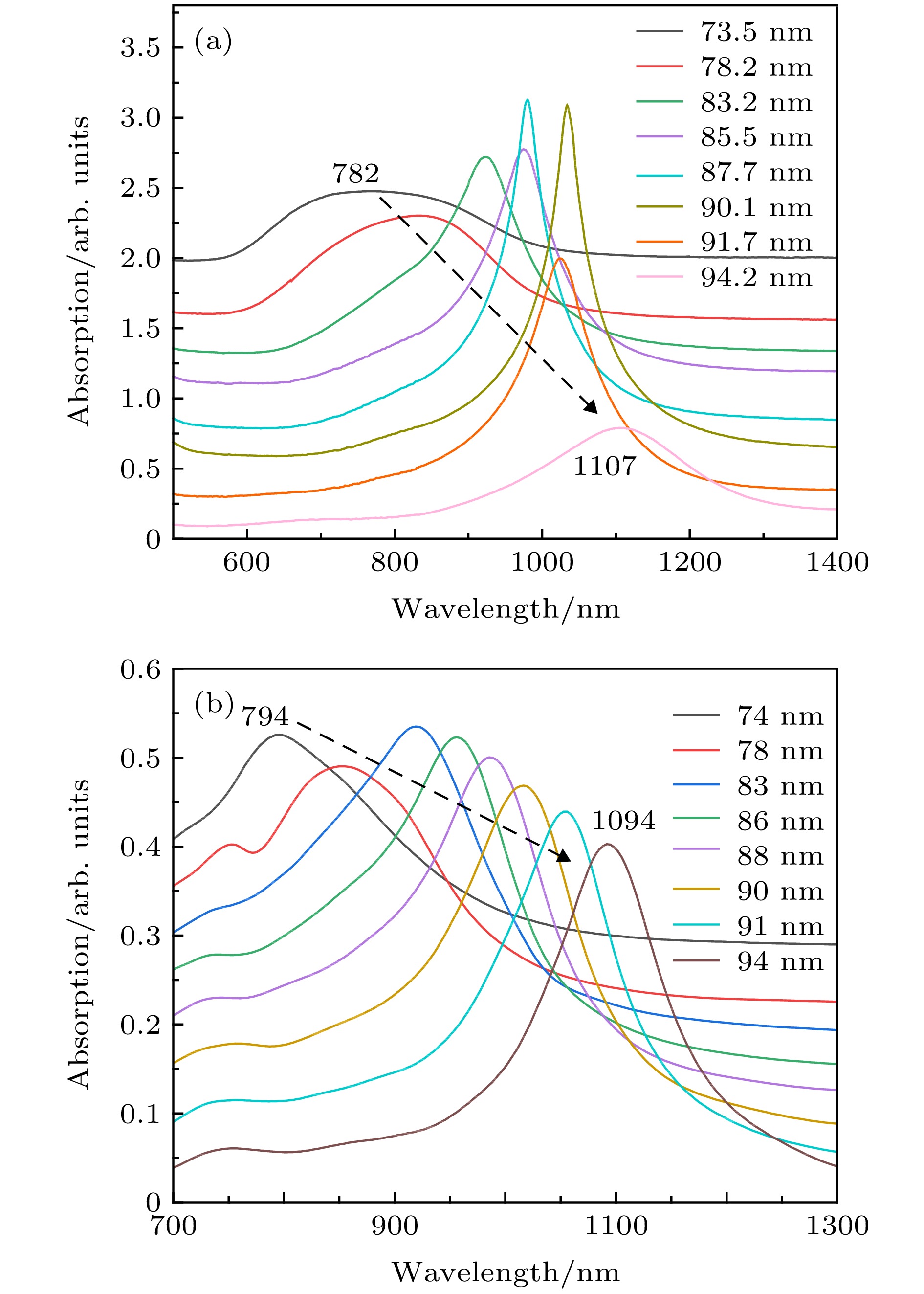

图 5 不同粒径(D) Ag纳米球周期性阵列/不同厚度(T) Ag膜的SEM图 (a)−(n)及相应的粒径分布直方图(i)−(x) (a) D = 73.5 nm; (b) D = 78.2 nm; (c) D = 83.2 nm; (d) D = 85.5 nm; (e) D = 87.7 nm; (f) D = 90.1 nm; (g) D = 91.3 nm; (h) D = 91.7 nm; (i) D = 93.1 nm; (j) D = 94.2 nm; (k) T = 17.5; (l) T =18.2 nm; (m) T = 19.0 nm; (n) T = 19.7 nm

Fig. 5. (a)−(n) SEM images of Ag nanosphere arrays/Ag film and (i)−(x) their related size distribution histograms: (a) D = 73.5 nm; (b) D = 78.2 nm; (c) D = 83.2 nm; (d) D = 85.5 nm; (e) D = 87.7 nm; (f) D = 90.1 nm; (g) D = 91.3 nm; (h) D = 91.7 nm; (i) D = 93.1 nm; (j) D = 94.2 nm; (k) T = 17.5 nm; (l) T = 18.2 nm; (m) T = 19.0 nm; (n) T = 19.7 nm.

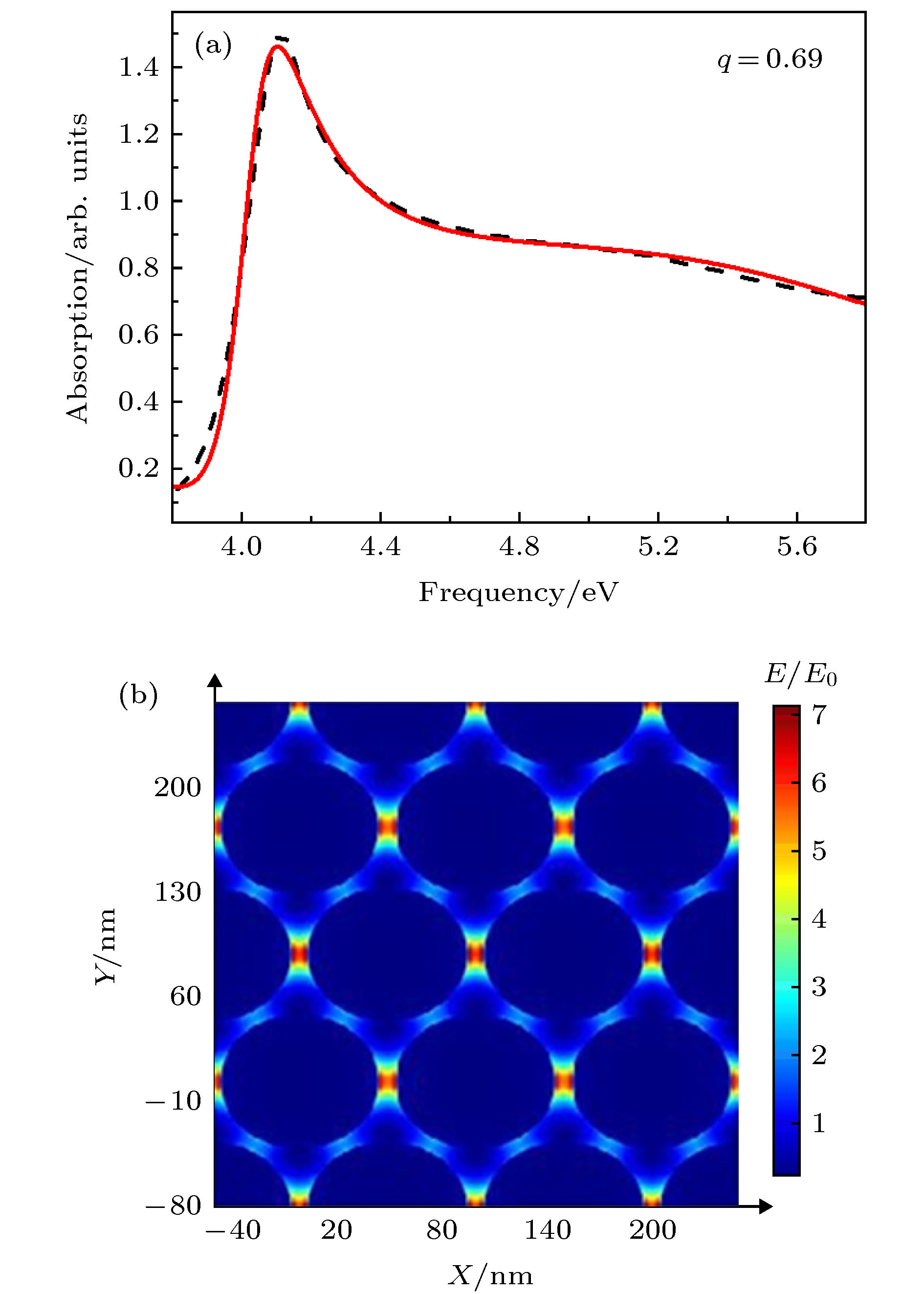

图 8 (a)紫外波段Ag纳米颗粒实验测得吸收光谱(黑色虚线), 以及根据(3)式拟合得到的吸收光谱(红色); (b) Ag纳米球阵列在437 nm波长下x-y平面(z = 0)的极化电场分布

Fig. 8. (a) UV absorption spectra of Ag nanosphere arrays (black dashed line is experimental results; red line corresponds to σt obtained by fitting the Eq. (3); (b) polarized field distributions on the x-y plane (z = 0) of the Ag nano-sphere array excited 437 nm.

-

[1] Wang S Q, Xu L P, Wen Y Q, Du H W, Wang S T, Zhang X J 2013 Nanoscale 5 4284

Google Scholar

Google Scholar

[2] Shipway A N, Katz E, Willner I 2000 ChemPhysChem 1 18

Google Scholar

Google Scholar

[3] Prakash J, Harris R A, Swart H C 2016 Int. Rev. Phys. Chem. 35 353

Google Scholar

Google Scholar

[4] Fuku K, Hayashi R, Takakura S, Kamegawa T, Mori K, Yamashita H 2013 Angew. Chem. Int. Ed. 52 7446

Google Scholar

Google Scholar

[5] Yan B, Yang X X, Fang J Y, Huang Y D, Qin H, Qin S Q 2015 Chin. Phys. B 24 15203

Google Scholar

Google Scholar

[6] 张喆, 柳倩, 祁志美 2013 62 060703

Google Scholar

Google Scholar

Zhang Z, Liu Q, Qi Z M 2013 Acta Phys. Sin. 62 060703

Google Scholar

Google Scholar

[7] Offermans P, Schaafsma M C, Rodriguez S R K, Zhang Y C, Crego-Calama M, Brongersma S H, Rivas J G 2015 ACS Nano 5 5151

[8] Ren K, Yin P, Zhou Y, Cao X, Dong C, Cui L, Liu H, Du X 2017 Small 13 1700867

Google Scholar

Google Scholar

[9] Mi Y, Wen L Y, Xu R, Wang Z J, Cao D W, Fang Y G, Lei Y 2016 Adv. Energy Mater. 6 1501496

Google Scholar

Google Scholar

[10] 叶松, 王向贤, 侯宜栋, 张志友, 杜惊雷 2014 65 087802

Google Scholar

Google Scholar

Ye S, Wang X, Hou Y D, Zhang Z Y, Du J L 2014 Acta Phys. Sin. 65 087802

Google Scholar

Google Scholar

[11] Zhang J, Dong L, Yu S H 2015 Sci. Bull. 60 785

Google Scholar

Google Scholar

[12] Khan Y, Li A R, Chang L, Li L D 2018 Sens. Actuator, B 255 1298

Google Scholar

Google Scholar

[13] Xiong B, Zhou R, Hao J R, Jia Y H, He Y, Yeung E S 2013 Nat. Commun. 4 1708

Google Scholar

Google Scholar

[14] Jung H Y, Yeo I S, Kim T U, Ki H C, Gu H B 2018 Appl. Surf. Sci. 432 266

Google Scholar

Google Scholar

[15] Wu K, Li T, Schmidt M S, Rindzevicius T, Boisen A, Ndoni S 2018 Adv. Funct. Mater. 28 1704818

Google Scholar

Google Scholar

[16] Zhan Z B, Xu R, Mi Y, Zhao H P, Lei Y 2015 ACS Nano 9 4583

Google Scholar

Google Scholar

[17] Ji N, Ruan W D, Li Z S, Wang C X, Yang Z, Zhao B 2013 J. Raman Spectrosc. 44 1

Google Scholar

Google Scholar

[18] King N S, Liu L F, Yang X, Cerjan B, Everitt H O, Nordlander P, Halas N J 2015 ACS Nano 9 10628

Google Scholar

Google Scholar

[19] Zhan Z B, Xu R, Zheng X Z, Fu Q, Wu M H, Lei Y 2016 Nanotechnol. 27 445301

Google Scholar

Google Scholar

[20] Minamimoto H, Oikawa S, Hayashi T, Shibazaki A, Li X W, Murakoshi K 2018 J. Phys. Chem. C 122 14162

Google Scholar

Google Scholar

[21] Zhang C, Wu K, Ling B, Li X F 2016 J. Photonics Energy 6 042502

Google Scholar

Google Scholar

[22] González-Rubio G, Díaz-Núñez P, Rivera A, Prada A, Tardajos G, González-Izquierdo J, Bañares L, Llombart P, Macdowell L G, Palafox M A, Liz-Marzán L M, Peña-Rodríguez O, Guerrero-Martínez A 2017 Science 358 640

Google Scholar

Google Scholar

[23] Wang L C, Liu Z Q, Yi X Y, Zhang Y Y, Li H J, Li G M, Wang G H 2016 J. Appl. Phys. 119 1685

Google Scholar

Google Scholar

[24] Gromov D G, Pavlova L M, Savitsky A I, Trifonov A Y 2015 Appl. Phys. A 118 1297

Google Scholar

Google Scholar

[25] Liu Z H, Ye J 2016 Nanoscale 8 17665

Google Scholar

Google Scholar

[26] Marimuthu A, Zhang J W, Linic S 2013 Science 339 1590

Google Scholar

Google Scholar

[27] Ji N, Ruan W D, Wang C X, Lu C, Zhao B 2009 Langmuir 25 11869

Google Scholar

Google Scholar

[28] Zhang S P, Bao K, Halas N J, Xu H X, Nordlander P 2011 Nano Lett. 11 1657

Google Scholar

Google Scholar

[29] 屈炜, 李静 2017 新技术新工艺 5 15

Google Scholar

Google Scholar

Qu W, Li J 2017 New Technol. New Process 5 15

Google Scholar

Google Scholar

[30] Zhan Y H, Lei D Y, Li X F, Maier S A 2014 Nanoscale 6 4705

Google Scholar

Google Scholar

[31] 张佳, 牧凯军, 王俊俏, 范春珍, 梁二军 2017 光散射学报 29 1007

Google Scholar

Google Scholar

Zhang J, Mu K J, Wang J X, Fan C Z, Liang E J 2017 J. Light Scatt. 29 1007

Google Scholar

Google Scholar

[32] Knight M W, Wu Y P, Lassiter J B, Nordlander P, Halas N J 2009 Nano Lett. 9 2188

Google Scholar

Google Scholar

[33] Wu Y P, Nordlander P 2010 J. Phys. Chem. C 114 7302

Google Scholar

Google Scholar

[34] Benjamin G, Olivier Martin J F 2011 ACS Nano 5 8999

Google Scholar

Google Scholar

[35] Wang M S, Krasnok A, Zhang T Y, Scarabelli L, Liu H, Wu Z L, Luis M, Marzán L, Terrones M, Alù A, Zheng Y B 2018 Adv. Mater. 3 1705779

Google Scholar

Google Scholar

[36] Sherry L J, Chang S H, Schatz G C, Van Duyne R P, Wiley B J, Xia Y 2005 Nano Lett. 5 2034

Google Scholar

Google Scholar

[37] Yin J, Zang Y S, Xu B B, Li S P, Kang J Y, Fang Y Y, Wu Z H, Li J 2014 Nanoscale 6 3934

Google Scholar

Google Scholar

[38] Catchpole K R, Polman A 2008 Opt. Express 16 21793

Google Scholar

Google Scholar

[39] 黄昕乾, 姚若河 2018 真空科学与技术学报 38 791

Google Scholar

Google Scholar

Huang X Q, Yao R H 2018 Chin. J. Vacuum Sci. Technol. 38 791

Google Scholar

Google Scholar

[40] Cristiano M, Christoph H, Luis G P J, Judith L, Agustín M, Luis M, Liz M 2018 ACS Nano 12 8531

Google Scholar

Google Scholar

计量

- 文章访问数: 14675

- PDF下载量: 177

- 被引次数: 0

下载:

下载: