-

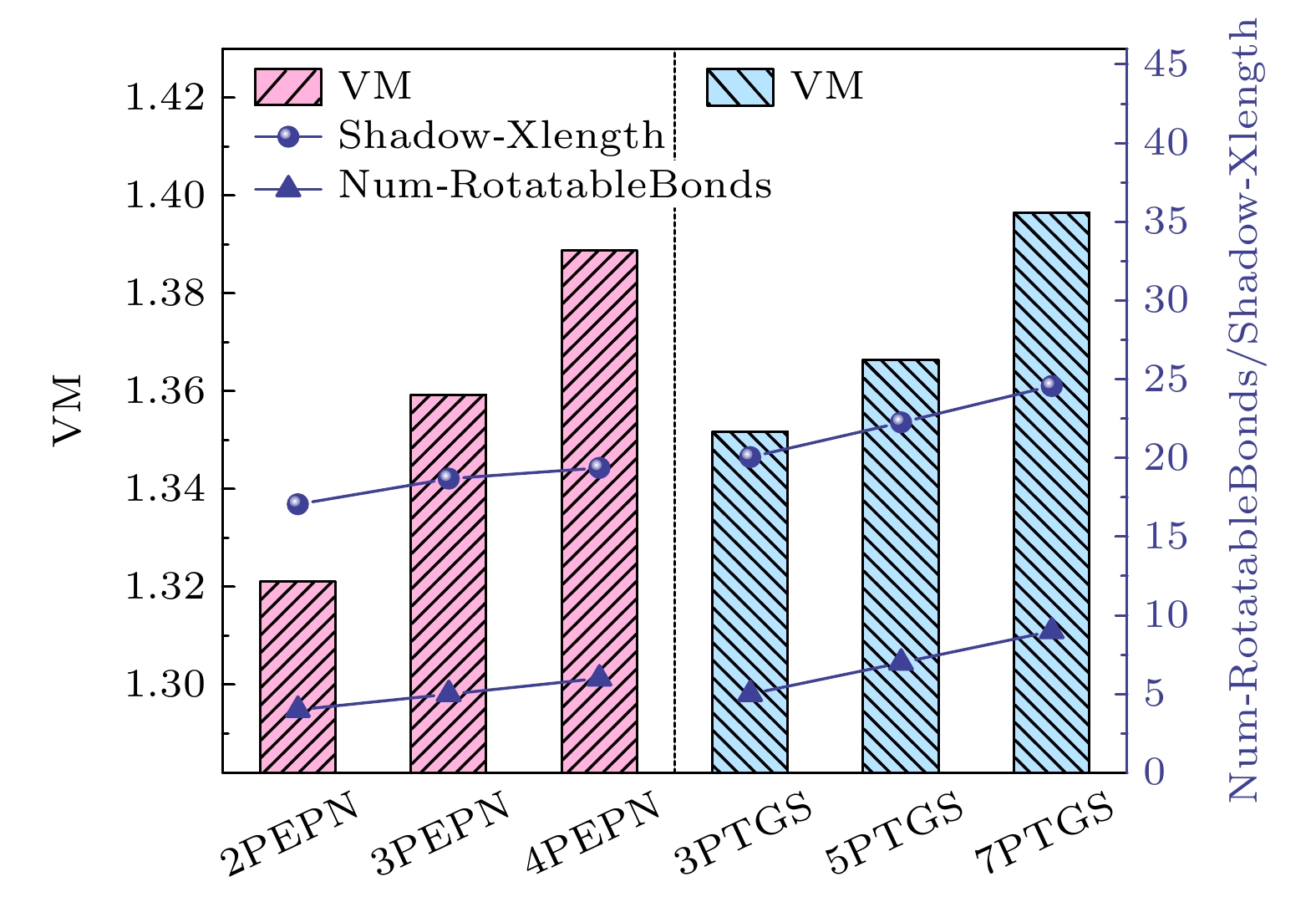

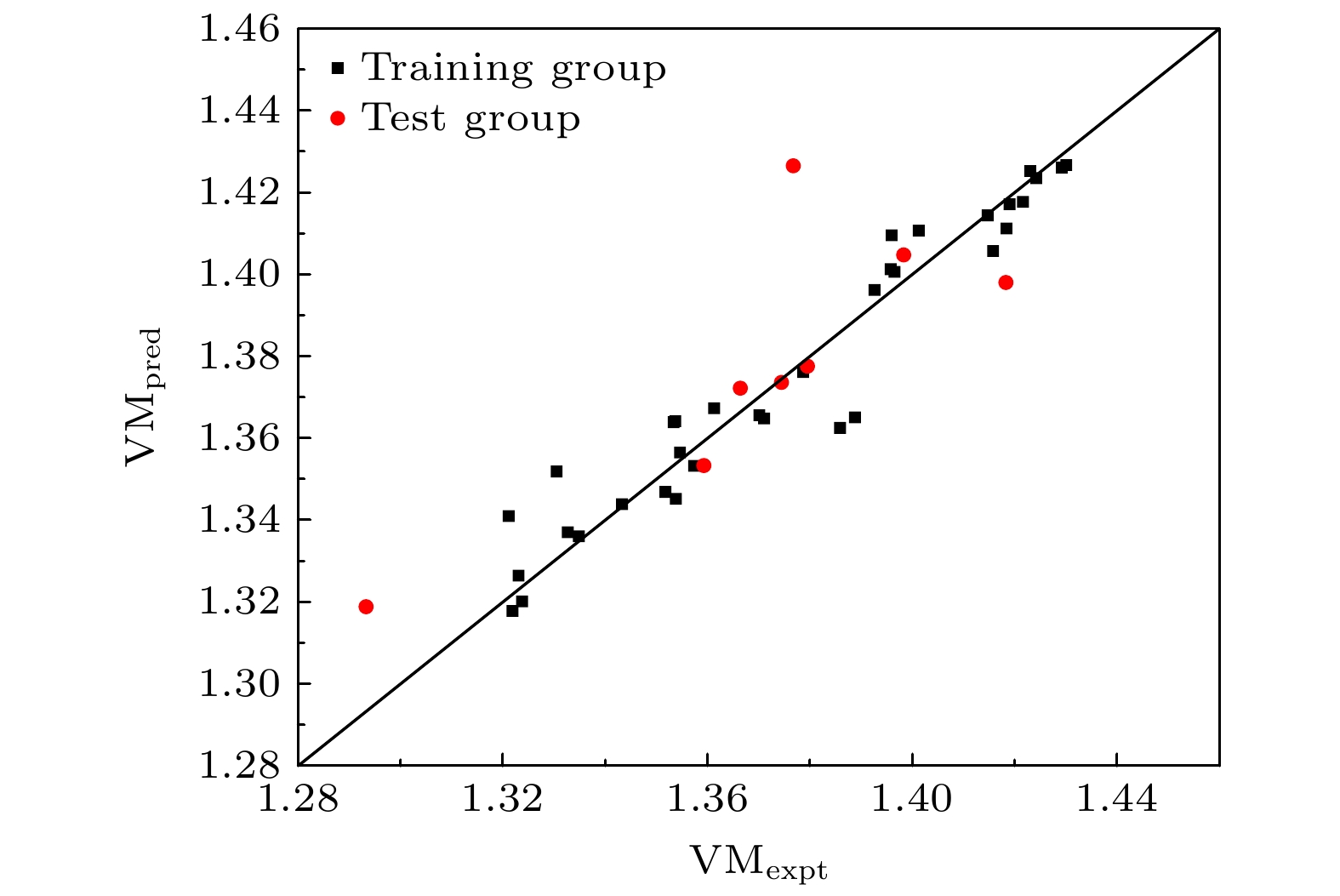

Nematic liquid crystal materials designed for optics, microwave communication tuning, etc. need high response speed, which is related to the rotational viscosity and the birefringent index of the liquid crystal. In order to achieve a wide tuning range of phase modulation, the nematic liquid crystals often employ large π-electron conjugated systems and large polar groups to enhance the birefringence and dielectric anisotropy of the liquid crystal molecule, which, however, increases the viscosity of the liquid crystal material, deteriorating the response speed of the microwave device. Herein, we explore the viscosity of the nematic liquid crystal from the perspective of liquid crystal compound structure by testing the viscosity of our designed and synthesized forty-two different nematic liquid crystals by using a rotating rheometer at 25 ℃. To the best of our knowledge, the BPNN-QSAR quantitative structure-activity model between nematic liquid crystal molecular structure and viscosity is established for the first time. The correlation coefficient between the predicted value and the experimental value is q2 = 0.607 > 0.5, indicating that the model can be used to predict the viscosity performances of liquid crystal compounds. Besides, the molecular structure descriptors affecting the viscosity properties are explored. Based on the practical application and this model, seven liquid crystal molecules of two series with large birefringent index are designed and tested. The viscosity predicted by the BPNN model is smaller than that of the molecules of the same type and matches with the measured viscosity.

-

Keywords:

- nematic liquid crystal /

- viscosity /

- molecular structure /

- quantitative structure-activity relationship

[1] Demus D, Goodbye J W, Gray G W 1998 Handbook of Liquid Crystals Chichester (Wiley-VCH) p237

[2] 杨傅子 2008 物理学进展 28 107

Google Scholar

Google Scholar

Yang F Z 2008 Prog. Phys. 28 107

Google Scholar

Google Scholar

[3] 曹召良, 穆全全, 胡立发 2008 液晶与显示 23 157

Google Scholar

Google Scholar

Cao Z L, Mu Q Q, Hu L F 2008 Liq. Cryst. Disp. 23 157

Google Scholar

Google Scholar

[4] 李潭, 王震, 张智勇 2017 液晶与显示 32 862

Google Scholar

Google Scholar

Li T, Wang Z, Zhang Z Y 2017 Liq. Cryst. Disp. 32 862

Google Scholar

Google Scholar

[5] Qiu L L, Zhu L, Xu Y 2020 IEEE T. Antenn. Progag. 685680

Google Scholar

Google Scholar

[6] Robert C, Zbigniew C, Yuriy G 2018 Liq. Cryst. Rev. 6 17

Google Scholar

Google Scholar

[7] Alihosseini F, Ahmadi V, Mir A 2015 Liq. Cryst. 42 1638

Google Scholar

Google Scholar

[8] Jiang D, Liu Y, Li X 2019 IEEE Access 7 126265

Google Scholar

Google Scholar

[9] Kundtz N 2014 Microwave 57 56

[10] Nishikawa H, Shiroshita K, Higuchi H 2017 Adv. Mater. 29 1702354

Google Scholar

Google Scholar

[11] Mandle R J, Cowling S J, Goodby J W 2017 Phys. Chem. Chem. Phys. 19 11429

Google Scholar

Google Scholar

[12] Zhao X, Zhou J 2021 Proc. Natl. Acad. Sci. 118 21111

Google Scholar

Google Scholar

[13] 赵秀虎, 黄明俊, Satoshiay A 2023 液晶与显示 38 77

Google Scholar

Google Scholar

Zhao X H, Huang M J, Satoshiay A 2023 Liq. Cryst. Disp. 38 77

Google Scholar

Google Scholar

[14] Li B X, Xiao R L, Paladugu S 2019 Opt. Express 27 3861

Google Scholar

Google Scholar

[15] 杨槐, 王萌, 张兰英 2015 CN 106701105 B 9

Yang H, Wang M, Zhang L Y 2015 CN Patent 106701105 B 9

[16] 高鸿锦 2011 液晶化学 (北京: 清华大学出版社)第48页

Gao J H 2011 Liquid Crystals Chemistry (Beijing: Qinghua University Press) p48

[17] Chen C Y, Tsai T R, Pan C L, Pan R P 2003 Appl. Phys. Lett. 83 4497

Google Scholar

Google Scholar

[18] Reuter M G K, Garbat K, Vieweg N, Fischer B N, Dąbrowski R, Koch M, Dziaduszek J, Urban S 2013 J. Mater. Chem. C 1 4457

Google Scholar

Google Scholar

[19] 张智勇, 刘可庆, 戴志群 2014 液晶与显示 29 873

Google Scholar

Google Scholar

Zhang Z Y, Liu K Q, Dai Z Q 2014 Liq. Cryst. Disp. 29 873

Google Scholar

Google Scholar

[20] Herman J, Dziaduszek J, Dąbrowski R 2013 Liq. Cryst. 40 1174

Google Scholar

Google Scholar

[21] 张然, 彭增辉, 刘永刚 2009 液晶与显示 6 789

Zhang R, Peng Z H, Liu Y G 2009 Liq. Cryst. Disp. 6 789

[22] Bock F J, Kneppe H, Schneider F 1986 Liq. Cryst. 1 239

Google Scholar

Google Scholar

[23] Belyaev V V 1989 Russ. Chem. Rev. 58 917

Google Scholar

Google Scholar

[24] Gauza S, Jiao M, Wu S T 2008 Liq. Cryst. 35 1401

Google Scholar

Google Scholar

[25] Gauza S, Kula P, Liang X 2009 Mol. Cryst. Liq. Cryst. 509 47

Google Scholar

Google Scholar

[26] 刘运, 张智勇, 任占冬 2010 液晶与显示 4 490

Google Scholar

Google Scholar

Liu Y, Zhang Z Y, Ren Z D 2010 Liq. Cryst. Disp. 4 490

Google Scholar

Google Scholar

[27] Deng M M, Wang Y, Zhang Z 2012 Chin. J. Chem. 29 1093

Google Scholar

Google Scholar

[28] Soltani T, Fouzai M, Dhaoudi H 2016 Phase Transi. 89 622

Google Scholar

Google Scholar

[29] Bulsara A R, Maren A J, Schmera G 1993 Biol. Cybern. 70 145

Google Scholar

Google Scholar

[30] 袁永娜 2010 博士学位论文(兰州: 兰州大学)

Yuan Y N 2010 Ph. D. Dissertation (Lanzhou: Lanzhou University

[31] Hansch C, Steward A R 1964 J. Med. Chem. 7 691

Google Scholar

Google Scholar

[32] 王婷婷, 戴康, 王展, 高新蕾 2014 华中师范大学学报 48 379

Google Scholar

Google Scholar

Wang T T, Dai K, Wang Z, Gao X L 2014 J. Central China Normal Univ. 48 379

Google Scholar

Google Scholar

[33] Dąbrowski R, Dziaduszek J, Ziółek A 2007 Opto-Electro. Rev. 15 47

Google Scholar

Google Scholar

[34] Li J, Hu M, Chen R 2021 J. Mol. Liq. 325 115236

Google Scholar

Google Scholar

[35] 莫玲超, 梁晓琴, 安忠维 2013 应用化学 30 861

Google Scholar

Google Scholar

Mo L C, Liang X Q, An Z W 2013 Appl. Chem. 30 861

Google Scholar

Google Scholar

[36] 王婷婷, 戴康, 王展 2017 摩擦学学报 37 495

Google Scholar

Google Scholar

Wang T T, Dai K, Wang Z 2017 J. Frict. 37 495

Google Scholar

Google Scholar

[37] 王登菊, 周如金, 郎春燕 2012 计算机与应用化学 29 457

Google Scholar

Google Scholar

Wang D J, Zhou R J, Lang C Y 2012 Comput. Appl. Chem. 29 457

Google Scholar

Google Scholar

[38] Hall L H, Mohney B, Kier L B 1991 J. Chem. Inf. Comp. Sci. 31 76

Google Scholar

Google Scholar

[39] Hall L H, Kier L B 2000 J. Chem. Inf. Comp. Sci. 40 784

Google Scholar

Google Scholar

[40] 金印 2019 硕士学位论文(成都: 电子科技大学)

Jin Y 2019 M. S. Thesis (Chengdu: University of Electronic Science and Technology of China

-

表 1 液晶化合物相变温度及25 ℃测试黏度值

Table 1. Phase transition temperature and 25 ℃ test viscosity value of liquid crystal compounds.

序号 化合物 分子结构 分子量/(g·mol–1) 混晶黏度η/

(mPa·s–1)相变温度T/℃ 1 3CC2

236.25 19.647 Cr –8.3 N 93.0 Iso 2 3CC4

264.28 20.983 Cr –10.9 N 66.8 Iso 3 5CPF

248.19 23.914 Liquid 4 3CPO1

232.18 21.619 Cr 32.0 Iso 5 5PP1

238.17 22.624 Cr 48.0 Iso 6 3GPS

271.08 24.313 Cr 45.0 Iso 7 2CPUS

357.14 23.961 Cr 50.0 N 175.0 Iso 8 5CPUS

399.18 24.874 Cr 50.5 N 196.3 Iso 9 3PGUF

344.12 24.694 Cr 62.5 Iso 10 5PGUF

372.15 25.021 Cr 56.4 Iso 11 5PGUS

411.13 26.486 Cr 57.4 N 159.2 Iso 12 5CPGUF

454.23 25.983 Cr 62.23 S 70

N 215 Iso13 5CPGUS

493.21 26.400 Cr 71.53 N 234.15 Iso 14 5PGUOCF3

438.14 26.242 Cr 47.4 N 69.3 Iso 15 5CPGUOCF3

520.22 26.558 Cr 58.10 S 82.6

N 230.35 Iso16 4PGPUF

434.17 24.884 Cr 96.8

SmC 111.9

SmA 214.6

N 231.4 Iso17 5PP(2)GIP4

478.30 26.865 Cr 53.55 S 72.65

N 109.84 Iso18 3PUQUF

428.10 25.191 Cr 47.2 Iso 19 3PGUQUF

522.12 26.205 Cr 88 N 135 Iso 20 3CEPC3

370.29 21.039 Cr 116.7 N 205.9 Iso 21 2CEPPN

333.17 21.072 Cr 89.0 N 245.6 Iso 22 3CPEP3

364.24 22.042 Cr 100.7 N 202.9 Iso 23 3CPEGN

365.18 23.498 Cr 107.1 N 214.4 Iso 24 2PEPN

251.09 20.946 Cr 77.6 N 80.9 Iso 25 3PEPN

265.11 22.869 Cr 108.1 N 113.5 Iso 51.9 N 26 4PEPN

279.13 24.478 Cr 71.3 N 74.2 Iso 27 3PTGS

295.08 22.476 Cr 55.22 S 69.37 Iso 28 5PTGS

323.11 23.248 Cr 50.59 N 90.59 Iso 29 7PTGS

351.15 24.016 Cr 41.98 N 45.06 Iso 30 5PTPO2

292.18 21.512 Cr 65.6 N 95.3 Iso 88.3 N 31 5PTUS

341.1 22.577 Cr 43.99 Iso 32 5CPTUS

423.18 22.974 Cr 62 N 228 Iso 33 5PPTUS

417.14 23.809 Cr 55.0 S 119.0 N 208.5 Iso 34 4PUTGS

421.11 22.559 Cr 93 Iso 35 2PTPP3

360.17 22.768 Cr 73.5 N 186 Iso 36 3PTPP2

360.17 22.583 Cr 73 N 189 Iso 37 3PTPP4

388.20 23.682 Cr 66.1 S 88.0 N 169.5 Iso 38 4PTPP3

388.29 23.445 Cr 38.5 S 60.0 N 174.0 Iso 39 4PTGTP4

444.21 26.201 Cr 78 N 180 Iso 40 4PTGTP5

458.22 26.918 Cr 72.12 N 172.81 Iso 41 5PP(1)PUF

444.21 25.014 Cr 76.9 N 127.6 Iso 42 5PPI(1)PUF

444.21 24.608 Cr 77.4 N 134 Iso 43 5CB

249.15 25.010 Cr 24 N 35.3 Iso 注: Cr, 各向异性晶体相; S, 近晶相; N, 向列相; Iso, 各向同性; SmA, SmA相态; SmC, SmC相态. 表 2 BPNN模型的结果

Table 2. Results of BPNN model.

网络结构 R2 R2 (cross-validated) q2 12-4-1 0.9238 0.5089 0.6070 表 3 训练组与测试组液晶化合物的试验黏度量度及预测黏度量度

Table 3. VMexpt and VMpred of liquid compounds in the training group and test group

No. Compounds η/(mPa·s) $ {{\mathrm{VM}}}_{{\mathrm{expt}}} $ $ {{\mathrm{VM}}}_{{\mathrm{pred}}} $ $ \Delta {\mathrm{VM}} $ δ 1* 3CC2 19.647 1.293 1.319 0.026 0.020 2 3CC4 20.983 1.322 1.318 0.004 0.003 3 5CPF 23.914 1.379 1.376 0.002 0.002 4 3CPO1 21.619 1.335 1.336 0.001 0.001 5 5PP1 22.624 1.355 1.357 0.002 0.001 6 3GPS 24.313 1.386 1.363 0.023 0.017 7* 2CPUS 23.961 1.380 1.378 0.002 0.001 8 5CPUS 24.874 1.396 1.401 0.006 0.004 9 3PGUF 24.694 1.393 1.396 0.004 0.002 10* 5PGUF 25.021 1.398 1.405 0.006 0.004 11 5PGUS 26.486 1.423 1.425 0.002 0.001 12 5CPGUF 25.983 1.415 1.414 0.000 0.001 13 5CPGUS 26.400 1.422 1.418 0.004 0.003 14 5PGUOCF3 26.242 1.419 1.417 0.002 0.001 15 5CPGUOCF3 26.558 1.424 1.424 –0.001 0.000 16 4PGPUF 24.884 1.396 1.410 0.014 0.010 17 5PP(2)GIP4 26.865 1.429 1.426 0.003 0.002 18 3PUQUF 25.191 1.401 1.411 0.010 0.007 19 3PGUQUF 26.205 1.418 1.411 0.007 0.005 20 3CEPC3 21.039 1.323 1.326 0.003 0.002 21 2CEPPN 21.072 1.324 1.320 0.003 0.003 22 3CPEP3 22.042 1.343 1.344 0.001 0.001 23 3CPEGN 23.498 1.371 1.365 0.006 0.004 24 2PEPN 20.946 1.321 1.341 0.020 0.015 25* 3PEPN 22.869 1.359 1.353 0.006 0.004 26 4PEPN 24.478 1.389 1.365 0.024 0.017 27 3PTGS 22.476 1.352 1.347 0.005 0.004 28* 5PTGS 23.248 1.366 1.372 0.006 0.004 29 7PTGS 24.916 1.396 1.401 0.004 0.004 30 5PTPO2 21.512 1.333 1.337 0.004 0.003 31 5PTUS 22.577 1.354 1.364 0.011 0.007 32 5CPTUS 22.974 1.361 1.367 0.006 0.004 33* 5PPTUS 23.809 1.377 1.427 0.050 0.036 34 4PUTGS 22.559 1.353 1.364 0.011 0.008 35 2PTPP3 22.768 1.357 1.353 0.004 0.003 36 3PTPP2 22.583 1.354 1.345 0.009 0.007 37* 3PTPP4 23.682 1.374 1.374 -0.001 0.001 38 4PTPP3 23.445 1.370 1.366 0.004 0.003 39* 4PTGTP4 26.201 1.418 1.398 0.020 0.014 40 4PTGTP5 26.918 1.430 1.427 -0.003 0.002 41 5PP(1)PUF 25.014 1.398 1.412 0.014 0.010 42 5PPI(1)PUF 24.608 1.391 1.406 0.015 0.011 注: *为测试组数据. 表 4 结构描述符及相关分子结构信息、对应敏感度

Table 4. Structural descriptors and related molecular structure information, and corresponding sensitivity.

描述符 结构信息 敏感度 ES-Count-aasC 代表具有两个芳香键和一个单键的碳的电拓扑状态 (Electrotopological State, Estate)和电子结构信息 0.999735 Dipole-X 指示静电场中分子的强度和取向行为的3D电子描述符 0.947414 Num-RotatableBonds 可旋转键, 定义为既不在环中又不在末端的重原子之间的单键, 即连接到仅与

氢相连的重原子. 作为一种特殊情况, 酰胺C—N键是不可旋转的0.814023 Shadow-Xlength 阴影X长度, 表征分子形状的一组几何描述符, 代表分子在x维度上的长度 0.307771 ES-Sum-sssCH 计算具有三个单键的CH的电拓扑状态(Estate)总和 0.208536 JX Balaban指数 0.118169 ES-Count-tsC 代表具有一个三键的碳的电拓扑状态(Estate)计数 –0.707114 ES-Count-ssCH2 代表具有两个单键的CH2的电拓扑状态(Estate)计数 –0.671564 Wiener 维纳指数, 代表分子中所有重原子对之间存在的化学键的总和 –0.653192 ES-Sum-sF 计算F原子的电拓扑状态(Estate) –0.400111 ES-Count-sF F原子的电拓扑状态(Estate)计数 –0.400111 ALogP 使用Ghose和Crippen发表的基于原子的方法计算辛醇-水分配系(LogP) –0.128786 注: ES-Sum-xxx: 某原子电子结构和拓扑结构计算总和; ES-Count-xxx: 某种类型的原子在分子中出现的数目; -xxx中s, 单键; d, 双键; t, 三键; a, 芳香键[38,39]. -

[1] Demus D, Goodbye J W, Gray G W 1998 Handbook of Liquid Crystals Chichester (Wiley-VCH) p237

[2] 杨傅子 2008 物理学进展 28 107

Google Scholar

Google Scholar

Yang F Z 2008 Prog. Phys. 28 107

Google Scholar

Google Scholar

[3] 曹召良, 穆全全, 胡立发 2008 液晶与显示 23 157

Google Scholar

Google Scholar

Cao Z L, Mu Q Q, Hu L F 2008 Liq. Cryst. Disp. 23 157

Google Scholar

Google Scholar

[4] 李潭, 王震, 张智勇 2017 液晶与显示 32 862

Google Scholar

Google Scholar

Li T, Wang Z, Zhang Z Y 2017 Liq. Cryst. Disp. 32 862

Google Scholar

Google Scholar

[5] Qiu L L, Zhu L, Xu Y 2020 IEEE T. Antenn. Progag. 685680

Google Scholar

Google Scholar

[6] Robert C, Zbigniew C, Yuriy G 2018 Liq. Cryst. Rev. 6 17

Google Scholar

Google Scholar

[7] Alihosseini F, Ahmadi V, Mir A 2015 Liq. Cryst. 42 1638

Google Scholar

Google Scholar

[8] Jiang D, Liu Y, Li X 2019 IEEE Access 7 126265

Google Scholar

Google Scholar

[9] Kundtz N 2014 Microwave 57 56

[10] Nishikawa H, Shiroshita K, Higuchi H 2017 Adv. Mater. 29 1702354

Google Scholar

Google Scholar

[11] Mandle R J, Cowling S J, Goodby J W 2017 Phys. Chem. Chem. Phys. 19 11429

Google Scholar

Google Scholar

[12] Zhao X, Zhou J 2021 Proc. Natl. Acad. Sci. 118 21111

Google Scholar

Google Scholar

[13] 赵秀虎, 黄明俊, Satoshiay A 2023 液晶与显示 38 77

Google Scholar

Google Scholar

Zhao X H, Huang M J, Satoshiay A 2023 Liq. Cryst. Disp. 38 77

Google Scholar

Google Scholar

[14] Li B X, Xiao R L, Paladugu S 2019 Opt. Express 27 3861

Google Scholar

Google Scholar

[15] 杨槐, 王萌, 张兰英 2015 CN 106701105 B 9

Yang H, Wang M, Zhang L Y 2015 CN Patent 106701105 B 9

[16] 高鸿锦 2011 液晶化学 (北京: 清华大学出版社)第48页

Gao J H 2011 Liquid Crystals Chemistry (Beijing: Qinghua University Press) p48

[17] Chen C Y, Tsai T R, Pan C L, Pan R P 2003 Appl. Phys. Lett. 83 4497

Google Scholar

Google Scholar

[18] Reuter M G K, Garbat K, Vieweg N, Fischer B N, Dąbrowski R, Koch M, Dziaduszek J, Urban S 2013 J. Mater. Chem. C 1 4457

Google Scholar

Google Scholar

[19] 张智勇, 刘可庆, 戴志群 2014 液晶与显示 29 873

Google Scholar

Google Scholar

Zhang Z Y, Liu K Q, Dai Z Q 2014 Liq. Cryst. Disp. 29 873

Google Scholar

Google Scholar

[20] Herman J, Dziaduszek J, Dąbrowski R 2013 Liq. Cryst. 40 1174

Google Scholar

Google Scholar

[21] 张然, 彭增辉, 刘永刚 2009 液晶与显示 6 789

Zhang R, Peng Z H, Liu Y G 2009 Liq. Cryst. Disp. 6 789

[22] Bock F J, Kneppe H, Schneider F 1986 Liq. Cryst. 1 239

Google Scholar

Google Scholar

[23] Belyaev V V 1989 Russ. Chem. Rev. 58 917

Google Scholar

Google Scholar

[24] Gauza S, Jiao M, Wu S T 2008 Liq. Cryst. 35 1401

Google Scholar

Google Scholar

[25] Gauza S, Kula P, Liang X 2009 Mol. Cryst. Liq. Cryst. 509 47

Google Scholar

Google Scholar

[26] 刘运, 张智勇, 任占冬 2010 液晶与显示 4 490

Google Scholar

Google Scholar

Liu Y, Zhang Z Y, Ren Z D 2010 Liq. Cryst. Disp. 4 490

Google Scholar

Google Scholar

[27] Deng M M, Wang Y, Zhang Z 2012 Chin. J. Chem. 29 1093

Google Scholar

Google Scholar

[28] Soltani T, Fouzai M, Dhaoudi H 2016 Phase Transi. 89 622

Google Scholar

Google Scholar

[29] Bulsara A R, Maren A J, Schmera G 1993 Biol. Cybern. 70 145

Google Scholar

Google Scholar

[30] 袁永娜 2010 博士学位论文(兰州: 兰州大学)

Yuan Y N 2010 Ph. D. Dissertation (Lanzhou: Lanzhou University

[31] Hansch C, Steward A R 1964 J. Med. Chem. 7 691

Google Scholar

Google Scholar

[32] 王婷婷, 戴康, 王展, 高新蕾 2014 华中师范大学学报 48 379

Google Scholar

Google Scholar

Wang T T, Dai K, Wang Z, Gao X L 2014 J. Central China Normal Univ. 48 379

Google Scholar

Google Scholar

[33] Dąbrowski R, Dziaduszek J, Ziółek A 2007 Opto-Electro. Rev. 15 47

Google Scholar

Google Scholar

[34] Li J, Hu M, Chen R 2021 J. Mol. Liq. 325 115236

Google Scholar

Google Scholar

[35] 莫玲超, 梁晓琴, 安忠维 2013 应用化学 30 861

Google Scholar

Google Scholar

Mo L C, Liang X Q, An Z W 2013 Appl. Chem. 30 861

Google Scholar

Google Scholar

[36] 王婷婷, 戴康, 王展 2017 摩擦学学报 37 495

Google Scholar

Google Scholar

Wang T T, Dai K, Wang Z 2017 J. Frict. 37 495

Google Scholar

Google Scholar

[37] 王登菊, 周如金, 郎春燕 2012 计算机与应用化学 29 457

Google Scholar

Google Scholar

Wang D J, Zhou R J, Lang C Y 2012 Comput. Appl. Chem. 29 457

Google Scholar

Google Scholar

[38] Hall L H, Mohney B, Kier L B 1991 J. Chem. Inf. Comp. Sci. 31 76

Google Scholar

Google Scholar

[39] Hall L H, Kier L B 2000 J. Chem. Inf. Comp. Sci. 40 784

Google Scholar

Google Scholar

[40] 金印 2019 硕士学位论文(成都: 电子科技大学)

Jin Y 2019 M. S. Thesis (Chengdu: University of Electronic Science and Technology of China

Catalog

Metrics

- Abstract views: 3557

- PDF Downloads: 66

- Cited By: 0

DownLoad:

DownLoad: