-

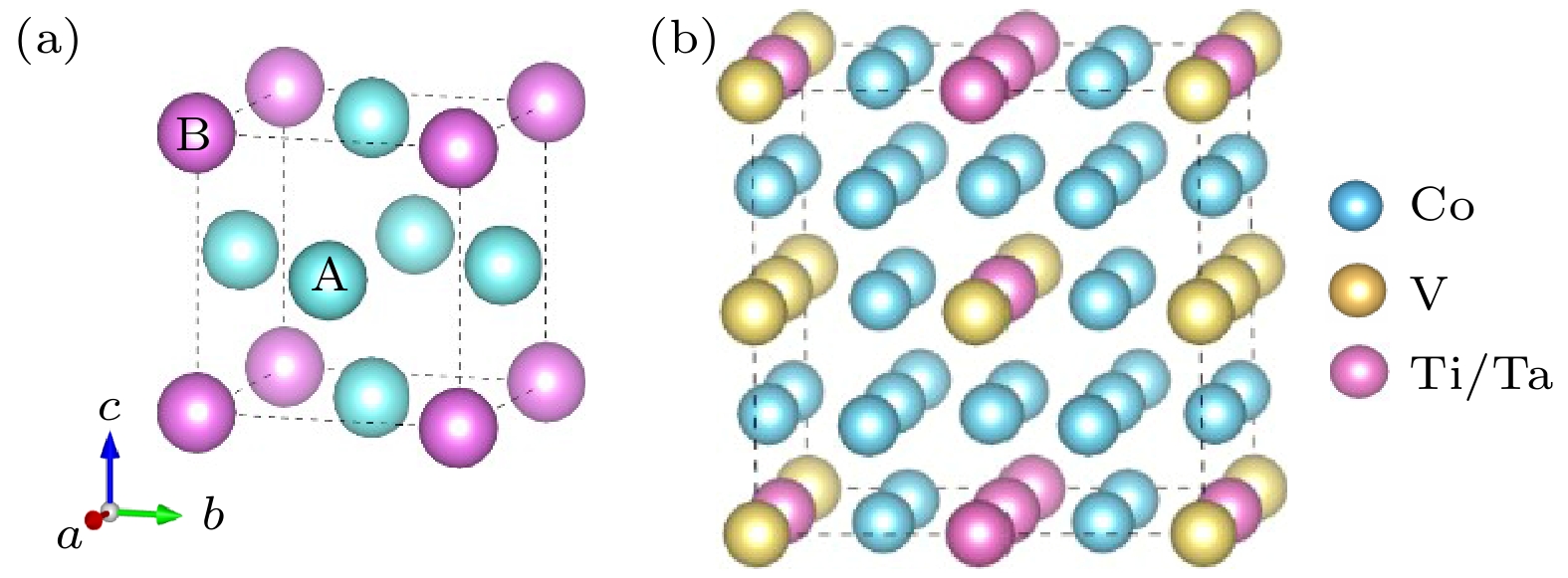

This research focuses on enhancing Co-based high-temperature alloys by using γ' precipitate phases to address the structural metastability of γ'-Co3(Al, W). By adding Ti and Ta, the γ'-Co3(V, Ti) and γ'-Co3(V, Ta) of Co-V alloys are stabilized, surpassing the performance of traditional Co-Al-W alloys. Utilizing a 2×2×2 supercell model and density functional theory (DFT), we investigate these alloys' phase stabilities and mechanical, thermodynamic, and electronic properties. Our findings show that γ'-Co3(V, Ti) phase and γ'-Co3(V, Ta) phases are stable at 0 K, evidenced by negative formation enthalpies and stable phonon spectra. Mechanical analysis confirms their stabilities through elastic constants and detailed evaluations of properties such as bulk modulus, shear modulus, and Young’s modulus, revealing excellent resistance to deformation and ductility. The electronic structure analysis further distinguishes γ'-Co3(V, Ta) for superior electronic stability, which is attributed to its lower state density and deviation from “pseudogap” peaks. Thermodynamically, the quasi-harmonic Debye model highlights the γ'-Co3(V, Ti) phase’s temperature-sensitive thermal expansion coefficient, while γ'-Co3(V, Ta) maintains higher stability at elevated temperatures. As temperature rises, both phases show decreased resistance to deformation, though they maintain comparable heat resistance due to low-temperature dependency. These results suggest that Co-V-Ti alloy and Co-V-Ta alloy can maintain their γ' phase stability at higher temperatures, enhancing Co-based high-temperature alloys’ performances and phase stabilities. This progress is crucial for developing new Co-based superalloys, and is of great significance for their applications and performance optimization.

-

Keywords:

- superalloys /

- first-principles calculation /

- structural stability /

- thermodynamic properties.

[1] Reed R C 2006 The Superalloys: Fundamentals and Applications (Cambridge: Cambridge University Press

[2] Liu S, Liu C, Ge L, Zhang X, Yu T, Yan P, Wang C Y 2017 Scr. Mater 138 100

Google Scholar

Google Scholar

[3] Schafrik R E, Sprague R 2004 Adv. Mater. Process. 162 41

[4] Pollock T M, Tin S 2006 J. Propul. Power 22 361

Google Scholar

Google Scholar

[5] Pan Y, Zhang X 2023 J. Mater. Res. Technol. 24 1792

Google Scholar

Google Scholar

[6] Pan Y, Wen M 2018 Vacuum 156 419

Google Scholar

Google Scholar

[7] Pan Y, Pu D L, Li Y Q, Zheng Q H 2020 Mater. Sci. Eng. B 259 114580

Google Scholar

Google Scholar

[8] Pan Y, Jin C 2017 Vacuum 143 165

Google Scholar

Google Scholar

[9] Pan Y 2023 J. Mater. Res. Technol. 26 8813

Google Scholar

Google Scholar

[10] Sato J, Omori T, Oikawa K, Ohnuma I, Kainuma R, Ishida K 2006 Science 312 90

Google Scholar

Google Scholar

[11] Kobayashi S, Tsukamoto Y, Takasugi T, Chinen H, Omori T, Ishida K, Zaefferer S 2009 Intermetallics 17 1085

Google Scholar

Google Scholar

[12] Ooshima M, Tanaka K, Okamoto N L, Kishida K, Inui H 2010 J. Alloys Compd. 508 71

Google Scholar

Google Scholar

[13] Kobayashi S, Tsukamoto Y, Takasugi T 2011 Intermetallics 19 1908

Google Scholar

Google Scholar

[14] Xue F, Zhou H J, Ding X F, Wang M L, Feng Q 2013 Mater. Lett. 112 215

Google Scholar

Google Scholar

[15] Yan H Y, Vorontsov V A, Dye D 2014 Intermetallics 48 44

Google Scholar

Google Scholar

[16] Liu J, Yu J J, Yang Y H, Zhou Y Z, Sun X F 2019 Mater. Sci. Eng. A 745 404

Google Scholar

Google Scholar

[17] Volz N, Xue F, Zenk C H, Bezold A, Gabel S, Subramanyam A P A, Drautz R, Hammerschmidt T, Makineni S K, Gault B, Göken M, Neumeier S 2021 Acta Mater. 214 117019

Google Scholar

Google Scholar

[18] Volz N, Xue F, Bezold A, Zenk C H, Fries S G, Schreuer J, Neumeier S, Göken M 2021 Metall. Mater. Trans. A 52 3931

Google Scholar

Google Scholar

[19] Guo J, Xiao B, Li Y, Zhai D, Tang Y, Du W, Liu Y 2021 Comput. Mater. Sci. 200 110787

Google Scholar

Google Scholar

[20] Makineni S K, Nithin B, Chattopadhyay K 2015 Acta Mater. 85 85

Google Scholar

Google Scholar

[21] Makineni S K, Nithin B, Chattopadhyay K 2015 Scr. Mater. 98 36

Google Scholar

Google Scholar

[22] Ruan J J, Wang C P, Yang S Y, Omori T, Yang T, Kimura Y, Liu X J, Kainuma R, Ishida K 2016 J. Alloys Compd. 664 141

Google Scholar

Google Scholar

[23] Bocchini P J, Sudbrack C K, Noebe R D, Dunand D C, Seidman D N 2017 Mater. Sci. Eng. A 705 122

Google Scholar

Google Scholar

[24] Yao Q, Zhu Y, Wang Y 2011 Physica B 406 1542

Google Scholar

Google Scholar

[25] Jiang C 2008 Scr. Mater. 59 1075

Google Scholar

Google Scholar

[26] Liu X, Wang Y, Xu W-W, Han J, Wang C 2020 J. Alloys Compd. 820 153179

Google Scholar

Google Scholar

[27] Wang Z, Zhang J, Zhang Y, Jin H, Zhang W 2020 J. Phys. Soc. Jpn. 89 124714

Google Scholar

Google Scholar

[28] Tang Y, Xiao B, Chen J, Liu F, Du W, Guo J, Liu Y, Liu Y 2022 Metall. Mater. Trans. A 54 450

Google Scholar

Google Scholar

[29] Xi S, Chen L, Bao L, Han J, Yu J, Li Z, Xu W, Bin D, Wang C, Liu X 2022 Mater. Today Commun. 30 102931

Google Scholar

Google Scholar

[30] Guo J, Xiao B, Tang Y, Li Y, Zhai D, Fan X, Liu Y 2024 Comput. Mater. Sci. 233 112767

Google Scholar

Google Scholar

[31] van de Walle A, Asta M, Ceder G 2002 Calphad 26 539

Google Scholar

Google Scholar

[32] Wang J, Yip S, Phillpot S R, Wolf D 1993 Phys. Rev. Lett. 71 4182

Google Scholar

Google Scholar

[33] Shang S, Wang Y, Liu Z-k 2007 Appl. Phys. Lett. 90 101909

Google Scholar

Google Scholar

[34] Wang S Q, Ye H Q 2003 J. Phys.: Condens. Matter 15 5307

Google Scholar

Google Scholar

[35] Anderson O L 1963 J. Phys. Chem. Solids 24 909

Google Scholar

Google Scholar

[36] Simmons G, Wang H F 1971 Single Crystal Elastic Constants and Calculated Aggregate Properties: A Handbook (Cambridge: M.I.T. Press

[37] Chen X-Q, Niu H, Li D, Li Y 2011 Intermetallics 19 1275

Google Scholar

Google Scholar

[38] Yan S, Wang Y, Tao F, Ren J 2022 J. Phys. Chem. A 126 8771

Google Scholar

Google Scholar

[39] Kim D, Shang S, Liu Z K 2012 Acta Mater. 60 1846

Google Scholar

Google Scholar

[40] Moruzzi V L, Janak J F, Schwarz K 1988 Phys. Rev. B 37 790

Google Scholar

Google Scholar

[41] Hill R 1952 Proc. Phys. Soc. A 65 349

Google Scholar

Google Scholar

[42] Hohenberg P, Kohn W 1964 Phys. Rev. 136 B864

Google Scholar

Google Scholar

[43] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

Google Scholar

Google Scholar

[44] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[45] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[46] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[47] Togo A 2023 J. Phys. Soc. Jpn. 92 012001

Google Scholar

Google Scholar

[48] Xu W W, Han J J, Wang Y, Wang C P, Liu X J, Liu Z K 2013 Acta Mater. 61 5437

Google Scholar

Google Scholar

[49] Rao P V M, Murthy K S, Suryanarayana S V, Naidu S V N 1992 Phys. Status Solidi A 133 231

Google Scholar

Google Scholar

[50] Rzyman K, Moser Z, Watson R E, Weinert M 1996 J. Phase Equilib. 17 173

Google Scholar

Google Scholar

[51] Born M 1939 J. Chem. Phys. 7 591

Google Scholar

Google Scholar

[52] Ali H, Chen R, Wu B, Xie T L, Weng L J, Wen J S, Yao Q P, Su L J, Zhao Y, Zhao P H, Sa B S, Liu Y, Wang C X, Su H, Hayat A 2022 Arab. J. Chem. 15 104278

Google Scholar

Google Scholar

[53] Stassis C, Loong C K, Theisen C, Nicklow R M 1982 Phys. Rev. B 26 4106

Google Scholar

Google Scholar

[54] Kayser F X, Stassis C 1981 Phys. Status Solidi A 64 335

Google Scholar

Google Scholar

[55] Tanaka K, Ohashi T, Kishida K, Inui H 2007 Appl. Phys. Lett. 91 181907

Google Scholar

Google Scholar

[56] Wang V, Xu N, Liu J C, Tang G, Geng W 2019 Comput. Phys. Commun. 267 108033

Google Scholar

Google Scholar

[57] Raheem Z 2019 Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials

[58] Pugh S F 1954 Philos. Mag. Ser. 45 823

Google Scholar

Google Scholar

[59] Pettifor D G 1992 Mater. Sci. Technol. 8 345

Google Scholar

Google Scholar

[60] Hu W C, Liu Y, Li D J, Zeng X Q, Xu C S 2014 Comput. Mater. Sci. 83 27

Google Scholar

Google Scholar

[61] Eberhart M E 1996 Acta Materialia 44 2495

Google Scholar

Google Scholar

[62] Jones H 1957 Acta Crystallogr. 10 390

Google Scholar

Google Scholar

[63] Wang Y, Wang J J, Zhang H, Manga V R, Shang S, Chen L Q, Liu Z K 2010 J. Phys.: Condens. Matter 22 225404

Google Scholar

Google Scholar

-

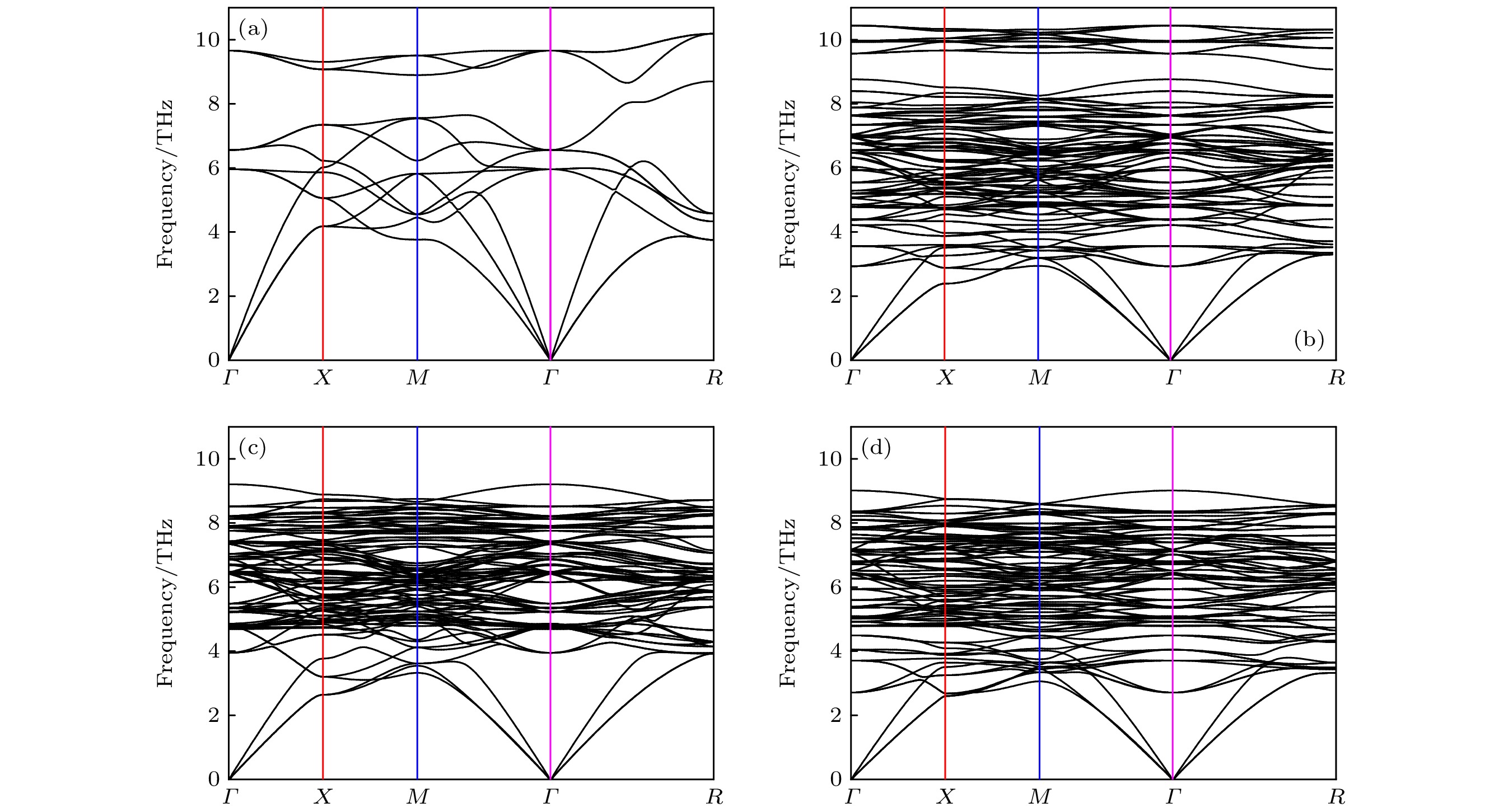

图 2 沿布里渊区高对称点连接方向计算得到的声子色散曲线 (a) γ'-Ni3Al; (b) γ'-Co3(Al, W); (c) γ'-Co3(V, Ti); (d) γ'-Co3(V, Ta), 横轴上单位为2π/a的高对称点分别为Γ = (0, 0, 0), X = (0, 0.5, 0), M = (0.5, 0.5, 0), R = (0.5, 0.5, 0.5)

Figure 2. Phonon dispersion curve calculated along the connection direction of high symmetry points in the Brillouin zone: (a) γ'-Ni3Al; (b) γ'-Co3(Al, W); (c) γ'-Co3(V, Ti); (d) γ'-Co3(V, Ta). On the horizontal axis (unit of 2π/a) the high symmetry points are: Γ = (0, 0, 0), X = (0, 0.5, 0), M = (0.5, 0.5, 0), R = (0.5, 0.5, 0.5).

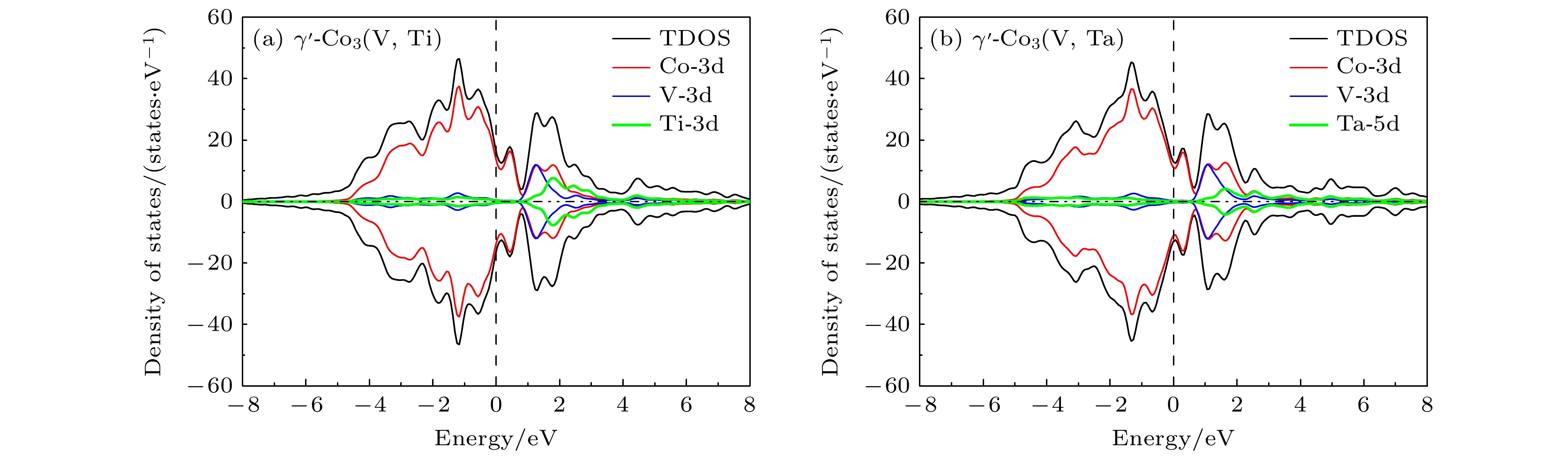

图 4 γ'-Co3(V, M) (M = Ti, Ta)相 (a) 热膨胀系数, (b) 等压热容CV和等容热容CP, (c) 焓H, (d) 熵S与温度的关系曲线

Figure 4. Relation curves of (a) coefficient of thermal expansion, (b) constant pressure heat capacity and constant volume heat capacity, (c) enthalpy, (d) entropy with temperature of γ'-Co3(V, M) (M = Ti, Ta) phases.

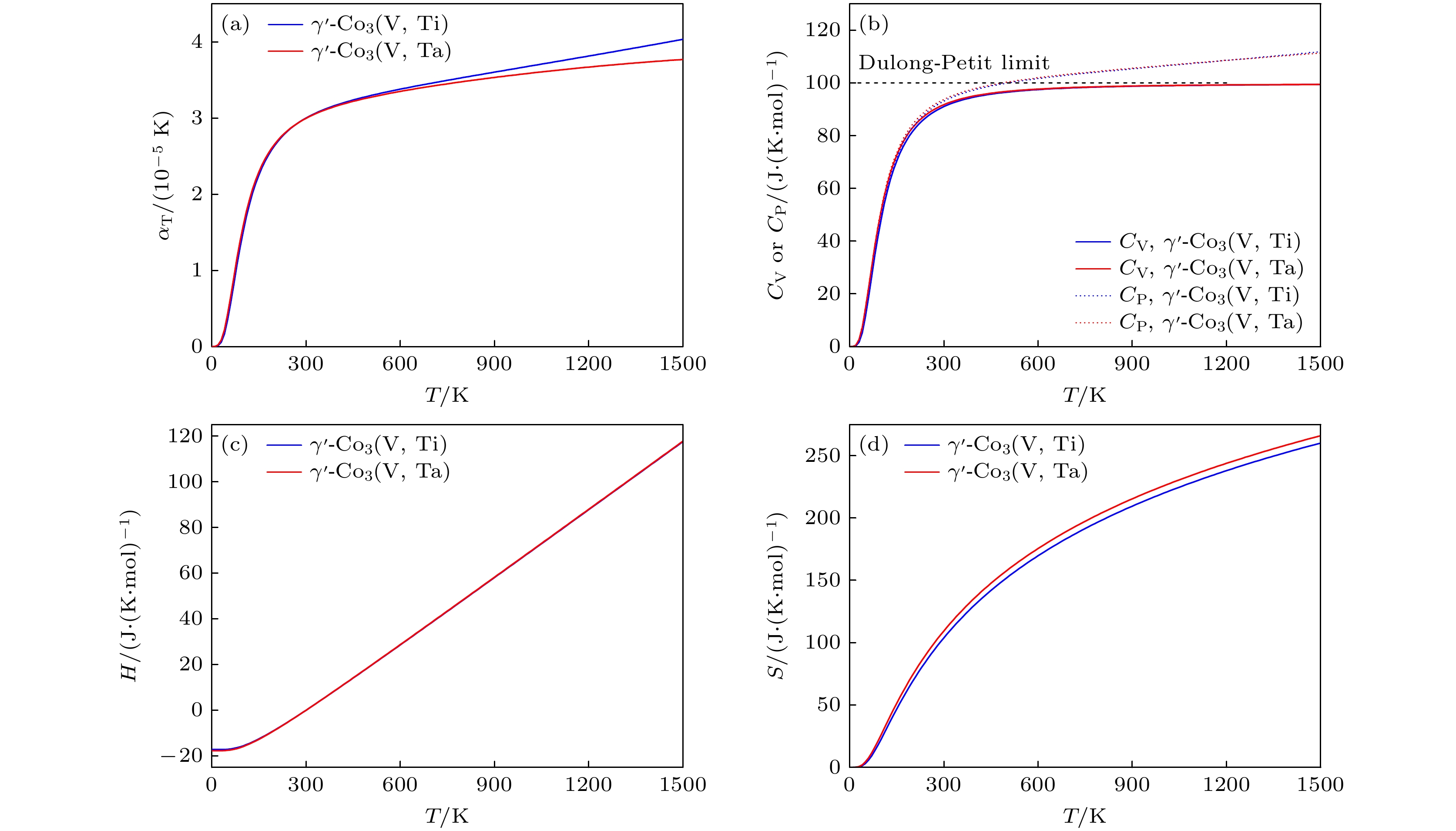

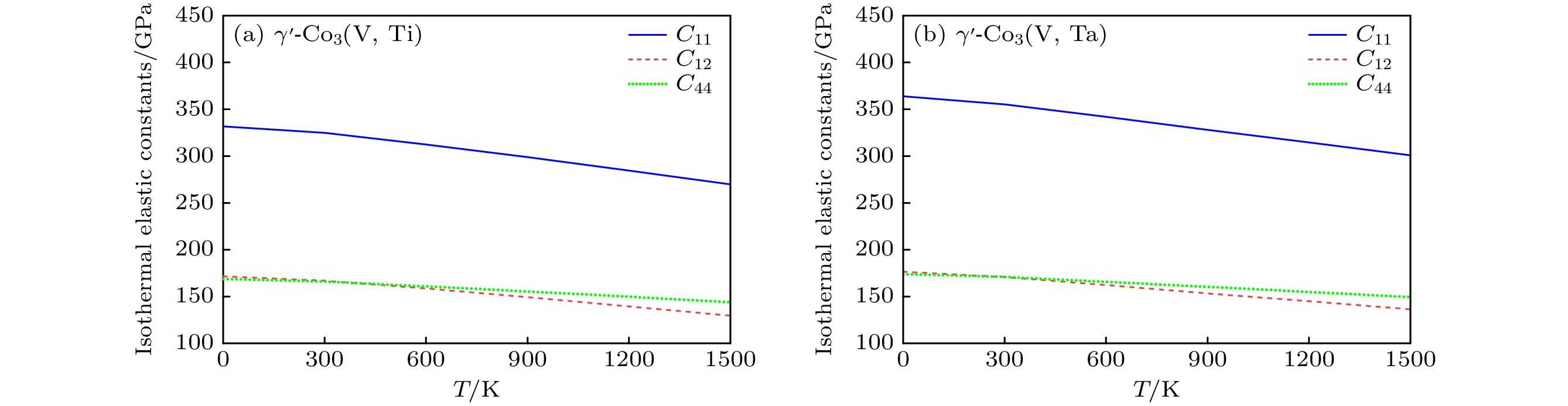

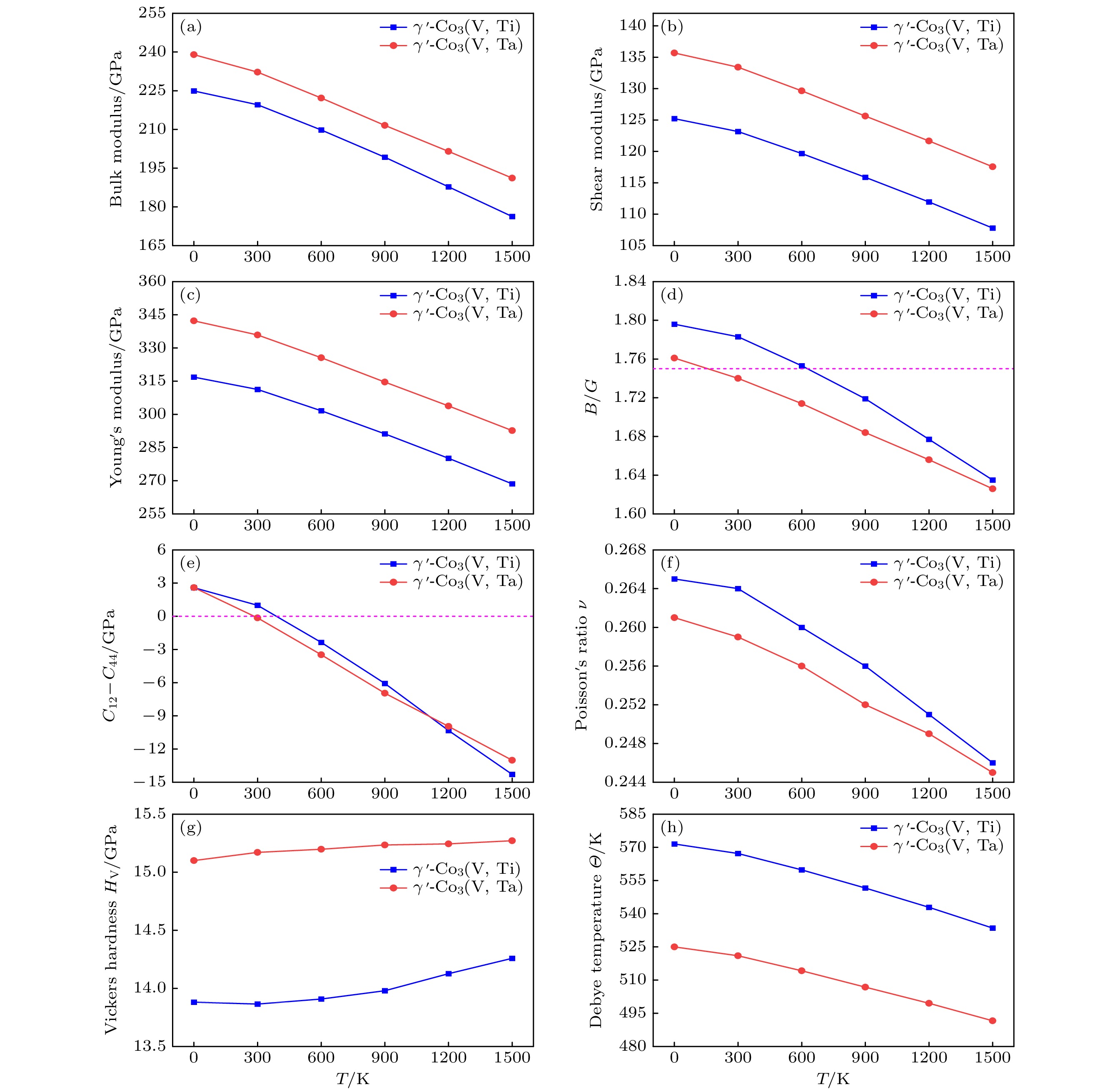

图 6 γ'-Co3(V, M) (M = Ti, Ta)相的体积模量B、剪切模量G、杨氏模量E、B/G值、柯西压力C12-C44、泊松比υ、维氏硬度HV以及德拜温度ΘD在有限温度下的变化趋势

Figure 6. Change trend of volume modulus B, shear modulus G, Young's modulus E, B/G value, Poisson's ratio υ, Vickers hardness HV and Debye temperature ΘD of γ'-Co3(V, M) (M = Ti, Ta) phases at finite temperature.

表 1 γ'-Co3(V, M) (M = Ti, Ta)相的平衡晶格常数a、体积V、密度ρ和形成焓ΔHf

Table 1. Equilibrium lattice constant a, volume V, density ρ and formation enthalpy $ \Delta {H}_{{\mathrm{f}}} $ of γ'-Co3(V, M) (M = Ti, Ta) phase alloy.

Materials Ni3Al Co3(Al, W) Co3(V, Ti) Co3(V, Ta) Cal. a) Cal. b) Exp. c) d) Cal a) Cal. b) Exp. e) Cal. a) Cal. a) a /Å 3.566 3.568 3.572 3.563 3.566 3.599 3.537 3.577 V /Å3 45.361 45.423 45.576 45.216 45.347 46.617 44.249 45.761 ρ/(g·cm–3) 7.433 7.427 7.405 10.364 10.334 10.056 8.489 10.623 $ \Delta {H}_{{\mathrm{f}}}/ $(kJ·mol–1) –41.399 –42.613 –41.3 d) –13.194 –14.958 — –21.678 –20.568 注: a) This work; b) Ref. [48], GGA-PAW; c) Ref.[49], experiment; d) Ref. [50], experiment; e) Ref.[10], experiment. 表 2 γ'-Co3(V, M) (M = Ti, Ta)相的弹性常数Cij、体积模量B、剪切模量G、杨氏模量E、B/G值、泊松比υ、柯西压力C12 – C44、维氏硬度HV以及德拜温度ΘD

Table 2. Elastic constants Cij, bulk modulus B, shear modulus G, Young’s modulus E, B/G value, Poisson’s ratio υ, Cauchy pressure C12 – C44, Vickers hardness HV and Debye temperature ΘD of γ'-Co3(V, M) (M = Ti, Ta) phases.

Materials Ni3Al Co3(Al, W) Co3(V, Ti) Co3(V, Ta) Cal.a) Cal.b) Exp.c)d) Cal a) Cal.e) Exp.f) Cal.a) Cal.a) C11 /GPa 232 238.85 223 334 304 271 344 369 C12 /GPa 153 146.07 148 189 181 172 178 176 C44/GPa 125 126.61 125 182 177 162 174 173 B/GPa 179 176.98 173 237 222 205 233 240 G/GPa 79 84.68 77 126 116 101 130 137 E/GPa 206 219.10 201 320 296 260 327 345 B/G 2.267 2.090 2.250 1.886 1.92 2.03 1.802 1.754 υ 0.308 0.290 0.310 0.275 0.278 0.290 0.266 0.260 C12–C44 /GPa 28 19.46 23 8 4 10 4 3 HV/GPa 6.83 11.65 — 12.99 — — 14.153 15.3 ΘD/K 482.7 — 470d 514.6 — — 580.4 527.4 注: a) This work; b) Ref.[52], GGA-PBE; c) Ref. [53], experiment; d) Ref. [54], experiment; e) Ref. [26], GGA-PBE; f) Ref.[55], experiment. 表 3 0—1500 K不同温度下γ'-Co3(V, M) (M = Ti, Ta)相的独立等温弹性常数$ C_{ij}^{{T}} $和多晶模量, 例如弹性模量B (GPa)、剪切模量G (GPa)、杨氏模量E (GPa)、B/G值和泊松比υ、以及维氏硬度HV (GPa)、德拜温度Θ (K)

Table 3. Independent isothermal elastic constant $ C_{ij}^{{T}} $ and polycrystalline modulus such as elastic modulus B (GPa), shear modulus G (GPa), Young’s modulus E (GPa), B/G value and Poisson’s ratio υ of γ'-Co3(V, M) (M = Ti, Ta) phases at different temperatures from 0—1500 K, And Vickers hardness HV (GPa), Debye temperature Θ (K).

Materials T C11 C12 C44 B G E B/G υ HV Θ Co3(V, Ti) 0 332 171 169 225 125 317 1.80 0.265 13.88 571.5 300 325 167 166 220 123 311 1.78 0.264 13.87 567.2 600 312 159 161 210 120 302 1.75 0.260 13.91 559.8 900 299 149 155 199 116 291 1.72 0.256 13.98 551.6 1200 284 139 150 188 112 280 1.68 0.251 14.13 542.9 1500 270 129 144 176 108 269 1.64 0.246 14.26 533.5 Co3(V, Ta) 0 364 176 174 239 136 342 1.76 0.261 15.10 525.0 300 355 171 171 232 133 336 1.74 0.259 15.17 521.0 600 342 162 166 222 130 326 1.71 0.256 15.20 514.2 900 328 153 160 212 126 315 1.68 0.252 15.24 506.8 1200 315 145 155 202 122 304 1.66 0.249 15.24 499.5 1500 301 136 149 191 118 293 1.63 0.245 15.27 491.6 -

[1] Reed R C 2006 The Superalloys: Fundamentals and Applications (Cambridge: Cambridge University Press

[2] Liu S, Liu C, Ge L, Zhang X, Yu T, Yan P, Wang C Y 2017 Scr. Mater 138 100

Google Scholar

Google Scholar

[3] Schafrik R E, Sprague R 2004 Adv. Mater. Process. 162 41

[4] Pollock T M, Tin S 2006 J. Propul. Power 22 361

Google Scholar

Google Scholar

[5] Pan Y, Zhang X 2023 J. Mater. Res. Technol. 24 1792

Google Scholar

Google Scholar

[6] Pan Y, Wen M 2018 Vacuum 156 419

Google Scholar

Google Scholar

[7] Pan Y, Pu D L, Li Y Q, Zheng Q H 2020 Mater. Sci. Eng. B 259 114580

Google Scholar

Google Scholar

[8] Pan Y, Jin C 2017 Vacuum 143 165

Google Scholar

Google Scholar

[9] Pan Y 2023 J. Mater. Res. Technol. 26 8813

Google Scholar

Google Scholar

[10] Sato J, Omori T, Oikawa K, Ohnuma I, Kainuma R, Ishida K 2006 Science 312 90

Google Scholar

Google Scholar

[11] Kobayashi S, Tsukamoto Y, Takasugi T, Chinen H, Omori T, Ishida K, Zaefferer S 2009 Intermetallics 17 1085

Google Scholar

Google Scholar

[12] Ooshima M, Tanaka K, Okamoto N L, Kishida K, Inui H 2010 J. Alloys Compd. 508 71

Google Scholar

Google Scholar

[13] Kobayashi S, Tsukamoto Y, Takasugi T 2011 Intermetallics 19 1908

Google Scholar

Google Scholar

[14] Xue F, Zhou H J, Ding X F, Wang M L, Feng Q 2013 Mater. Lett. 112 215

Google Scholar

Google Scholar

[15] Yan H Y, Vorontsov V A, Dye D 2014 Intermetallics 48 44

Google Scholar

Google Scholar

[16] Liu J, Yu J J, Yang Y H, Zhou Y Z, Sun X F 2019 Mater. Sci. Eng. A 745 404

Google Scholar

Google Scholar

[17] Volz N, Xue F, Zenk C H, Bezold A, Gabel S, Subramanyam A P A, Drautz R, Hammerschmidt T, Makineni S K, Gault B, Göken M, Neumeier S 2021 Acta Mater. 214 117019

Google Scholar

Google Scholar

[18] Volz N, Xue F, Bezold A, Zenk C H, Fries S G, Schreuer J, Neumeier S, Göken M 2021 Metall. Mater. Trans. A 52 3931

Google Scholar

Google Scholar

[19] Guo J, Xiao B, Li Y, Zhai D, Tang Y, Du W, Liu Y 2021 Comput. Mater. Sci. 200 110787

Google Scholar

Google Scholar

[20] Makineni S K, Nithin B, Chattopadhyay K 2015 Acta Mater. 85 85

Google Scholar

Google Scholar

[21] Makineni S K, Nithin B, Chattopadhyay K 2015 Scr. Mater. 98 36

Google Scholar

Google Scholar

[22] Ruan J J, Wang C P, Yang S Y, Omori T, Yang T, Kimura Y, Liu X J, Kainuma R, Ishida K 2016 J. Alloys Compd. 664 141

Google Scholar

Google Scholar

[23] Bocchini P J, Sudbrack C K, Noebe R D, Dunand D C, Seidman D N 2017 Mater. Sci. Eng. A 705 122

Google Scholar

Google Scholar

[24] Yao Q, Zhu Y, Wang Y 2011 Physica B 406 1542

Google Scholar

Google Scholar

[25] Jiang C 2008 Scr. Mater. 59 1075

Google Scholar

Google Scholar

[26] Liu X, Wang Y, Xu W-W, Han J, Wang C 2020 J. Alloys Compd. 820 153179

Google Scholar

Google Scholar

[27] Wang Z, Zhang J, Zhang Y, Jin H, Zhang W 2020 J. Phys. Soc. Jpn. 89 124714

Google Scholar

Google Scholar

[28] Tang Y, Xiao B, Chen J, Liu F, Du W, Guo J, Liu Y, Liu Y 2022 Metall. Mater. Trans. A 54 450

Google Scholar

Google Scholar

[29] Xi S, Chen L, Bao L, Han J, Yu J, Li Z, Xu W, Bin D, Wang C, Liu X 2022 Mater. Today Commun. 30 102931

Google Scholar

Google Scholar

[30] Guo J, Xiao B, Tang Y, Li Y, Zhai D, Fan X, Liu Y 2024 Comput. Mater. Sci. 233 112767

Google Scholar

Google Scholar

[31] van de Walle A, Asta M, Ceder G 2002 Calphad 26 539

Google Scholar

Google Scholar

[32] Wang J, Yip S, Phillpot S R, Wolf D 1993 Phys. Rev. Lett. 71 4182

Google Scholar

Google Scholar

[33] Shang S, Wang Y, Liu Z-k 2007 Appl. Phys. Lett. 90 101909

Google Scholar

Google Scholar

[34] Wang S Q, Ye H Q 2003 J. Phys.: Condens. Matter 15 5307

Google Scholar

Google Scholar

[35] Anderson O L 1963 J. Phys. Chem. Solids 24 909

Google Scholar

Google Scholar

[36] Simmons G, Wang H F 1971 Single Crystal Elastic Constants and Calculated Aggregate Properties: A Handbook (Cambridge: M.I.T. Press

[37] Chen X-Q, Niu H, Li D, Li Y 2011 Intermetallics 19 1275

Google Scholar

Google Scholar

[38] Yan S, Wang Y, Tao F, Ren J 2022 J. Phys. Chem. A 126 8771

Google Scholar

Google Scholar

[39] Kim D, Shang S, Liu Z K 2012 Acta Mater. 60 1846

Google Scholar

Google Scholar

[40] Moruzzi V L, Janak J F, Schwarz K 1988 Phys. Rev. B 37 790

Google Scholar

Google Scholar

[41] Hill R 1952 Proc. Phys. Soc. A 65 349

Google Scholar

Google Scholar

[42] Hohenberg P, Kohn W 1964 Phys. Rev. 136 B864

Google Scholar

Google Scholar

[43] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

Google Scholar

Google Scholar

[44] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[45] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[46] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[47] Togo A 2023 J. Phys. Soc. Jpn. 92 012001

Google Scholar

Google Scholar

[48] Xu W W, Han J J, Wang Y, Wang C P, Liu X J, Liu Z K 2013 Acta Mater. 61 5437

Google Scholar

Google Scholar

[49] Rao P V M, Murthy K S, Suryanarayana S V, Naidu S V N 1992 Phys. Status Solidi A 133 231

Google Scholar

Google Scholar

[50] Rzyman K, Moser Z, Watson R E, Weinert M 1996 J. Phase Equilib. 17 173

Google Scholar

Google Scholar

[51] Born M 1939 J. Chem. Phys. 7 591

Google Scholar

Google Scholar

[52] Ali H, Chen R, Wu B, Xie T L, Weng L J, Wen J S, Yao Q P, Su L J, Zhao Y, Zhao P H, Sa B S, Liu Y, Wang C X, Su H, Hayat A 2022 Arab. J. Chem. 15 104278

Google Scholar

Google Scholar

[53] Stassis C, Loong C K, Theisen C, Nicklow R M 1982 Phys. Rev. B 26 4106

Google Scholar

Google Scholar

[54] Kayser F X, Stassis C 1981 Phys. Status Solidi A 64 335

Google Scholar

Google Scholar

[55] Tanaka K, Ohashi T, Kishida K, Inui H 2007 Appl. Phys. Lett. 91 181907

Google Scholar

Google Scholar

[56] Wang V, Xu N, Liu J C, Tang G, Geng W 2019 Comput. Phys. Commun. 267 108033

Google Scholar

Google Scholar

[57] Raheem Z 2019 Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials

[58] Pugh S F 1954 Philos. Mag. Ser. 45 823

Google Scholar

Google Scholar

[59] Pettifor D G 1992 Mater. Sci. Technol. 8 345

Google Scholar

Google Scholar

[60] Hu W C, Liu Y, Li D J, Zeng X Q, Xu C S 2014 Comput. Mater. Sci. 83 27

Google Scholar

Google Scholar

[61] Eberhart M E 1996 Acta Materialia 44 2495

Google Scholar

Google Scholar

[62] Jones H 1957 Acta Crystallogr. 10 390

Google Scholar

Google Scholar

[63] Wang Y, Wang J J, Zhang H, Manga V R, Shang S, Chen L Q, Liu Z K 2010 J. Phys.: Condens. Matter 22 225404

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7982

- PDF Downloads: 152

- Cited By: 0

DownLoad:

DownLoad: