-

2,6-diamino-3,5-dinitropyrazine-1-oxide (LLM-105) is a typical high-energy and low-sensitivity energetic material (EM), which has excellent detonation performance and thermal stability. In the quasi-harmonic approximation, the dispersion corrected density functional theory is used to study the intermolecular interactions and thermodynamic properties of energetic LLM-105 crystal. By introducing the zero-point energy and temperature effect corrections, PBE-D3 dispersion correction scheme can significantly improve the calculation accuracy of structural parameters at an experimental temperature (294 K). The temperature dependent lattice parameters and thermal expansion coefficients exhibit strong anisotropy, especially the thermal expansivity in b-axis orientation (intermolecular layers) is much higher than that in the ac plane (intramolecular layers). Through Hirshfeld surface and fingerprint analysis, it is found that the intermolecular interactions of LLM-105 are mainly O···H hydrogen bonding interactions. The change of intermolecular interactions will result in the rotation of nitro group, which can contribute to forming new hydrogen-bonding interaction pattern. Mulliken population analysis shows that the bond order of C—NO2 bond is more sensitive to the change of temperature, so this bond may be a trigger bond for the high-temperature decomposition reaction of LLM-105. The fundamental thermodynamic properties of EMs can not only provide key parameters for mesoscopic or macroscopic thermodynamic simulations, but also gain theoretical insights into the temperature effects of EMs. Specific heat capacity reflects the amount of heat to be supplied to heating the matter and it is important to make the risk assessment of EMs during storage or when exposed to external thermal stimuli. Herein, the basic thermodynamic parameters, such as heat capacity, entropy, bulk modulus and elastic constants under different conditions are predicted. Among them, the calculated heat capacity and entropy describe the nonlinear behaviors within a temperature range of 0 to 500 K, and the calculated isobaric heat capacity Cp(T) is in good agreement with the available experimental measurements. The elasticity of material describes the macroscopic response of crystal to external force, and the bulk modulus B0 of molecular crystal can be determined through the equation of state, which is an important parameter for evaluating material stiffness. The bulk modulus under adiabatic condition is in reasonable agreement with experimental value, and the evolution of bulk modulus with temperature reflects the softening behavior of LLM-105 at temperature. Furthermore, the complete set of second-order elastic constants (SOECs) of LLM-105 is calculated and 13 independent SOECs (C11, C12, C13, C15, C22, C23, C25, C33, C35, C44, C46, C55, C66) are predicted. With the increasing temperature, all elastic constants gradually decrease due to the weakening of intermolecular interactions of LLM-105. Overall, these results will fundamentally provide a deep understanding of temperature effects and serve as a reference for the experimental measurement of the thermodynamic parameters of EMs. -

Keywords:

- LLM-105 /

- thermodynamic properties /

- intermolecular interactions /

- quasi-harmonic approximation

[1] 王泽山 2006 含能材料概论 (哈尔滨: 哈尔滨工业大学出版社) 第4—8页

Wang Z S 2006 Introduction to Energetic Material (Harbin: Harbin Institute of Technology Press) pp4–8

[2] Zhang C Y, Wang X C, Huang H 2008 J. Am. Chem. Soc. 130 8359

Google Scholar

Google Scholar

[3] Jiao F B, Xiong Y, Li H Z, Zhang C Y 2018 Cryst. Eng. Comm 20 1757

Google Scholar

Google Scholar

[4] Gilardi R D, Butcher R J 2001 Acta Crystallogr. E 57 o657

Google Scholar

Google Scholar

[5] Tarver C M, Urtiew P A, Tran T D 2005 J. Energ. Mater. 23 183

Google Scholar

Google Scholar

[6] Averkiev B B, Antipin M Y, Yudin I L, Sheremetev A B 2002 J. Mol. Struc. 606 139

Google Scholar

Google Scholar

[7] Li G, Zhang C Y 2020 J. Hazard. Mater. 398 122910

Google Scholar

Google Scholar

[8] Miao M S, Sun Y H, Zurek E, Lin H Q 2020 Nat. Rev. Chem. 4 508

Google Scholar

Google Scholar

[9] Gump J C, Stoltz C A, Mason B P, Freedman B G, Ball J R, Peiris S M 2011 J. Appl. Phys. 110 073523

Google Scholar

Google Scholar

[10] Stavrou E, Riad Manaa M, Zaug J M, et al. 2015 J. Chem. Phys. 143 144506

Google Scholar

Google Scholar

[11] Xu Z L, Su H, Zhou X Q, et al. 2019 J. Phys. Chem. C 123 1110

Google Scholar

Google Scholar

[12] Xu Z L, Chen Q, Li X D, et al. 2020 J. Phys. Chem. C 124 2399

Google Scholar

Google Scholar

[13] Manaa M R, Kuo I F, Fried L E 2014 J. Chem. Phys. 141 064702

Google Scholar

Google Scholar

[14] Wang J K, Xiong Y, Li H Z, Zhang C Y 2018 J. Phys. Chem. C 122 1109

Google Scholar

Google Scholar

[15] Wang X, Zeng Q, Li J S, Yang M L 2019 ACS Omega 4 21054

Google Scholar

Google Scholar

[16] Wu Q, Yang C H, Pan Y, Xiang F, Liu Z C, Zhu W H, Xiao H M 2013 J. Mol. Model. 19 5159

Google Scholar

Google Scholar

[17] Zong H H, Zhang L, Zhang W B, Jiang S L, Yu Y, Chen J 2017 J. Mol. Model. 23 275

Google Scholar

Google Scholar

[18] Yuan W S, Hong D, Luo Y X, Li X H, Liu F S, Liu Z T, Liu Q J 2023 Spectrochim. Acta A 303 123170

Google Scholar

Google Scholar

[19] Yu Q, Zhao C D, Li J S 2022 J. Therm. Anal. Calorim. 147 12965

Google Scholar

Google Scholar

[20] Li J Y, Zhang H B, Wen M P, Xu J J, Liu X F, Sun J 2016 J. Energ. Mater. 34 170

Google Scholar

Google Scholar

[21] Ma R, Sun W C, Picu C R 2021 Int. J. Solids Struct. 232 111170

Google Scholar

Google Scholar

[22] Menikoff R, Sewell T D 2002 Combust. Theor. Model. 6 103

Google Scholar

Google Scholar

[23] Chen J, Qiao Z Q, Wang L L, Nie F D, Yang G C, Huang H 2011 Mater. Lett. 65 1018

Google Scholar

Google Scholar

[24] Yu Q, Zhao C D, Liao L Y, Li H Z, Sui H L, Yin Y, Li J S 2020 Phys. Chem. Chem. Phys. 22 13729

Google Scholar

Google Scholar

[25] Jiang J, Liu J Y, Chen Y H, Wu Q H, Ju Z Y, Zhang S H 2021 Mol. Simulat. 47 678

Google Scholar

Google Scholar

[26] Xiao Q, Sui H L, Hao X F, Chen J, Yin Y, Yu Q, Yang X L, Ju X 2020 Spectrochim. Acta A 240 118577

Google Scholar

Google Scholar

[27] Dovesi R, Orlando R, Erba A, et al. 2014 Int. J. Quantum Chem. 114 1287

Google Scholar

Google Scholar

[28] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[29] Grimme S 2011 Wires. Comput. Mol. Sci. 1 211

Google Scholar

Google Scholar

[30] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[31] Fischer T H, Almlof J 1992 J. Phys. Chem. 96 9768

Google Scholar

Google Scholar

[32] Fan J Y, Su Y, Zheng Z Y, Zhao J J 2021 J. Phys. Condens. Mat. 33 275702

Google Scholar

Google Scholar

[33] Parwani A V 2009 CrystEngComm 11 19

Google Scholar

Google Scholar

[34] Spackman M A, McKinnon J J 2002 CrystEngComm 4 378

Google Scholar

Google Scholar

[35] Weese R K, Burnham A K, Turner H C, Tran T D 2007 J. Therm. Anal. Calorim. 89 465

Google Scholar

Google Scholar

[36] Ma H X, Song J R, Zhao F Q, Gao H X, Hu R Z 2008 Chin. J. Chem. 26 1997

Google Scholar

Google Scholar

[37] Drebushchak V A 2020 J. Therm. Anal. Calorim. 142 1097

Google Scholar

Google Scholar

[38] Hooks D E, Ramos K J, Bolme C A, Cawkwell M J 2015 Propell. Explos. Pyrot. 40 333

Google Scholar

Google Scholar

[39] Fan J Y, Su Y, Zhang Q Y, Zhao J J 2019 Comp. Mater. Sci. 161 379

Google Scholar

Google Scholar

[40] 位付景, 张伟斌, 董闯, 陈华 2023 72 096201

Google Scholar

Google Scholar

Wei F J, Zhang W B, Dong C, Chen H 2023 Acta Phys. Sin. 72 096201

Google Scholar

Google Scholar

[41] Stevens L L, Velisavljevic N, Hooks D E, Dattelbaum D M 2008 Propell. Explos. Pyrot. 33 286

Google Scholar

Google Scholar

[42] Nye J F 1985 Physical Properties of Crystals: Their Representation by Tensors and Matrices (New York: Oxford University Press) pp131–148

-

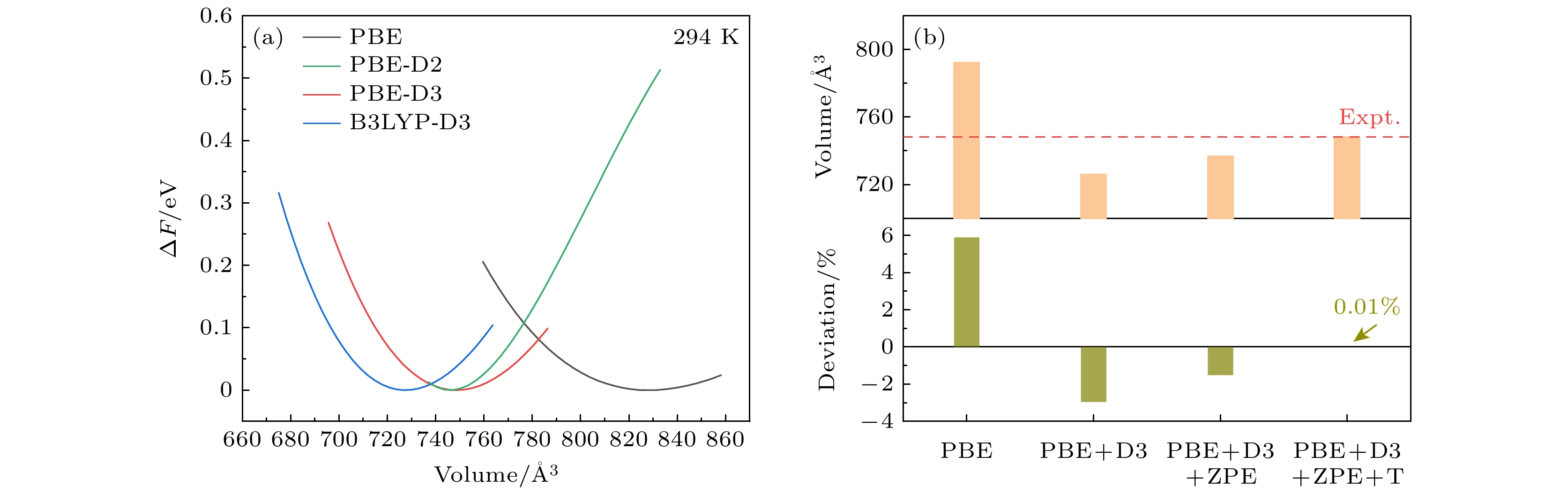

图 1 (a) 实验温度下, 不同泛函结合不同色散修正方案计算的F-V曲线; (b) PBE泛函结合D3色散修正方案、零点能效应和温度效应计算的LLM-105的晶胞体积以及与实验的误差

Figure 1. (a) F-V curves calculated at experimental temperature using different functional and dispersion correction schemes; (b) PBE functional combined with D3 dispersion correction scheme, zero point energy effect and temperature effect calculation of LLM-105 cell volume and experimental error.

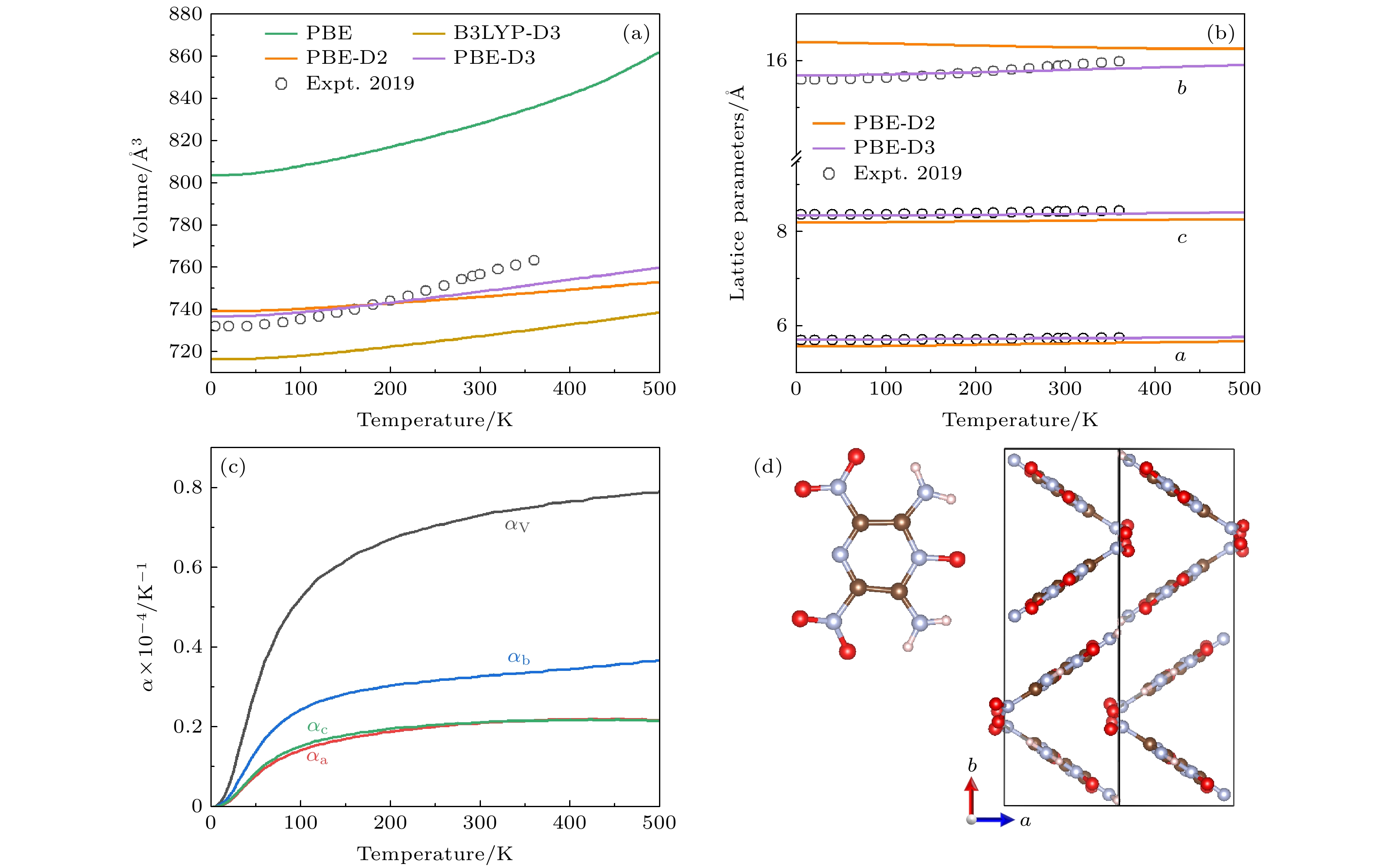

图 2 计算和实验测量[11]的LLM-105晶胞体积(a)和晶格参数(b)随温度的演化; (c) LLM-105的热膨胀系数随温度的演化; (d) LLM-105的分子结构和层间堆垛示意图, 其中粉色代表氢原子, 棕色代表碳原子, 蓝色代表氮原子, 红色代表氧原子

Figure 2. Calculated cell volume (a) and lattice parameters (b) at elevated temperature, compared with experimental values[11]; (c) variation of thermal expansion coefficient of LLM-105 with temperature increasing; (d) diagram of molecular structure and interlayer stacking of LLM-105, where the pink, brown, blue and red balls represent hydrogen, carbon, nitrogen and oxygen atoms, respectively.

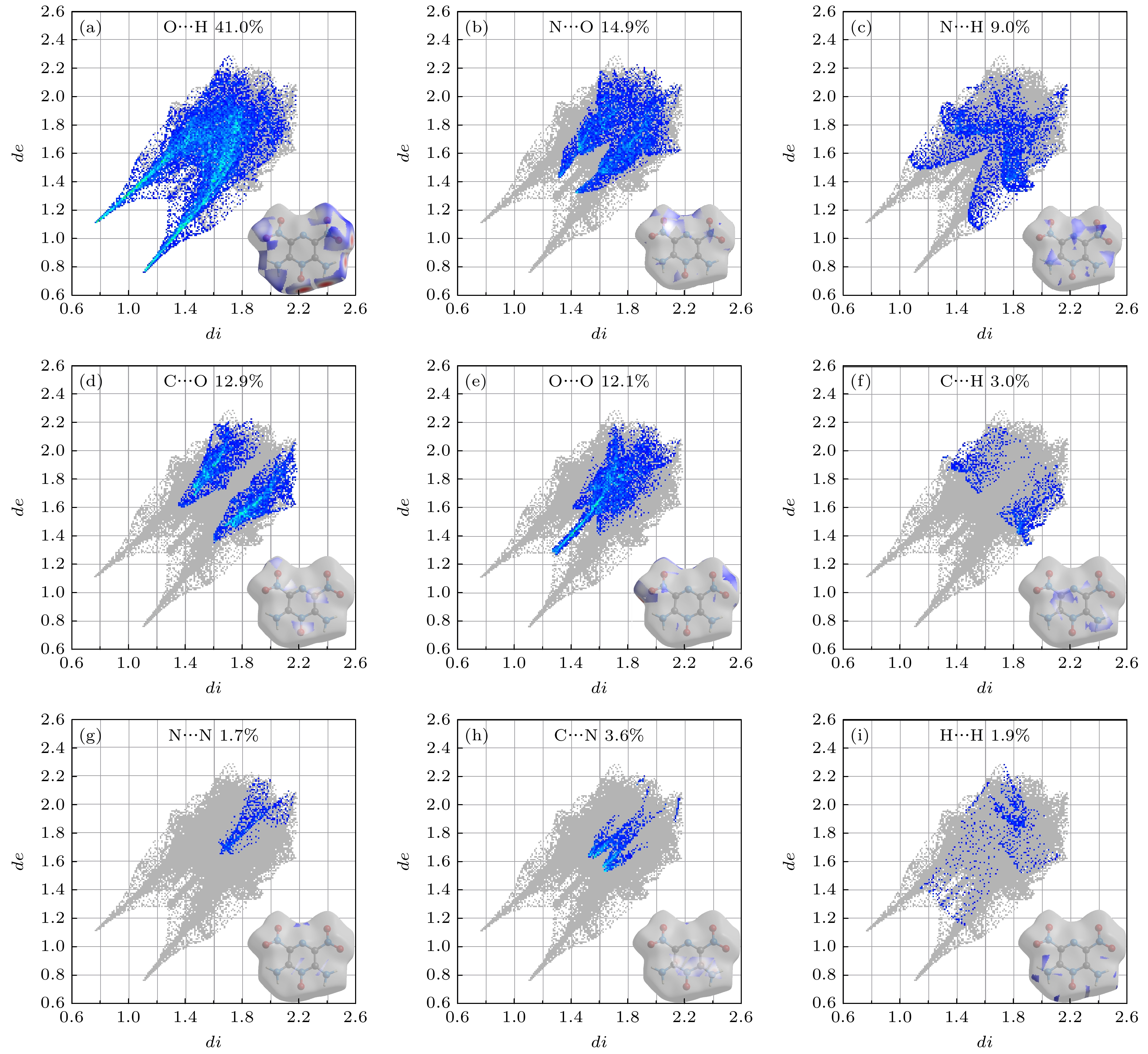

图 3 LLM-105晶体的 Hirshfeld表面、指纹图及其分子间相互作用对表面的相对贡献, 灰色区域表示LLM-105 晶体的 Hirshfeld 表面及其映射的二维指纹图, 其中蓝色和红色区域分别表示原子周围的正、负静电势

Figure 3. Hirshfeld, fingerprint, and intermolecular interactions of LLM-105 crystal, the gray area represents the Hirshfeld surface of LLM-105 crystal and its mapped two-dimensional fingerprint, where the blue and red areas represent the positive and negative electrostatic potential of the atoms, respectively.

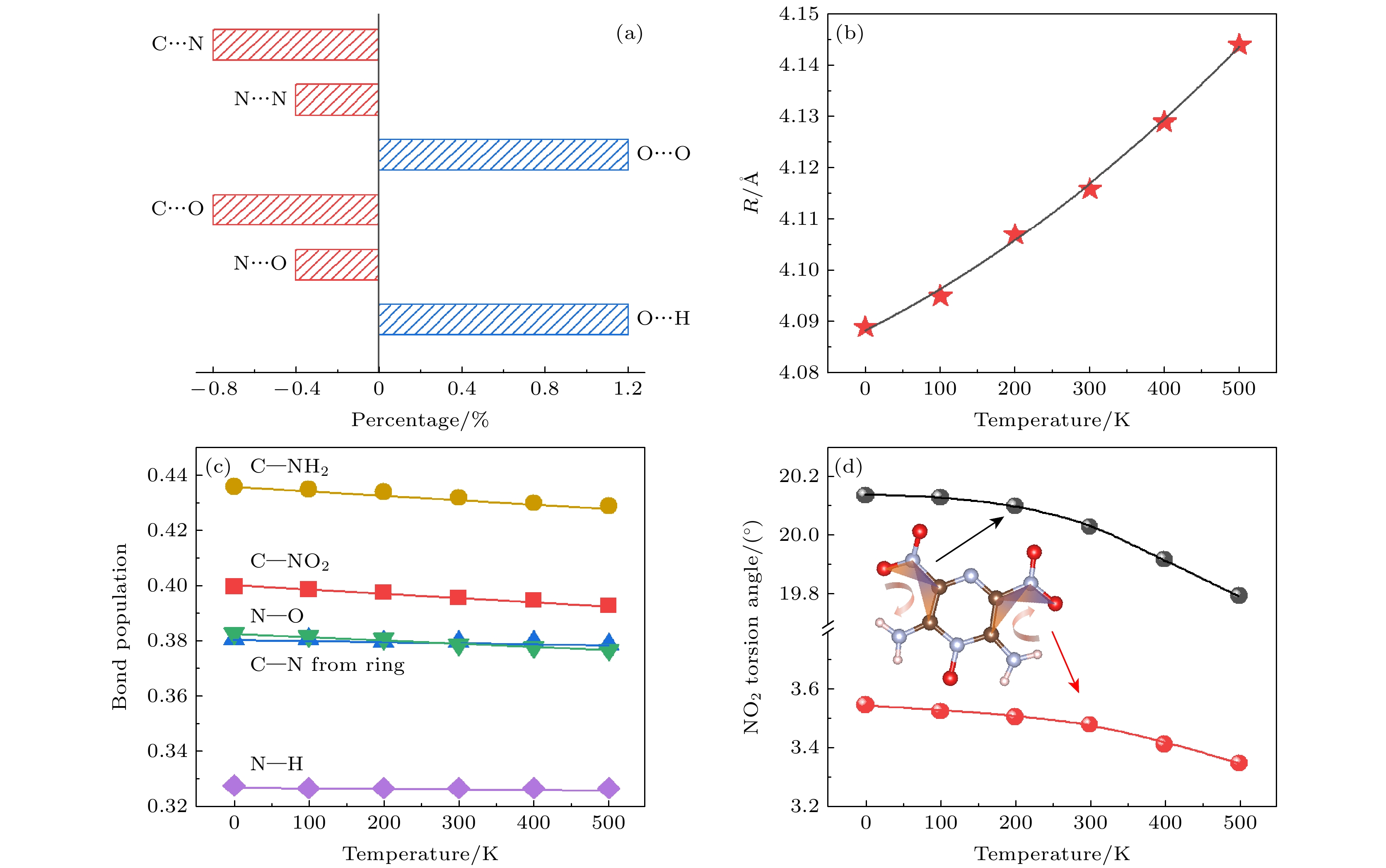

图 4 (a) 0—500 K范围内, LLM-105晶体分子间相互作用的变化量; (b) 层间分子的质心距离随温度的变化; (c) LLM-105分子中化学键布居数随温度的变化; (d) 计算的硝基(—NO2)与C—N环平面所成二面角随温度的变化

Figure 4. (a) Changes of intermolecular interactions of LLM-105 crystals at 0–500 K; (b) evolution of centroid distance of interlayer molecules under temperature; (c) variation of the bond population in LLM-105 molecules with temperature increasing; (d) calculated dihedral angle between nitro group (—NO2) and C—N ring plane with temperature increasing.

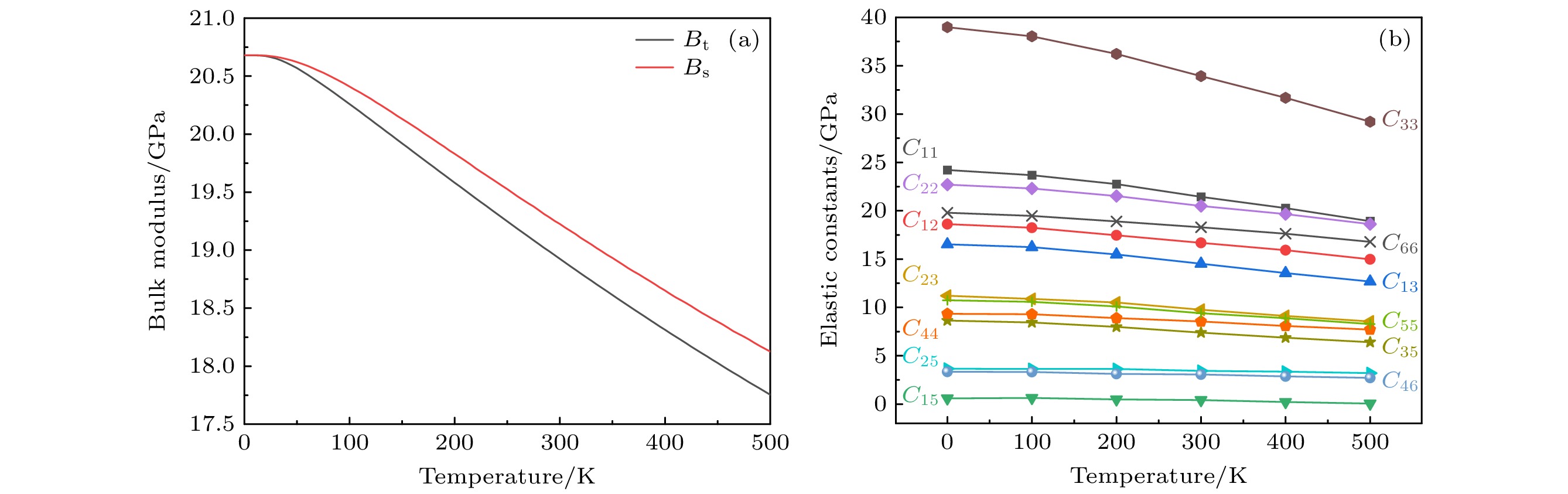

图 6 (a) 等温(Bt)和绝热(Bs)条件下LLM-105晶体的体模量随温度的变化; (b) LLM-105晶体的二阶弹性常数完全集及其随温度的变化

Figure 6. (a) Variation of bulk modulus of LLM-105 crystal under isothermal (Bt) and adiabatic (Bs) conditions with temperature increasing; (b) the complete set of second-order elastic constants of LLM-105 crystal and its temperature dependence.

表 1 实验温度下色散修正方案(PBE-D2/D3)结合零点能和温度效应计算的LLM-105结构参数及其与实验值之间的偏差

Table 1. Structural parameters of LLM-105 calculated by dispersion correction scheme (PBE-D2/D3) combined with zero-point energy and temperature effects at experimental temperature. The deviation is given under each calculated value.

V/Å3 a/Å b/Å c/Å β/(°) Expt.[4] 748.16 5.716 15.850 8.414 101.041 PBE-D2 745.83 5.62 16.30 8.25 99.46 (–0.31%) (–1.60%) (2.82%) (–1.96%) (–1.57%) PBE-D3 748.26 5.74 15.81 8.39 100.39 (0.01%) (0.36%) (–0.25%) (–0.32%) (–0.65%) -

[1] 王泽山 2006 含能材料概论 (哈尔滨: 哈尔滨工业大学出版社) 第4—8页

Wang Z S 2006 Introduction to Energetic Material (Harbin: Harbin Institute of Technology Press) pp4–8

[2] Zhang C Y, Wang X C, Huang H 2008 J. Am. Chem. Soc. 130 8359

Google Scholar

Google Scholar

[3] Jiao F B, Xiong Y, Li H Z, Zhang C Y 2018 Cryst. Eng. Comm 20 1757

Google Scholar

Google Scholar

[4] Gilardi R D, Butcher R J 2001 Acta Crystallogr. E 57 o657

Google Scholar

Google Scholar

[5] Tarver C M, Urtiew P A, Tran T D 2005 J. Energ. Mater. 23 183

Google Scholar

Google Scholar

[6] Averkiev B B, Antipin M Y, Yudin I L, Sheremetev A B 2002 J. Mol. Struc. 606 139

Google Scholar

Google Scholar

[7] Li G, Zhang C Y 2020 J. Hazard. Mater. 398 122910

Google Scholar

Google Scholar

[8] Miao M S, Sun Y H, Zurek E, Lin H Q 2020 Nat. Rev. Chem. 4 508

Google Scholar

Google Scholar

[9] Gump J C, Stoltz C A, Mason B P, Freedman B G, Ball J R, Peiris S M 2011 J. Appl. Phys. 110 073523

Google Scholar

Google Scholar

[10] Stavrou E, Riad Manaa M, Zaug J M, et al. 2015 J. Chem. Phys. 143 144506

Google Scholar

Google Scholar

[11] Xu Z L, Su H, Zhou X Q, et al. 2019 J. Phys. Chem. C 123 1110

Google Scholar

Google Scholar

[12] Xu Z L, Chen Q, Li X D, et al. 2020 J. Phys. Chem. C 124 2399

Google Scholar

Google Scholar

[13] Manaa M R, Kuo I F, Fried L E 2014 J. Chem. Phys. 141 064702

Google Scholar

Google Scholar

[14] Wang J K, Xiong Y, Li H Z, Zhang C Y 2018 J. Phys. Chem. C 122 1109

Google Scholar

Google Scholar

[15] Wang X, Zeng Q, Li J S, Yang M L 2019 ACS Omega 4 21054

Google Scholar

Google Scholar

[16] Wu Q, Yang C H, Pan Y, Xiang F, Liu Z C, Zhu W H, Xiao H M 2013 J. Mol. Model. 19 5159

Google Scholar

Google Scholar

[17] Zong H H, Zhang L, Zhang W B, Jiang S L, Yu Y, Chen J 2017 J. Mol. Model. 23 275

Google Scholar

Google Scholar

[18] Yuan W S, Hong D, Luo Y X, Li X H, Liu F S, Liu Z T, Liu Q J 2023 Spectrochim. Acta A 303 123170

Google Scholar

Google Scholar

[19] Yu Q, Zhao C D, Li J S 2022 J. Therm. Anal. Calorim. 147 12965

Google Scholar

Google Scholar

[20] Li J Y, Zhang H B, Wen M P, Xu J J, Liu X F, Sun J 2016 J. Energ. Mater. 34 170

Google Scholar

Google Scholar

[21] Ma R, Sun W C, Picu C R 2021 Int. J. Solids Struct. 232 111170

Google Scholar

Google Scholar

[22] Menikoff R, Sewell T D 2002 Combust. Theor. Model. 6 103

Google Scholar

Google Scholar

[23] Chen J, Qiao Z Q, Wang L L, Nie F D, Yang G C, Huang H 2011 Mater. Lett. 65 1018

Google Scholar

Google Scholar

[24] Yu Q, Zhao C D, Liao L Y, Li H Z, Sui H L, Yin Y, Li J S 2020 Phys. Chem. Chem. Phys. 22 13729

Google Scholar

Google Scholar

[25] Jiang J, Liu J Y, Chen Y H, Wu Q H, Ju Z Y, Zhang S H 2021 Mol. Simulat. 47 678

Google Scholar

Google Scholar

[26] Xiao Q, Sui H L, Hao X F, Chen J, Yin Y, Yu Q, Yang X L, Ju X 2020 Spectrochim. Acta A 240 118577

Google Scholar

Google Scholar

[27] Dovesi R, Orlando R, Erba A, et al. 2014 Int. J. Quantum Chem. 114 1287

Google Scholar

Google Scholar

[28] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[29] Grimme S 2011 Wires. Comput. Mol. Sci. 1 211

Google Scholar

Google Scholar

[30] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[31] Fischer T H, Almlof J 1992 J. Phys. Chem. 96 9768

Google Scholar

Google Scholar

[32] Fan J Y, Su Y, Zheng Z Y, Zhao J J 2021 J. Phys. Condens. Mat. 33 275702

Google Scholar

Google Scholar

[33] Parwani A V 2009 CrystEngComm 11 19

Google Scholar

Google Scholar

[34] Spackman M A, McKinnon J J 2002 CrystEngComm 4 378

Google Scholar

Google Scholar

[35] Weese R K, Burnham A K, Turner H C, Tran T D 2007 J. Therm. Anal. Calorim. 89 465

Google Scholar

Google Scholar

[36] Ma H X, Song J R, Zhao F Q, Gao H X, Hu R Z 2008 Chin. J. Chem. 26 1997

Google Scholar

Google Scholar

[37] Drebushchak V A 2020 J. Therm. Anal. Calorim. 142 1097

Google Scholar

Google Scholar

[38] Hooks D E, Ramos K J, Bolme C A, Cawkwell M J 2015 Propell. Explos. Pyrot. 40 333

Google Scholar

Google Scholar

[39] Fan J Y, Su Y, Zhang Q Y, Zhao J J 2019 Comp. Mater. Sci. 161 379

Google Scholar

Google Scholar

[40] 位付景, 张伟斌, 董闯, 陈华 2023 72 096201

Google Scholar

Google Scholar

Wei F J, Zhang W B, Dong C, Chen H 2023 Acta Phys. Sin. 72 096201

Google Scholar

Google Scholar

[41] Stevens L L, Velisavljevic N, Hooks D E, Dattelbaum D M 2008 Propell. Explos. Pyrot. 33 286

Google Scholar

Google Scholar

[42] Nye J F 1985 Physical Properties of Crystals: Their Representation by Tensors and Matrices (New York: Oxford University Press) pp131–148

Catalog

Metrics

- Abstract views: 5723

- PDF Downloads: 145

- Cited By: 0

DownLoad:

DownLoad: