-

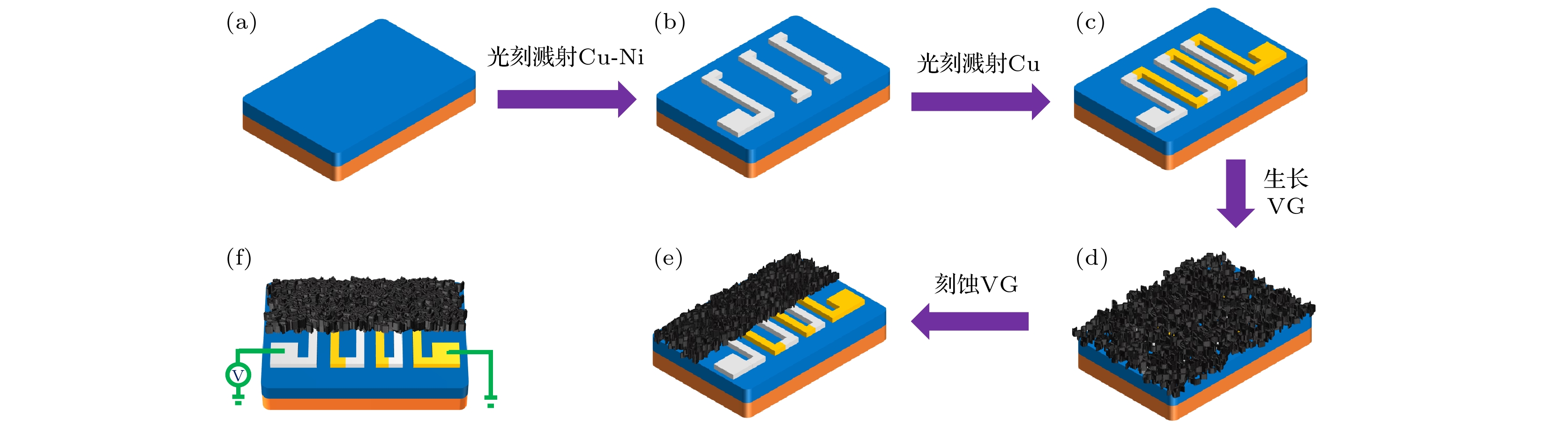

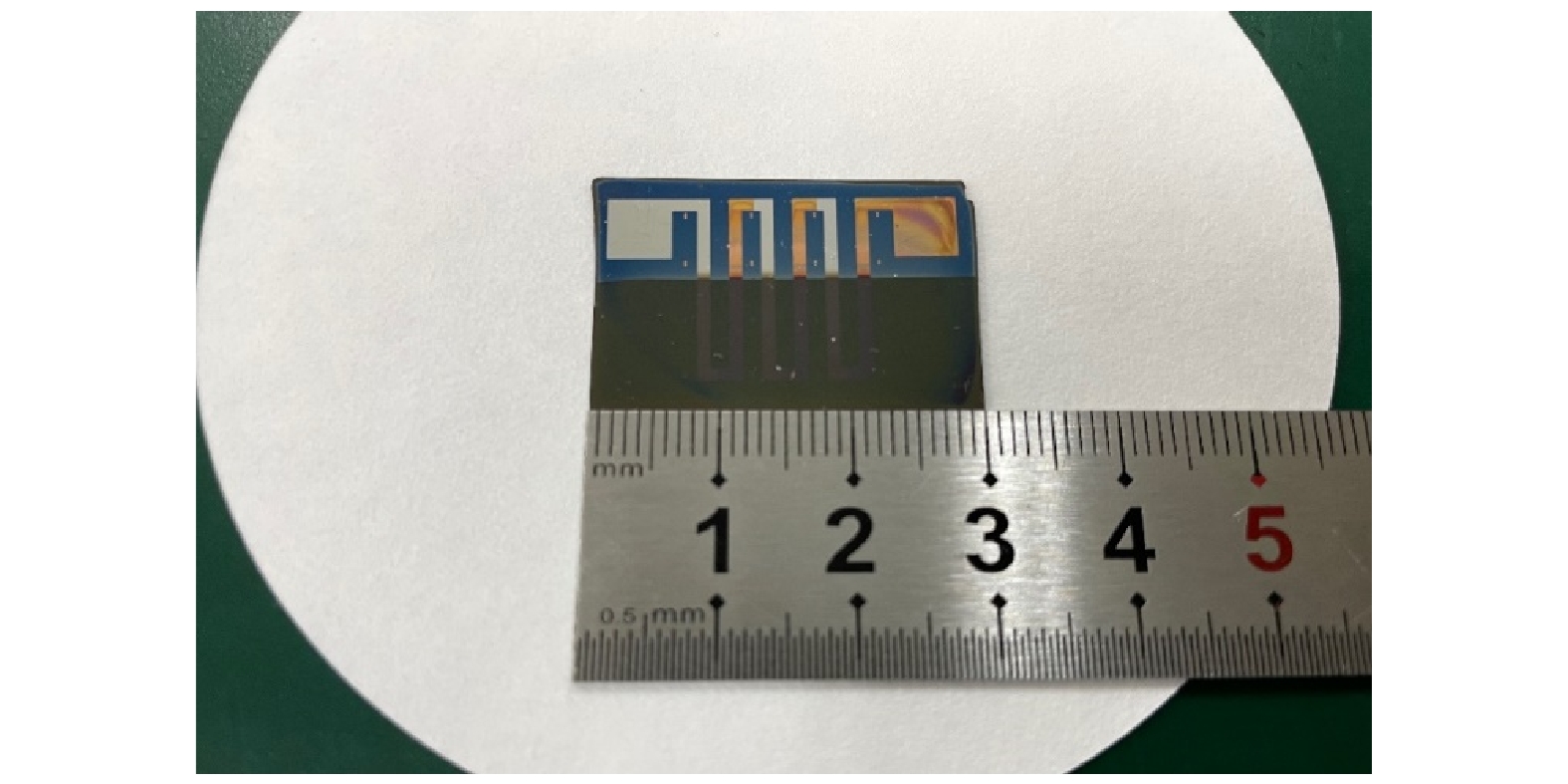

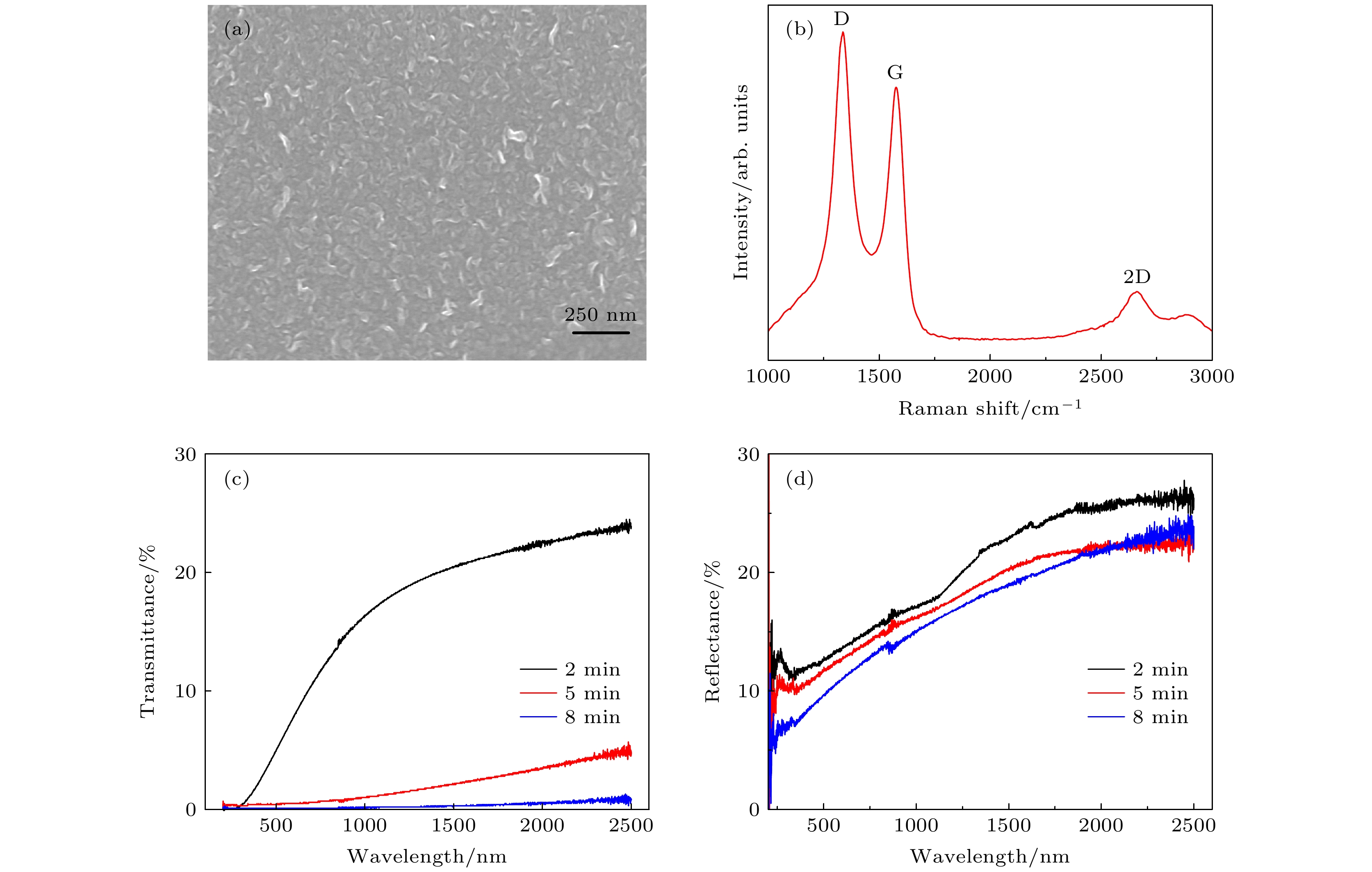

Thermopile infrared detector is a kind of detector device mainly composed of thermocouple as the basic unit. Because of its simple principle, no need of cooling equipment, and other advantages, it has been widely used in various fields of production and life. However, the absorption rates of the materials in conventional thermopile devices are poor, and the majority of them are incompatible with microfabrication methods. In this work, a metal thermopile infrared detector with vertical graphene (VG) is designed and fabricated. The VG is grown via plasma enhanced chemical vapor deposition, and retained at the device’s thermal ends to provide the thermopile IR detector’s wideband and high response characteristics. The detector achieves a room temperature responsivity reaching a value as high as 1.53 V/W at 792 nm, which can increase the response results about 28 times and reduce the response time to 0.8 ms compared with the thermopile detector without VG. After systematically measuring the response results, it is finally found that there are three main mechanisms responsible for the response on the composite device. The first one is the response generated by the metal thermopile itself alone. The second one is the response increased eventually by the contribution of VG covered at the metal thermal junction that expands the temperature difference. The last one is the response generated by the temperature gradient existing inside the VG on the surface of the device after the absorption of heat. The portion of each partial response mechanism in the total response is also analyzed, providing a new reference direction for analyzing the response generation mechanism of thermopile detectors with other absorbing materials. The process is compatible with the microfabrication, while the device performance is enhanced and suitable for mass production. Furthermore, by utilizing the surface plasmon resonance to combine VG with metal nanoparticles, the material’s light absorption is found to be enhanced significantly under the same conditions, and the resulting thermal voltage can be increased to 6 times. The results indicate that VG promises to possess practical applications, in many fields such as photoelectric sensing and power production devices. This technology provides a new method to manufacture high-performance thermopile infrared detectors and other sensor devices.

-

Keywords:

- vertical graphene /

- thermopiles /

- infrared detectors /

- surface plasmon resonance

[1] Xia F, Mueller T, Lin Y, Valdes-Garcia A, Avouris P 2009 Nat. Nanotechnol. 4 839

Google Scholar

Google Scholar

[2] Mittendorff M, Winnerl S, Kamann J, Eroms J, Weiss D, Schneider H, Helm M 2013 Appl. Phys. Lett. 103 021113

Google Scholar

Google Scholar

[3] Compton O C, Nguyen S B T 2010 Small 6 711

Google Scholar

Google Scholar

[4] Katsnelson M I 2007 Mater. Today 10 20

[5] Nair R R, Blake P, Grigorenko A N, Novoselov K S, Booth T J, Stauber T, Peres N M R, Geim A K 2008 Science 320 1308

Google Scholar

Google Scholar

[6] Liu C, Chang Y, Norris T B, Zhong Z 2014 Nat. Nanotechnol. 9 273

Google Scholar

Google Scholar

[7] Shi S F, Xu X, Ralph D C, McEuen P L 2011 Nano Lett. 11 1814

Google Scholar

Google Scholar

[8] Emani N K, Chung T F, Ni X, Kildishev A V, Chen Y P, Boltasseva A 2012 Nano Lett. 12 5202

Google Scholar

Google Scholar

[9] Lee H, Heo K, Park J, Park Y, Noh S, Kim K S, Lee C, Hong B H, Jian J, Hong S 2012 J. Mater. Chem. 22 8372

Google Scholar

Google Scholar

[10] Babichev A V, Zhang H, Lavenus P, Julien F H, Egorov A Y, Lin Y T, Tu L W, Tchernycheva M 2013 Appl. Phys. Lett. 103 201103

Google Scholar

Google Scholar

[11] Konstantatos G, Badioli M, Gaudreau L, Osmond J, Bernechea M, De Arquer P G F, Gatti F, Koppens F H 2012 Nat. Nanotechnol. 7 363

Google Scholar

Google Scholar

[12] Bo Z, Yang Y, Chen J, Yu K, Yan J, Cen K 2013 Nanoscale 5 5180

Google Scholar

Google Scholar

[13] Bo Z, Mao S, Han Z J, Cen K, Chen J, Ostrikov K K 2015 Chem. Soc. Rev. 44 2108

Google Scholar

Google Scholar

[14] Zhu W, Xue Z Y, Wang G, Zhao M H, Chen D, Guo Q L, Liu Z D, Feng X Q, Ding G Q, Chu P K, Di Z F 2020 ACS Appl. Nano Mater. 3 6915

Google Scholar

Google Scholar

[15] Yu K, Wang P, Lu G, Chen K H, Bo Z, Chen J 2011 J. Phys. Chem. Lett. 2 537

Google Scholar

Google Scholar

[16] Graf A, Arndt M, Sauer M, Gerlach G 2007 Meas. Sci. Technol. 18 R59

Google Scholar

Google Scholar

[17] Chaglla E J S, Celik N, Balachandran W 2018 Sensors 18 3315

Google Scholar

Google Scholar

[18] Moisello E, Malcovati P, Bonizzoni E 2021 Micromachines 12 148

Google Scholar

Google Scholar

[19] Buchner R, Sosna C, Maiwald M, Benecke W, Lang W 2006 Sens. Actuators, A 130 262

[20] Dijkstra M, Lammerink T S, de Boer M J, Berenschot E J W, Wiegerink R J, Elwenspoek M 2014 J. Microelectromech. Syst. 23 908

Google Scholar

Google Scholar

[21] Randjelovic D, Petropoulos A, Kaltsas G, Stojanovic M, Lazic Z, Djuric Z, Matic M 2008 Sens. Actuators, A 141 404

Google Scholar

Google Scholar

[22] Yoo K P, Hong H P, Lee M J, Min S J, Park C W, Choi W S, Min N K 2011 Meas. Sci. Technol. 22 115206

Google Scholar

Google Scholar

[23] Itoigawa K, Ueno H, Shiozaki M, Toriyama T, Sugiyama S 2005 J. Micromech. Microeng. 15 S233

Google Scholar

Google Scholar

[24] Dhawan R, Madusanka P, Hu G Y, Debord J, Tran T, Maggio K, Edwards H, Lee M 2020 Nat. Commun. 11 4362

Google Scholar

Google Scholar

[25] Xu D H, Wang Y L, Xiong B, Li T 2017 Front. Mech. Eng. 12 557

Google Scholar

Google Scholar

[26] Shahmarvandi E K, Ghaderi M, Wolffenbuttel R F 2016 J. Phys. Conf. Ser. 757 012033

Google Scholar

Google Scholar

[27] Xu D, Xiong B, Wang Y 2010 IEEE Electron Device Lett. 31 512

Google Scholar

Google Scholar

[28] Zhang C C, Mao H Y, Shi M, Xiong J J, Long K W, Chen D P 2020 33rd IEEE International Confence on Micro Electro Mechannical Systems (MEMS 2020) Vancouver, Canada, January 18–22, 2020 p949

[29] Qian F, Deng J, Xiong F, Dong Y, Xu C 2020 Opt. Mater. Express 10 2909

Google Scholar

Google Scholar

[30] Li X, Zhu M, Du M, Lv Z, Zhang L, Li Y, Yang Y, Yang T, Li X, Wang K, Zhu Y, Fang Y 2016 Small 12 549

Google Scholar

Google Scholar

[31] Tian W, Wang Y, Zhou H, Wang Y L, Li T 2020 J. Microelectromech Syst. 29 36

Google Scholar

Google Scholar

[32] Sofiane B M, Sébastien E, Thomas B, Laurent T, Pascal V, Danick B, Jean-Paul G, Laurent C 2015 Microsyst. Technol. 21 1627

Google Scholar

Google Scholar

[33] Allen L H, Patrick K H, Nathaniel M G, Sungjae H, Yong C S, Yi S, Matthew C, Madan D, Anantha P C, Jing K, Pablo J, Tomás P 2015 Nano Lett. 15 7211

Google Scholar

Google Scholar

[34] Willets K A, Van Duyne, R P 2007 Ann. Rev. Phys. Chem. 58 267

Google Scholar

Google Scholar

-

图 6 VG热电堆探测器在792 nm下的测试结果 (a) 响应测试示意图; (b) 仅有金属的器件光照在左端; (c) 仅有金属的器件光照在右端; (d) 带有VG的器件光照在左端; (e) 带有VG的器件光照在中点; (f) 带有VG的器件光照在右端

Figure 6. Measure results of VG thermopile detector at 792 nm: (a) Measure schematic diagram; (b) metal-only device (laser on the left end); (c) metal-only device (laser on the right end); (d) with VG device (laser on the left end); (e) with VG device (laser on the midpoint); (f) with VG device (laser on the right end).

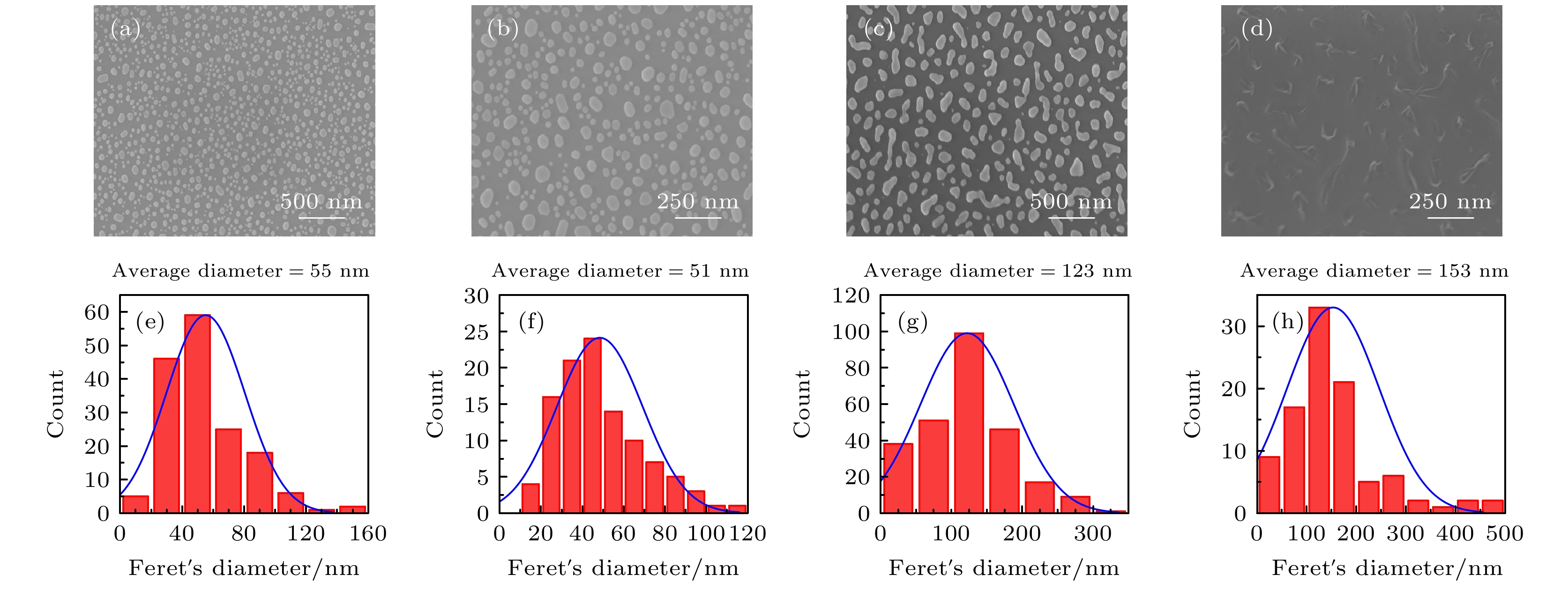

图 8 厚度为8 nm Au薄膜和Ag薄膜退火后的SEM图和粒径统计直方图 (a) Au退火700 ℃; (b) Au退火 900 ℃; (c) Ag退火 300 ℃; (d) Ag退火 700 ℃; (e)—(h) 相对应的粒径统计直方图结果

Figure 8. SEM images and particle size statistical histograms of 8 nm thick Au films and Ag films after annealing: (a) Au annealed at 700 ℃; (b) Au annealed at 900 ℃; (c) Ag annealed at 300 ℃; (d) Ag annealed at 700 ℃; (e)–(h) corresponding particle size statistical histogram results.

表 1 不同种热电堆红外探测器的参数比较

Table 1. Parameter comparison of different thermopile infrared detectors.

-

[1] Xia F, Mueller T, Lin Y, Valdes-Garcia A, Avouris P 2009 Nat. Nanotechnol. 4 839

Google Scholar

Google Scholar

[2] Mittendorff M, Winnerl S, Kamann J, Eroms J, Weiss D, Schneider H, Helm M 2013 Appl. Phys. Lett. 103 021113

Google Scholar

Google Scholar

[3] Compton O C, Nguyen S B T 2010 Small 6 711

Google Scholar

Google Scholar

[4] Katsnelson M I 2007 Mater. Today 10 20

[5] Nair R R, Blake P, Grigorenko A N, Novoselov K S, Booth T J, Stauber T, Peres N M R, Geim A K 2008 Science 320 1308

Google Scholar

Google Scholar

[6] Liu C, Chang Y, Norris T B, Zhong Z 2014 Nat. Nanotechnol. 9 273

Google Scholar

Google Scholar

[7] Shi S F, Xu X, Ralph D C, McEuen P L 2011 Nano Lett. 11 1814

Google Scholar

Google Scholar

[8] Emani N K, Chung T F, Ni X, Kildishev A V, Chen Y P, Boltasseva A 2012 Nano Lett. 12 5202

Google Scholar

Google Scholar

[9] Lee H, Heo K, Park J, Park Y, Noh S, Kim K S, Lee C, Hong B H, Jian J, Hong S 2012 J. Mater. Chem. 22 8372

Google Scholar

Google Scholar

[10] Babichev A V, Zhang H, Lavenus P, Julien F H, Egorov A Y, Lin Y T, Tu L W, Tchernycheva M 2013 Appl. Phys. Lett. 103 201103

Google Scholar

Google Scholar

[11] Konstantatos G, Badioli M, Gaudreau L, Osmond J, Bernechea M, De Arquer P G F, Gatti F, Koppens F H 2012 Nat. Nanotechnol. 7 363

Google Scholar

Google Scholar

[12] Bo Z, Yang Y, Chen J, Yu K, Yan J, Cen K 2013 Nanoscale 5 5180

Google Scholar

Google Scholar

[13] Bo Z, Mao S, Han Z J, Cen K, Chen J, Ostrikov K K 2015 Chem. Soc. Rev. 44 2108

Google Scholar

Google Scholar

[14] Zhu W, Xue Z Y, Wang G, Zhao M H, Chen D, Guo Q L, Liu Z D, Feng X Q, Ding G Q, Chu P K, Di Z F 2020 ACS Appl. Nano Mater. 3 6915

Google Scholar

Google Scholar

[15] Yu K, Wang P, Lu G, Chen K H, Bo Z, Chen J 2011 J. Phys. Chem. Lett. 2 537

Google Scholar

Google Scholar

[16] Graf A, Arndt M, Sauer M, Gerlach G 2007 Meas. Sci. Technol. 18 R59

Google Scholar

Google Scholar

[17] Chaglla E J S, Celik N, Balachandran W 2018 Sensors 18 3315

Google Scholar

Google Scholar

[18] Moisello E, Malcovati P, Bonizzoni E 2021 Micromachines 12 148

Google Scholar

Google Scholar

[19] Buchner R, Sosna C, Maiwald M, Benecke W, Lang W 2006 Sens. Actuators, A 130 262

[20] Dijkstra M, Lammerink T S, de Boer M J, Berenschot E J W, Wiegerink R J, Elwenspoek M 2014 J. Microelectromech. Syst. 23 908

Google Scholar

Google Scholar

[21] Randjelovic D, Petropoulos A, Kaltsas G, Stojanovic M, Lazic Z, Djuric Z, Matic M 2008 Sens. Actuators, A 141 404

Google Scholar

Google Scholar

[22] Yoo K P, Hong H P, Lee M J, Min S J, Park C W, Choi W S, Min N K 2011 Meas. Sci. Technol. 22 115206

Google Scholar

Google Scholar

[23] Itoigawa K, Ueno H, Shiozaki M, Toriyama T, Sugiyama S 2005 J. Micromech. Microeng. 15 S233

Google Scholar

Google Scholar

[24] Dhawan R, Madusanka P, Hu G Y, Debord J, Tran T, Maggio K, Edwards H, Lee M 2020 Nat. Commun. 11 4362

Google Scholar

Google Scholar

[25] Xu D H, Wang Y L, Xiong B, Li T 2017 Front. Mech. Eng. 12 557

Google Scholar

Google Scholar

[26] Shahmarvandi E K, Ghaderi M, Wolffenbuttel R F 2016 J. Phys. Conf. Ser. 757 012033

Google Scholar

Google Scholar

[27] Xu D, Xiong B, Wang Y 2010 IEEE Electron Device Lett. 31 512

Google Scholar

Google Scholar

[28] Zhang C C, Mao H Y, Shi M, Xiong J J, Long K W, Chen D P 2020 33rd IEEE International Confence on Micro Electro Mechannical Systems (MEMS 2020) Vancouver, Canada, January 18–22, 2020 p949

[29] Qian F, Deng J, Xiong F, Dong Y, Xu C 2020 Opt. Mater. Express 10 2909

Google Scholar

Google Scholar

[30] Li X, Zhu M, Du M, Lv Z, Zhang L, Li Y, Yang Y, Yang T, Li X, Wang K, Zhu Y, Fang Y 2016 Small 12 549

Google Scholar

Google Scholar

[31] Tian W, Wang Y, Zhou H, Wang Y L, Li T 2020 J. Microelectromech Syst. 29 36

Google Scholar

Google Scholar

[32] Sofiane B M, Sébastien E, Thomas B, Laurent T, Pascal V, Danick B, Jean-Paul G, Laurent C 2015 Microsyst. Technol. 21 1627

Google Scholar

Google Scholar

[33] Allen L H, Patrick K H, Nathaniel M G, Sungjae H, Yong C S, Yi S, Matthew C, Madan D, Anantha P C, Jing K, Pablo J, Tomás P 2015 Nano Lett. 15 7211

Google Scholar

Google Scholar

[34] Willets K A, Van Duyne, R P 2007 Ann. Rev. Phys. Chem. 58 267

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5217

- PDF Downloads: 101

- Cited By: 0

DownLoad:

DownLoad: