-

Minimizing friction is a goal that has long been pursued in history. The role of micro-electromechanical system and nano-electromechanical system (MEMS/NEMS) in electronic devices is becoming more and more important. Due to the increasingly small size of the device, large surface-to-volume ratio leads to severe friction and wear problems of the device, thus limiting its performance. Graphene is considered as a good lubricating material in MEMS/NEMS due to its extremely thin size and excellent anti-friction effect. The study of nano-friction properties of graphene is of great significance in further developing the MEMS/NEMS. In this work, microporous arrays are prepared on a SiO2/Si substrate, and graphene is stripped on the micropores to form a suspension structure. The friction properties of suspended graphene and supported graphene are measured by using atomic force microscope. The results show that the nanofriction on suspended graphene is significantly reduced compared with that on supported graphene. The supported graphene experiences a frictional enhancement effect because of the puckering effect, while the friction enhancing effect disappears in the suspended graphene. With the increase of graphene thickness, the out-of-plane stiffness increases gradually, and the friction difference between suspended graphene and supported graphene decreases gradually. In addition, the nanofriction properties of suspended graphene under new tip and pretreated tip are also different. The friction between the pretreated tip and graphene is significantly higher than that between the new tip and graphene. The surface friction difference between the suspended graphene and the supported graphene decreases when the pretreated tip is used compared with the new tip. This work demonstrates that the deformability of atomic-scale structures can provide an additional channel of regulating the friction of contact interfaces. By comparing the changes of surface friction between the suspended graphene and the supported graphene with different thickness and tip sizes, the influence of out-of-surface deformation on the friction of graphene is revealed, thus providing theoretical guidance for effectively improving the friction performance of graphene solid lubricant.

-

Keywords:

- graphene /

- friction /

- atomic force microscope /

- puckering effect

[1] Hainsworth S 2008 Tribology on the Small Scale: A Bottom Up Approach to Friction, Lubrication, and Wear (New York: Oxford University Press) pp3−10

[2] Kim H J, Kim D E 2009 Int. J. Precis. Eng. Manuf. 10 141

[3] Lee C G, Li Q Y, Kalb W, Liu X Z, Berger H, Carpick R W, Hone J 2010 Science 328 76

Google Scholar

Google Scholar

[4] Filleter T, Mcchesney J L, Bostwick A, Rotenberg E, Emtsev K V, Seyller T, Horn K, Bennewitz R 2009 Phys. Rev. Lett. 102 086102

Google Scholar

Google Scholar

[5] Zeng X Z, Peng Y T, Lang H J 2017 Carbon 118 233

Google Scholar

Google Scholar

[6] Zhang H W, Guo Z R, Gao H, Chang T 2015 Carbon 94 60

Google Scholar

Google Scholar

[7] Elinski M B, Liu Z T, Spear J C, Batteas J D 2017 J. Phys. D: Appl. Phys. 50 103003

Google Scholar

Google Scholar

[8] Frank I W, Tanenbaum D M 2007 J. Vac. Sci. Technol., B 25 2558

Google Scholar

Google Scholar

[9] Lee C G, Wei X D, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[10] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Kim P, Stormer H L 2007 Solid State Commun. 146 351

[11] Hu K M, Xue Z Y, Liu Y Q, Long H, Peng B, Yan H, Di Z F, Wang X, Lin L W, Zhang W M 2019 Small 15 1804337

Google Scholar

Google Scholar

[12] Zhang S, Hou Y, Li S Z, Liu L Q, Zhang Z, Feng X Q, Li Q Y 2019 Proc. Natl. Acad. Sci. U. S. A 116 24452

Google Scholar

Google Scholar

[13] Deng Z, Klimov N N, Solares S D, Li T, Xu H, Cannara R J 2013 Langmuir 29 235

Google Scholar

Google Scholar

[14] Ye Z, Martini A 2014 Langmuir 30 14707

Google Scholar

Google Scholar

[15] Bunch J S, Van Der Zande A M, Verbridge S S, Frank L W, Tanenbaum D M, Parpia J M, Craighead H G, McEuen P L 2007 Science 315 490

Google Scholar

Google Scholar

[16] Xu K, Wang K, Zhao W, Bao W Z, Liu E, Ren Y F, Wang Miao, Fu Y J, Zeng J W, Li Z G, Zhou W, Song F Q, Wang X R, Shi Y, Wan X G, Fuhrer M S, Wang B G, Qiao Z H, Miao F, Xing D Y 2015 Nat. Commun. 6 8119

Google Scholar

Google Scholar

[17] Medyanik S N, Liu W K, Sung I H, Robert W 2006 Phys. Rev. Lett. 97 136106

Google Scholar

Google Scholar

[18] 钱林茂, 田煜, 温诗铸 2013 纳米摩擦学 (北京: 科学出版社) 第168−173页

Qian L M, Tian Y, Wen S T 2013 Nanotribology (Beijing: Science Press) pp168−173 (in Chinese)

[19] Li S Z, Li Q Y, Carpick R W, Gumbsch P, Liu X Z, Ding X D, Sun J, Li J 2016 Nature 539 541

Google Scholar

Google Scholar

[20] Popov V L, Gray J A T 2012 Z. Angew. Math. Mech. 92 683

Google Scholar

Google Scholar

[21] 张涛, 王慧, 胡元中 2001 摩擦学学报 05 396

Google Scholar

Google Scholar

Zhang T, Wang H, Hu Y Z 2001 Tribology 05 396

Google Scholar

Google Scholar

[22] Fang L, Liu D M, Guo Y, Liao Z M, Luo J B, Wen S Z 2017 Nanotechnology 28 245703

Google Scholar

Google Scholar

-

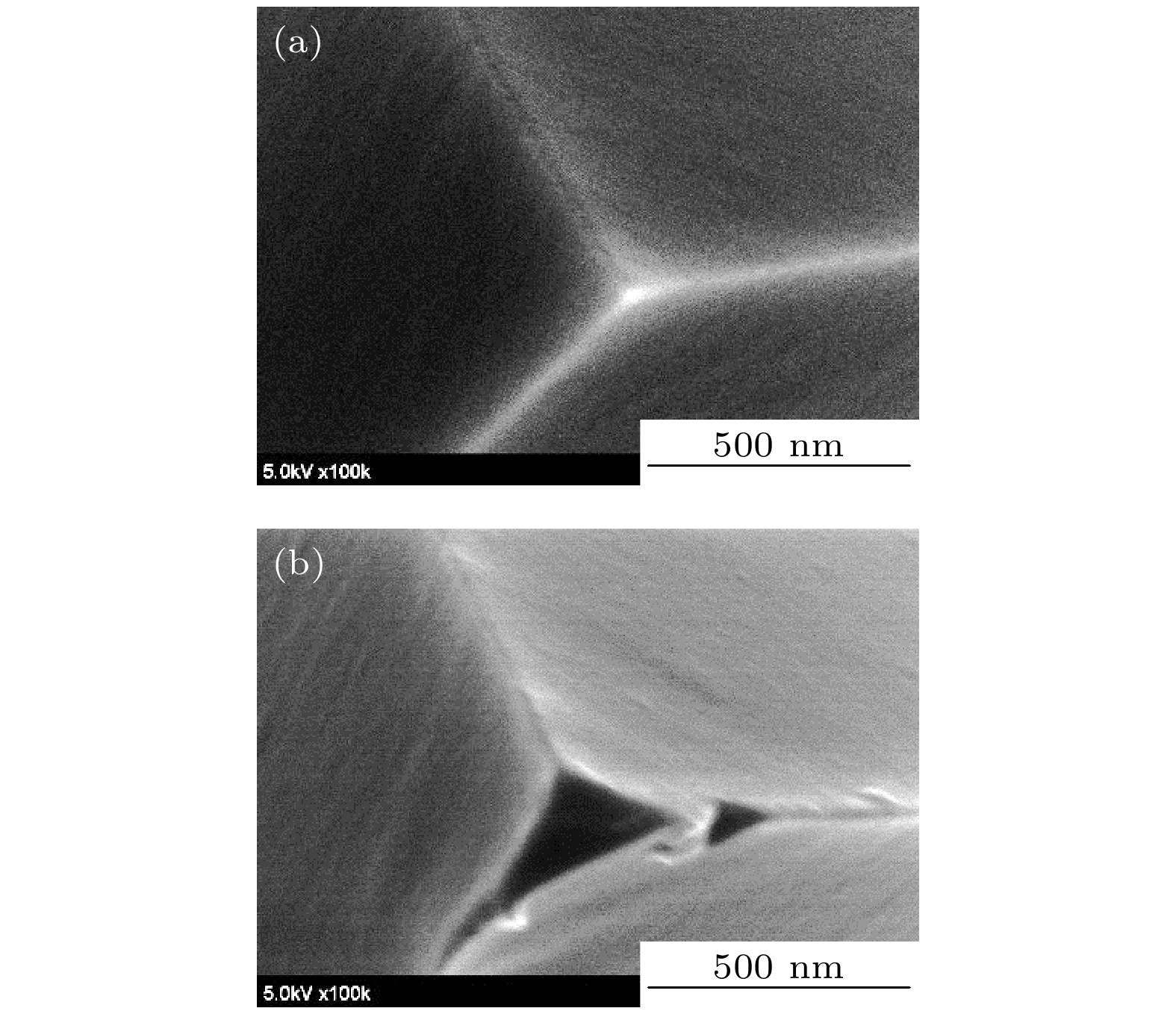

图 2 (a) 悬浮石墨烯形貌图, 中心白框为悬浮石墨烯测试区域, 黑框为支撑石墨烯测试区域; (b) 悬浮与支撑区域摩擦力-载荷关系; (c) 支撑石墨烯侧向力曲线(150 nN载荷); (d) 悬浮石墨烯侧向力曲线(150 nN载荷)

Figure 2. (a) Topography of suspended graphene, the white box is the test area for suspended graphene, the white box is the test area for supported graphene; (b) friction versus load data measured on the suspended graphene and supported graphene; (c) lateral force curves (load of 150 nN) measured on supported graphene and (d) suspended graphene.

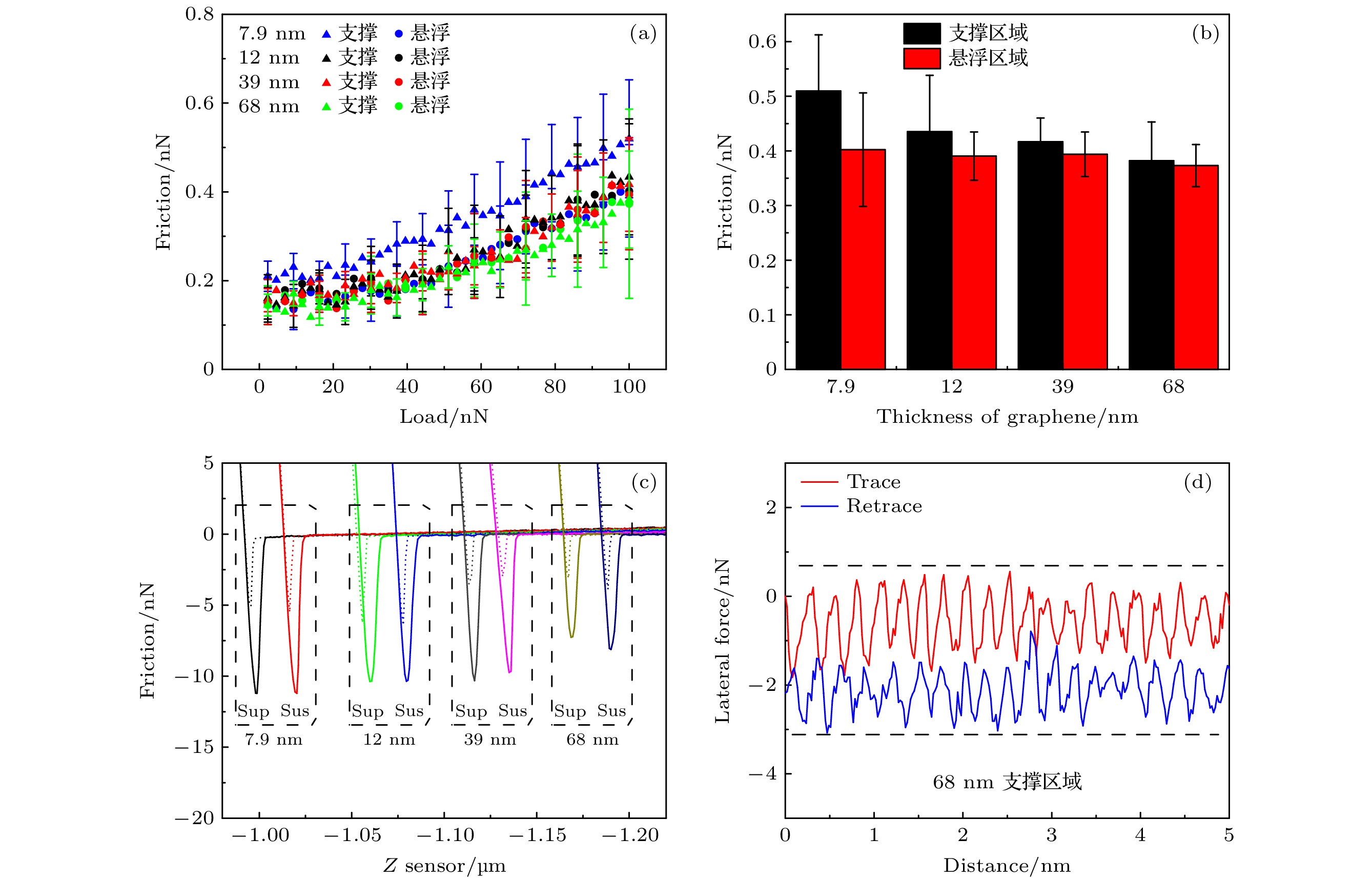

图 3 (a) 不同厚度支撑与悬浮石墨烯的摩擦力-载荷曲线; (b) 不同厚度支撑与悬浮石墨烯的摩擦力(100 nN载荷); (c) 不同厚度支撑与悬浮石墨烯法向力-位移曲线; (d) 支撑状态下厚层石墨烯(68 nm)侧向力曲线(150 nN载荷)

Figure 3. (a) Friction versus load data measured on the suspended graphene and supported graphene of different thickness; (b) the friction of supported and suspended graphene of different thickness (load of 100 nN); (c) force-distance curves measured on suspended and supported graphene of different thickness; (d) lateral force curves (load of 150 nN) measured on supported thick grapheme (68 nm).

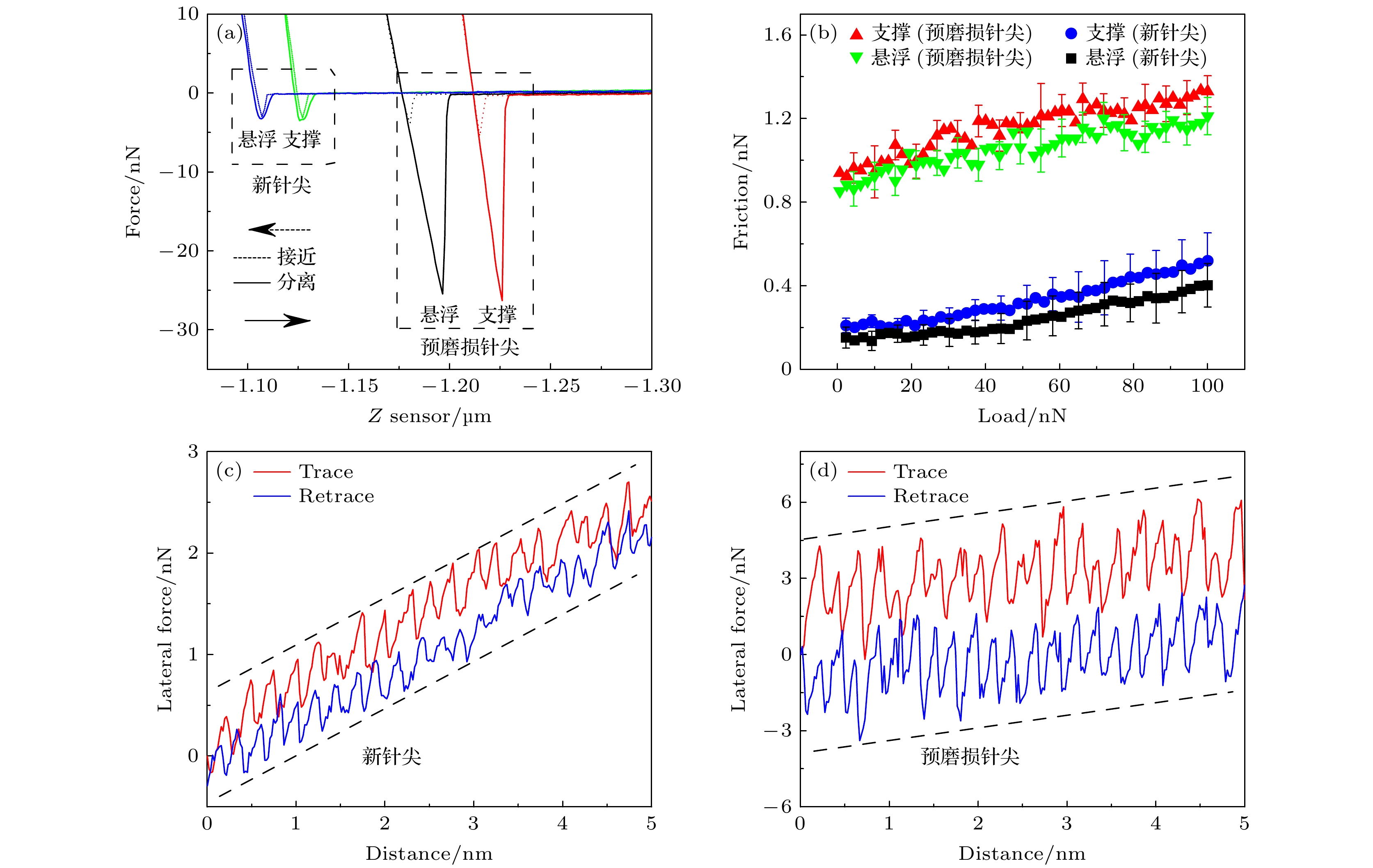

图 6 (a) 新针尖和预磨损针尖分别与悬浮石墨烯与支撑石墨烯的力-位移曲线; (b) 新针尖和预磨损针尖分别与悬浮石墨烯与支撑石墨烯间的摩擦力-载荷关系; (c) 新针尖和(d) 预磨损针尖测量的支撑石墨烯侧向力曲线(150 nN载荷)

Figure 6. (a) Force-distance curves measured on suspended and supported graphene under new tip and pretreated tip; (b) friction-load image of the new probe tip and pretreated tip on the supported graphene and suspended graphene; (c) and (d) lateral force curves measured on supported graphene measured by different tips (load of 150 nN).

表 1 实验所用的试剂信息

Table 1. The reagent information used in the experiment.

序号 名称 型号/规格 生产公司 1 光刻胶 AZ5214 苏州锐材半导体有限公司 2 显影剂 NMD-

3/2.38%长春应化(常熟)有限公司 3 氟化铵(NH4F) 优级纯 国药化试 4 氢氟酸(HF) 化学纯 国药化试 5 乙醇 分析纯 国药化试 6 丙酮 分析纯 国药化试 7 异丙醇 分析纯 国药化试 -

[1] Hainsworth S 2008 Tribology on the Small Scale: A Bottom Up Approach to Friction, Lubrication, and Wear (New York: Oxford University Press) pp3−10

[2] Kim H J, Kim D E 2009 Int. J. Precis. Eng. Manuf. 10 141

[3] Lee C G, Li Q Y, Kalb W, Liu X Z, Berger H, Carpick R W, Hone J 2010 Science 328 76

Google Scholar

Google Scholar

[4] Filleter T, Mcchesney J L, Bostwick A, Rotenberg E, Emtsev K V, Seyller T, Horn K, Bennewitz R 2009 Phys. Rev. Lett. 102 086102

Google Scholar

Google Scholar

[5] Zeng X Z, Peng Y T, Lang H J 2017 Carbon 118 233

Google Scholar

Google Scholar

[6] Zhang H W, Guo Z R, Gao H, Chang T 2015 Carbon 94 60

Google Scholar

Google Scholar

[7] Elinski M B, Liu Z T, Spear J C, Batteas J D 2017 J. Phys. D: Appl. Phys. 50 103003

Google Scholar

Google Scholar

[8] Frank I W, Tanenbaum D M 2007 J. Vac. Sci. Technol., B 25 2558

Google Scholar

Google Scholar

[9] Lee C G, Wei X D, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[10] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Kim P, Stormer H L 2007 Solid State Commun. 146 351

[11] Hu K M, Xue Z Y, Liu Y Q, Long H, Peng B, Yan H, Di Z F, Wang X, Lin L W, Zhang W M 2019 Small 15 1804337

Google Scholar

Google Scholar

[12] Zhang S, Hou Y, Li S Z, Liu L Q, Zhang Z, Feng X Q, Li Q Y 2019 Proc. Natl. Acad. Sci. U. S. A 116 24452

Google Scholar

Google Scholar

[13] Deng Z, Klimov N N, Solares S D, Li T, Xu H, Cannara R J 2013 Langmuir 29 235

Google Scholar

Google Scholar

[14] Ye Z, Martini A 2014 Langmuir 30 14707

Google Scholar

Google Scholar

[15] Bunch J S, Van Der Zande A M, Verbridge S S, Frank L W, Tanenbaum D M, Parpia J M, Craighead H G, McEuen P L 2007 Science 315 490

Google Scholar

Google Scholar

[16] Xu K, Wang K, Zhao W, Bao W Z, Liu E, Ren Y F, Wang Miao, Fu Y J, Zeng J W, Li Z G, Zhou W, Song F Q, Wang X R, Shi Y, Wan X G, Fuhrer M S, Wang B G, Qiao Z H, Miao F, Xing D Y 2015 Nat. Commun. 6 8119

Google Scholar

Google Scholar

[17] Medyanik S N, Liu W K, Sung I H, Robert W 2006 Phys. Rev. Lett. 97 136106

Google Scholar

Google Scholar

[18] 钱林茂, 田煜, 温诗铸 2013 纳米摩擦学 (北京: 科学出版社) 第168−173页

Qian L M, Tian Y, Wen S T 2013 Nanotribology (Beijing: Science Press) pp168−173 (in Chinese)

[19] Li S Z, Li Q Y, Carpick R W, Gumbsch P, Liu X Z, Ding X D, Sun J, Li J 2016 Nature 539 541

Google Scholar

Google Scholar

[20] Popov V L, Gray J A T 2012 Z. Angew. Math. Mech. 92 683

Google Scholar

Google Scholar

[21] 张涛, 王慧, 胡元中 2001 摩擦学学报 05 396

Google Scholar

Google Scholar

Zhang T, Wang H, Hu Y Z 2001 Tribology 05 396

Google Scholar

Google Scholar

[22] Fang L, Liu D M, Guo Y, Liao Z M, Luo J B, Wen S Z 2017 Nanotechnology 28 245703

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8175

- PDF Downloads: 140

- Cited By: 0

DownLoad:

DownLoad: