-

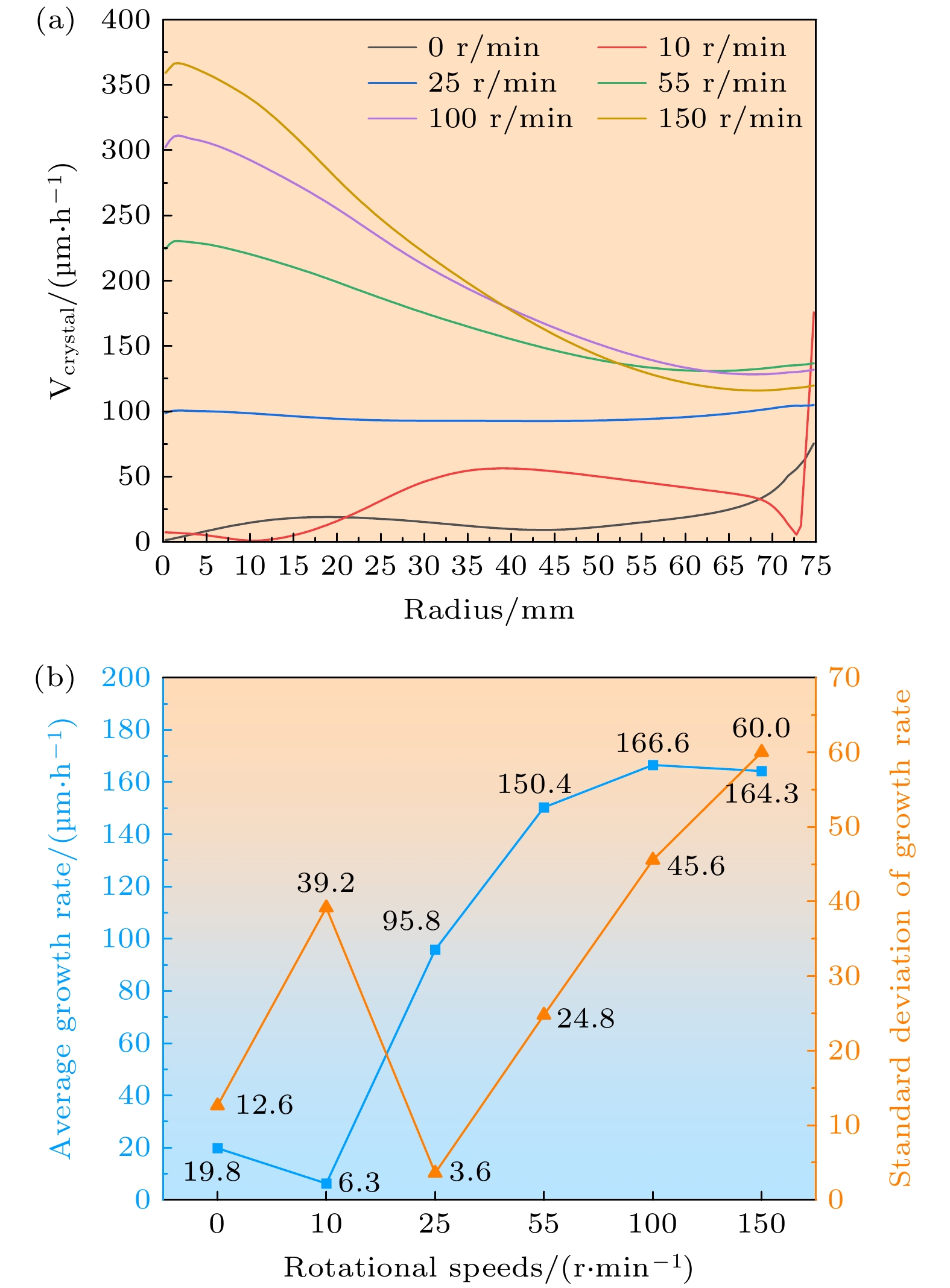

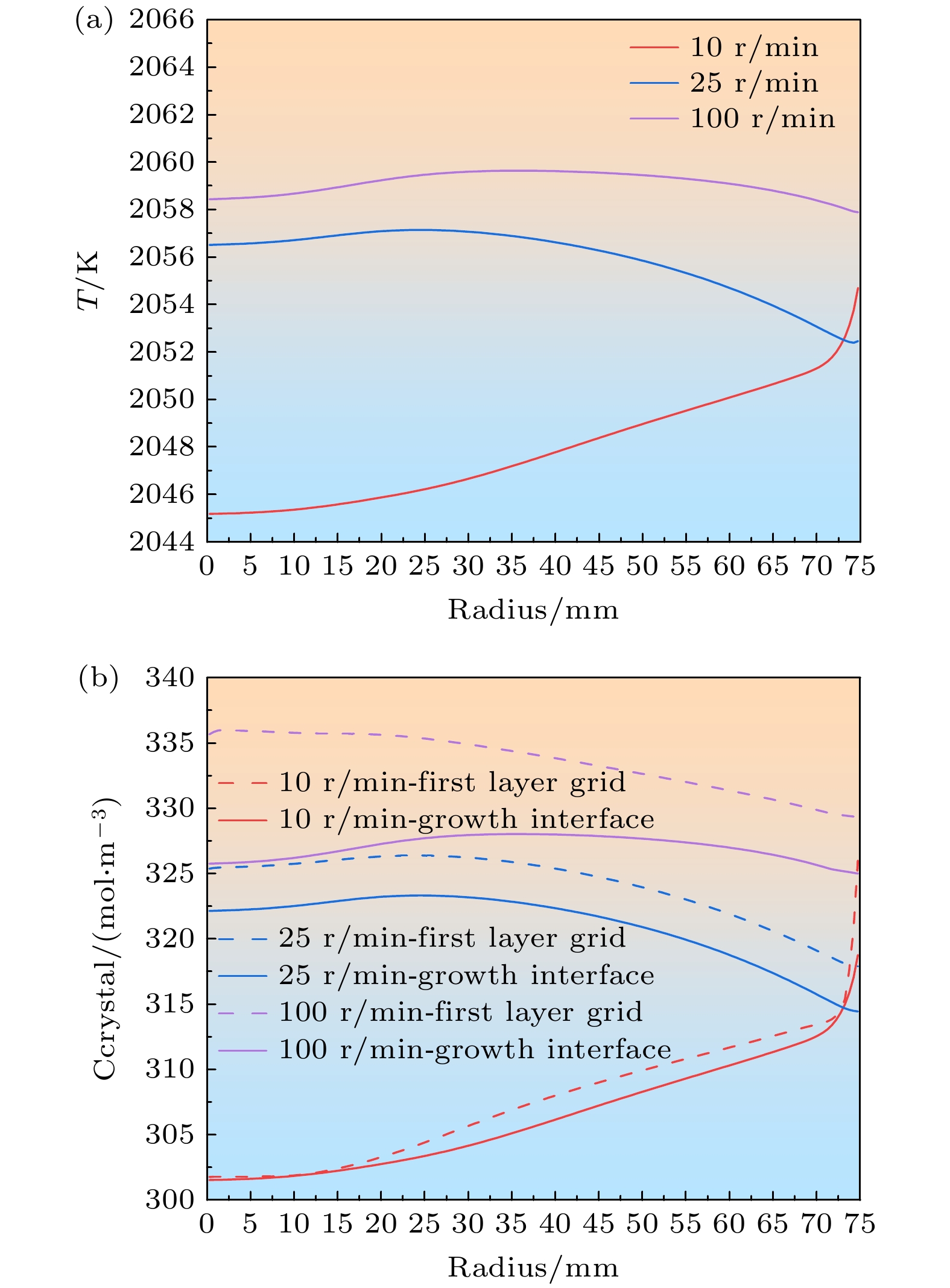

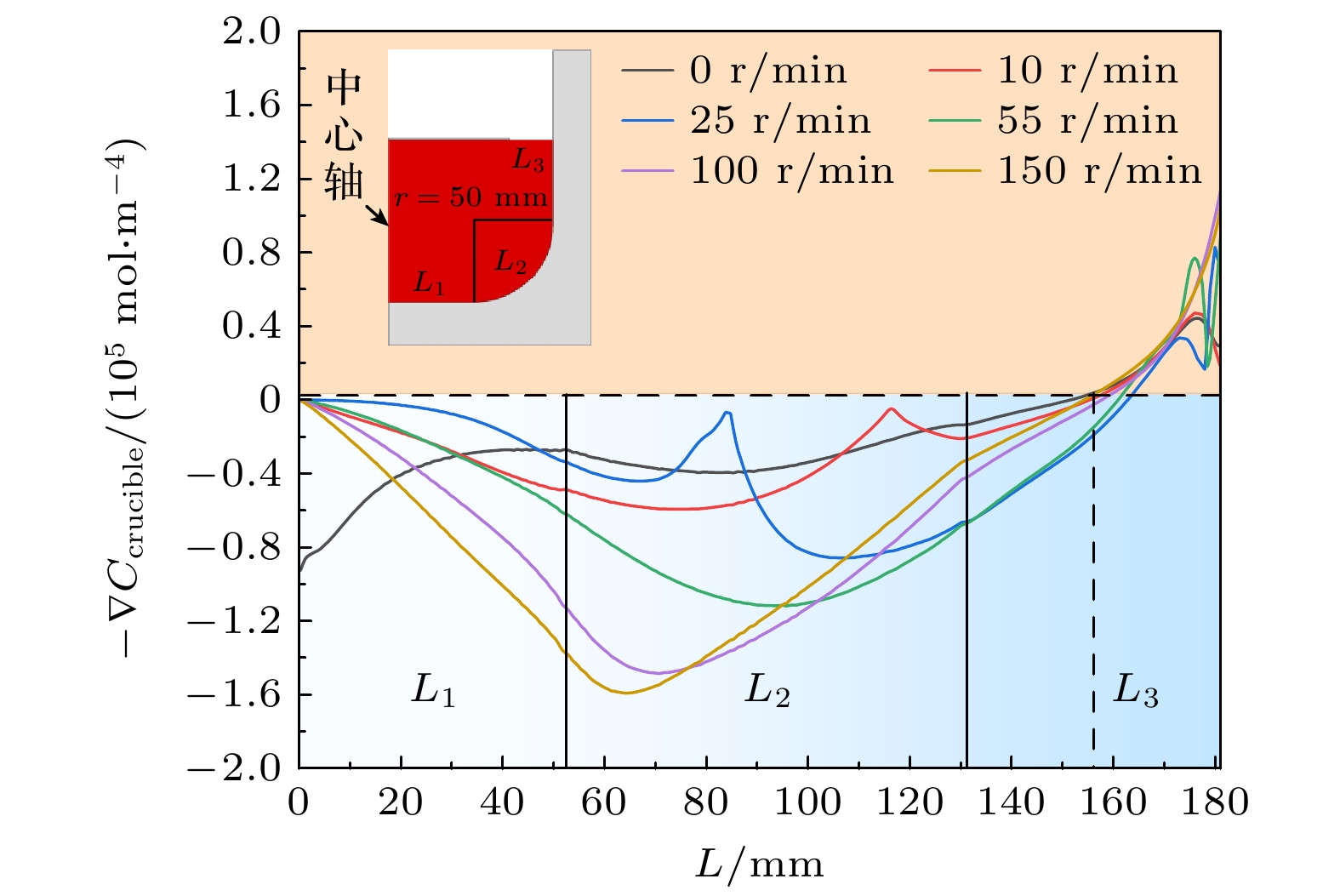

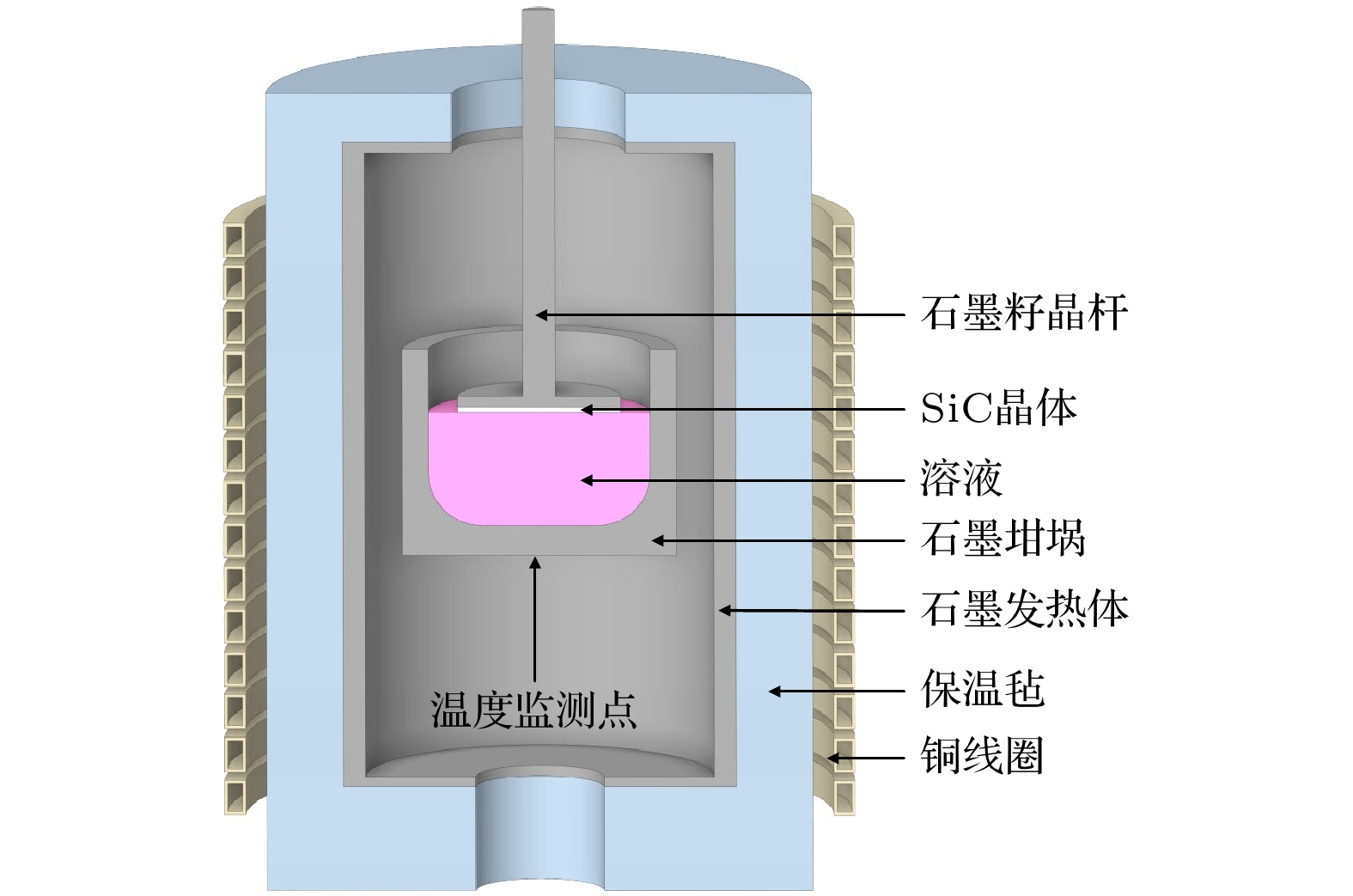

溶液法是生长低缺陷高品质碳化硅(SiC)单晶的重要方法, 针对6英寸溶液法生长SiC单晶系统, 建立了感应加热和热质传递全局数值分析模型, 考虑了洛伦兹力、离心力、热浮力以及表面张力对溶液流动的耦合作用, 研究了晶体旋转对溶液中速度场、温度场、碳浓度场、晶体生长速率以及坩埚壁面碳溶解析出的影响规律. 结果表明, 溶液中洛伦兹力的存在使得低晶体转速下的流场十分复杂, 晶体转速需要控制在合适的范围内, 使得生长界面下方由输运决定的碳浓度分布与生长界面处由温度决定的碳浓度分布相协调, 才能获得均匀且高的SiC单晶生长速率. 晶体转速过小使得SiC单晶生长速率很低, 过大导致生长速率径向均匀性下降, 转速为25 r/min时SiC单晶的平均生长速率较高且沿径向分布均匀性较好. 进一步分析了溶液-坩埚交界面碳组分的溶解和析出, 定位了坩埚壁面溶解较快区域和SiC多晶颗粒生成区域, 并结合速度场预测了多晶颗粒的去向. 研究结果为溶液法生长6英寸SiC单晶提供了科学依据.The top-seeded solution growth (TSSG) method is a critical technique for growing low-defect and high-quality silicon carbide (SiC) single crystals. A comprehensive numerical analysis model including induction heating, heat and mass transfer is developed for growing 6-inch SiC single crystals. The coupling effects of Lorentz force, centrifugal force, thermal buoyancy force and surface tension on the solution flow are considered, and the effects of crystal rotation speed on the velocity field, temperature field, carbon concentration field, crystal growth rate and carbon dissolution and precipitation on the crucible wall are systematically investigated. The results indicate that the Lorentz force in the solution results in a more complex flow field at low crystal rotation speeds. The crystal rotation speed should be controlled within the appropriate range to ensure that the carbon concentration distribution beneath the growth interface determined by the transport mode is coordinated with that at the growth interface determined by the temperature, which is beneficial for the uniform and high growth rate of SiC single crystals. Low rotation speeds reduce the growth rate of SiC single crystals, while high rotation speeds lead radial uniformity of growth rate to decrease. At a rotation speed of 25 r/min, the average growth rate of SiC single crystals is higher and the radial distribution uniformity is better. Further analysis is conducted on the dissolution and precipitation of carbon at the solution-crucible interface, and the regions, where the crucible wall dissolves quickly and SiC polycrystalline particles are generated, are located. The transport directions of polycrystalline particles are predicted based on the velocity field. The research results provide a scientific basis for growing 6-inch SiC single crystals by TSSG method.

-

Keywords:

- top-seeded solution growth /

- silicon carbide single crystal /

- crystal rotation /

- numerical simulation

[1] Matsunami H, Kimoto T 1997 Mater. Sci. Eng. , R 20 125

Google Scholar

Google Scholar

[2] Meyer C, Philip P 2005 Cryst. Growth Des. 5 1145

Google Scholar

Google Scholar

[3] 刘东静, 周福, 陈帅阳, 胡志亮 2023 72 157901

Google Scholar

Google Scholar

Liu D J, Zhou F, Chen S Y, Hu Z L 2023 Acta Phys. Sin. 72 157901

Google Scholar

Google Scholar

[4] Yang N J, Song B, Wang W J, Li H 2022 Crystengcomm 24 3475

Google Scholar

Google Scholar

[5] Kimoto T 2016 Prog. Cryst. Growth Charact. Mater. 62 329

Google Scholar

Google Scholar

[6] Xiao S Y, Harada S, Murayama K, Ujihara T 2016 Cryst. Growth Des. 16 5136

Google Scholar

Google Scholar

[7] Ujihara T, Maekawa R, Tanaka R, Sasaki K, Kuroda K, Takeda Y 2008 J. Cryst. Growth 310 1438

Google Scholar

Google Scholar

[8] Wang G B, Sheng D, Li H, et al. 2023 Crystengcomm 25 560

Google Scholar

Google Scholar

[9] Umezaki T, Koike D, Horio A, Harada S, Ujihara T 2014 15th International Conference on Silicon Carbide and Related Materials (ICSCRM) Miyazaki, Japan, September 29–October 4, 2014 p63

[10] Dang Y F, Zhu C, Ikumi M, et al. 2021 Crystengcomm 23 1982

Google Scholar

Google Scholar

[11] Yamamoto T, Okano Y, Ujihara T, Dost S 2017 J. Cryst. Growth 470 75

Google Scholar

Google Scholar

[12] Umezaki T, Koike D, Harada S, Ujihara T 2016 Jpn. J. Appl. Phys. 55 125601

Google Scholar

Google Scholar

[13] Mercier F, Dedulle J M, Chaussende D, Pons M 2010 J. Cryst. Growth 312 155

Google Scholar

Google Scholar

[14] Ha M T, Shin Y J, Lee M H, Kim C J, Jeong S M 2018 Phys. Status Solidi A 215 1701017

Google Scholar

Google Scholar

[15] Kusunoki K, Kishida Y, Seki K 2019 Mater. Sci. Forum (Switzerland) 963 85

Google Scholar

Google Scholar

[16] Ha M T, Shin Y J, Bae S Y, Park S Y, Jeong S M 2019 J. Korean Ceram. Soc. 56 589

Google Scholar

Google Scholar

[17] Su Hun C, Young Gon K, Yun Ji S, et al. 2018 Mater. Sci. Forum (Switzerland) 924 27

Google Scholar

Google Scholar

[18] Liu B T, Yu Y, Tang X, Gao B 2020 J. Cryst. Growth 533 125406

Google Scholar

Google Scholar

[19] Yoon J Y, Lee M H, Kim Y, Seo W S, Shul Y G, Lee W J, Jeong S M 2017 Jpn. J. Appl. Phys. 56 065501

Google Scholar

Google Scholar

[20] Li F C, He L, Yan Z Y, Qi X F, Ma W C, Chen J L, Xu Y K, Hu Z G 2023 J. Cryst. Growth 607 127112

Google Scholar

Google Scholar

[21] Sui Z R, Xu L B, Cui C, Wang R, Pi X D, Yang D R, Han X F 2024 Crystengcomm 26 1022

Google Scholar

Google Scholar

[22] Fujii K, Takei K, Aoshima M, et al. 2015 Mater. Sci. Forum (Switzerland) 821–823 35

Google Scholar

Google Scholar

[23] Liu Y H, Li M Y, Yan Z Y, et al. 2024 J. Cryst. Growth 643 127801

Google Scholar

Google Scholar

[24] Mercier F, Nishizawa S 2011 8th European Conference on Silicon Carbide and Related Materials Oslo, Norway, August 29–September 2, 2011 p32

[25] Ariyawong K, Dedulle J M, Chaussende D 2014 15th International Conference on Silicon Carbide and Related Materials (ICSCRM) Miyazaki, Japan, September 29–October 04, 2014 p71

[26] Mercier F, Nishizawa S 2013 J. Cryst. Growth 362 99

Google Scholar

Google Scholar

[27] Wang L, Horiuchi T, Sekimoto A, Okano Y, Ujihara T, Dost S 2018 J. Cryst. Growth 498 140

Google Scholar

Google Scholar

[28] Ha M T, Lich L V, Shin Y J, Bae S Y, Lee M H, Jeong S M 2020 Materials 13 651

Google Scholar

Google Scholar

[29] Wang L, Takehara Y, Sekimoto A, Okano Y, Ujihara T, Dost S 2020 Crystals 10 111

Google Scholar

Google Scholar

[30] Li Z Y, Yang Y, Wang J L, Luo J P, Liu L J 2024 Proceedings of the 11th International Workshop on Modeling in Crystal Growth, ROMANIA, September 22–25, 2024 p573198

[31] Weiss J, Csendes Z J 1982 IEEE Transactions on Power Apparatus and Systems 101 3796

Google Scholar

Google Scholar

[32] Tavakoli M H 2008 Cryst. Growth Des. 8 483

Google Scholar

Google Scholar

[33] Lefebure J, Dedulle J M, Ouisse T, Chaussende D 2012 Cryst. Growth Des. 12 909

Google Scholar

Google Scholar

[34] Liu B T, Yu Y, Tang X, Gao B 2019 J. Cryst. Growth 527 125248

Google Scholar

Google Scholar

[35] Hayashi Y, Mitani T, Komatsu N, Kato T, Okumura H 2019 J. Cryst. Growth 523 125151

Google Scholar

Google Scholar

-

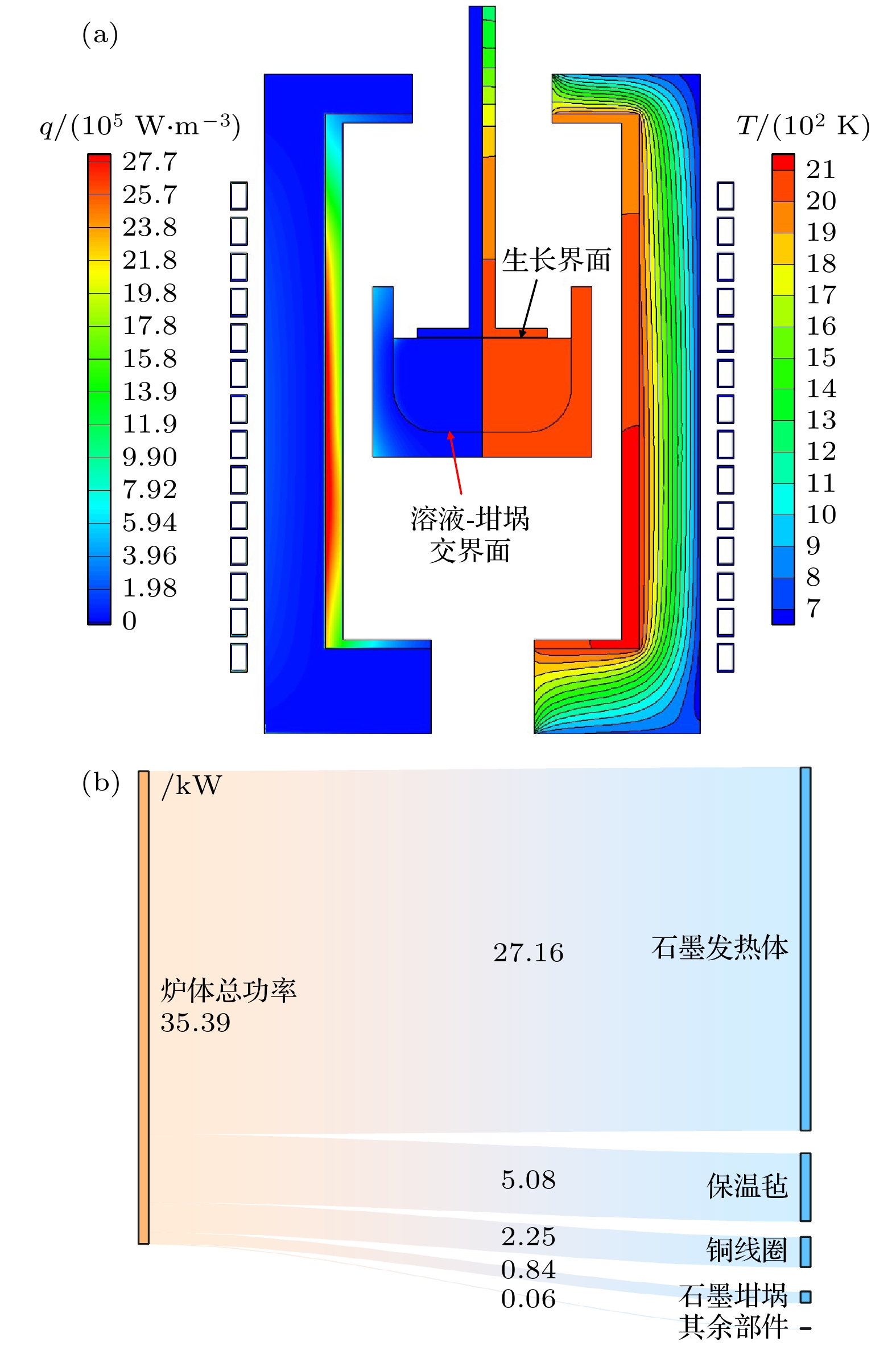

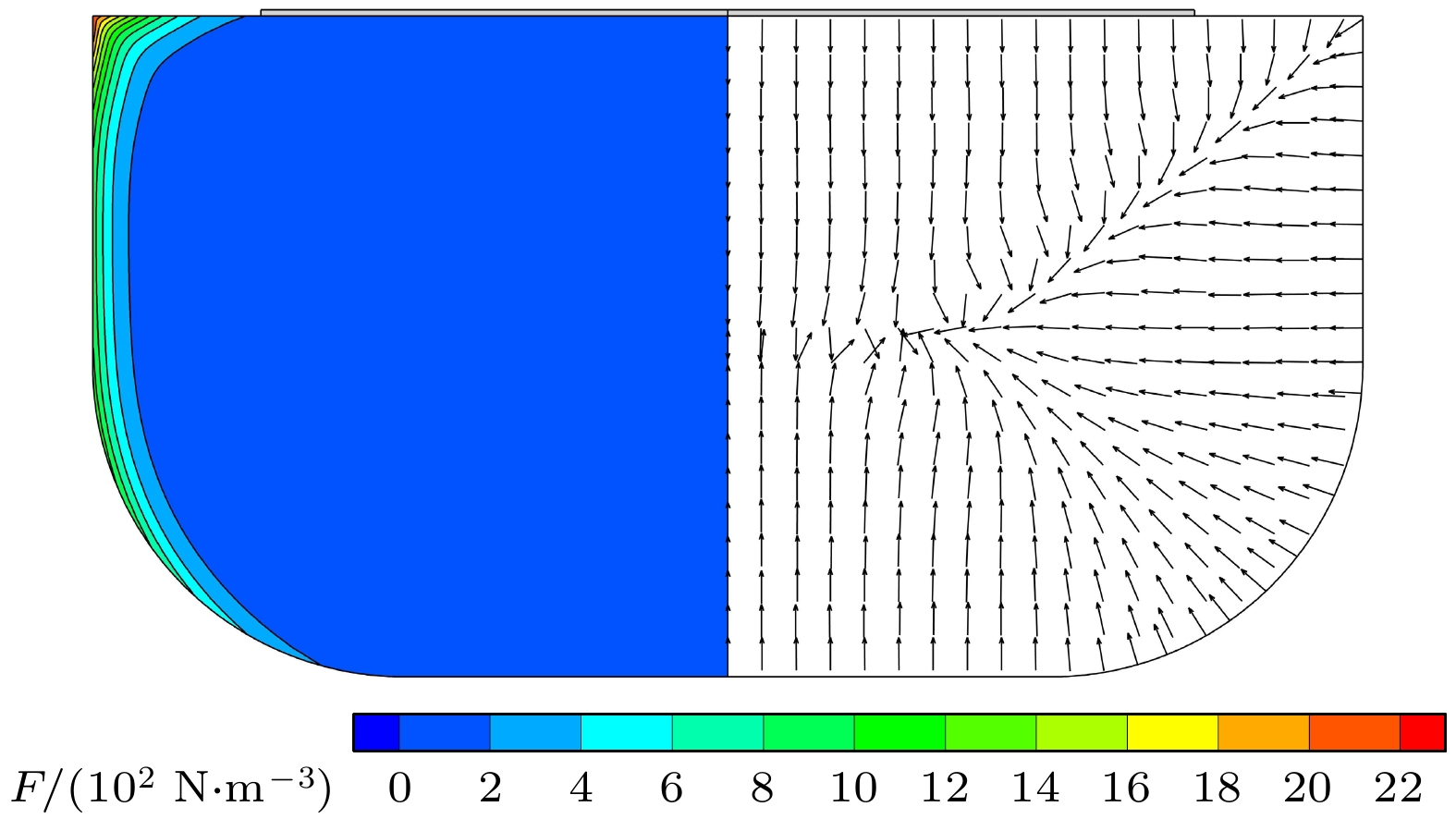

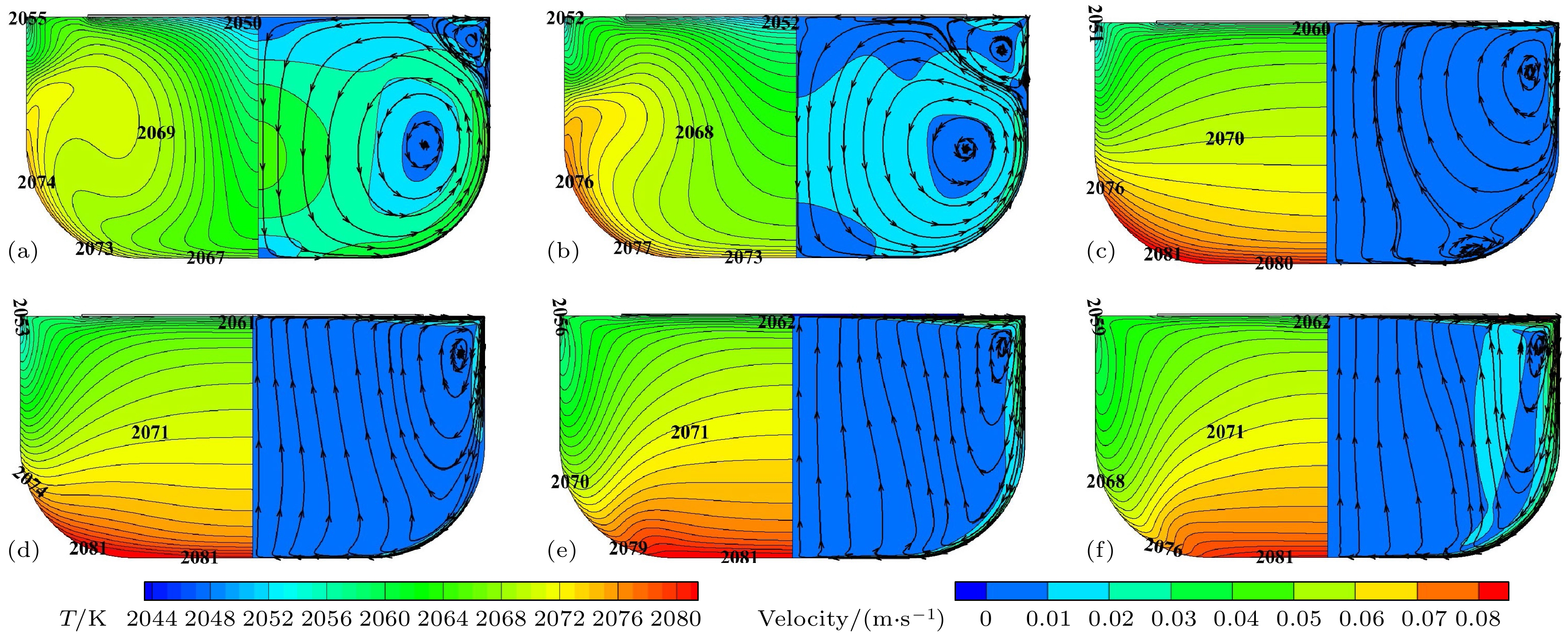

图 4 不考虑洛伦兹力时不同晶体转速下溶液中的温度场(左侧)和速度场(右侧) (a) 0 r/min; (b) 10 r/min; (c) 25 r/min; (d) 55 r/min; (e) 100 r/min; (f) 150 r/min

Fig. 4. Temperature (left: ∆T = 1 K) and velocity fields (right: ∆u = 0.01 m/s) in the solution at different crystal rotation rates without considering Lorentz force: (a) 0 r/min; (b) 10 r/min; (c) 25 r/min; (d) 55 r/min; (e) 100 r/min; (f) 150 r/min.

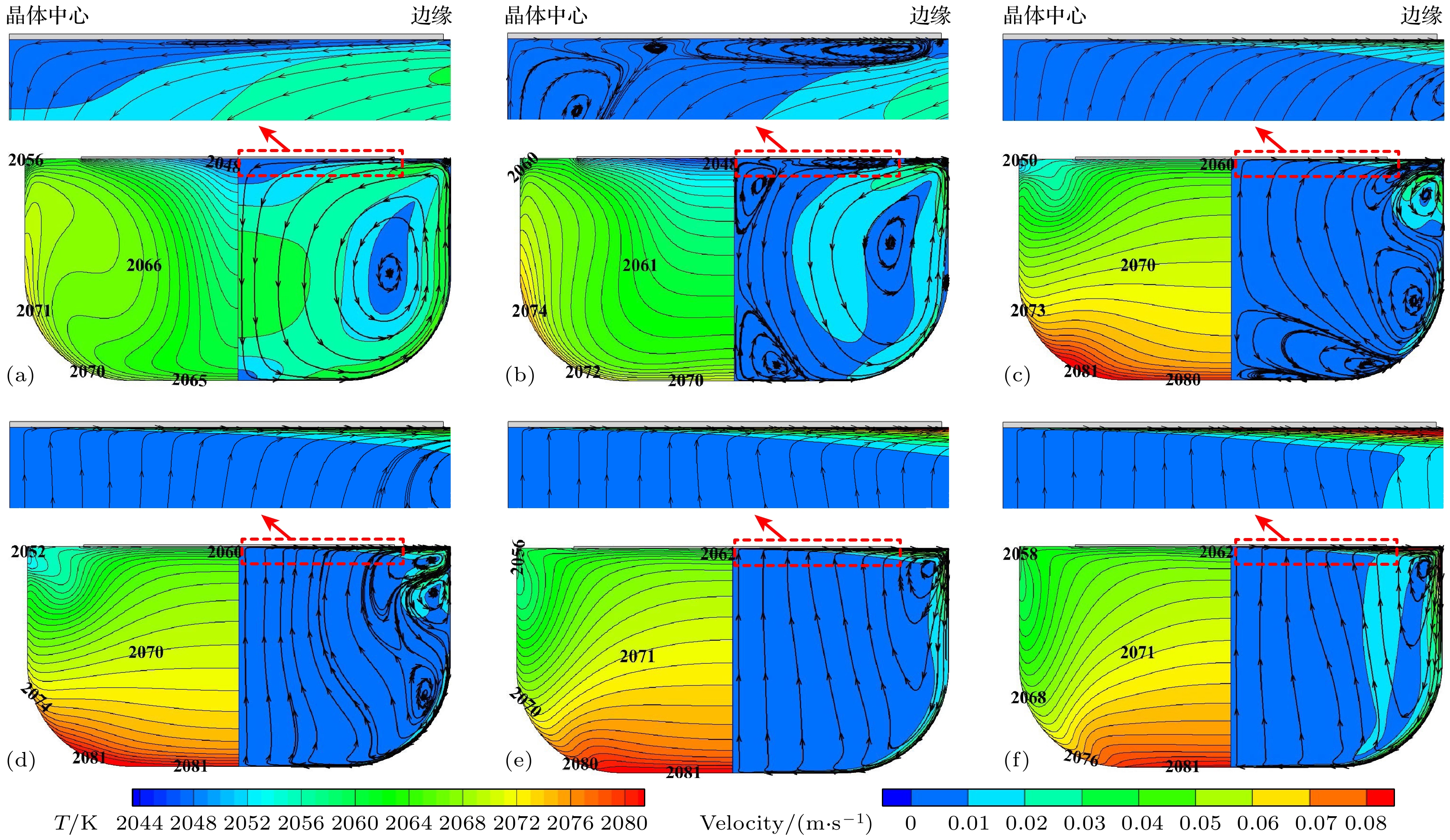

图 5 考虑洛伦兹力时不同晶体转速下溶液中的温度场(左侧)和速度场(右侧) (a) 0 r/min; (b) 10 r/min; (c) 25 r/min; (d) 55 r/min; (e) 100 r/min; (f) 150 r/min

Fig. 5. Temperature (left: ∆T = 1 K) and velocity fields (right: ∆u = 0.01 m/s) in the solution at different crystal rotation rates considering Lorentz force: (a) 0 r/min; (b) 10 r/min; (c) 25 r/min; (d) 55 r/min; (e) 100 r/min; (f) 150 r/min.

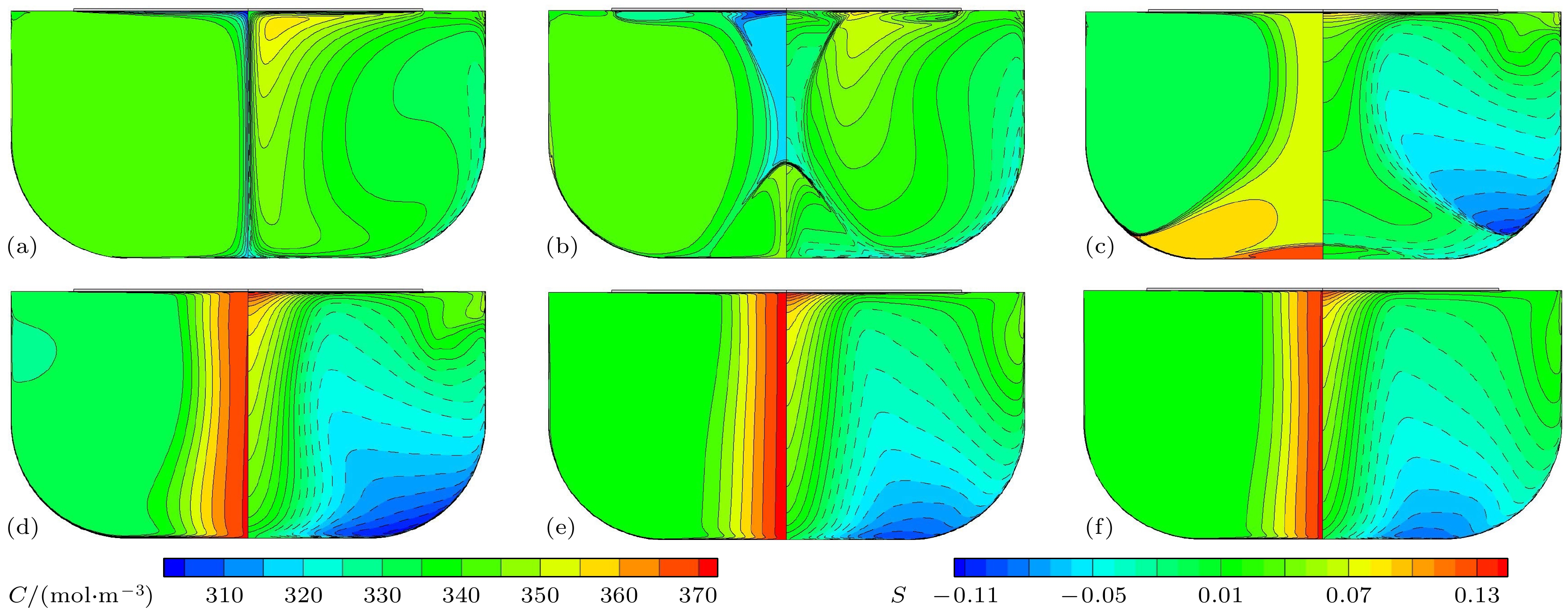

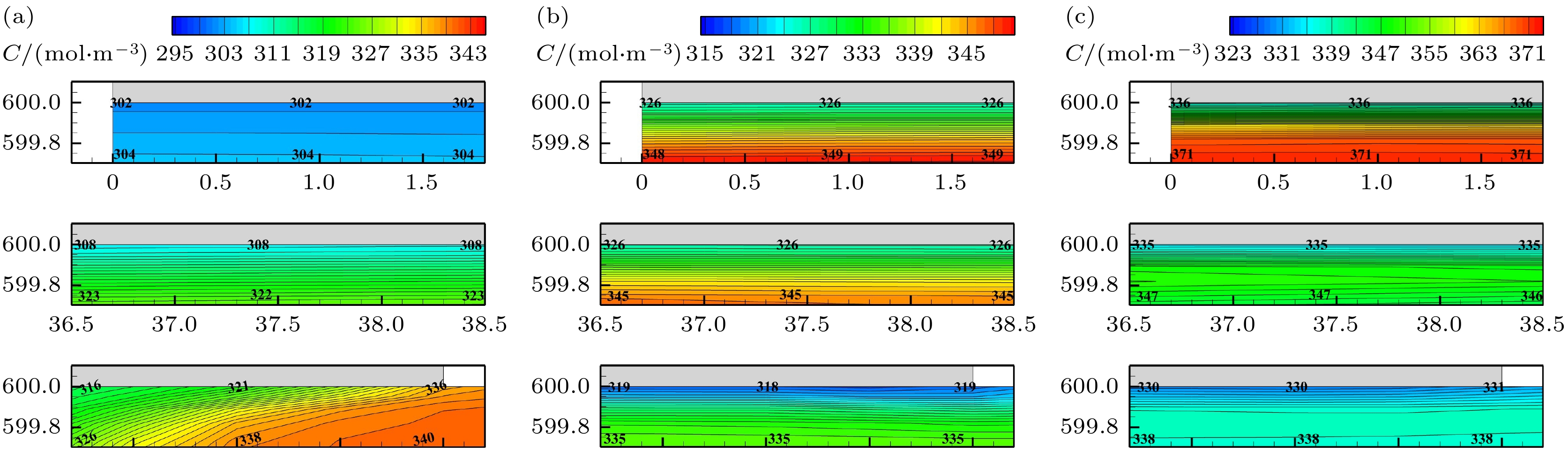

图 6 不同晶体转速下溶液中的碳浓度(左侧)与过饱和度(右侧)分布 (a) 0 r/min; (b) 10 r/min; (c) 25 r/min; (d) 55 r/min; (e) 100 r/min; (f) 150 r/min

Fig. 6. Distribution of carbon concentration (left: $\Delta C$= 5 mol/m3) and supersaturation (right: $\Delta S$= 0.001) in the solution at different crystal rotation rates: (a) 0 r/min; (b) 10 r/min; (c) 25 r/min; (d) 55 r/min; (e) 100 r/min; (f) 150 r/min.

Materials Parameters Value Units Si Density 2550 kg/m3 Viscosity 8×10–4 Pa·s Electrical conductivity 1.2×106 S/m Thermal conductivity 65 W/(m·K) Specific heat 1000 J/(kg·K) Thermal expansion coefficient 0.00014 1/K Surface tension –2.5×10–4 N/m·K Surface emissivity 0.3 — SiC Density 3216 kg/m3 Electrical conductivity 1000 S/m Thermal conductivity 30 W/(m·K) Specific heat 1290 J/(kg·K) Surface emissivity 0.5 — Graphite Electrical conductivity 75400 S/m Thermal conductivity 150×300/T W/(m·K) Surface emissivity 0.9 — Carbon felt Electrical conductivity 430 S/m Thermal conductivity 0.336 W/(m·K) Surface emissivity 0.8 — Copper Electrical conductivity 5.99×107 S/m Thermal conductivity 400 W/(m·K) Surface emissivity 0.5 — -

[1] Matsunami H, Kimoto T 1997 Mater. Sci. Eng. , R 20 125

Google Scholar

Google Scholar

[2] Meyer C, Philip P 2005 Cryst. Growth Des. 5 1145

Google Scholar

Google Scholar

[3] 刘东静, 周福, 陈帅阳, 胡志亮 2023 72 157901

Google Scholar

Google Scholar

Liu D J, Zhou F, Chen S Y, Hu Z L 2023 Acta Phys. Sin. 72 157901

Google Scholar

Google Scholar

[4] Yang N J, Song B, Wang W J, Li H 2022 Crystengcomm 24 3475

Google Scholar

Google Scholar

[5] Kimoto T 2016 Prog. Cryst. Growth Charact. Mater. 62 329

Google Scholar

Google Scholar

[6] Xiao S Y, Harada S, Murayama K, Ujihara T 2016 Cryst. Growth Des. 16 5136

Google Scholar

Google Scholar

[7] Ujihara T, Maekawa R, Tanaka R, Sasaki K, Kuroda K, Takeda Y 2008 J. Cryst. Growth 310 1438

Google Scholar

Google Scholar

[8] Wang G B, Sheng D, Li H, et al. 2023 Crystengcomm 25 560

Google Scholar

Google Scholar

[9] Umezaki T, Koike D, Horio A, Harada S, Ujihara T 2014 15th International Conference on Silicon Carbide and Related Materials (ICSCRM) Miyazaki, Japan, September 29–October 4, 2014 p63

[10] Dang Y F, Zhu C, Ikumi M, et al. 2021 Crystengcomm 23 1982

Google Scholar

Google Scholar

[11] Yamamoto T, Okano Y, Ujihara T, Dost S 2017 J. Cryst. Growth 470 75

Google Scholar

Google Scholar

[12] Umezaki T, Koike D, Harada S, Ujihara T 2016 Jpn. J. Appl. Phys. 55 125601

Google Scholar

Google Scholar

[13] Mercier F, Dedulle J M, Chaussende D, Pons M 2010 J. Cryst. Growth 312 155

Google Scholar

Google Scholar

[14] Ha M T, Shin Y J, Lee M H, Kim C J, Jeong S M 2018 Phys. Status Solidi A 215 1701017

Google Scholar

Google Scholar

[15] Kusunoki K, Kishida Y, Seki K 2019 Mater. Sci. Forum (Switzerland) 963 85

Google Scholar

Google Scholar

[16] Ha M T, Shin Y J, Bae S Y, Park S Y, Jeong S M 2019 J. Korean Ceram. Soc. 56 589

Google Scholar

Google Scholar

[17] Su Hun C, Young Gon K, Yun Ji S, et al. 2018 Mater. Sci. Forum (Switzerland) 924 27

Google Scholar

Google Scholar

[18] Liu B T, Yu Y, Tang X, Gao B 2020 J. Cryst. Growth 533 125406

Google Scholar

Google Scholar

[19] Yoon J Y, Lee M H, Kim Y, Seo W S, Shul Y G, Lee W J, Jeong S M 2017 Jpn. J. Appl. Phys. 56 065501

Google Scholar

Google Scholar

[20] Li F C, He L, Yan Z Y, Qi X F, Ma W C, Chen J L, Xu Y K, Hu Z G 2023 J. Cryst. Growth 607 127112

Google Scholar

Google Scholar

[21] Sui Z R, Xu L B, Cui C, Wang R, Pi X D, Yang D R, Han X F 2024 Crystengcomm 26 1022

Google Scholar

Google Scholar

[22] Fujii K, Takei K, Aoshima M, et al. 2015 Mater. Sci. Forum (Switzerland) 821–823 35

Google Scholar

Google Scholar

[23] Liu Y H, Li M Y, Yan Z Y, et al. 2024 J. Cryst. Growth 643 127801

Google Scholar

Google Scholar

[24] Mercier F, Nishizawa S 2011 8th European Conference on Silicon Carbide and Related Materials Oslo, Norway, August 29–September 2, 2011 p32

[25] Ariyawong K, Dedulle J M, Chaussende D 2014 15th International Conference on Silicon Carbide and Related Materials (ICSCRM) Miyazaki, Japan, September 29–October 04, 2014 p71

[26] Mercier F, Nishizawa S 2013 J. Cryst. Growth 362 99

Google Scholar

Google Scholar

[27] Wang L, Horiuchi T, Sekimoto A, Okano Y, Ujihara T, Dost S 2018 J. Cryst. Growth 498 140

Google Scholar

Google Scholar

[28] Ha M T, Lich L V, Shin Y J, Bae S Y, Lee M H, Jeong S M 2020 Materials 13 651

Google Scholar

Google Scholar

[29] Wang L, Takehara Y, Sekimoto A, Okano Y, Ujihara T, Dost S 2020 Crystals 10 111

Google Scholar

Google Scholar

[30] Li Z Y, Yang Y, Wang J L, Luo J P, Liu L J 2024 Proceedings of the 11th International Workshop on Modeling in Crystal Growth, ROMANIA, September 22–25, 2024 p573198

[31] Weiss J, Csendes Z J 1982 IEEE Transactions on Power Apparatus and Systems 101 3796

Google Scholar

Google Scholar

[32] Tavakoli M H 2008 Cryst. Growth Des. 8 483

Google Scholar

Google Scholar

[33] Lefebure J, Dedulle J M, Ouisse T, Chaussende D 2012 Cryst. Growth Des. 12 909

Google Scholar

Google Scholar

[34] Liu B T, Yu Y, Tang X, Gao B 2019 J. Cryst. Growth 527 125248

Google Scholar

Google Scholar

[35] Hayashi Y, Mitani T, Komatsu N, Kato T, Okumura H 2019 J. Cryst. Growth 523 125151

Google Scholar

Google Scholar

计量

- 文章访问数: 656

- PDF下载量: 29

- 被引次数: 0

下载:

下载: