-

非晶合金高温流变行为是理解其结构演化与动力学行为的重要窗口, 阐明其动力学弛豫行为与流变行为的内秉性关联是理解非晶固体变形行为的重要研究内容之一. 本文基于动态力学分析仪从激活体积和缺陷演化动力学角度系统探究了三种La基非晶合金的高温流变行为与动力学弛豫特征的耦合机理. 在自由体积理论框架下通过应变率跳跃实验, 揭示了非晶合金的流变应力随温度和应变率变化的双曲正弦依赖关系, 建立了高温流变激活能与α弛豫过程的关联. 参考应变率与温度正相关, 反映非晶合金结构非均匀性对原子扩散速率的调控. 此外, β弛豫激活能与高温流变平均激活能呈相反趋势, 为β弛豫作为α弛豫前驱过程提供理论依据. 缺陷湮灭与生成速率的动态竞争主导了非晶合金的高温流变行为, 以动力学参量定量描述了非晶合金热力耦合变形特征. 研究结果为非晶合金高温变形机制的微观解释提供了实验数据与理论指导, 有利于优化其高温加工与成型工艺.This study aims to establish the intrinsic link between the high-temperature rheological behavior and kinetic relaxation characteristics of La-based metallic glasses. By conducting dynamic mechanical analysis and high-temperature tensile strain-rate jump experiments on three La-based metallic glasses with significant β relaxation, and combining the findings within the free volume theory framework, their high-temperature rheological properties are investigated systematically. The results show that the steady-state flow stress and activation volume evolution trend are consistent within the normalized temperature range. The average activation energy for high-temperature rheology aligns with the activation energy range of α relaxation, confirming the strong association between rheological behavior and α relaxation. The activation energy for β relaxation shows an opposite trend, indicating that it may precede α relaxation. A dynamic competition between defect annihilation and generation governs the rheological behavior, and kinetic parameters reveal the temperature and strain-rate sensitivity of metallic glasses. This study lays a theoretical foundation for optimizing the high-temperature mechanical properties of La-based metallic glasses and also provides new insights into understanding the coupling relationship between multi-scale relaxation behavior and rheological mechanisms in metallic glasses.

[1] Wang W H 2019 Prog. Mater. Sci. 106 100561

Google Scholar

Google Scholar

[2] Yu H B, Gao L, Gao J Q, Samwer K 2024 Natl. Sci. Rev. 11 nwae091

Google Scholar

Google Scholar

[3] Alem S A A, Sabzvand M H, Govahi P, Poormehrabi P, Hasanzadeh Azar M, Salehi Siouki S, Rashidi R, Angizi S, Bagherifard S 2025 Adv. Compos. Hybrid Mater. 8 3

Google Scholar

Google Scholar

[4] 王壮, 金凡, 李伟, 阮嘉艺, 王龙飞, 吴雪莲, 张义坤, 袁晨晨 2024 73 217101

Google Scholar

Google Scholar

Wang Z, Jin F, Li W, Ruan J Y, Wang L F, Wu X L, Zhang Y K, Yuan C C 2024 Acta Phys. Sin. 73 217101

Google Scholar

Google Scholar

[5] Wang W H, Yang Y, Nieh T G, Liu C T 2015 Intermetallics 67 81

Google Scholar

Google Scholar

[6] Fan Z, Li Q, Fan C, Wang H, Zhang X 2019 J. Mater. Res. 34 1595

Google Scholar

Google Scholar

[7] 王军强, 欧阳酥 2017 66 176102

Google Scholar

Google Scholar

Wang J Q, Ouyang S 2017 Acta Phys. Sin. 66 176102

Google Scholar

Google Scholar

[8] Liang S Y, Zhang L T, Wang Y J, Wang B, Pelletier J M, Qiao J C 2024 Int. J. Fatigue 187 108446

Google Scholar

Google Scholar

[9] Tong Y, Song L, Gao Y, Fan L, Li F, Yang Y, Mo G, Liu Y, Shui X, Zhang Y, Gao M, Huo J, Qiao J, Pineda E, Wang J Q 2023 Nat. Commun. 14 8407

Google Scholar

Google Scholar

[10] Gallino I, Cangialosi D, Evenson Z, Schmitt L, Hechler S, Stolpe M, Ruta B 2018 Acta Mater. 144 400

Google Scholar

Google Scholar

[11] Li W, Zuo X F, Liu R, Pang C M, Jin F, Zhu W W, Yuan C C 2024 Int. J. Plast. 174 103893

Google Scholar

Google Scholar

[12] Kelly J P, Fuller S M, Seo K, Novitskaya E, Eliasson V, Hodge A M, Graeve O A 2016 Mater. Des. 93 26

Google Scholar

Google Scholar

[13] Zhang Y, Li C, Fu X, Hou S, Li C, Kou S, Li X 2025 J. Alloys Compd. 1020 179364

Google Scholar

Google Scholar

[14] 武振伟, 汪卫华 2020 69 066101

Google Scholar

Google Scholar

Wu Z W, Wang W H 2020 Acta Phys. Sin. 69 066101

Google Scholar

Google Scholar

[15] Qiao J C, Wang Q, Pelletier J M, Kato H, Casalini R, Crespo D, Pineda E, Yao Y, Yang Y 2019 Prog. Mater. Sci. 104 250

Google Scholar

Google Scholar

[16] Zhang L T, Wang Y J, Yang Y, Qiao J C 2022 Sci. China-Phys. Mech. Astron. 65 106111

Google Scholar

Google Scholar

[17] Ding Y, Shi F, Wang X, Bai Y, Wang Z, Hu L 2024 Acta Mater. 266 119698

Google Scholar

Google Scholar

[18] Zhu F, Song S, Reddy K M, Hirata A, Chen M 2018 Nat. Commun. 9 3965

Google Scholar

Google Scholar

[19] Jiao W, Wen P, Peng H L, Bai H Y, Sun B A, Wang W H 2013 Appl. Phys. Lett. 102 101903

Google Scholar

Google Scholar

[20] Meng S, Hao Q, Wang B, Wang Y, Pineda E, Qiao J 2025 J. Appl. Phys. 137 055108

Google Scholar

Google Scholar

[21] Qiao J C, Pineda E 2025 Eur. J. Phys. 46 035501

Google Scholar

Google Scholar

[22] Monnier X, Cangialosi D, Ruta B, Busch R, Gallino I 2020 Sci. Adv. 6 1454

Google Scholar

Google Scholar

[23] Duan Y J, Zhang L T, Qiao J C, Wang Y J, Yang Y, Wada T, Kato H, Pelletier J M, Pineda E, Crespo D 2022 Phys. Rev. Lett. 129 175501

Google Scholar

Google Scholar

[24] Yu H B, Shen X, Wang Z, Gu L, Wang W H, Bai H Y 2012 Phys. Rev. Lett. 108 5

Google Scholar

Google Scholar

[25] Liang D D, Wang X D, Ge K, Cao Q P, Jiang J Z 2014 J. Non-Cryst. Solids 383 97

Google Scholar

Google Scholar

[26] Wang W H 2012 Prog. Mater. Sci. 57 487

Google Scholar

Google Scholar

[27] Zhang L T, Wang Y J, Pineda E, Yang Y, Qiao J C 2022 Int. J. Plast. 157 103402

Google Scholar

Google Scholar

[28] Zhu Y, Shang T, Yuan J, Song Z, Luo W, Zhang J, Li M 2024 J. Non-Cryst. Solids 645 123196

Google Scholar

Google Scholar

[29] Su S, Zhao W, Su X, Shadangi Y, Jin Z, Ning Z, Zhang Y, Sun J, Huang Y 2025 J. Mater. Sci. Technol. 227 304

Google Scholar

Google Scholar

[30] Su S, Liu C Y, Su X, Shadangi Y, Cao G Y, Ning Z L, Sun J F, Huang Y J, Eckert J 2025 Rare Metals 120501

[31] Spaepen F 1977 Acta Metall. 25 407

Google Scholar

Google Scholar

[32] Bletry M, Guyot P, Bréchet Y, Blandin J J, Soubeyroux J L 2007 Acta Mater. 55 6331

Google Scholar

Google Scholar

[33] Homer E R, Schuh C A 2009 Acta Mater. 57 2823

Google Scholar

Google Scholar

[34] Anand L, Su C 2007 Acta Mater. 55 3735

Google Scholar

Google Scholar

[35] Rao W, Chen Y, Dai L H 2022 Int. J. Plast. 154 103309

Google Scholar

Google Scholar

[36] Liang S Y, Zhang L T, Wang B, Wang Y J, Pineda E, Qiao J C 2024 Intermetallics 164 108115

Google Scholar

Google Scholar

[37] Hao Q, Lü G J, Pineda E, Pelletier J M, Wang Y J, Yang Y, Qiao J C 2024 Int. J. Plast. 175 103926

Google Scholar

Google Scholar

[38] Mo J, Shen B, Wan Y, Zhou Z, Sun B, Liang X 2020 J. Non-Cryst. Solids 528 119742

Google Scholar

Google Scholar

[39] Yuan S, Liang A, Liu C, Tian L, Mousseau N, Branicio P S 2023 Phys. Rev. Mater. 7 123603

Google Scholar

Google Scholar

[40] Liang S Y, Zhu F, Wang Y J, Pineda E, Wada T, Kato H, Qiao J C 2024 Int. J. Eng. Sci. 205 104146

Google Scholar

Google Scholar

[41] 黄蓓蓓, 郝奇, 吕国建, 乔吉超 2023 72 136101

Google Scholar

Google Scholar

Huang B B, Hao Q, Lü G J, Qiao J C 2023 Acta Phys. Sin. 72 136101

Google Scholar

Google Scholar

[42] Gong X, Wang X D, Xu T, Cao Q, Zhang D, Jiang J Z 2021 J. Phys. Chem. B 125 657

Google Scholar

Google Scholar

[43] Jiang W, Zhao Y, Zhang B 2021 J. Non-Cryst. Solids 571 121062

Google Scholar

Google Scholar

[44] Li R, Pang S, Ma C, Zhang T 2007 Acta Mater. 55 3719

Google Scholar

Google Scholar

[45] Anand L, Su C 2005 J. Mech. Phys. Solids 53 1362

Google Scholar

Google Scholar

[46] Meduri C, Hasan M, Adam S, Kumar G 2018 J. Alloys Compd. 732 922

Google Scholar

Google Scholar

[47] Li L, Homer E R, Schuh C A 2013 Acta Mater. 61 3347

Google Scholar

Google Scholar

[48] Kato H, Igarashi H, Inoue A 2008 Mater. Lett. 62 1592

Google Scholar

Google Scholar

[49] Liu Y, Yang Z, Yang Y, Luo J, Huang X 2024 J. Non-Cryst. Solids 629 122891

Google Scholar

Google Scholar

[50] Bian X L, Wang G, Chen H C, Yan L, Wang J G, Wang Q, Hu P F, Ren J L, Chan K C, Zheng N, Teresiak A, Gao Y L, Zhai Q J, Eckert J, Beadsworth J, Dahmen K A, Liaw P K 2016 Acta Mater. 106 66

Google Scholar

Google Scholar

[51] Yoo B G, Park K W, Lee J C, Ramamurty U, Jang J I 2009 J. Mater. Res. 24 1405

Google Scholar

Google Scholar

[52] Cheng Y T, Hao Q, Pelletier J M, Pineda E, Qiao J C 2021 Int. J. Plast. 146 103107

Google Scholar

Google Scholar

[53] Lass E A, Zhu A, Shiflet G J, Joseph Poon S 2011 Acta Mater. 59 6341

Google Scholar

Google Scholar

[54] Pan S, Zheng G P, Qiao J, Niu X, Wang W, Qin J 2019 J. Alloys Compd. 799 450

Google Scholar

Google Scholar

[55] Acharya A, Widom M 2017 J. Mech. Phys. Solids 104 1

Google Scholar

Google Scholar

[56] Rao W, Chen Y, Dai L H, Jiang M Q 2025 J. Mech. Phys. Solids 196 106002

Google Scholar

Google Scholar

[57] Jiang J, Lu Z, Shen J, Wada T, Kato H, Chen M 2021 Nat. Commun. 12 3843

Google Scholar

Google Scholar

[58] Schirmacher W, Ruocco G, Mazzone V 2015 Phys. Rev. Lett. 115 015901

Google Scholar

Google Scholar

[59] 孟绍怡, 郝奇, 吕国建, 乔吉超 2023 72 076101

Google Scholar

Google Scholar

Meng S Y, Hao Q, Lü G J, Qiao J C 2023 Acta Phys. Sin. 72 076101

Google Scholar

Google Scholar

[60] Xing G H, Hao Q, Zhu F, Wang Y J, Yang Y, Kato H, Pineda E, Lan S, Qiao J 2024 Sci. China-Phys. Mech. Astron. 67 256111

Google Scholar

Google Scholar

[61] Ju J D, Atzmon M 2014 Acta Mater. 74 183

Google Scholar

Google Scholar

[62] Yamasaki T, Maeda S, Yokoyama Y, Okai D, Fukami T, Kimura H M, Inoue A 2006 Intermetallics 14 1102

Google Scholar

Google Scholar

[63] Hasan O A, Boyce M C 1995 Polym. Eng. Sci. 35 331

Google Scholar

Google Scholar

[64] Wu F F, Zhang Z F, Mao S X 2009 Acta Mater. 57 257

Google Scholar

Google Scholar

[65] Qiao J W, Zhang Y, Jia H L, Yang H J, Liaw P K, Xu B S 2012 Appl. Phys. Lett. 100 121902

Google Scholar

Google Scholar

[66] Wu L, Zhu Z, Liu D, Fu H, Li H, Wang A, Zhang H, Li Z, Zhang L, Zhang H 2020 J. Mater. Sci. Technol. 37 64

Google Scholar

Google Scholar

[67] 江双双, 朱力, 刘思楠, 杨詹詹, 兰司, 王寅岗 2022 71 058101

Google Scholar

Google Scholar

Jiang S S, Zhu L, Liu S N, Yang Z Z, Lan S, Wang Y G 2022 Acta Phys. Sin. 71 058101

Google Scholar

Google Scholar

-

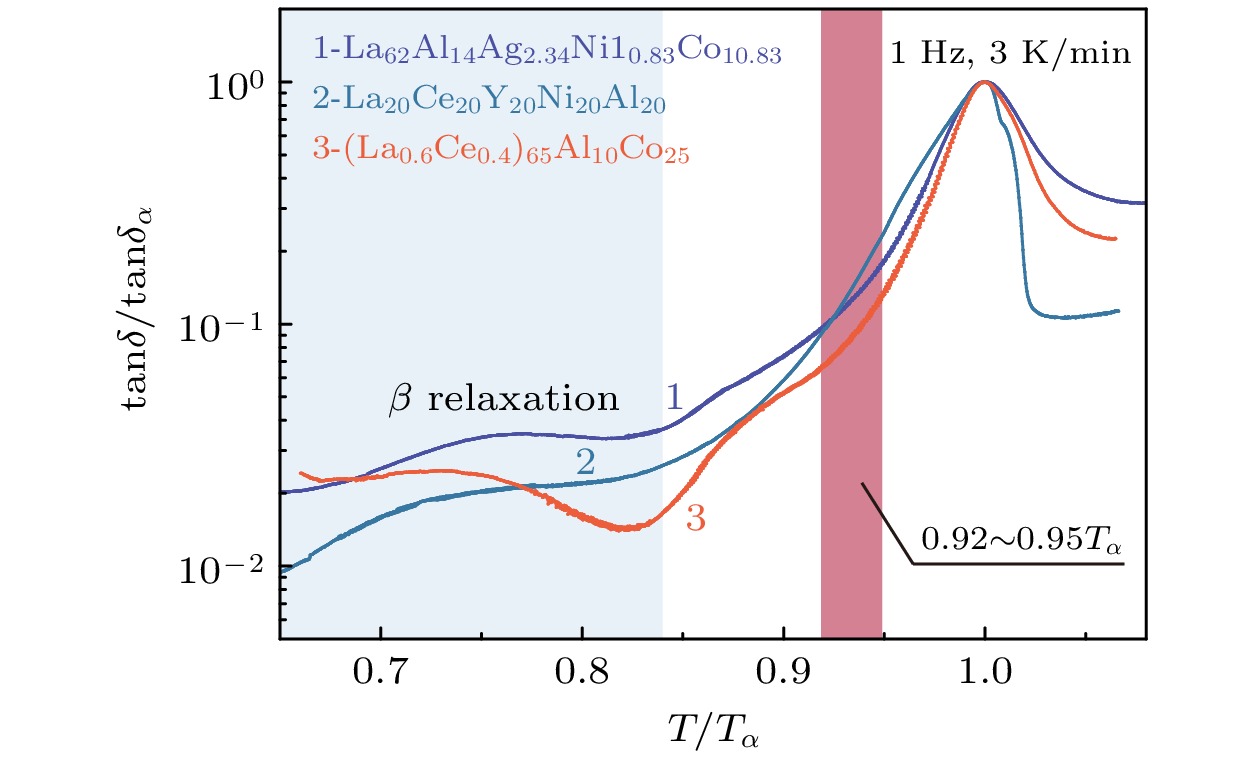

图 1 La62Al14Ag2.34Ni10.83Co10.83, La20Ce20Y20Ni20Al20和(La0.6Ce0.4)65Al10Co25非晶合金归一化内耗随归一化温度的演化(驱动频率: 1 Hz; 升温速率: 3 K/min)

Fig. 1. Evolution of the normalized internal friction with the normalized temperature for La62Al14Ag2.34Ni10.83Co10.83, La20Ce20Y20Ni20Al20 and (La0.6Ce0.4)65Al10Co25 metallic glasses (driving frequency: 1 Hz; heating rate: 3 K/min).

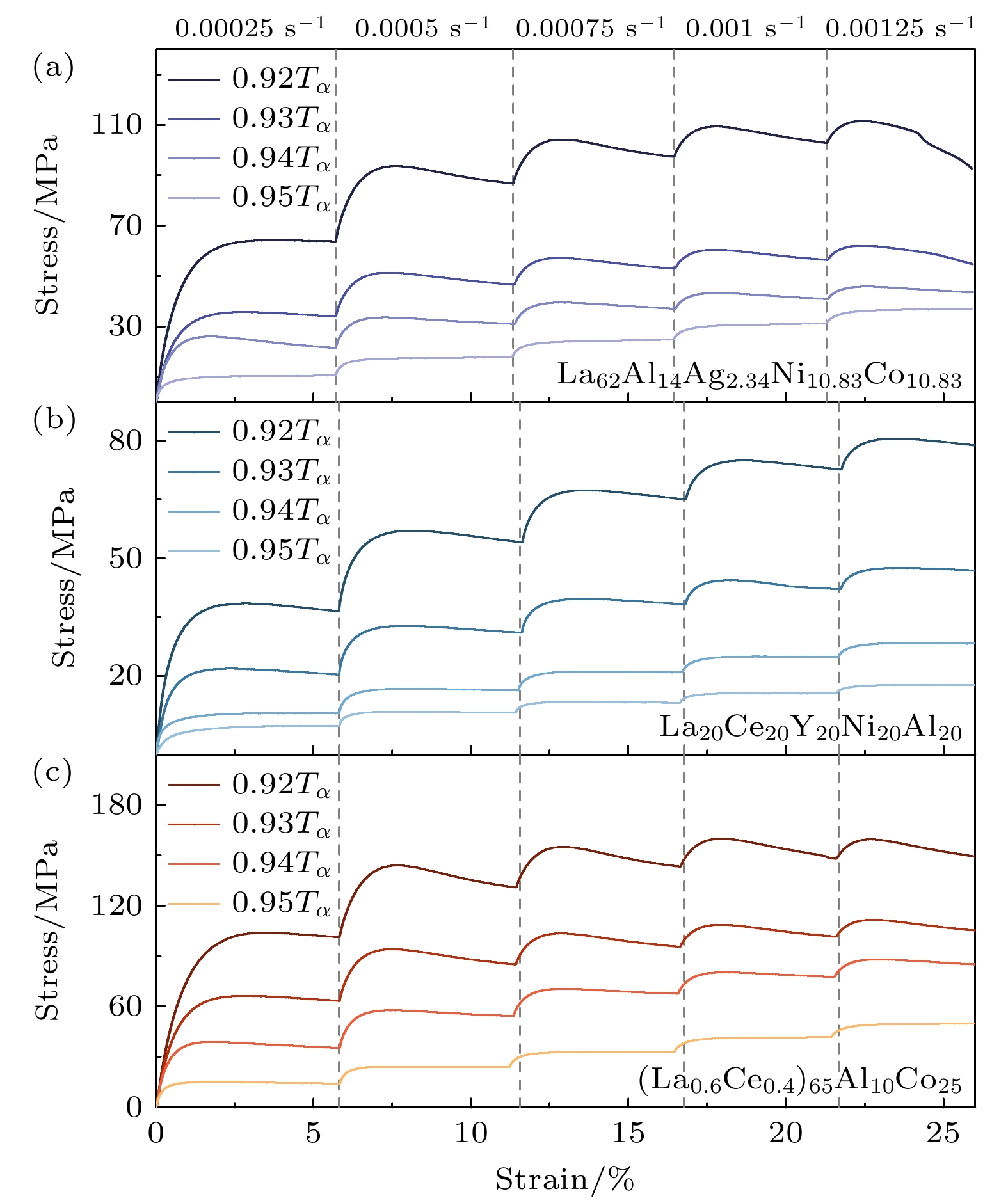

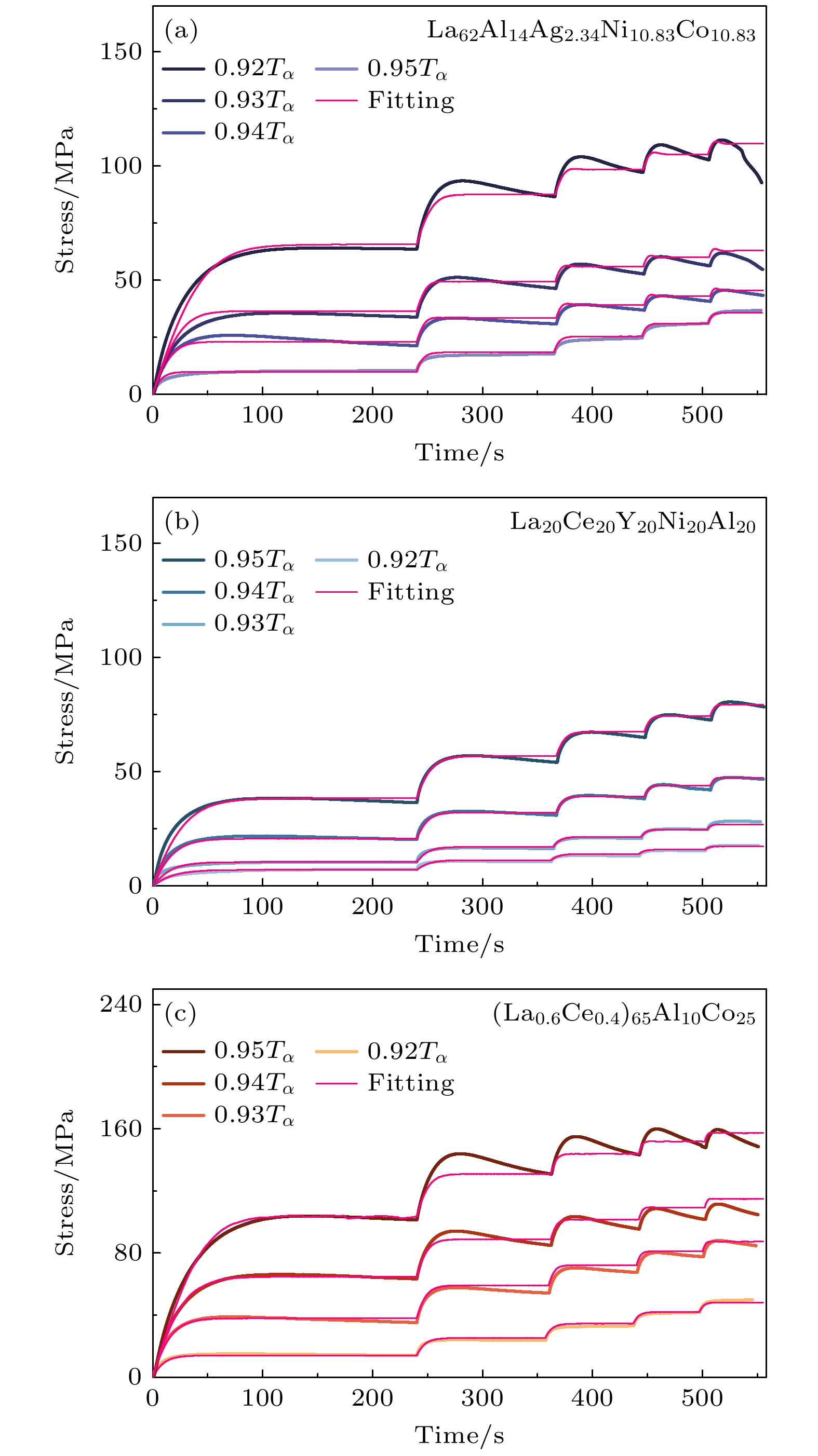

图 2 在0.92Tα, 0.93Tα, 0.94Tα, 0.95Tα下, (a) La62Al14Ag2.34Ni10.83Co10.83, (b) La20Ce20Y20Ni20Al20和(c) (La0.6Ce0.4)65Al10Co25非晶合金拉伸应变率跳跃实验(应变率: 2.5×10–4 —1.25×10–3 s–1)的应力-应变曲线

Fig. 2. Stress-strain curves from tensile strain-rate jump experiments (strain rate ranging from 2.5×10–4 to 1.25×10–3 s–1) of (a) La62Al14Ag2.34Ni10.83Co10.83, (b) La20Ce20Y20Ni20Al20 and (c) (La0.6Ce0.4)65Al10Co25 metallic glasses at 0.92Tα, 0.93Tα, 0.94Tα and 0.95Tα, respectively.

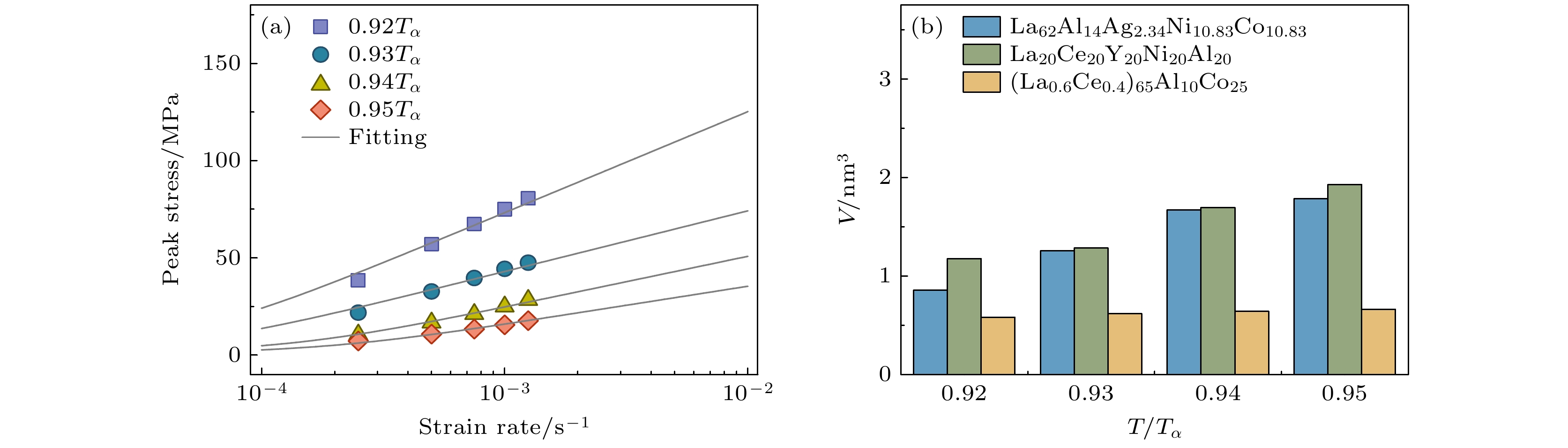

图 3 (a) La20Ce20Y20Ni20Al20非晶合金(La-2)在高温拉伸应变率跳过程中峰值应力随应变率的演化及其基于(1)式的拟合曲线; (b) La基非晶合金峰值应力处激活体积随归一化温度的演化

Fig. 3. (a) Evolution of the peak stress with the strain rate during the high-temperature tensile strain-rate jump process of La20Ce20Y20Ni20Al20 metallic glass (La-2) and the fitting curves based on Eq. (1); (b) evolution of the activation volume at the peak stress of La-based metallic glasses with the normalized temperature.

图 4 (a) La基非晶合金的参考应变率$ {\dot{\varepsilon }}_{0} $与归一化温度的关系; (b) La基非晶合金在0.92Tα—0.95Tα时无外力作用下扩散的平均激活能

Fig. 4. (a) Relationship between the reference strain rate $ {\dot{\varepsilon }}_{0} $ and the normalized temperature of La-based metallic glasses; (b) average activation energy for diffusion without an applied force of La-based metallic glasses at 0.92Tα–0.95Tα.

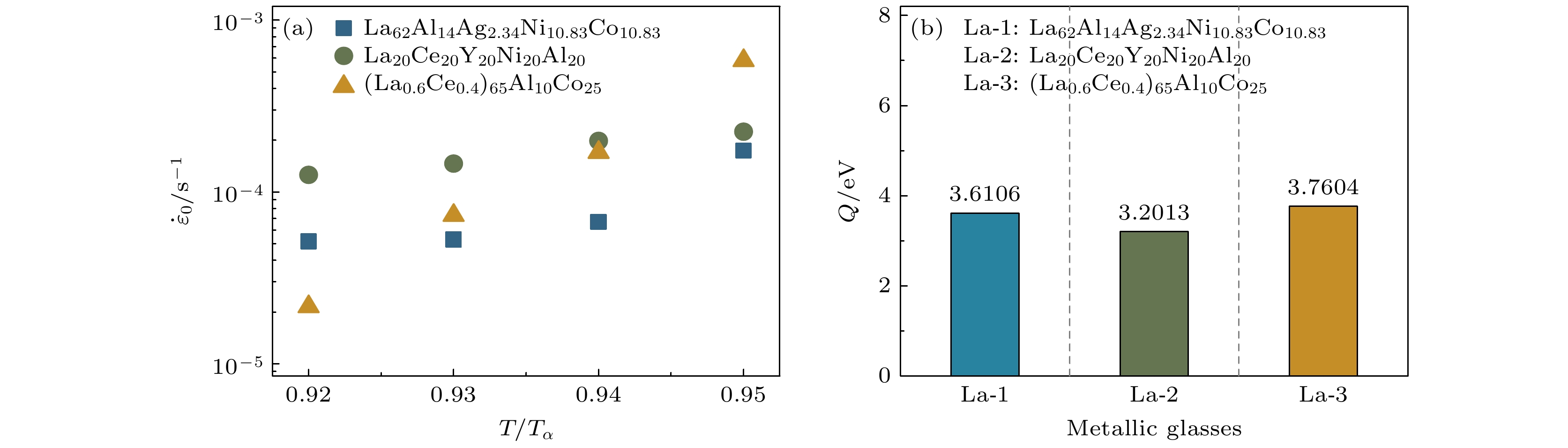

图 5 (a) 350—390 K温度下La20Ce20Y20Ni20Al20非晶合金(La-2)内耗的频率谱; (b) La基非晶合金体系β弛豫过程中激励频率与峰值温度之间的关系及Arrhenius拟合; (c) 三种La基非晶合金体系的β弛豫激活能

Fig. 5. (a) Frequency spectra of the internal friction of the La20Ce20Y20Ni20Al20 metallic glass (La-2) at temperatures ranging from 350 to 390 K; (b) relationship between the driving frequency and the peak temperature during β relaxation process in the La-based metallic glasses, along with the Arrhenius fitting; (c) activation energies of β relaxation for the La-based metallic glasses.

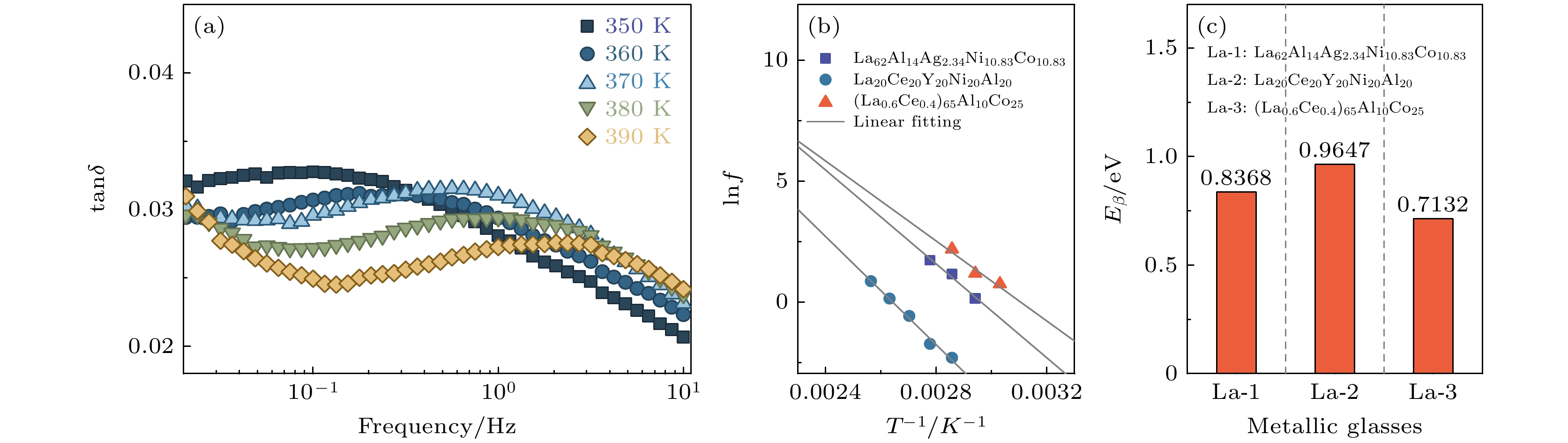

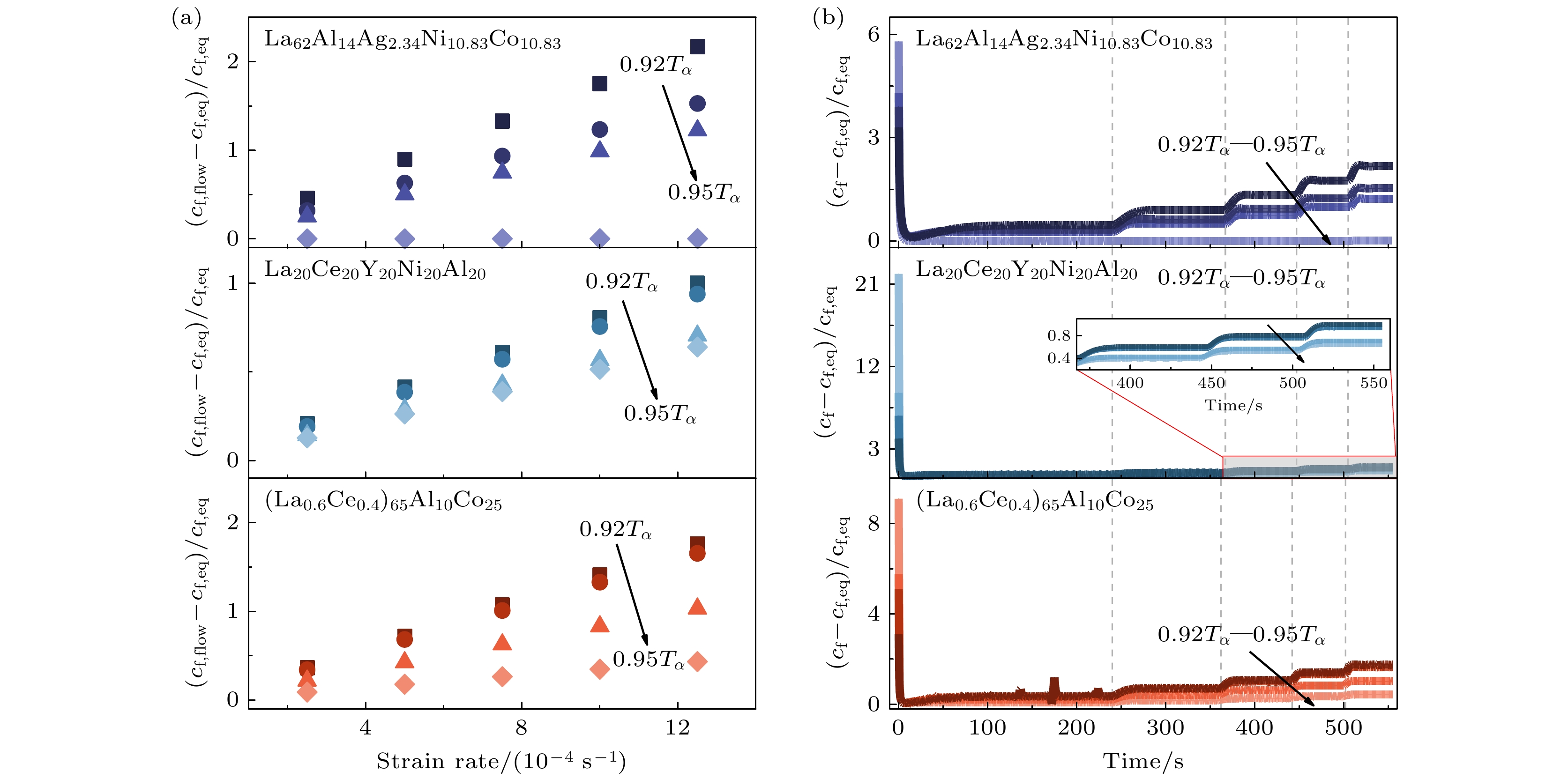

图 7 (a) La基非晶合金流变阶段相对缺陷浓度随应变率及温度的演化; (b) La基非晶合金高温拉伸应变率跳过程中相对缺陷浓度演化

Fig. 7. (a) Evolution of the relative defect concentration with strain rate and temperature during the rheological stage of La-based metallic glasses; (b) evolution of the relative defect concentration during the high-temperature tensile strain-rate jump process of La-based metallic glasses.

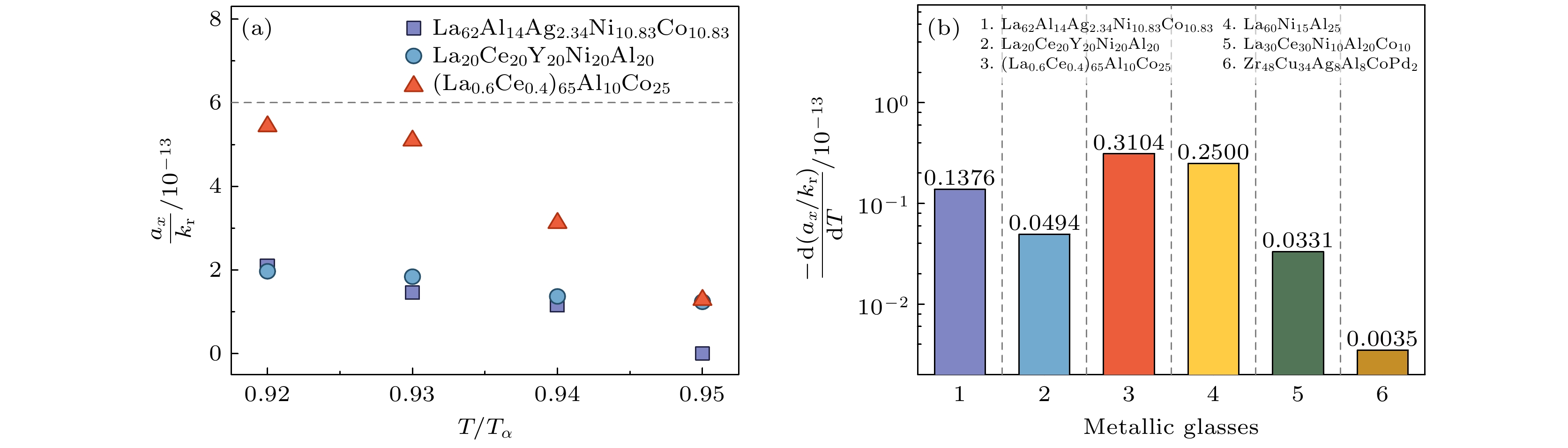

图 8 (a) La基非晶合金缺陷生成速率与湮灭速率的比值随温度的演化; (b) 不同非晶合金的$ -{\mathrm{d}}({a}_{x}/{k}_{{\mathrm{r}}})/{\mathrm{d}}T $

Fig. 8. (a) Evolution of the ratio between the defect generation rate and the annihilation rate with temperature for La-based metallic glasses; (b) $ -{\mathrm{d}}({a}_{x}/{k}_{{\mathrm{r}}})/{\mathrm{d}}T $ for different metallic glasses.

-

[1] Wang W H 2019 Prog. Mater. Sci. 106 100561

Google Scholar

Google Scholar

[2] Yu H B, Gao L, Gao J Q, Samwer K 2024 Natl. Sci. Rev. 11 nwae091

Google Scholar

Google Scholar

[3] Alem S A A, Sabzvand M H, Govahi P, Poormehrabi P, Hasanzadeh Azar M, Salehi Siouki S, Rashidi R, Angizi S, Bagherifard S 2025 Adv. Compos. Hybrid Mater. 8 3

Google Scholar

Google Scholar

[4] 王壮, 金凡, 李伟, 阮嘉艺, 王龙飞, 吴雪莲, 张义坤, 袁晨晨 2024 73 217101

Google Scholar

Google Scholar

Wang Z, Jin F, Li W, Ruan J Y, Wang L F, Wu X L, Zhang Y K, Yuan C C 2024 Acta Phys. Sin. 73 217101

Google Scholar

Google Scholar

[5] Wang W H, Yang Y, Nieh T G, Liu C T 2015 Intermetallics 67 81

Google Scholar

Google Scholar

[6] Fan Z, Li Q, Fan C, Wang H, Zhang X 2019 J. Mater. Res. 34 1595

Google Scholar

Google Scholar

[7] 王军强, 欧阳酥 2017 66 176102

Google Scholar

Google Scholar

Wang J Q, Ouyang S 2017 Acta Phys. Sin. 66 176102

Google Scholar

Google Scholar

[8] Liang S Y, Zhang L T, Wang Y J, Wang B, Pelletier J M, Qiao J C 2024 Int. J. Fatigue 187 108446

Google Scholar

Google Scholar

[9] Tong Y, Song L, Gao Y, Fan L, Li F, Yang Y, Mo G, Liu Y, Shui X, Zhang Y, Gao M, Huo J, Qiao J, Pineda E, Wang J Q 2023 Nat. Commun. 14 8407

Google Scholar

Google Scholar

[10] Gallino I, Cangialosi D, Evenson Z, Schmitt L, Hechler S, Stolpe M, Ruta B 2018 Acta Mater. 144 400

Google Scholar

Google Scholar

[11] Li W, Zuo X F, Liu R, Pang C M, Jin F, Zhu W W, Yuan C C 2024 Int. J. Plast. 174 103893

Google Scholar

Google Scholar

[12] Kelly J P, Fuller S M, Seo K, Novitskaya E, Eliasson V, Hodge A M, Graeve O A 2016 Mater. Des. 93 26

Google Scholar

Google Scholar

[13] Zhang Y, Li C, Fu X, Hou S, Li C, Kou S, Li X 2025 J. Alloys Compd. 1020 179364

Google Scholar

Google Scholar

[14] 武振伟, 汪卫华 2020 69 066101

Google Scholar

Google Scholar

Wu Z W, Wang W H 2020 Acta Phys. Sin. 69 066101

Google Scholar

Google Scholar

[15] Qiao J C, Wang Q, Pelletier J M, Kato H, Casalini R, Crespo D, Pineda E, Yao Y, Yang Y 2019 Prog. Mater. Sci. 104 250

Google Scholar

Google Scholar

[16] Zhang L T, Wang Y J, Yang Y, Qiao J C 2022 Sci. China-Phys. Mech. Astron. 65 106111

Google Scholar

Google Scholar

[17] Ding Y, Shi F, Wang X, Bai Y, Wang Z, Hu L 2024 Acta Mater. 266 119698

Google Scholar

Google Scholar

[18] Zhu F, Song S, Reddy K M, Hirata A, Chen M 2018 Nat. Commun. 9 3965

Google Scholar

Google Scholar

[19] Jiao W, Wen P, Peng H L, Bai H Y, Sun B A, Wang W H 2013 Appl. Phys. Lett. 102 101903

Google Scholar

Google Scholar

[20] Meng S, Hao Q, Wang B, Wang Y, Pineda E, Qiao J 2025 J. Appl. Phys. 137 055108

Google Scholar

Google Scholar

[21] Qiao J C, Pineda E 2025 Eur. J. Phys. 46 035501

Google Scholar

Google Scholar

[22] Monnier X, Cangialosi D, Ruta B, Busch R, Gallino I 2020 Sci. Adv. 6 1454

Google Scholar

Google Scholar

[23] Duan Y J, Zhang L T, Qiao J C, Wang Y J, Yang Y, Wada T, Kato H, Pelletier J M, Pineda E, Crespo D 2022 Phys. Rev. Lett. 129 175501

Google Scholar

Google Scholar

[24] Yu H B, Shen X, Wang Z, Gu L, Wang W H, Bai H Y 2012 Phys. Rev. Lett. 108 5

Google Scholar

Google Scholar

[25] Liang D D, Wang X D, Ge K, Cao Q P, Jiang J Z 2014 J. Non-Cryst. Solids 383 97

Google Scholar

Google Scholar

[26] Wang W H 2012 Prog. Mater. Sci. 57 487

Google Scholar

Google Scholar

[27] Zhang L T, Wang Y J, Pineda E, Yang Y, Qiao J C 2022 Int. J. Plast. 157 103402

Google Scholar

Google Scholar

[28] Zhu Y, Shang T, Yuan J, Song Z, Luo W, Zhang J, Li M 2024 J. Non-Cryst. Solids 645 123196

Google Scholar

Google Scholar

[29] Su S, Zhao W, Su X, Shadangi Y, Jin Z, Ning Z, Zhang Y, Sun J, Huang Y 2025 J. Mater. Sci. Technol. 227 304

Google Scholar

Google Scholar

[30] Su S, Liu C Y, Su X, Shadangi Y, Cao G Y, Ning Z L, Sun J F, Huang Y J, Eckert J 2025 Rare Metals 120501

[31] Spaepen F 1977 Acta Metall. 25 407

Google Scholar

Google Scholar

[32] Bletry M, Guyot P, Bréchet Y, Blandin J J, Soubeyroux J L 2007 Acta Mater. 55 6331

Google Scholar

Google Scholar

[33] Homer E R, Schuh C A 2009 Acta Mater. 57 2823

Google Scholar

Google Scholar

[34] Anand L, Su C 2007 Acta Mater. 55 3735

Google Scholar

Google Scholar

[35] Rao W, Chen Y, Dai L H 2022 Int. J. Plast. 154 103309

Google Scholar

Google Scholar

[36] Liang S Y, Zhang L T, Wang B, Wang Y J, Pineda E, Qiao J C 2024 Intermetallics 164 108115

Google Scholar

Google Scholar

[37] Hao Q, Lü G J, Pineda E, Pelletier J M, Wang Y J, Yang Y, Qiao J C 2024 Int. J. Plast. 175 103926

Google Scholar

Google Scholar

[38] Mo J, Shen B, Wan Y, Zhou Z, Sun B, Liang X 2020 J. Non-Cryst. Solids 528 119742

Google Scholar

Google Scholar

[39] Yuan S, Liang A, Liu C, Tian L, Mousseau N, Branicio P S 2023 Phys. Rev. Mater. 7 123603

Google Scholar

Google Scholar

[40] Liang S Y, Zhu F, Wang Y J, Pineda E, Wada T, Kato H, Qiao J C 2024 Int. J. Eng. Sci. 205 104146

Google Scholar

Google Scholar

[41] 黄蓓蓓, 郝奇, 吕国建, 乔吉超 2023 72 136101

Google Scholar

Google Scholar

Huang B B, Hao Q, Lü G J, Qiao J C 2023 Acta Phys. Sin. 72 136101

Google Scholar

Google Scholar

[42] Gong X, Wang X D, Xu T, Cao Q, Zhang D, Jiang J Z 2021 J. Phys. Chem. B 125 657

Google Scholar

Google Scholar

[43] Jiang W, Zhao Y, Zhang B 2021 J. Non-Cryst. Solids 571 121062

Google Scholar

Google Scholar

[44] Li R, Pang S, Ma C, Zhang T 2007 Acta Mater. 55 3719

Google Scholar

Google Scholar

[45] Anand L, Su C 2005 J. Mech. Phys. Solids 53 1362

Google Scholar

Google Scholar

[46] Meduri C, Hasan M, Adam S, Kumar G 2018 J. Alloys Compd. 732 922

Google Scholar

Google Scholar

[47] Li L, Homer E R, Schuh C A 2013 Acta Mater. 61 3347

Google Scholar

Google Scholar

[48] Kato H, Igarashi H, Inoue A 2008 Mater. Lett. 62 1592

Google Scholar

Google Scholar

[49] Liu Y, Yang Z, Yang Y, Luo J, Huang X 2024 J. Non-Cryst. Solids 629 122891

Google Scholar

Google Scholar

[50] Bian X L, Wang G, Chen H C, Yan L, Wang J G, Wang Q, Hu P F, Ren J L, Chan K C, Zheng N, Teresiak A, Gao Y L, Zhai Q J, Eckert J, Beadsworth J, Dahmen K A, Liaw P K 2016 Acta Mater. 106 66

Google Scholar

Google Scholar

[51] Yoo B G, Park K W, Lee J C, Ramamurty U, Jang J I 2009 J. Mater. Res. 24 1405

Google Scholar

Google Scholar

[52] Cheng Y T, Hao Q, Pelletier J M, Pineda E, Qiao J C 2021 Int. J. Plast. 146 103107

Google Scholar

Google Scholar

[53] Lass E A, Zhu A, Shiflet G J, Joseph Poon S 2011 Acta Mater. 59 6341

Google Scholar

Google Scholar

[54] Pan S, Zheng G P, Qiao J, Niu X, Wang W, Qin J 2019 J. Alloys Compd. 799 450

Google Scholar

Google Scholar

[55] Acharya A, Widom M 2017 J. Mech. Phys. Solids 104 1

Google Scholar

Google Scholar

[56] Rao W, Chen Y, Dai L H, Jiang M Q 2025 J. Mech. Phys. Solids 196 106002

Google Scholar

Google Scholar

[57] Jiang J, Lu Z, Shen J, Wada T, Kato H, Chen M 2021 Nat. Commun. 12 3843

Google Scholar

Google Scholar

[58] Schirmacher W, Ruocco G, Mazzone V 2015 Phys. Rev. Lett. 115 015901

Google Scholar

Google Scholar

[59] 孟绍怡, 郝奇, 吕国建, 乔吉超 2023 72 076101

Google Scholar

Google Scholar

Meng S Y, Hao Q, Lü G J, Qiao J C 2023 Acta Phys. Sin. 72 076101

Google Scholar

Google Scholar

[60] Xing G H, Hao Q, Zhu F, Wang Y J, Yang Y, Kato H, Pineda E, Lan S, Qiao J 2024 Sci. China-Phys. Mech. Astron. 67 256111

Google Scholar

Google Scholar

[61] Ju J D, Atzmon M 2014 Acta Mater. 74 183

Google Scholar

Google Scholar

[62] Yamasaki T, Maeda S, Yokoyama Y, Okai D, Fukami T, Kimura H M, Inoue A 2006 Intermetallics 14 1102

Google Scholar

Google Scholar

[63] Hasan O A, Boyce M C 1995 Polym. Eng. Sci. 35 331

Google Scholar

Google Scholar

[64] Wu F F, Zhang Z F, Mao S X 2009 Acta Mater. 57 257

Google Scholar

Google Scholar

[65] Qiao J W, Zhang Y, Jia H L, Yang H J, Liaw P K, Xu B S 2012 Appl. Phys. Lett. 100 121902

Google Scholar

Google Scholar

[66] Wu L, Zhu Z, Liu D, Fu H, Li H, Wang A, Zhang H, Li Z, Zhang L, Zhang H 2020 J. Mater. Sci. Technol. 37 64

Google Scholar

Google Scholar

[67] 江双双, 朱力, 刘思楠, 杨詹詹, 兰司, 王寅岗 2022 71 058101

Google Scholar

Google Scholar

Jiang S S, Zhu L, Liu S N, Yang Z Z, Lan S, Wang Y G 2022 Acta Phys. Sin. 71 058101

Google Scholar

Google Scholar

计量

- 文章访问数: 405

- PDF下载量: 10

- 被引次数: 0

下载:

下载: