-

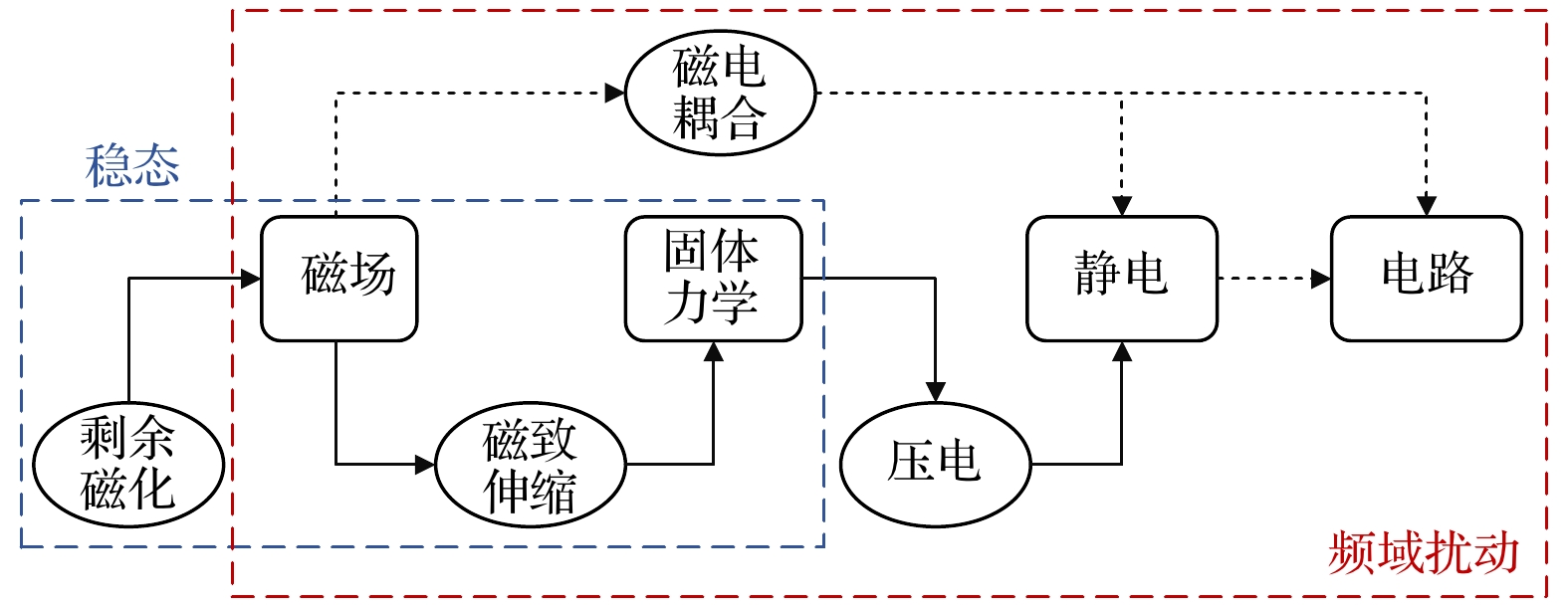

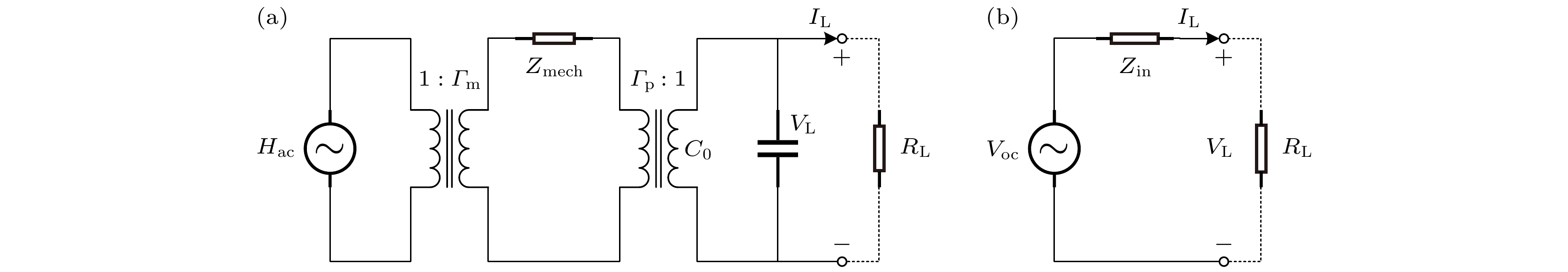

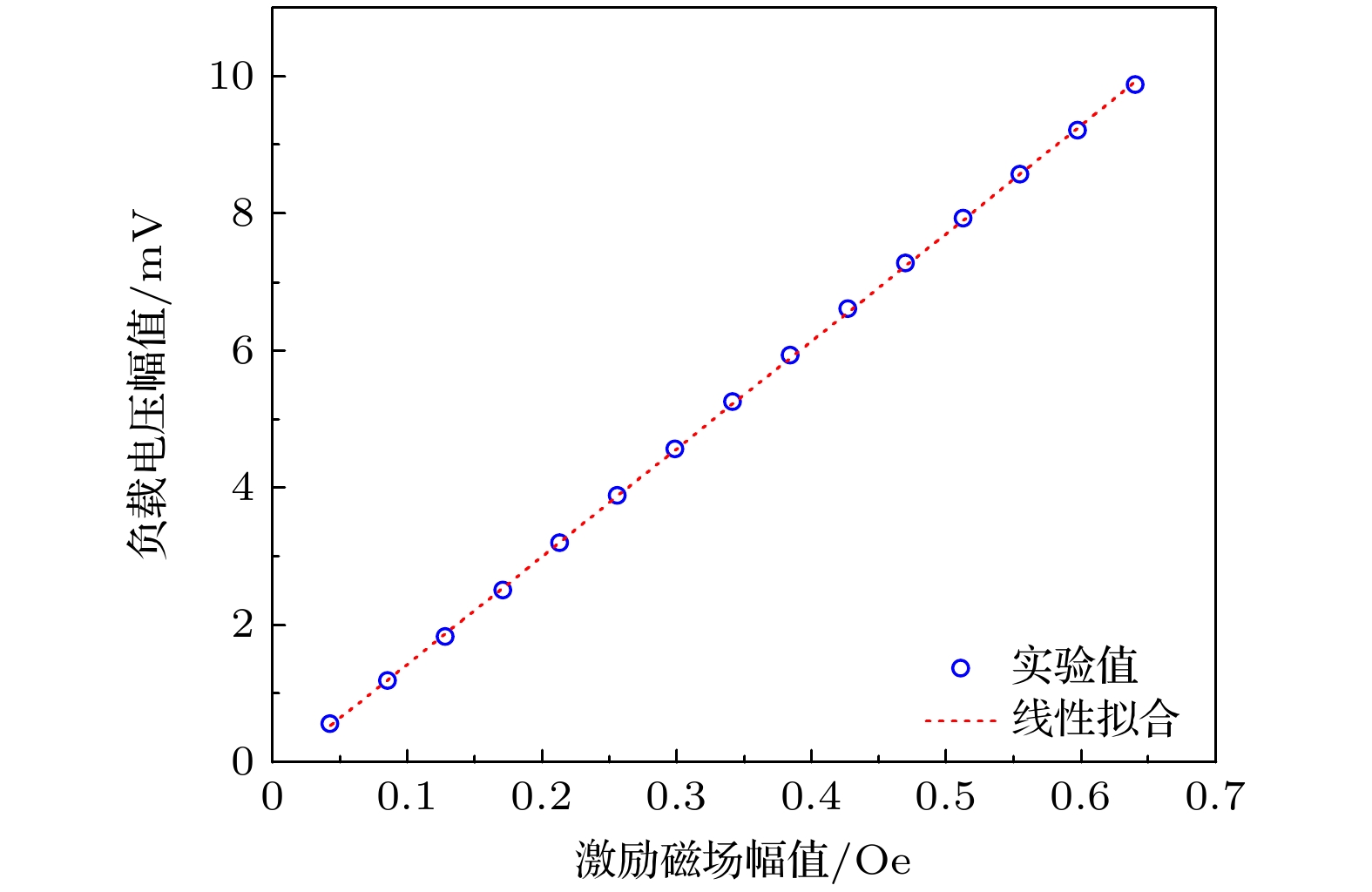

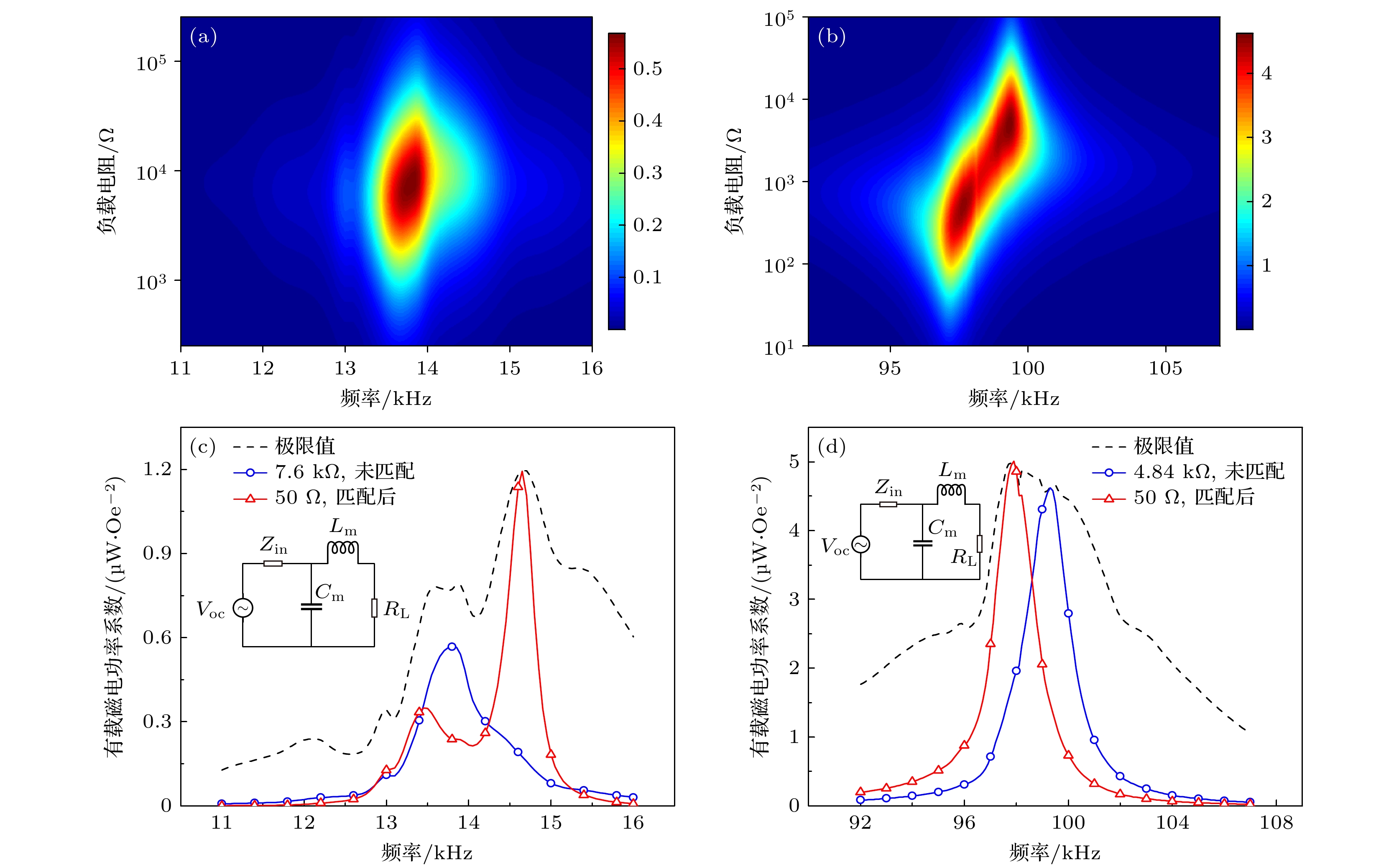

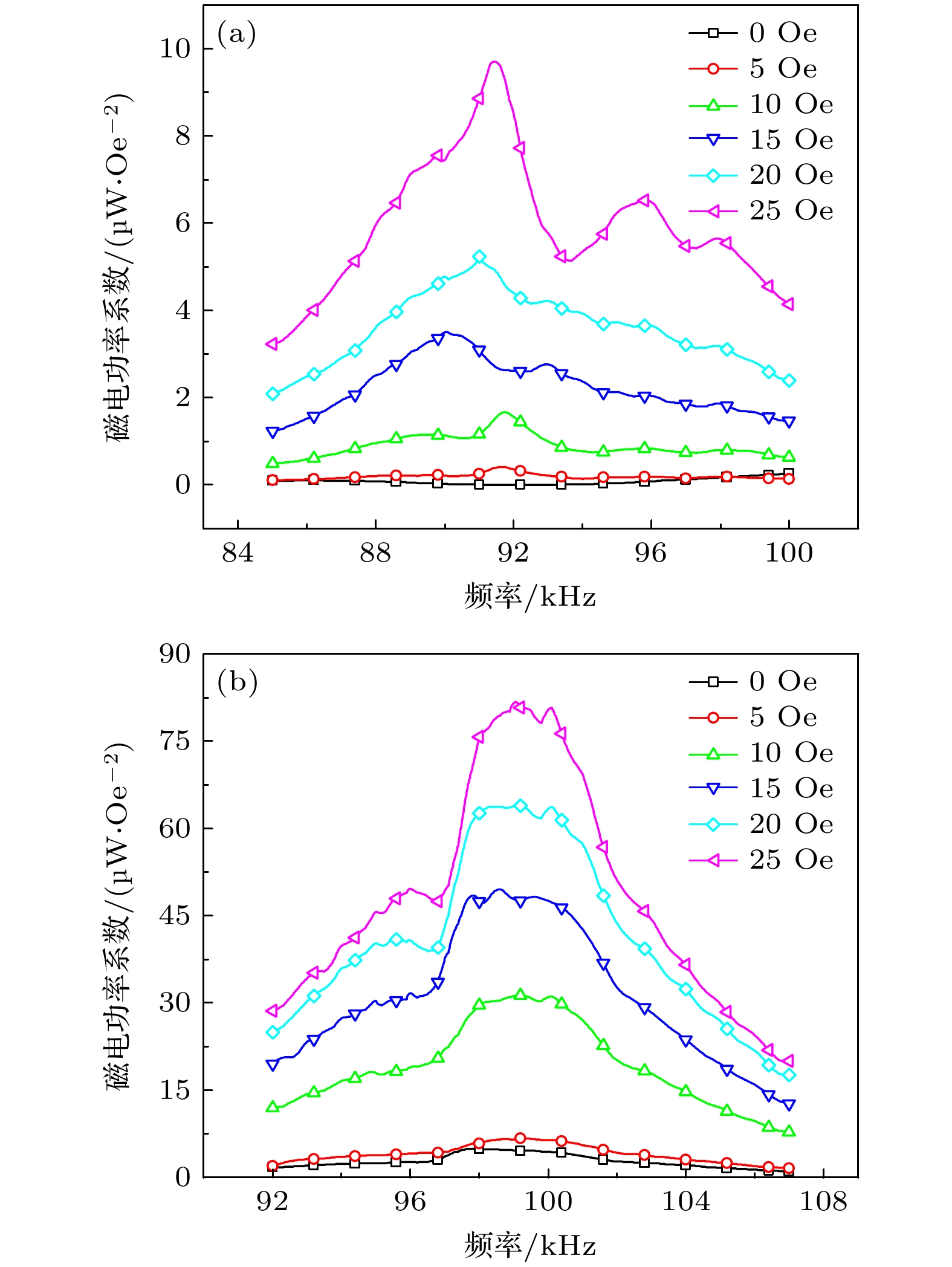

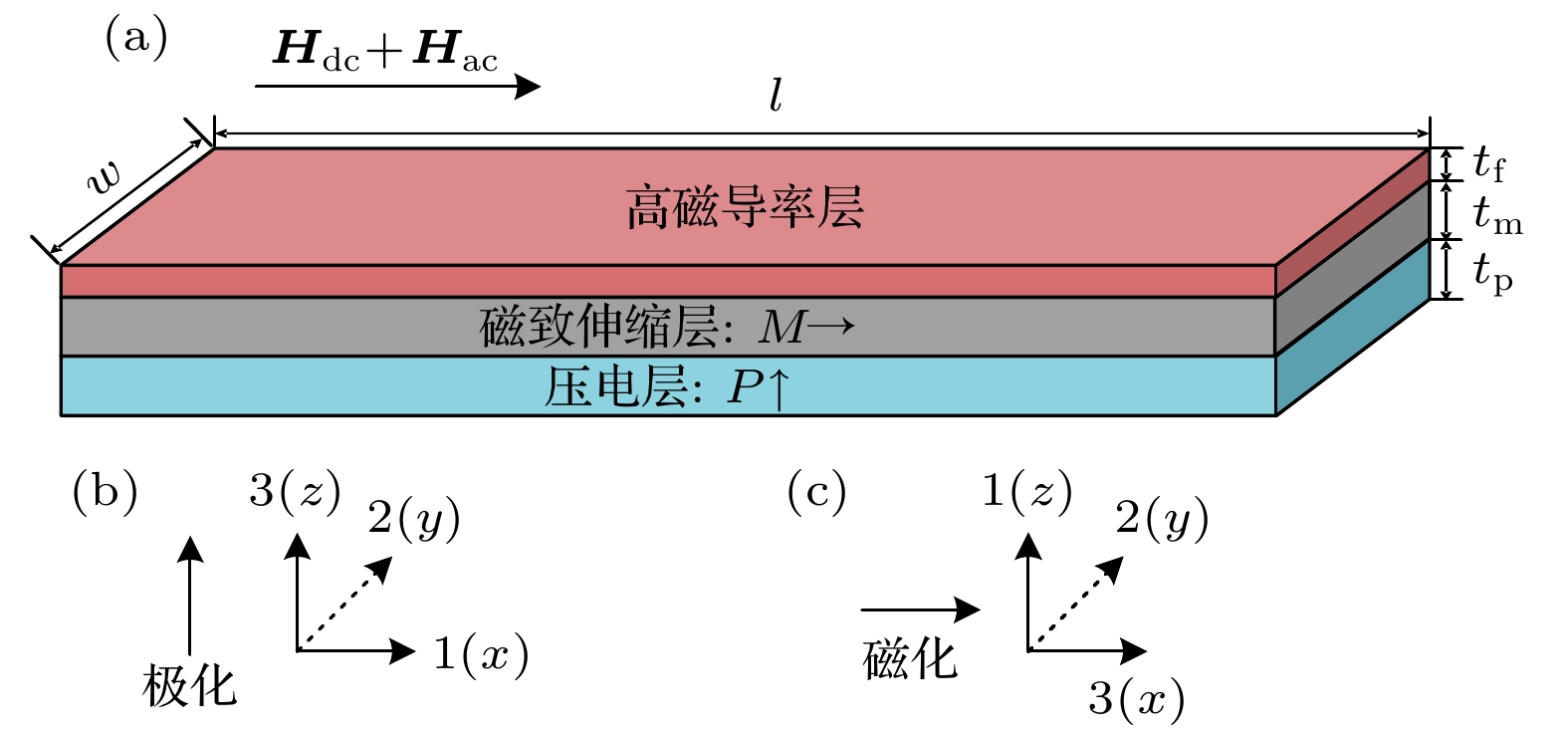

基于磁化等效和非线性磁致伸缩本构关系, 建立了L-T模式下的自偏置磁电换能器的多物理场耦合仿真模型, 研究了弯曲、伸缩谐振模式下的磁电耦合性能. 在所建模型基础上, 制备了相应的实验样品进行测试. 实测结果与仿真数据相吻合, 从而验证了模型的准确性和有效性. 实测结果表明, Metglas/Galfenol/PZT-5A结构在伸缩谐振模式下展现出更为显著的自偏置磁电效应, 其磁电系数为10.7 V·cm–1·Oe–1@99.4 kHz, 磁电功率系数为5.01 μW·Oe–2@97.9 kHz. 无需阻抗匹配, 其有载磁电功率系数最高可达4.62 μW·Oe–2@99.3 kHz. 施加外部偏置磁场至25 Oe, 磁电系数可提升至47.06 V·cm–1·Oe–1@99.4 kHz, 磁电功率系数提升至82.13 μW·Oe–2@99 kHz. 进一步的仿真研究表明, 高磁导率层厚度的增加能显著提升自偏置磁电换能器的性能: 当Metglas层厚度增加至90 μm时, 磁电系数和功率系数分别提升至原先的2.47倍和6.96倍. 自偏置磁电换能器具备减少对外部偏置磁场依赖的能力, 为磁电复合材料在低频无线功率传输系统中的应用与发展提供了新途径.Compared with single-phase multiferroic materials, magnetoelectric (ME) composites composed of piezoelectric and magnetostrictive materials have great ME coupling, and have received widespread attention in various application fields. The application of ME devices in wireless power transfer (WPT) is attractive due to their compactness and ability to operate at lower frequencies than conventional coils. However, traditional ME composites rely on permanent magnets or electromagnets to provide biased magnetic fields, thus leading to problems such as high noise, large size, and high cost, which significantly hinder the advancement of miniaturized and high-performance ME devices. To solve this problem, a self-biased ME laminated structure based on the magnetization grading effect is proposed in this work. Using the equivalent magnetization and nonlinear magnetostrictive constitutive relationship, a finite element simulation model for a self-biased ME transducer operating in L-T mode is constructed. The ME coupling performances without DC bias in bending vibration mode and stretching vibration mode are studied. Based on the model, the corresponding experimental samples are prepared for measurement. The measurement results are in agreement with the simulation data, thereby validating the accuracy and effectiveness of the model. The measured results show that the Metglas/Galfenol/PZT-5A structure can exhibit more significant self-biased ME effect under the stretching resonance mode than under bending resonance mode. Its ME coefficient attains a notable value of 10.7 V·cm–1·Oe–1 at 99.4 kHz, while ME power coefficient reaches 5.01 μW·Oe–2 at 97.9 kHz. Its on-load ME power coefficient can reach up to 4.62 μW·Oe–2 at 99.3 kHz without impedance matching. When an external bias magnetic field of 25 Oe is applied, these performance indexes increase significantly to 47.06 V·cm–1·Oe–1 at 99.4 kHz and 82.13 μW·Oe–2 at 99.0 kHz, respectively. The simulation results further show that the performance of the self-biased ME transducer can be significantly improved by increasing the thickness of the high permeability layer. For example, by increasing the Metglas layer thickness from 30 μm to 90 μm, both the ME coefficient and ME power coefficient increase rapidly by 2.47 times and 6.96 times the original values, respectively. Self-biased ME transducers effectively reduce the dependence on external bias magnetic field, thereby providing a good approach for applying and developing ME composites in low-frequency WPT systems.

-

Keywords:

- magnetoelectric transducer /

- self-biased magnetoelectric effect /

- high permeability layer /

- magnetoelectric power coefficient

[1] Ou Z Y, Lu C J, Yang A C, Zhou H, Cao Z Q, Zhu R R, Gao H L 2019 Sens. Actuators A: Phys. 290 8

Google Scholar

Google Scholar

[2] Zhao Y X, Lu C J 2015 Rev. Sci. Instrum. 86 036101

Google Scholar

Google Scholar

[3] Chu Z Q, PourhosseiniAsl M, Dong S X 2018 J. Phys. D: Appl. Phys. 51 243001

Google Scholar

Google Scholar

[4] Mukherje D, Mallic D 2023 Appl. Phys. Lett. 122 014102

Google Scholar

Google Scholar

[5] Du Y J, Xu Y W, Wu J G, Qiao J C, Wang Z G, Hu Z Q, Jiang Z D, Liu M 2023 IEEE Trans. Antenn. Propag. 71 2167

Google Scholar

Google Scholar

[6] Niu Y P, Ren H 2021 Appl. Phys. Lett. 118 264104

Google Scholar

Google Scholar

[7] Sudersan S, Arockiarajan A 2019 Compos. Struct. 223 110924

Google Scholar

Google Scholar

[8] 周勇, 李纯健, 潘昱融 2018 67 077702

Google Scholar

Google Scholar

Zhou Y, Li C J, Pan Y R 2018 Acta Phys. Sin. 67 077702

Google Scholar

Google Scholar

[9] Han J, Zhang J J, Gao Y W 2018 J. Magn. Magn. Mater. 466 200

Google Scholar

Google Scholar

[10] Yao H, Shi Y, Gao Y W 2016 J. Magn. Magn. Mater. 401 1046

Google Scholar

Google Scholar

[11] 阳昌海, 文玉梅, 李平, 卞雷祥 2008 57 7292

Google Scholar

Google Scholar

Yang C H, Wen Y M, Li P, Bian L X 2008 Acta Phys. Sin. 57 7292

Google Scholar

Google Scholar

[12] Dong H M, Guo H H, Li J R, Li B J, Gan X X 2023 Phys. Scr. 98 065901

Google Scholar

Google Scholar

[13] Shi Y, Li L, Yang Y 2021 Chin. Phys. B 30 107503

Google Scholar

Google Scholar

[14] Lei B X, You Z X, Zhang Z D, Shi Y 2023 Acta Mech. Sin. 39 523120

Google Scholar

Google Scholar

[15] Niu L F, Shi Y, Gao Y W 2019 AIP Adv. 9 045216

Google Scholar

Google Scholar

[16] Kumar S D, Gupta S, Swain A B, Subramanian V, Padmanabhan M K, Mahajan R L 2021 J. Alloy. Compd. 858 157684

Google Scholar

Google Scholar

[17] Truong B D, Roundy S 2020 Smart Mater. Struct. 29 085053

Google Scholar

Google Scholar

[18] Lage E, Kirchhof C, Hrkac V, Kienle L, Jahns R, Knöchel R, Quandt E Meyners D 2012 Nature Mater. 11 523

Google Scholar

Google Scholar

[19] Röbisch V, Yarar E, Urs N O, Teliban I, Knöchel R, Mccoed J, Quandt E, Meyners D 2015 J. Appl. Phys. 117 17B513

Google Scholar

Google Scholar

[20] Zhou Y, Priya S 2014 J. Appl. Phys. 115 104107

Google Scholar

Google Scholar

[21] Zhang J J, Gao Y W 2015 Int. J. Solid. Struct. 69–70 291

Google Scholar

Google Scholar

[22] 文玉梅, 王东, 李平, 陈蕾, 吴治峄 2011 60 097506

Google Scholar

Google Scholar

Wen Y M, Wang D, Li P, Cheng L, Wu Z Y 2011 Acta Phys. Sin. 60 097506

Google Scholar

Google Scholar

[23] Lu C J, Li P, Wen Y M, Yang A C, Yang C, Wang D C, He W, Zhang J T 2014 Chin. Phys. B 23 117503

Google Scholar

Google Scholar

[24] Chen L, Li P, Wen Y M, Zhu Y 2015 Compos. Struct. 119 685

Google Scholar

Google Scholar

[25] Lu C J, Li P, Wen Y M, Yang A C, He W, Zhang J T, Yang J, Wen J, Zhu Y, Yu M 2013 Appl. Phys. A 113 413

Google Scholar

Google Scholar

[26] Shi Y, Lei B X, Wang Y K, Ye J J 2022 Compos. Struct. 300 116164

Google Scholar

Google Scholar

[27] Zhang J, Du H, Xia X, Fang C, Weng G J 2020 Mech. Mater. 151 103609

Google Scholar

Google Scholar

[28] Ma J N, Xin C Z, Ma J, Lin Y H, Nan C W 2016 Mater. Res. Express 3 125012

Google Scholar

Google Scholar

[29] Huang D Y, Lu C J, Han B, Wang X, Li C X, Xu C B, Gui J G, Lin C H 2014 Appl. Phys. Lett. 105 263502

Google Scholar

Google Scholar

[30] Yang S C, Cho K H, Park C S, Priya S S 2011 Appl. Phys. Lett. 99 202904

Google Scholar

Google Scholar

[31] Truong B D 2020 IEEE Sens. J. 20 5322

Google Scholar

Google Scholar

[32] Hosur S, Sriramdas R, Karan S K, Liu N, Priya S, Kiani M 2021 IEEE Trans. Biomed. Circuits Syst. 15 1079

Google Scholar

Google Scholar

[33] Saha O, Truong B D, Roundy S 2022 Smart Mater. Struct. 31 113001

Google Scholar

Google Scholar

[34] Kim W, Tuppen C A, Alrashdan F, Singer A, Weirnick R, Robinson J T 2023 J. Appl. Phys. 134 094103

Google Scholar

Google Scholar

[35] Liu X, Zheng X J 2005 Acta Mech. Sin. 21 278

Google Scholar

Google Scholar

[36] 李鸣鹤 2023 硕士学位论文 (长春: 吉林大学)

Li M H 2023 M. S. Thesis (Changchun: Jilin University

[37] 谢冰鸿, 徐国凯, 肖绍球, 喻忠军, 朱大立 2023 72 117501

Google Scholar

Google Scholar

Xie B H, Xu G K, Xiao S Q, Yu Z J, Zhu D L 2023 Acta Phys. Sin. 72 117501

Google Scholar

Google Scholar

[38] 罗志高 2019 大学物理实验 32 9

Google Scholar

Google Scholar

Luo Z G 2019 Phys. Exp. Coll. 32 9

Google Scholar

Google Scholar

[39] Li L, Chen X M 2008 Appl. Phys. Lett. 92 072903

Google Scholar

Google Scholar

[40] Zhang J T, Li P, Wen Y M, He W, Yang A C, Lu C J 2014 Sens. Actuators A 214 149

Google Scholar

Google Scholar

[41] Annapureddy V, Park S H, Song H, Ryu J 2023 J. Alloy. Compd. 957 170121

Google Scholar

Google Scholar

-

表 1 Galfenol和Metglas的材料参数

Table 1. Material parameters of Galfenol and Metglas.

名称 Galfenol Metglas 密度/(${\text{kg}} \cdot {{\text{m}}^{{{ - 3}}}}$) 7972 7250 杨氏模量/GPa 70 100 泊松比 0.37 0.34 初始磁化率 27 — 饱和磁致伸缩系数/10–6 320 — 饱和磁化强度/($ {\text{A}} \cdot {{\text{m}}^{{{ - 1}}}} $) 9.0×105 — 电导率/($ {\text{S}} \cdot {{\text{m}}^{{{ - 1}}}} $) 1.23×107 7.69×105 表 2 不同自偏置磁电换能器的性能指标对比

Table 2. Performance comparison of different self-biased magnetoelectric transducers.

-

[1] Ou Z Y, Lu C J, Yang A C, Zhou H, Cao Z Q, Zhu R R, Gao H L 2019 Sens. Actuators A: Phys. 290 8

Google Scholar

Google Scholar

[2] Zhao Y X, Lu C J 2015 Rev. Sci. Instrum. 86 036101

Google Scholar

Google Scholar

[3] Chu Z Q, PourhosseiniAsl M, Dong S X 2018 J. Phys. D: Appl. Phys. 51 243001

Google Scholar

Google Scholar

[4] Mukherje D, Mallic D 2023 Appl. Phys. Lett. 122 014102

Google Scholar

Google Scholar

[5] Du Y J, Xu Y W, Wu J G, Qiao J C, Wang Z G, Hu Z Q, Jiang Z D, Liu M 2023 IEEE Trans. Antenn. Propag. 71 2167

Google Scholar

Google Scholar

[6] Niu Y P, Ren H 2021 Appl. Phys. Lett. 118 264104

Google Scholar

Google Scholar

[7] Sudersan S, Arockiarajan A 2019 Compos. Struct. 223 110924

Google Scholar

Google Scholar

[8] 周勇, 李纯健, 潘昱融 2018 67 077702

Google Scholar

Google Scholar

Zhou Y, Li C J, Pan Y R 2018 Acta Phys. Sin. 67 077702

Google Scholar

Google Scholar

[9] Han J, Zhang J J, Gao Y W 2018 J. Magn. Magn. Mater. 466 200

Google Scholar

Google Scholar

[10] Yao H, Shi Y, Gao Y W 2016 J. Magn. Magn. Mater. 401 1046

Google Scholar

Google Scholar

[11] 阳昌海, 文玉梅, 李平, 卞雷祥 2008 57 7292

Google Scholar

Google Scholar

Yang C H, Wen Y M, Li P, Bian L X 2008 Acta Phys. Sin. 57 7292

Google Scholar

Google Scholar

[12] Dong H M, Guo H H, Li J R, Li B J, Gan X X 2023 Phys. Scr. 98 065901

Google Scholar

Google Scholar

[13] Shi Y, Li L, Yang Y 2021 Chin. Phys. B 30 107503

Google Scholar

Google Scholar

[14] Lei B X, You Z X, Zhang Z D, Shi Y 2023 Acta Mech. Sin. 39 523120

Google Scholar

Google Scholar

[15] Niu L F, Shi Y, Gao Y W 2019 AIP Adv. 9 045216

Google Scholar

Google Scholar

[16] Kumar S D, Gupta S, Swain A B, Subramanian V, Padmanabhan M K, Mahajan R L 2021 J. Alloy. Compd. 858 157684

Google Scholar

Google Scholar

[17] Truong B D, Roundy S 2020 Smart Mater. Struct. 29 085053

Google Scholar

Google Scholar

[18] Lage E, Kirchhof C, Hrkac V, Kienle L, Jahns R, Knöchel R, Quandt E Meyners D 2012 Nature Mater. 11 523

Google Scholar

Google Scholar

[19] Röbisch V, Yarar E, Urs N O, Teliban I, Knöchel R, Mccoed J, Quandt E, Meyners D 2015 J. Appl. Phys. 117 17B513

Google Scholar

Google Scholar

[20] Zhou Y, Priya S 2014 J. Appl. Phys. 115 104107

Google Scholar

Google Scholar

[21] Zhang J J, Gao Y W 2015 Int. J. Solid. Struct. 69–70 291

Google Scholar

Google Scholar

[22] 文玉梅, 王东, 李平, 陈蕾, 吴治峄 2011 60 097506

Google Scholar

Google Scholar

Wen Y M, Wang D, Li P, Cheng L, Wu Z Y 2011 Acta Phys. Sin. 60 097506

Google Scholar

Google Scholar

[23] Lu C J, Li P, Wen Y M, Yang A C, Yang C, Wang D C, He W, Zhang J T 2014 Chin. Phys. B 23 117503

Google Scholar

Google Scholar

[24] Chen L, Li P, Wen Y M, Zhu Y 2015 Compos. Struct. 119 685

Google Scholar

Google Scholar

[25] Lu C J, Li P, Wen Y M, Yang A C, He W, Zhang J T, Yang J, Wen J, Zhu Y, Yu M 2013 Appl. Phys. A 113 413

Google Scholar

Google Scholar

[26] Shi Y, Lei B X, Wang Y K, Ye J J 2022 Compos. Struct. 300 116164

Google Scholar

Google Scholar

[27] Zhang J, Du H, Xia X, Fang C, Weng G J 2020 Mech. Mater. 151 103609

Google Scholar

Google Scholar

[28] Ma J N, Xin C Z, Ma J, Lin Y H, Nan C W 2016 Mater. Res. Express 3 125012

Google Scholar

Google Scholar

[29] Huang D Y, Lu C J, Han B, Wang X, Li C X, Xu C B, Gui J G, Lin C H 2014 Appl. Phys. Lett. 105 263502

Google Scholar

Google Scholar

[30] Yang S C, Cho K H, Park C S, Priya S S 2011 Appl. Phys. Lett. 99 202904

Google Scholar

Google Scholar

[31] Truong B D 2020 IEEE Sens. J. 20 5322

Google Scholar

Google Scholar

[32] Hosur S, Sriramdas R, Karan S K, Liu N, Priya S, Kiani M 2021 IEEE Trans. Biomed. Circuits Syst. 15 1079

Google Scholar

Google Scholar

[33] Saha O, Truong B D, Roundy S 2022 Smart Mater. Struct. 31 113001

Google Scholar

Google Scholar

[34] Kim W, Tuppen C A, Alrashdan F, Singer A, Weirnick R, Robinson J T 2023 J. Appl. Phys. 134 094103

Google Scholar

Google Scholar

[35] Liu X, Zheng X J 2005 Acta Mech. Sin. 21 278

Google Scholar

Google Scholar

[36] 李鸣鹤 2023 硕士学位论文 (长春: 吉林大学)

Li M H 2023 M. S. Thesis (Changchun: Jilin University

[37] 谢冰鸿, 徐国凯, 肖绍球, 喻忠军, 朱大立 2023 72 117501

Google Scholar

Google Scholar

Xie B H, Xu G K, Xiao S Q, Yu Z J, Zhu D L 2023 Acta Phys. Sin. 72 117501

Google Scholar

Google Scholar

[38] 罗志高 2019 大学物理实验 32 9

Google Scholar

Google Scholar

Luo Z G 2019 Phys. Exp. Coll. 32 9

Google Scholar

Google Scholar

[39] Li L, Chen X M 2008 Appl. Phys. Lett. 92 072903

Google Scholar

Google Scholar

[40] Zhang J T, Li P, Wen Y M, He W, Yang A C, Lu C J 2014 Sens. Actuators A 214 149

Google Scholar

Google Scholar

[41] Annapureddy V, Park S H, Song H, Ryu J 2023 J. Alloy. Compd. 957 170121

Google Scholar

Google Scholar

计量

- 文章访问数: 4029

- PDF下载量: 121

- 被引次数: 0

下载:

下载: