-

液体中平动和转动的耦合性是凝聚态物理长期关注的问题之一, 本文采用介电谱方法同时获得了系列小分子液体中α弛豫的弛豫时间和探针离子的电导率. 样品包括具有不同分子形状和官能团的碳原子数跨度在3—14范围内的15种一元和二元小分子液体. 分析结果表明平动和转动的耦合性与液体分子的官能团并没有直接的对应关系, 对分子形状、大小和离子大小也不是十分敏感, 但是液体的微观结构是影响平动和转动耦合性的重要因素. 也就是, 无论在一元还是二元体系中, 液体的微观结构没有改变时电导率的倒数和弛豫时间与温度的依赖关系具有一致性, 这也为弛豫时间的测量提供了一种方法. 研究结果还表明, 液体中自身携带的杂质离子与定量掺入离子的电导率的温度依赖关系相同, 为电解质溶解度低的有机小分子液体中离子电导率行为的研究提供了思路. 本文中单羟基醇的实验结果也与单羟基醇中α弛豫而非Debye弛豫对应于体系结构弛豫的观点相一致.The coupling between translational motion and rotational motion in liquids is one of the long-standing concerns in condensed matter physics. The relaxation times of α relaxation and probe ion conductivities in a series of small molecular liquids, 15 types of single and binary small molecular liquids with different molecular shapes and functional groups when the number of carbon atoms is in a range from 3 to 14, are simultaneously obtained by dielectric spectroscopy method in this work. The results indicate that the coupling between translation and rotation is not directly related to the functional group of liquid molecules, nor very sensitive to the shape nor the size of molecules or ion size. However, the microstructure of liquid is a key factor affecting the coupling between translation and rotation. In other words, when the microstructure of the liquid is unchanged, the dependence of relaxation time on temperature is consistent with the dependence of conductivity reciprocal on temperature, whether in single small molecular liquids or in binary small molecular liquids, which provides a method for measuring relaxation time. The research results also show that the temperature dependence of the conductivity of the impurity ions carried by the liquid itself is consistent with the one of quantitatively doped ions, providing the ideas for investigating the ion conductivity behavior in organic small molecular liquids with low electrolyte solubilities. The experimental results of monohydroxy alcohol are consistent with the viewpoint that α relaxation rather than Debye relaxation corresponds to the system structure relaxation.

-

Keywords:

- coupling between translation and rotation /

- relaxation time /

- probe ion conductivity /

- small molecular liquid

[1] Shirai K, Watanabe K, Momida H 2022 J. Phys. : Condens. Matter 34 375902

Google Scholar

Google Scholar

[2] Ouyang L F, Shen J, Huang Y, Sun Y H, Bai H Y, Wang W H 2023 J. Appl. Phys. 133 85105

Google Scholar

Google Scholar

[3] Böhmer R, Gainaru C, Richert R 2014 Phys. Rep. 545 125

Google Scholar

Google Scholar

[4] Shen J, Zhang H P, Chen Z Q, Ouyang L F, Wang F R, Lu Z, Li M Z, Sun Y H, Bai H Y, Wang W H 2023 Acta Mater. 244 118554

Google Scholar

Google Scholar

[5] Singh A, Singh Y 2023 Phys. Rev. E 107 14119

Google Scholar

Google Scholar

[6] Volbers J C, Lauterböck L, Hofmann N, Glasmacher B 2016 Curr. Dir. Biomed. Eng. 2 315

Google Scholar

Google Scholar

[7] Zhu X C, Miller-Ezzy P, Gluis M, Zhao Y Y, Qin J G, Tang Y H, Liu Y B, Li X X 2023 Aquaculture 574 739650

Google Scholar

Google Scholar

[8] Novikov V N 2016 Chem. Phys. Lett. 659 133

Google Scholar

Google Scholar

[9] Dyre J C 2006 Rev. Mod. Phys. 78 953

Google Scholar

Google Scholar

[10] Kremer F 2002 J. Non-Cryst. Solids 305 1

Google Scholar

Google Scholar

[11] Iacob C, Sangoro J R, Serghei A, Naumov S, Korth Y, Kärger J, Friedrich C, Kremer F 2008 J. Chem. Phys. 129 234511

Google Scholar

Google Scholar

[12] Wang J, Cai Z Q, Kang H, Huo B K, Zhang Y H, Gao Y Q, Li Z J, Feng S D, Wang L M 2024 Mater. Design 238 112665

Google Scholar

Google Scholar

[13] Duan Y J, Nabahat M, Tong Y, Ortiz-Membrado L, Jiménez-Piqué E, Zhao K, Wang Y J, Yang Y, Wada T, Kato H, Pelletier J M, Qiao J C, Pineda E 2024 Phys. Rev. Lett. 132 56101

Google Scholar

Google Scholar

[14] Chen Y X, Feng S D, Lu X Q, Pan S P, Xia C Q, Wang L M 2023 J. Chem. Phys. 158 134511

Google Scholar

Google Scholar

[15] Duan Y J, Zhang L T, Qiao J C, Wang Y J, Yang Y, Wada T, Kato H, Pelletier J M, Pineda E, Crespo D 2022 Phys. Rev. Lett. 129 175501

Google Scholar

Google Scholar

[16] Zhao X Y, Wang L N, Yin H M, Zhou H W, Huang Y N 2019 Chin. Phys. B 28 86601

Google Scholar

Google Scholar

[17] Nernst W 1888 Z. Phys. Chem. 2 613

Google Scholar

Google Scholar

[18] Einstein A 1905 Ann. Phys. (Berlin) 17 549

Google Scholar

Google Scholar

[19] Claisse F, Koenig H P 1956 Acta Metallurgica 4 650

Google Scholar

Google Scholar

[20] Masuhr A, Waniuk T A, Busch R, Johnson W L 1999 Phys. Rev. Lett. 82 2290

Google Scholar

Google Scholar

[21] Wang L M and Sun M D 2010 J. Yanshan Univ. 34 471 [王利民, 孙明道 2010 燕山大学学报 34 471]

Google Scholar

Google Scholar

Wang L M and Sun M D 2010 J. Yanshan Univ. 34 471

Google Scholar

Google Scholar

[22] Tarjus G, Kivelson D 1995 J. Chem. Phys. 103 3071

Google Scholar

Google Scholar

[23] Khrapak S A 2022 J. Mol. Liq. 354 118840

Google Scholar

Google Scholar

[24] Griffin P J, Sangoro J R, Wang Y, Holt A P, Novikov V N, Sokolov A P, Wojnarowska Z, Paluch M, Kremer F 2013 Soft Matter 9 10373

Google Scholar

Google Scholar

[25] Swiergiel J, Bouteiller L, Jadzyn J 2014 Soft Matter 10 8457

Google Scholar

Google Scholar

[26] Kawasaki T, Kim K 2019 Sci. Rep. 9 8118

Google Scholar

Google Scholar

[27] Power G, Vij J K, Johari G P 2007 J. Phys. Chem. B 111 11201

Google Scholar

Google Scholar

[28] Xiao H, Zhang L, Yi J, Li S, Zhao B G, Zhai Q J, Gao Y L 2022 Intermetallics 143 107494

Google Scholar

Google Scholar

[29] Charbonneau P, Jin Y, Parisi G, Zamponi F 2014 Proc. National Academy Sci. 111 15025

Google Scholar

Google Scholar

[30] Starzonek S, Rzoska S J, Drozd-Rzoska A, Pawlus S, Biała E, Martinez-Garcia J C, Kistersky L 2015 Soft Matter 11 5554

Google Scholar

Google Scholar

[31] Zhao X Y, Wang L N, He Y F, Zhou H, Huang Y N 2020 Chem. Phys. 528 110473

Google Scholar

Google Scholar

[32] Ishai P B, Talary M S, Caduff A, Levy E, Feldman Y 2013 Meas. Sci. Technol. 24 102001

Google Scholar

Google Scholar

[33] Lunkenheimer P, Schneider U, Brand R, Loidl A 2000 Contemp. Phys. 41 15

Google Scholar

Google Scholar

[34] Huth H, Wang L M, Schick C, Richert R 2007 J. Chem. Phys. 126 104503

Google Scholar

Google Scholar

[35] Jakobsen B, Maggi C, Christensen T, Dyre J C 2008 J. Chem. Phys. 129 184502

Google Scholar

Google Scholar

[36] Gainaru C, Meier R, Schildmann S, Lederle C, Hiller W, Rössler E A, Böhmer R 2010 Phys. Rev. Lett. 105 258303

Google Scholar

Google Scholar

[37] Gainaru C, Kastner S, Mayr F, Lunkenheimer P, Schildmann S, Weber H J, Hiller W, Loidl A, Böhmer R 2011 Phys. Rev. Lett. 107 118304

Google Scholar

Google Scholar

[38] Bauer S, Burlafinger K, Gainaru C, Lunkenheimer P, Hiller W, Loidl A, Böhmer R 2013 J. Chem. Phys. 138 94505

Google Scholar

Google Scholar

[39] Lu G, Wang L N, Zhao X Y, He Y, Huang Y N 2021 Int. J. Mod. Phys. B 35 2150014

Google Scholar

Google Scholar

[40] Wang L N, Zhao X Y, Huang Y N 2019 Chin. Phys. Lett. 36 97701

Google Scholar

Google Scholar

[41] Ediger M D, Angell C A, Nagel S R 1996 J. Phys. Chem. 100 13200

Google Scholar

Google Scholar

[42] Zhang H, Zhong C, Douglas J F, Wang X D, Cao Q P, Zhang D X, Jiang J Z 2015 J. Chem. Phys. 142 164506

Google Scholar

Google Scholar

[43] Moynihan C T, Macedo P B, Montrose C J, Gupta P K 1976 Ann. Ny. Acad. Sci. 279 15

Google Scholar

Google Scholar

-

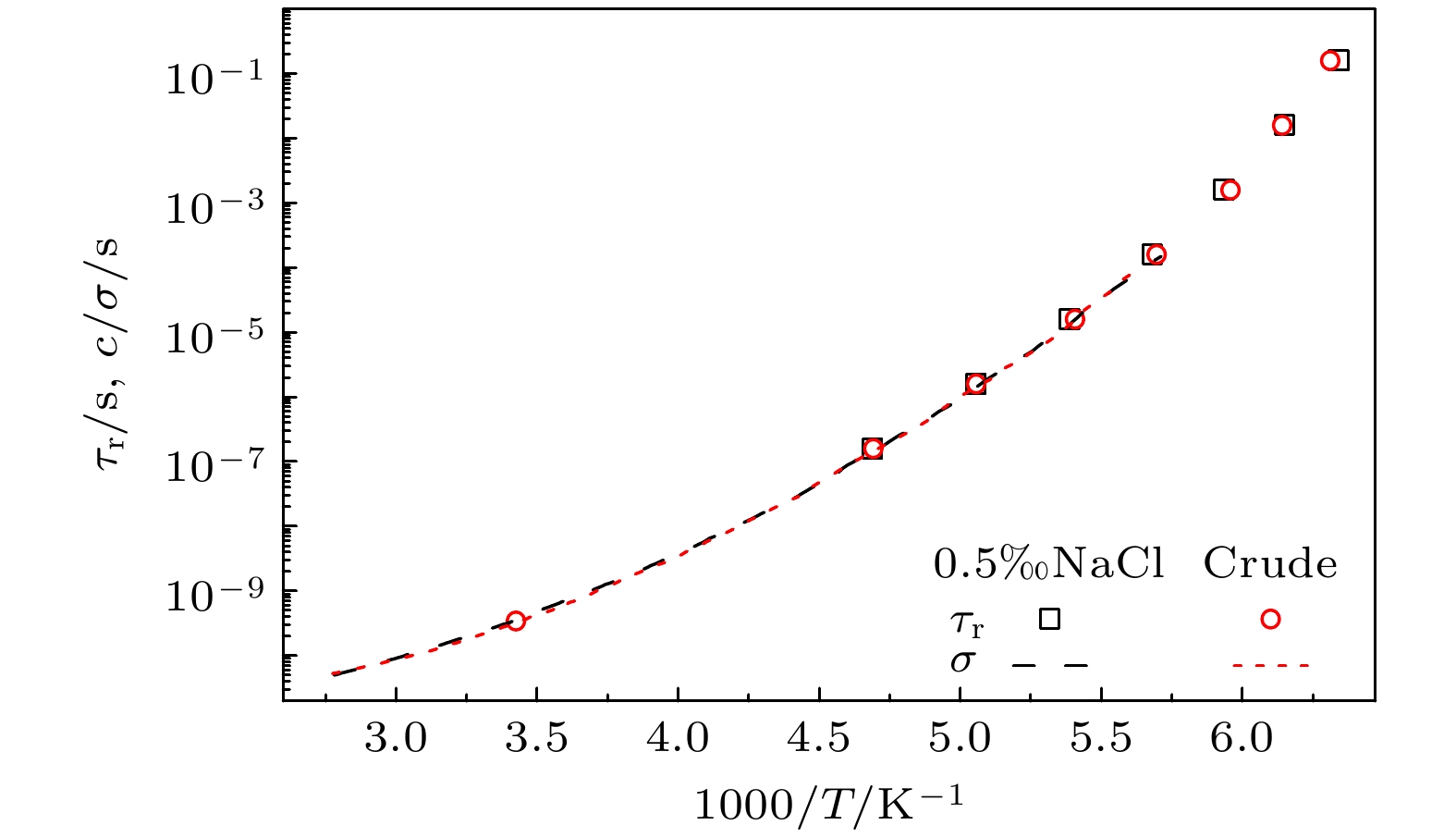

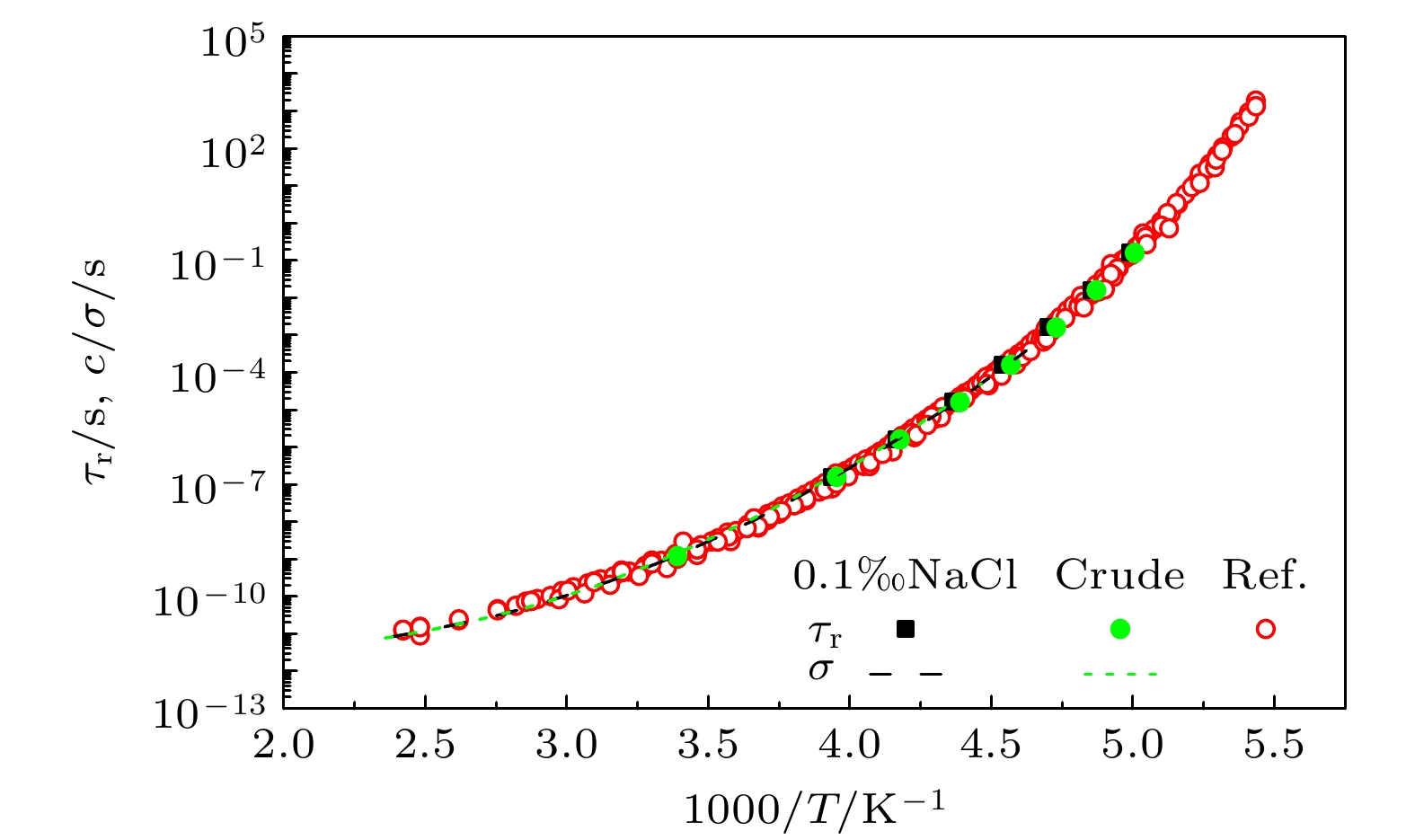

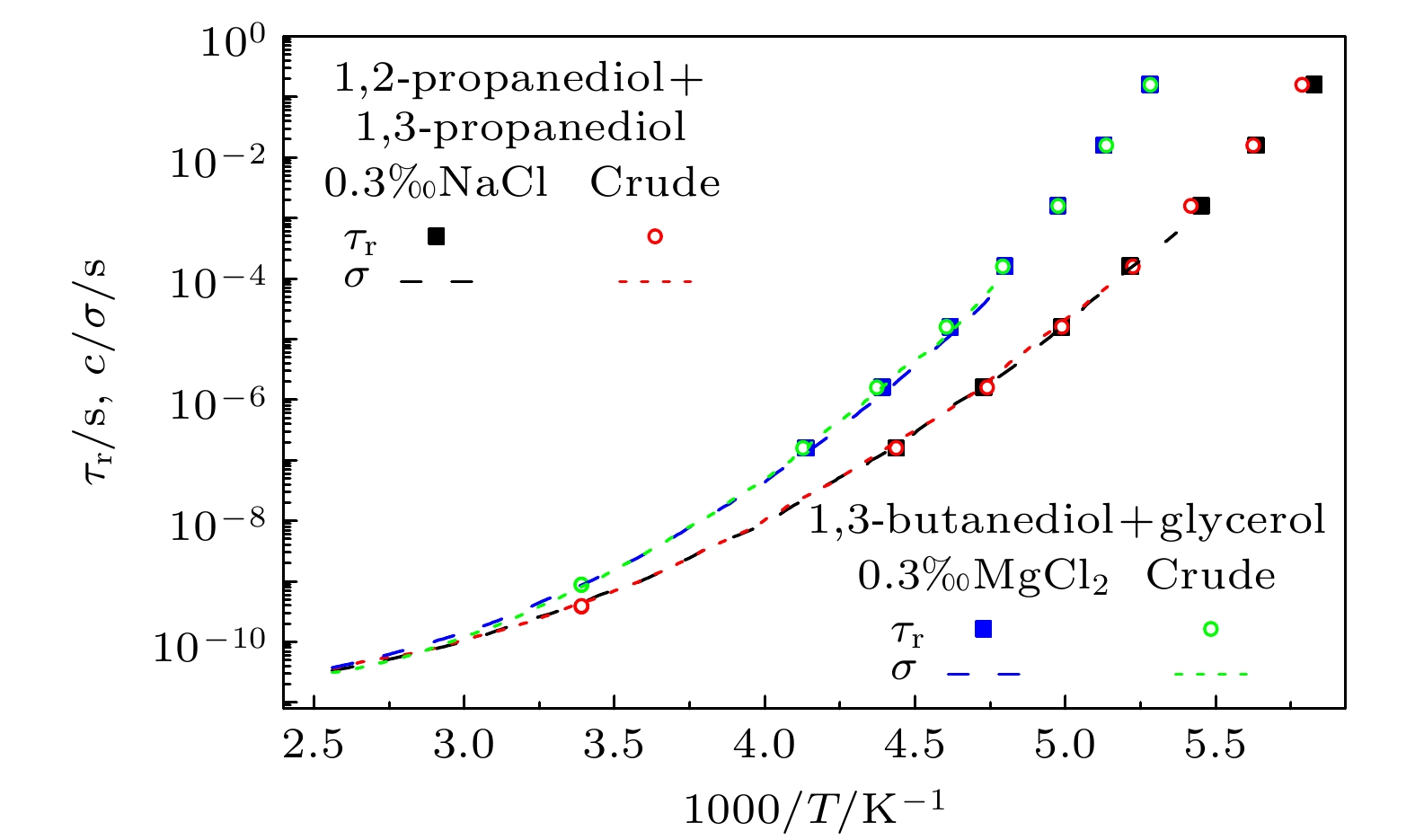

图 8 掺入0.3‰氯化钠的70%1,2-丙二醇和30%1, 3-丙二醇混合液体与掺入0.3‰氯化镁的70%1,3-丁二醇和30%丙三醇混合液体及其原始样品的$ {\tau }_{{\mathrm{r}}} $和$ \sigma $

Fig. 8. $ {\tau }_{{\mathrm{r}}} $ and $ \sigma $ of mixed liquid of 70% 1,2-propanediol and 30% 1,3-propanediol doped with 0.3‰ NaCl and mixed liquid of 70% 1,3-butanediol and 30% glycerol doped with 0.3‰ MgCl2 as well as their crude samples.

-

[1] Shirai K, Watanabe K, Momida H 2022 J. Phys. : Condens. Matter 34 375902

Google Scholar

Google Scholar

[2] Ouyang L F, Shen J, Huang Y, Sun Y H, Bai H Y, Wang W H 2023 J. Appl. Phys. 133 85105

Google Scholar

Google Scholar

[3] Böhmer R, Gainaru C, Richert R 2014 Phys. Rep. 545 125

Google Scholar

Google Scholar

[4] Shen J, Zhang H P, Chen Z Q, Ouyang L F, Wang F R, Lu Z, Li M Z, Sun Y H, Bai H Y, Wang W H 2023 Acta Mater. 244 118554

Google Scholar

Google Scholar

[5] Singh A, Singh Y 2023 Phys. Rev. E 107 14119

Google Scholar

Google Scholar

[6] Volbers J C, Lauterböck L, Hofmann N, Glasmacher B 2016 Curr. Dir. Biomed. Eng. 2 315

Google Scholar

Google Scholar

[7] Zhu X C, Miller-Ezzy P, Gluis M, Zhao Y Y, Qin J G, Tang Y H, Liu Y B, Li X X 2023 Aquaculture 574 739650

Google Scholar

Google Scholar

[8] Novikov V N 2016 Chem. Phys. Lett. 659 133

Google Scholar

Google Scholar

[9] Dyre J C 2006 Rev. Mod. Phys. 78 953

Google Scholar

Google Scholar

[10] Kremer F 2002 J. Non-Cryst. Solids 305 1

Google Scholar

Google Scholar

[11] Iacob C, Sangoro J R, Serghei A, Naumov S, Korth Y, Kärger J, Friedrich C, Kremer F 2008 J. Chem. Phys. 129 234511

Google Scholar

Google Scholar

[12] Wang J, Cai Z Q, Kang H, Huo B K, Zhang Y H, Gao Y Q, Li Z J, Feng S D, Wang L M 2024 Mater. Design 238 112665

Google Scholar

Google Scholar

[13] Duan Y J, Nabahat M, Tong Y, Ortiz-Membrado L, Jiménez-Piqué E, Zhao K, Wang Y J, Yang Y, Wada T, Kato H, Pelletier J M, Qiao J C, Pineda E 2024 Phys. Rev. Lett. 132 56101

Google Scholar

Google Scholar

[14] Chen Y X, Feng S D, Lu X Q, Pan S P, Xia C Q, Wang L M 2023 J. Chem. Phys. 158 134511

Google Scholar

Google Scholar

[15] Duan Y J, Zhang L T, Qiao J C, Wang Y J, Yang Y, Wada T, Kato H, Pelletier J M, Pineda E, Crespo D 2022 Phys. Rev. Lett. 129 175501

Google Scholar

Google Scholar

[16] Zhao X Y, Wang L N, Yin H M, Zhou H W, Huang Y N 2019 Chin. Phys. B 28 86601

Google Scholar

Google Scholar

[17] Nernst W 1888 Z. Phys. Chem. 2 613

Google Scholar

Google Scholar

[18] Einstein A 1905 Ann. Phys. (Berlin) 17 549

Google Scholar

Google Scholar

[19] Claisse F, Koenig H P 1956 Acta Metallurgica 4 650

Google Scholar

Google Scholar

[20] Masuhr A, Waniuk T A, Busch R, Johnson W L 1999 Phys. Rev. Lett. 82 2290

Google Scholar

Google Scholar

[21] Wang L M and Sun M D 2010 J. Yanshan Univ. 34 471 [王利民, 孙明道 2010 燕山大学学报 34 471]

Google Scholar

Google Scholar

Wang L M and Sun M D 2010 J. Yanshan Univ. 34 471

Google Scholar

Google Scholar

[22] Tarjus G, Kivelson D 1995 J. Chem. Phys. 103 3071

Google Scholar

Google Scholar

[23] Khrapak S A 2022 J. Mol. Liq. 354 118840

Google Scholar

Google Scholar

[24] Griffin P J, Sangoro J R, Wang Y, Holt A P, Novikov V N, Sokolov A P, Wojnarowska Z, Paluch M, Kremer F 2013 Soft Matter 9 10373

Google Scholar

Google Scholar

[25] Swiergiel J, Bouteiller L, Jadzyn J 2014 Soft Matter 10 8457

Google Scholar

Google Scholar

[26] Kawasaki T, Kim K 2019 Sci. Rep. 9 8118

Google Scholar

Google Scholar

[27] Power G, Vij J K, Johari G P 2007 J. Phys. Chem. B 111 11201

Google Scholar

Google Scholar

[28] Xiao H, Zhang L, Yi J, Li S, Zhao B G, Zhai Q J, Gao Y L 2022 Intermetallics 143 107494

Google Scholar

Google Scholar

[29] Charbonneau P, Jin Y, Parisi G, Zamponi F 2014 Proc. National Academy Sci. 111 15025

Google Scholar

Google Scholar

[30] Starzonek S, Rzoska S J, Drozd-Rzoska A, Pawlus S, Biała E, Martinez-Garcia J C, Kistersky L 2015 Soft Matter 11 5554

Google Scholar

Google Scholar

[31] Zhao X Y, Wang L N, He Y F, Zhou H, Huang Y N 2020 Chem. Phys. 528 110473

Google Scholar

Google Scholar

[32] Ishai P B, Talary M S, Caduff A, Levy E, Feldman Y 2013 Meas. Sci. Technol. 24 102001

Google Scholar

Google Scholar

[33] Lunkenheimer P, Schneider U, Brand R, Loidl A 2000 Contemp. Phys. 41 15

Google Scholar

Google Scholar

[34] Huth H, Wang L M, Schick C, Richert R 2007 J. Chem. Phys. 126 104503

Google Scholar

Google Scholar

[35] Jakobsen B, Maggi C, Christensen T, Dyre J C 2008 J. Chem. Phys. 129 184502

Google Scholar

Google Scholar

[36] Gainaru C, Meier R, Schildmann S, Lederle C, Hiller W, Rössler E A, Böhmer R 2010 Phys. Rev. Lett. 105 258303

Google Scholar

Google Scholar

[37] Gainaru C, Kastner S, Mayr F, Lunkenheimer P, Schildmann S, Weber H J, Hiller W, Loidl A, Böhmer R 2011 Phys. Rev. Lett. 107 118304

Google Scholar

Google Scholar

[38] Bauer S, Burlafinger K, Gainaru C, Lunkenheimer P, Hiller W, Loidl A, Böhmer R 2013 J. Chem. Phys. 138 94505

Google Scholar

Google Scholar

[39] Lu G, Wang L N, Zhao X Y, He Y, Huang Y N 2021 Int. J. Mod. Phys. B 35 2150014

Google Scholar

Google Scholar

[40] Wang L N, Zhao X Y, Huang Y N 2019 Chin. Phys. Lett. 36 97701

Google Scholar

Google Scholar

[41] Ediger M D, Angell C A, Nagel S R 1996 J. Phys. Chem. 100 13200

Google Scholar

Google Scholar

[42] Zhang H, Zhong C, Douglas J F, Wang X D, Cao Q P, Zhang D X, Jiang J Z 2015 J. Chem. Phys. 142 164506

Google Scholar

Google Scholar

[43] Moynihan C T, Macedo P B, Montrose C J, Gupta P K 1976 Ann. Ny. Acad. Sci. 279 15

Google Scholar

Google Scholar

计量

- 文章访问数: 4134

- PDF下载量: 65

- 被引次数: 0

下载:

下载: