-

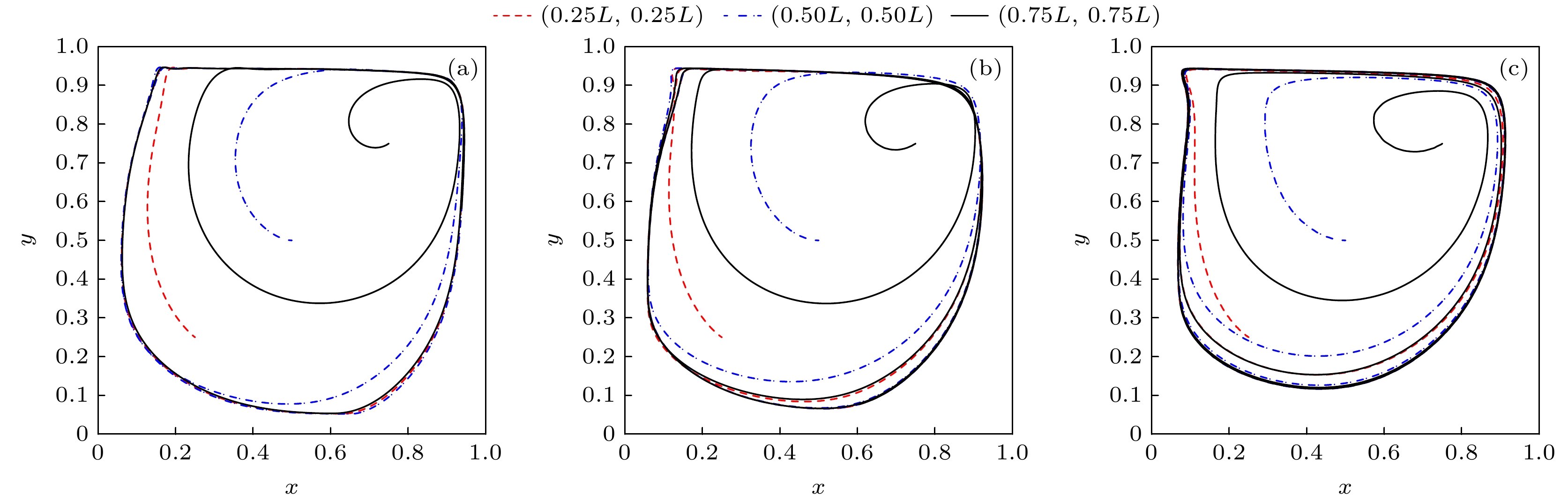

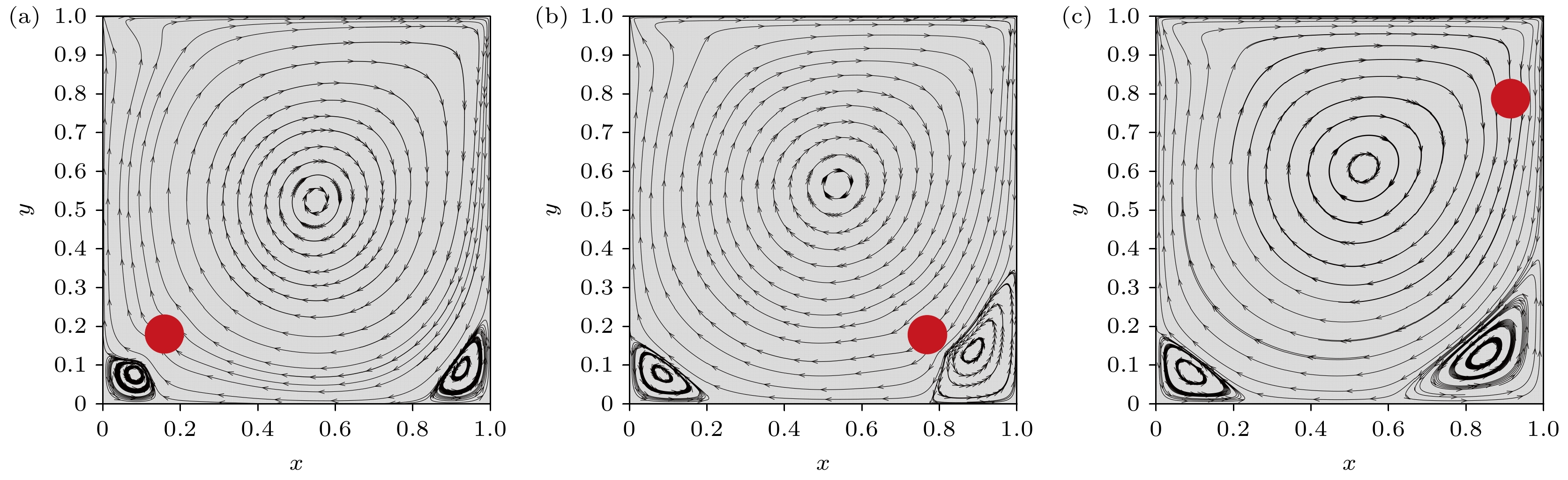

采用扩散界面格子Boltzmann模型研究了圆形颗粒在幂律流体方腔流中的运动, 重点分析了初始位置、幂律指数、颗粒大小对圆形颗粒在幂律流体顶盖驱动流中的运动的影响. 数值结果表明不同初始位置的圆形颗粒最终均能稳定在极限环上运动. 不同幂律指数的幂律流体对圆形颗粒运动的极限环有明显影响, 对于剪切增稠流体, 颗粒的运动速度明显增大, 极限环半径明显缩小; 对于剪切稀化流体, 左下角和右下角的次级涡收缩, 极限环向方腔的右下角移动. 圆形颗粒较小时, 颗粒的运动速度较快, 运动半径较大, 运动轨迹更接近流体的流线; 圆形颗粒较大时, 受到边界的限制, 极限环半径较小, 运动速度较慢. 此外, 还讨论了颗粒对顶盖驱动流主涡涡心位置的影响, 颗粒会将主涡涡心推向远离颗粒的方向.

-

关键词:

- 格子Boltzmann方法 /

- 圆形颗粒 /

- 幂律流体 /

- 顶盖驱动流

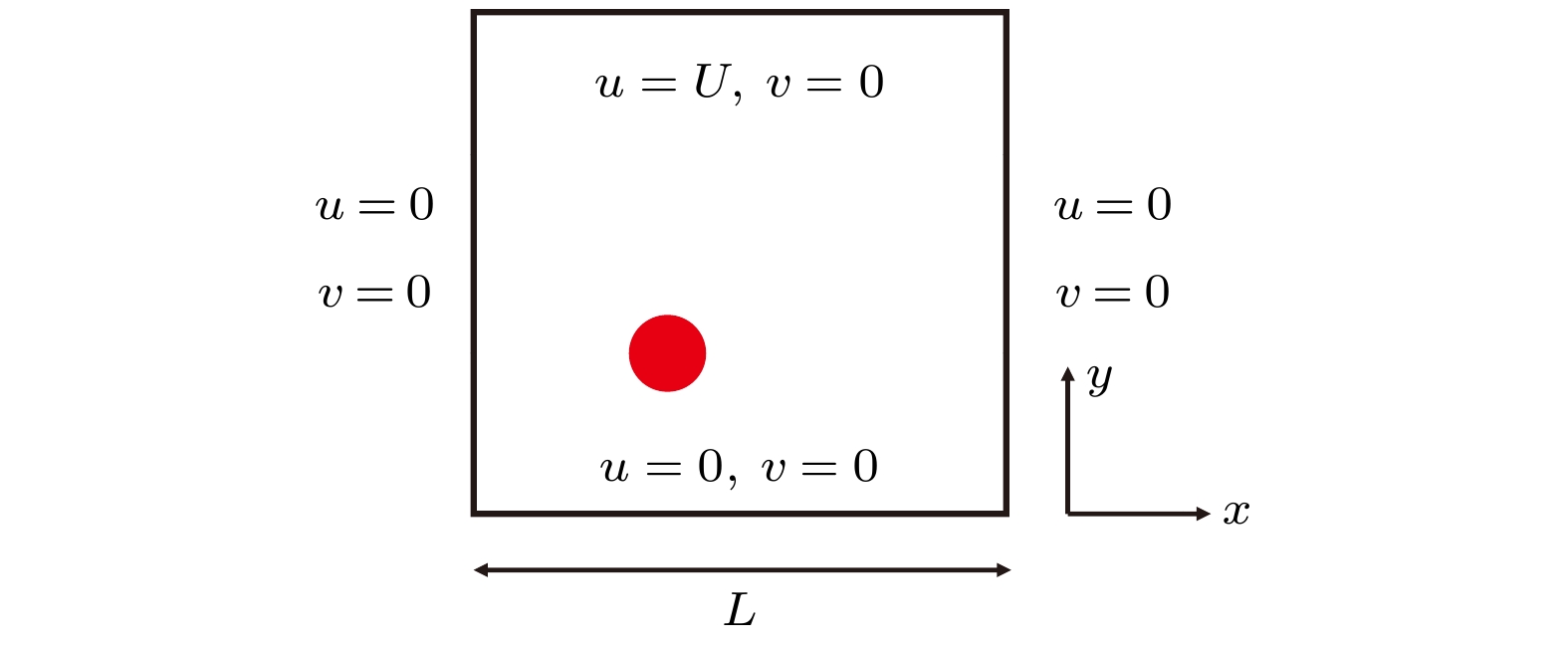

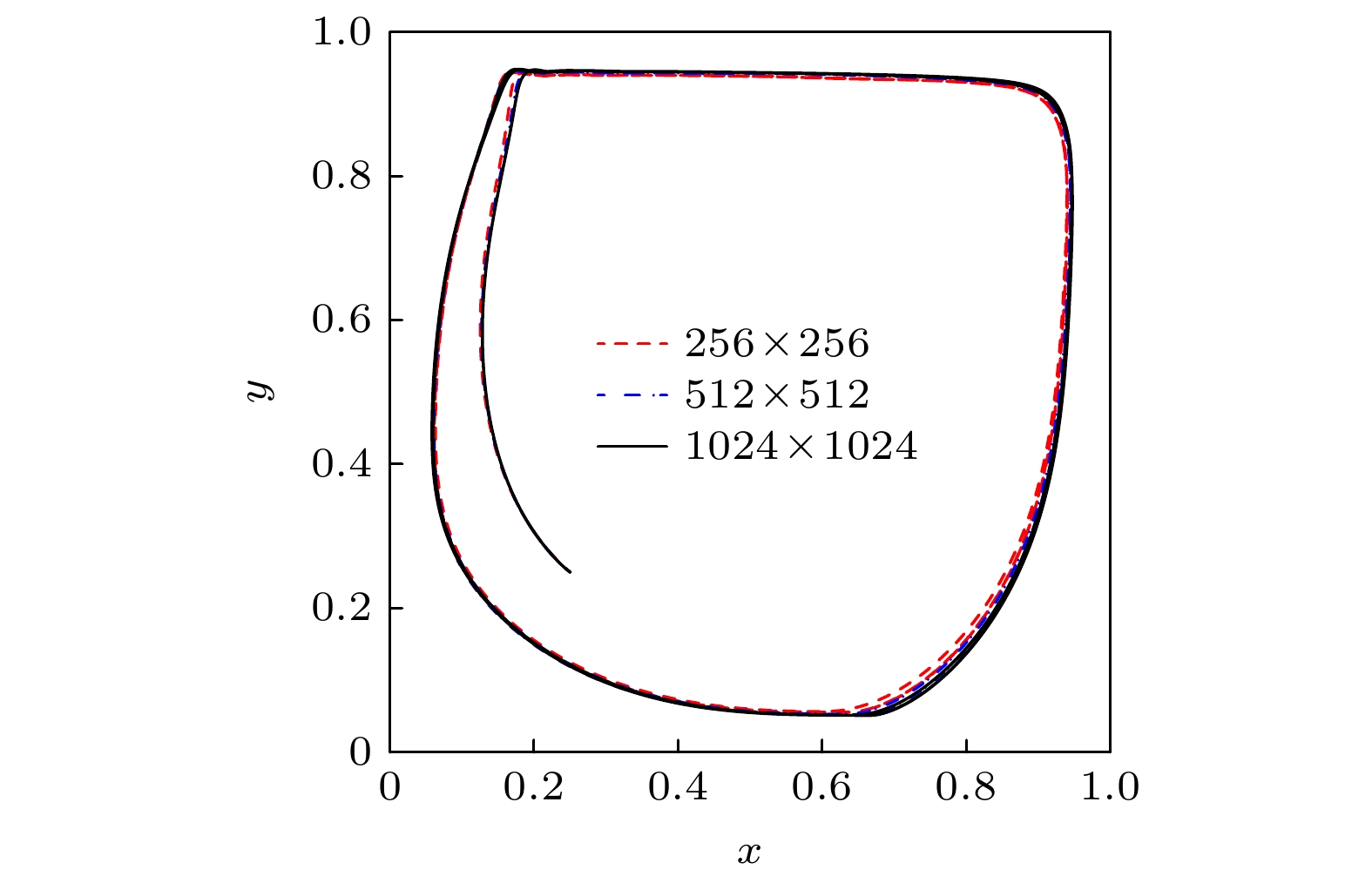

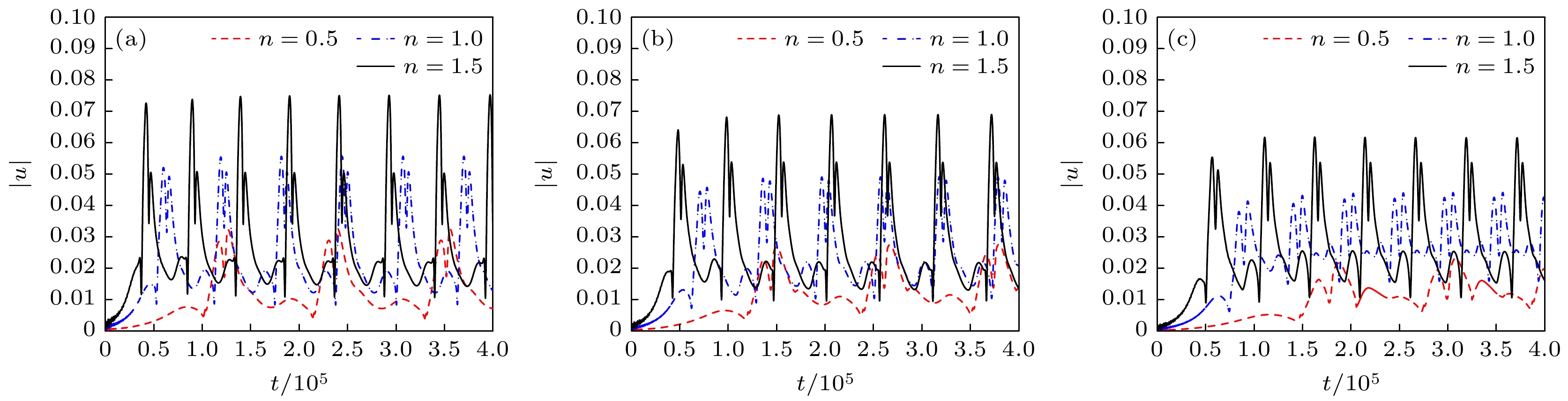

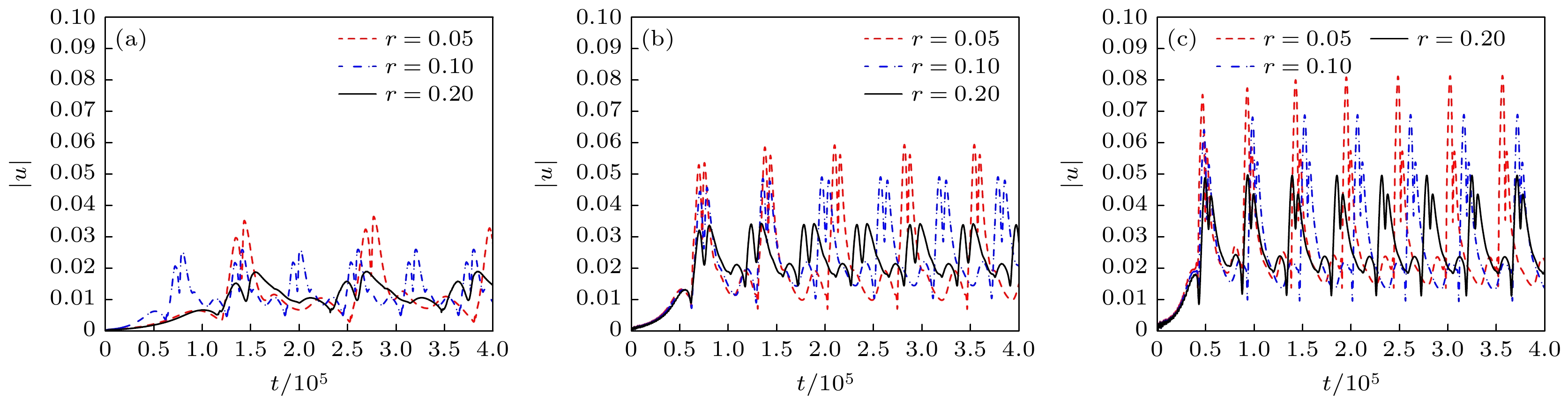

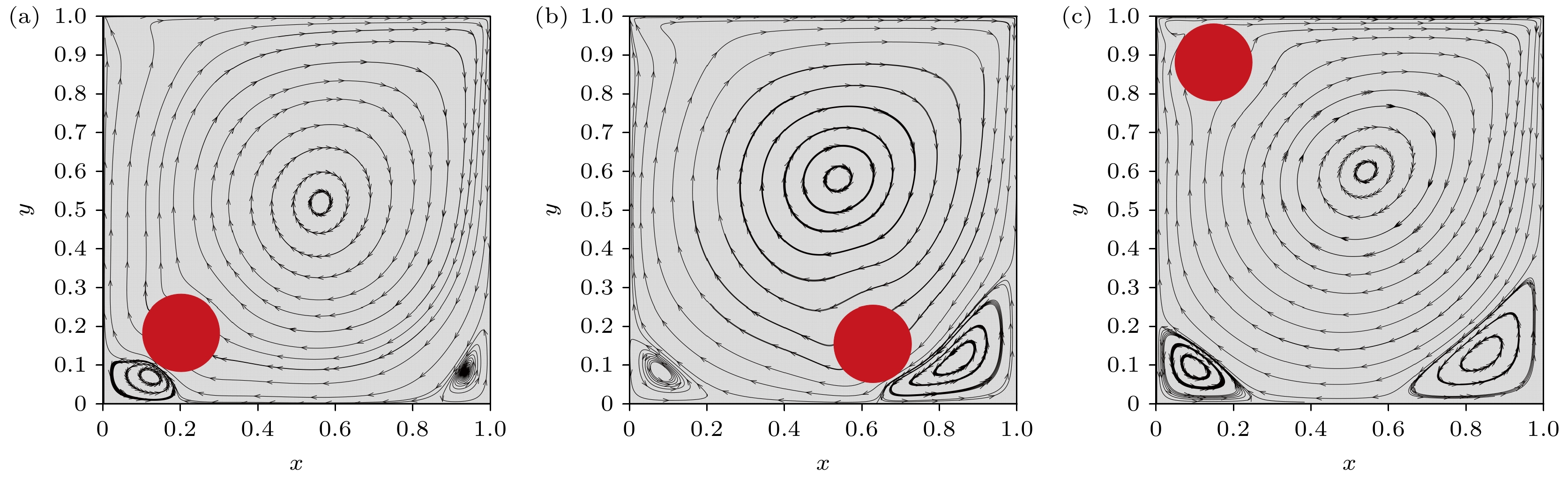

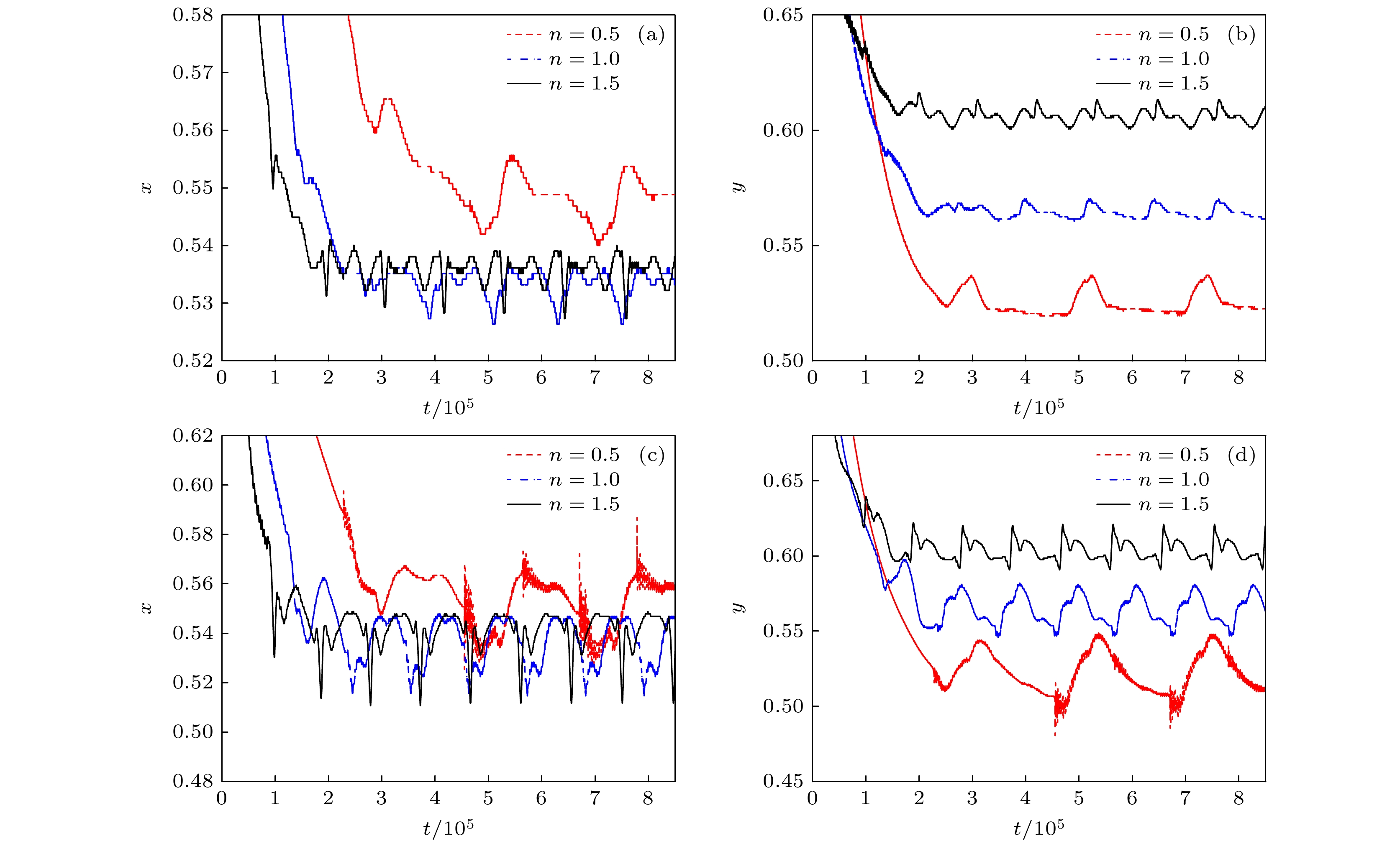

In this paper, the motion of a circular particle in a lid-driven square cavity with the power-law fluid is studied by using the diffuse interface lattice Boltzmann method, and the study mainly considers the effects of the particle's initial position, the power-law index, the Reynolds number, and the particle size. The numerical results show that the circular particle is first in a centrifugal motion under the effect of inertia, and it finally moves steadily on the limit cycle. Furthermore, it is also found that the initial position of the particle has no influence on the limit cycle. For a shear-thinning fluid flow, the limit cycle moves towards the bottom right corner of the square cavity. Moreover, the particle velocity is small, and the period of the particle motion is long. On the other hand, in the case of shear-thickening fluid flow, the limit cycle moves towards the top left corner of the cavity. In addition, the particle velocity is large, and the period of the particle motion is short.With the increase of Reynolds number, the limit cycle moves towards the bottom right corner of the square cavity, which is caused by a strong fluid flow field. Meanwhile, the particle velocity becomes larger, and the period of the particle motion is shorter. With the increase of particle size, the effect of confinement of the cavity boundary becomes significant, and the circular particle is pushed towards the center of the cavity. In this case, the limit cycle shrinks towards the center of the cavity. The circular particle squeezes the secondary vortices, especially when the circular particle is located in the bottom left, bottom right and top left corners. Additionally, the appearance of the circular particle has a significant influence on the position of the primary vortex, which changes periodically near the position of the primary vortex without the particle. It is also observed that the influence of the circular particle becomes more significant as its size increases and the power-law index decreases.-

Keywords:

- lattice Boltzmann method /

- circular particle /

- power-law /

- lid-driven cavity

[1] Chhabra R P 2006 Bubbles, Drops, and Particles in Non-Newtonian Fluids (Boca Raton: CRC Press) pp40-74

[2] 朱克勤 2006 力学与实践 28 1

Google Scholar

Google Scholar

Zhu K Q 2006 Mech. Eng. 28 1

Google Scholar

Google Scholar

[3] Saramito P, Roquet N 2001 Comput. Methods Appl. Mech. Eng. 190 5391

Google Scholar

Google Scholar

[4] Neofytou P 2005 Adv. Eng. Software 36 664

Google Scholar

Google Scholar

[5] Rafiee A 2008 Anziam J. 49 411

Google Scholar

Google Scholar

[6] Bell B C, Surana K S 1994 Int. J. Numer. Methods Fluids 18 127

Google Scholar

Google Scholar

[7] Papanastasiou T C, Boudouvis A G 1997 Comput. Geotech. 64 677

[8] Papanastasiou T C 1987 J. Rheol. 31 385

Google Scholar

Google Scholar

[9] Roquet N, Saramito P 2008 J. Non-Newtonian Fluid Mech. 155 101

Google Scholar

Google Scholar

[10] Tazangi H R, Goharrizi A S, Javaran E J 2021 Korea-Aust. Rheol. J. 33 293

Google Scholar

Google Scholar

[11] Schreiber R, Keller H B 1983 J. Comput. Phys. 49 310

Google Scholar

Google Scholar

[12] Botella O, Peyret R 1998 Comput. Fluids 27 421

Google Scholar

Google Scholar

[13] Erturk E, Corke T C 2005 Int. J. Numer. Methods Fluids 48 747

Google Scholar

Google Scholar

[14] Mendu S S, Das P K 2012 J. Non-Newtonian Fluid Mech. 175–176 10

[15] Li Q X, Hong N, Shi B C, Chai Z H 2014 Commun. Comput. Phys. 15 265

Google Scholar

Google Scholar

[16] Aguirre A, Castillo E, Cruchaga M, Codina R, Baiges J 2018 J. Non-Newton. Fluid Mech. 257 22

Google Scholar

Google Scholar

[17] Alleborn N, Raszillier H, Durst F 1999 Int. J. Heat Mass Trans. 42 833

Google Scholar

Google Scholar

[18] Stephen T, Nathan E 2007 Geology 35 1027

[19] Zhong H C, Zhou J, Du Z X, Xie L 2018 J. Aerosol Sci. 121 31

Google Scholar

Google Scholar

[20] Madankan R, Pouget S, Singla P, Bursik M, Dehn J, Jones M, Patra A, Pavolonis M, Pitman E B, Singh T, Webley P 2014 J. Comput. Phys. 271 39

Google Scholar

Google Scholar

[21] Yue G X, Cai R X, Lu J F, Zhang H 2017 Powder Technol. 316 18

Google Scholar

Google Scholar

[22] He W C, Lv X W, Pan F F, Li X Q, Yan Z M 2019 Powder Technol. 356 1087

Google Scholar

Google Scholar

[23] Sidik N A C, Attarzadeh S M R 2011 Int. J. Mech. 5 123

[24] Romanò F, Kuhlmann H C 2017 Theor. Comput. Fluid Dyn. 31 427

Google Scholar

Google Scholar

[25] Hu J J, Sun D K, Mao S H, Wu H M, Yu S Y, Xu M S 2022 J. Comput. Theor. Transp. 51 222

Google Scholar

Google Scholar

[26] Hu J J 2021 Int. J. Mod. Phys. C 32 1

[27] Hu J J 2020 Phys. Fluids 32 222

[28] Safdari A, Kim K C 2014 Comput. Math. Appl. 68 606

Google Scholar

Google Scholar

[29] Francescò R, Hendrik H C 2017 Theor. Comput. Fluid Dyn. 31 1

[30] Chen S, Doolen G D 1998 Rev. Fluid Mech. 30 329

Google Scholar

Google Scholar

[31] Succi S 2001 The Lattice Boltzmann Equation for Fluid Dynamics and Beyond (Oxford: Oxford University Press) pp3-38

[32] Guo Z L, Shu C 2013 Lattice Boltzmann Method and Its Applications in Engineering (Singapore: World Scientific Publishing Co.) pp10-21

[33] Krüger T, Kusumaatmaja H, Silva G, Shardt O, Kuzmin A, Viggen E M 2017 The Lattice Boltzmann Method: Principles and Practice (Switzerland: Springer International Publishing) pp61-65

[34] Feng J, Hu H H, Joseph D D 1994 J. Fluid Mech. 277 271

Google Scholar

Google Scholar

[35] Inamuro T, Maeba K, Ogino F 2000 Int. J. Multiphase. Flow 26 1981

Google Scholar

Google Scholar

[36] Shao X, Yu Z, Sun B 2008 Phys. Fluids 20 103307

Google Scholar

Google Scholar

[37] Noble D R, Torczynski J R 1998 Int. J. Modern Phys. C 9 1189

Google Scholar

Google Scholar

[38] Liu J, Huang C S, Chai Z H, Shi B C 2022 Comput. Fluids 233 105240

Google Scholar

Google Scholar

[39] Liu J, Chai Z H, Shi B C 2022 Phys. Rev. E 106 015306

Google Scholar

Google Scholar

[40] Boyd J, Buick J, Green S 2006 J. Phys. A 39 14241

Google Scholar

Google Scholar

[41] Tang G H, Li X F, He Y L, Tao W Q 2009 J. Non-Newton. Fluid Mech. 157 133

Google Scholar

Google Scholar

[42] Chai Z H, Shi B C, Guo Z L, Rong F M 2011 J. Non-Newton. Fluid Mech. 166 332

Google Scholar

Google Scholar

[43] Guo Z L, Zheng C G, Shi B C 2002 Chin. Phys. 11 366

Google Scholar

Google Scholar

-

图 13 主涡涡心位置的水平、竖直坐标坐标随时间变化图 (a) $ x $轴坐标, $ r = 0.1 $; (b) $ y $轴坐标, $ r = 0.1 $; (c) $ x $轴坐标, $ r = 0.2 $; (d) $ y $轴坐标, $ r = 0.2 $

Fig. 13. The evolutions of the x-axis and y-axis coordinates of position of primary vortex: (a) x-axis, $ r = 0.1 $; (b) y-axis, $ r = 0.1 $; (c) x-axis, $ r = 0.2 $; (d) y-axis, $ r = 0.2 $.

-

[1] Chhabra R P 2006 Bubbles, Drops, and Particles in Non-Newtonian Fluids (Boca Raton: CRC Press) pp40-74

[2] 朱克勤 2006 力学与实践 28 1

Google Scholar

Google Scholar

Zhu K Q 2006 Mech. Eng. 28 1

Google Scholar

Google Scholar

[3] Saramito P, Roquet N 2001 Comput. Methods Appl. Mech. Eng. 190 5391

Google Scholar

Google Scholar

[4] Neofytou P 2005 Adv. Eng. Software 36 664

Google Scholar

Google Scholar

[5] Rafiee A 2008 Anziam J. 49 411

Google Scholar

Google Scholar

[6] Bell B C, Surana K S 1994 Int. J. Numer. Methods Fluids 18 127

Google Scholar

Google Scholar

[7] Papanastasiou T C, Boudouvis A G 1997 Comput. Geotech. 64 677

[8] Papanastasiou T C 1987 J. Rheol. 31 385

Google Scholar

Google Scholar

[9] Roquet N, Saramito P 2008 J. Non-Newtonian Fluid Mech. 155 101

Google Scholar

Google Scholar

[10] Tazangi H R, Goharrizi A S, Javaran E J 2021 Korea-Aust. Rheol. J. 33 293

Google Scholar

Google Scholar

[11] Schreiber R, Keller H B 1983 J. Comput. Phys. 49 310

Google Scholar

Google Scholar

[12] Botella O, Peyret R 1998 Comput. Fluids 27 421

Google Scholar

Google Scholar

[13] Erturk E, Corke T C 2005 Int. J. Numer. Methods Fluids 48 747

Google Scholar

Google Scholar

[14] Mendu S S, Das P K 2012 J. Non-Newtonian Fluid Mech. 175–176 10

[15] Li Q X, Hong N, Shi B C, Chai Z H 2014 Commun. Comput. Phys. 15 265

Google Scholar

Google Scholar

[16] Aguirre A, Castillo E, Cruchaga M, Codina R, Baiges J 2018 J. Non-Newton. Fluid Mech. 257 22

Google Scholar

Google Scholar

[17] Alleborn N, Raszillier H, Durst F 1999 Int. J. Heat Mass Trans. 42 833

Google Scholar

Google Scholar

[18] Stephen T, Nathan E 2007 Geology 35 1027

[19] Zhong H C, Zhou J, Du Z X, Xie L 2018 J. Aerosol Sci. 121 31

Google Scholar

Google Scholar

[20] Madankan R, Pouget S, Singla P, Bursik M, Dehn J, Jones M, Patra A, Pavolonis M, Pitman E B, Singh T, Webley P 2014 J. Comput. Phys. 271 39

Google Scholar

Google Scholar

[21] Yue G X, Cai R X, Lu J F, Zhang H 2017 Powder Technol. 316 18

Google Scholar

Google Scholar

[22] He W C, Lv X W, Pan F F, Li X Q, Yan Z M 2019 Powder Technol. 356 1087

Google Scholar

Google Scholar

[23] Sidik N A C, Attarzadeh S M R 2011 Int. J. Mech. 5 123

[24] Romanò F, Kuhlmann H C 2017 Theor. Comput. Fluid Dyn. 31 427

Google Scholar

Google Scholar

[25] Hu J J, Sun D K, Mao S H, Wu H M, Yu S Y, Xu M S 2022 J. Comput. Theor. Transp. 51 222

Google Scholar

Google Scholar

[26] Hu J J 2021 Int. J. Mod. Phys. C 32 1

[27] Hu J J 2020 Phys. Fluids 32 222

[28] Safdari A, Kim K C 2014 Comput. Math. Appl. 68 606

Google Scholar

Google Scholar

[29] Francescò R, Hendrik H C 2017 Theor. Comput. Fluid Dyn. 31 1

[30] Chen S, Doolen G D 1998 Rev. Fluid Mech. 30 329

Google Scholar

Google Scholar

[31] Succi S 2001 The Lattice Boltzmann Equation for Fluid Dynamics and Beyond (Oxford: Oxford University Press) pp3-38

[32] Guo Z L, Shu C 2013 Lattice Boltzmann Method and Its Applications in Engineering (Singapore: World Scientific Publishing Co.) pp10-21

[33] Krüger T, Kusumaatmaja H, Silva G, Shardt O, Kuzmin A, Viggen E M 2017 The Lattice Boltzmann Method: Principles and Practice (Switzerland: Springer International Publishing) pp61-65

[34] Feng J, Hu H H, Joseph D D 1994 J. Fluid Mech. 277 271

Google Scholar

Google Scholar

[35] Inamuro T, Maeba K, Ogino F 2000 Int. J. Multiphase. Flow 26 1981

Google Scholar

Google Scholar

[36] Shao X, Yu Z, Sun B 2008 Phys. Fluids 20 103307

Google Scholar

Google Scholar

[37] Noble D R, Torczynski J R 1998 Int. J. Modern Phys. C 9 1189

Google Scholar

Google Scholar

[38] Liu J, Huang C S, Chai Z H, Shi B C 2022 Comput. Fluids 233 105240

Google Scholar

Google Scholar

[39] Liu J, Chai Z H, Shi B C 2022 Phys. Rev. E 106 015306

Google Scholar

Google Scholar

[40] Boyd J, Buick J, Green S 2006 J. Phys. A 39 14241

Google Scholar

Google Scholar

[41] Tang G H, Li X F, He Y L, Tao W Q 2009 J. Non-Newton. Fluid Mech. 157 133

Google Scholar

Google Scholar

[42] Chai Z H, Shi B C, Guo Z L, Rong F M 2011 J. Non-Newton. Fluid Mech. 166 332

Google Scholar

Google Scholar

[43] Guo Z L, Zheng C G, Shi B C 2002 Chin. Phys. 11 366

Google Scholar

Google Scholar

计量

- 文章访问数: 624

- PDF下载量: 30

- 被引次数: 0

下载:

下载: