-

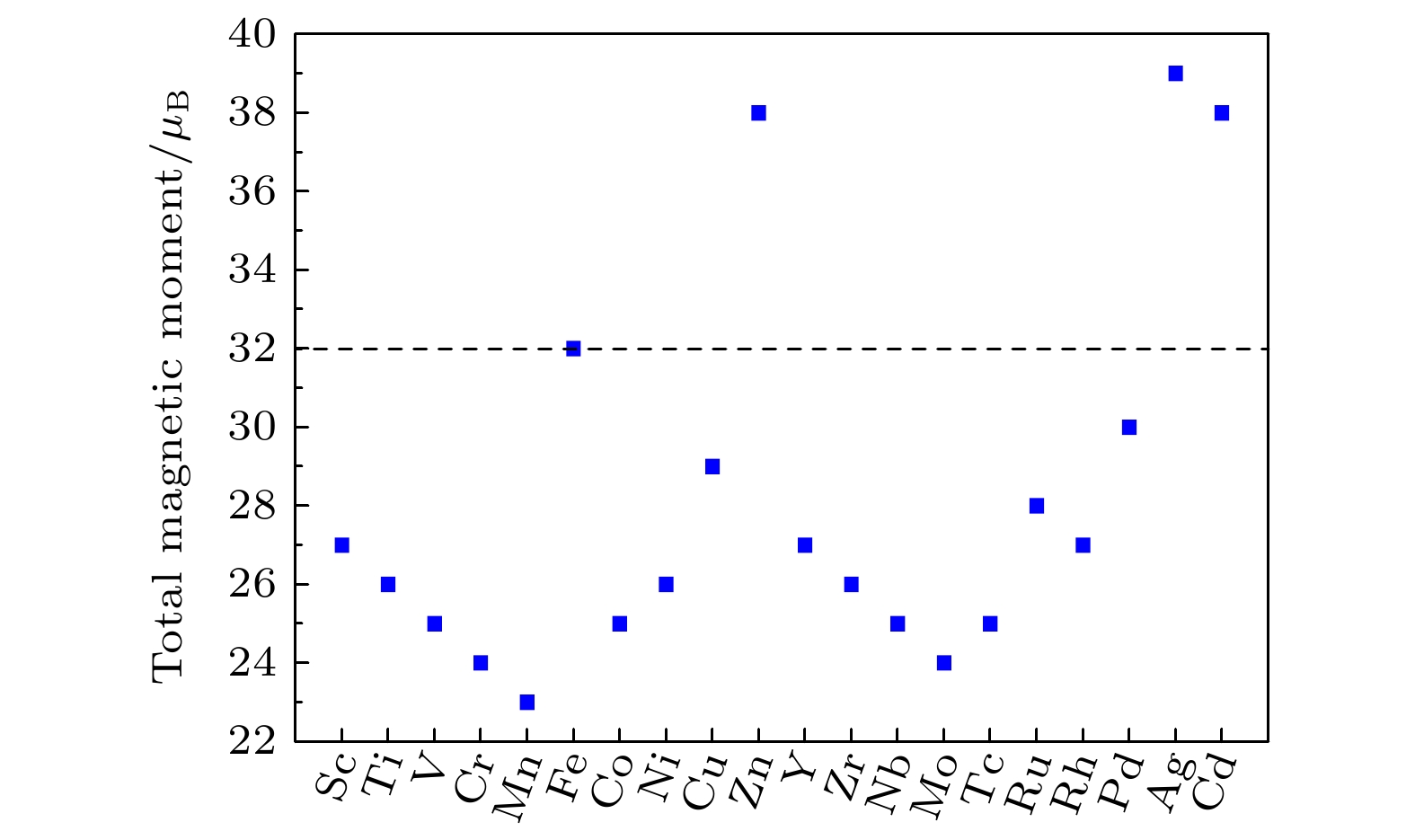

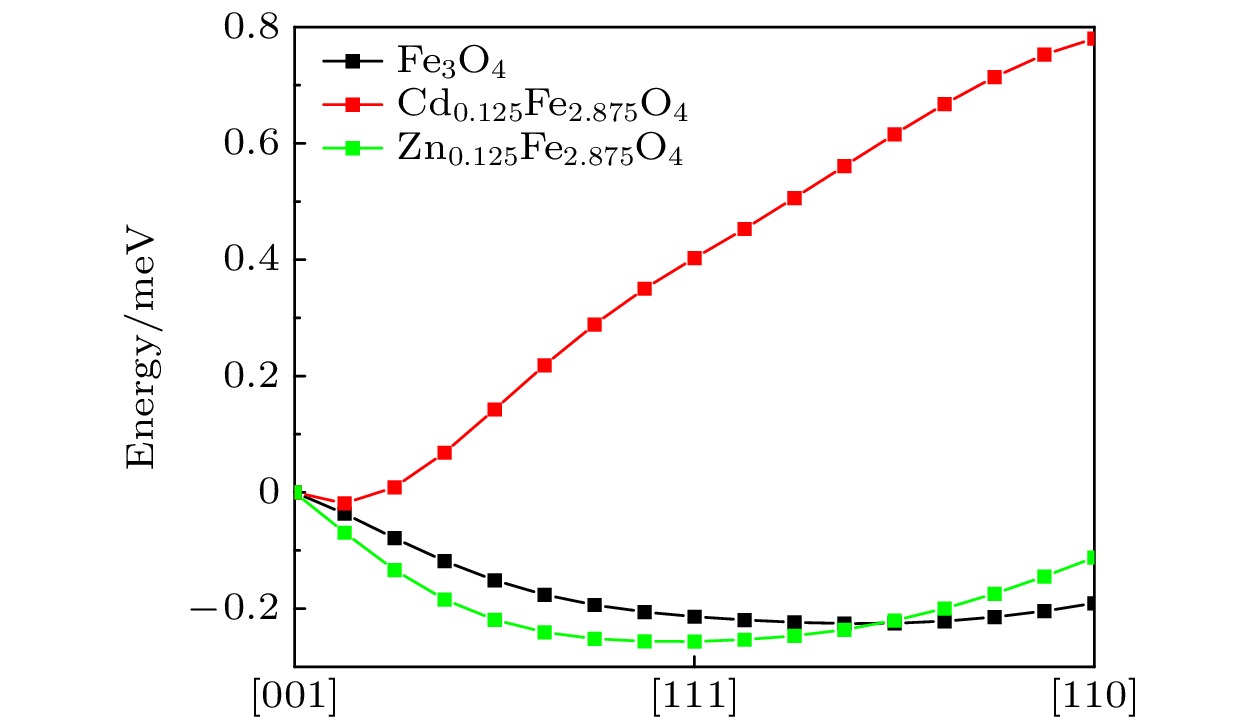

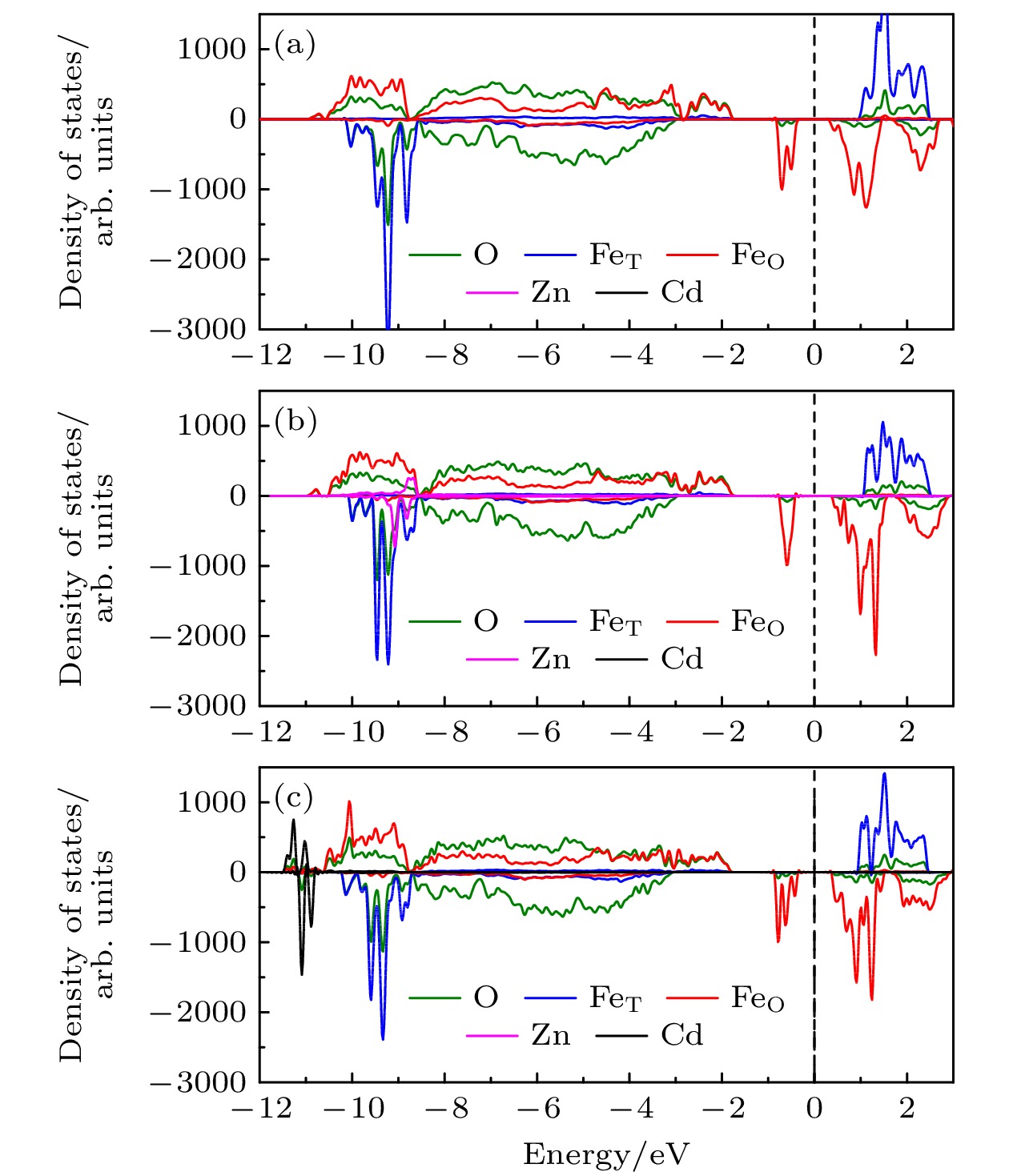

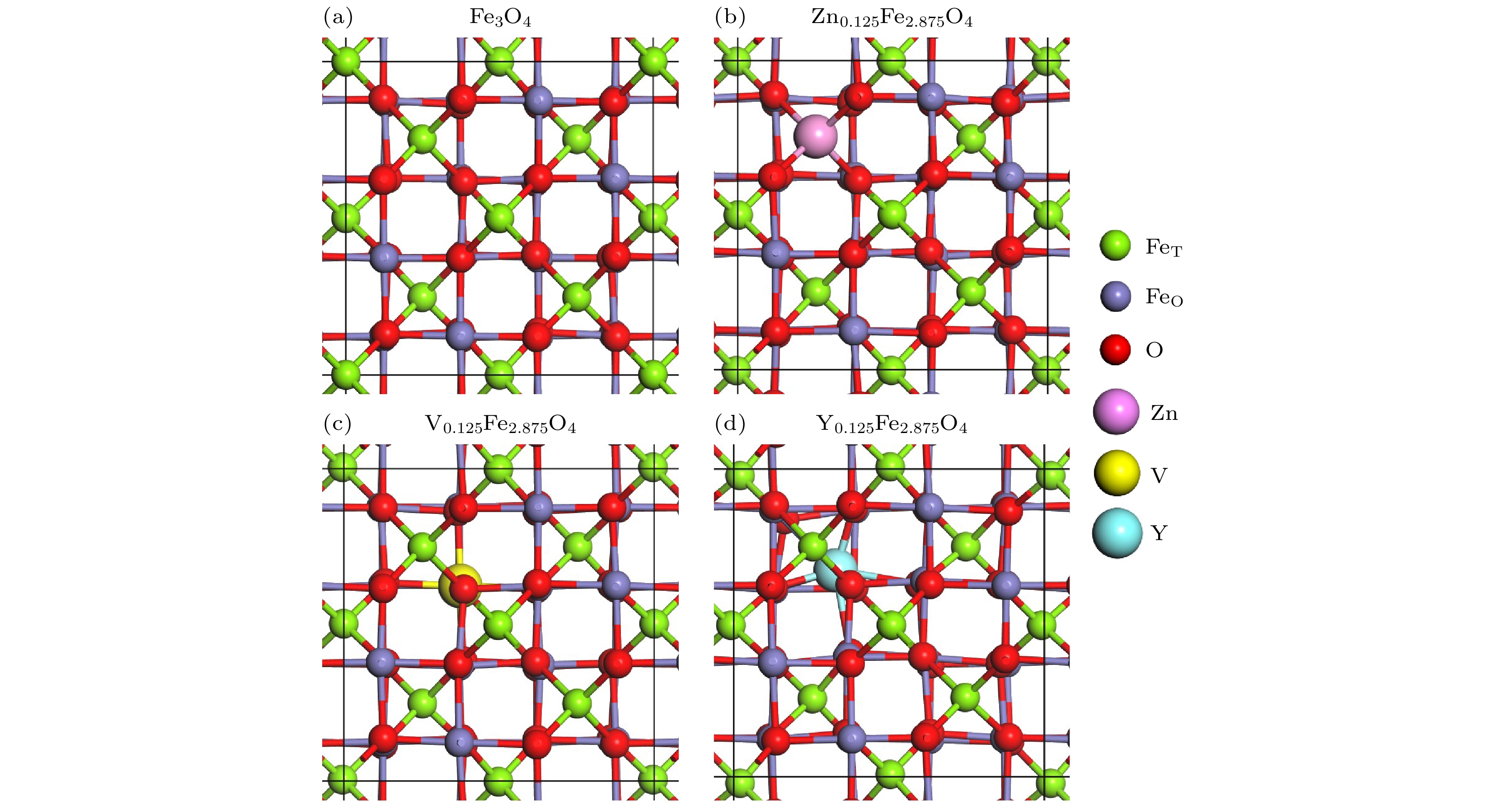

Magnetic Fe3O4 nanoparticles show promising applications in nanomedicine. The saturation magnetization (MS) and magnetic anisotropy are critical for the applications of Fe3O4 nanoparticles in drug delivery and magnetic hyperthermia. Here, by density functional computation, the doping effects of 3d and 4d transition metal elements (including Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Zr, Nb, Mo, Tc, Ru, Rh, Pd, Ag and Cd) on the magnetic properties of Fe3O4 are investigated in-depth. A conventional cell of Fe3O4, containing 24 Fe atoms and 32 O atoms, has been used to investigate the doping of group III elements. One 3d or 4d atom is doped in one conventional cell of Fe3O4, resulting in the formation of X0.125Fe2.875O4 where X represents the dopant. The results show that the doping of most 3d and 4d transition metal elements will reduce the total magnetic moment, while the doping of Ag, Zn and Cd in Fe3O4 will increase the total magnetic moment by 19%–22%. However, it is hard to dope Ag into Fe3O4 according to the positive formation energy. Therefore, Zn and Cd are good candidates to improve the MS of Fe3O4. The doping of Zn and Cd has also an influence on the magnetic anisotropy of Fe3O4. For Zn0.125Fe2.875O4, the magnetic anisotropy energy is about 0.25 meV per cell, which is slightly larger than that of intrinsic Fe3O4 (0.2 meV per cell). Interestingly, the doping of Cd (Cd0.125Fe2.875O4) will greatly increase the magnetic anisotropy energy to 0.8 meV per cell, which is significant for the specific absorption rate in the magnetic hyperthermia application. In addition, the doping of Zn and Cd will not induce any defect states in the band gap according to the density of states. Zn0.125Fe2.875O4 and Cd0.125Fe2.875O4 are both semiconducting and both the top of valence band and the bottom of conduction band originate from octahedral Fe. This is because the impurity states are very deep in energy. Our research results show that doping Cd is a feasible way to improve the performance of Fe3O4 as a material for drug delivery and magnetic hyperthermia.

-

Keywords:

- saturation magnetization /

- magnetic anisotropy /

- density functional theory /

- Fe3O4

[1] Perez J M, Josephson L, O'Loughlin T, Högemann D, Weissleder R 2002 Nat. Biotechnol. 20 816

Google Scholar

Google Scholar

[2] Liu J, Sun Z, Deng Y, Zou Y, Li C, Guo X, Xiong L, Gao Y, Li F, Zhao D 2009 Angew. Chem. Int. Ed. 48 5875

Google Scholar

Google Scholar

[3] Wu W, Wu Z, Yu T, Jiang C, Kim W S 2015 Sci. Technol. Adv. Mater. 16 023501

Google Scholar

Google Scholar

[4] Martinkova P, Brtnicky M, Kynicky J, Pohanka M 2018 Adv. Healthc. Mater. 7 1700932

Google Scholar

Google Scholar

[5] Pankhurst Q A, Thanh N T K, Jones S K, Dobson J 2009 J. Phys. D: Appl. Phys. 42 224001

Google Scholar

Google Scholar

[6] Gupta A K, Gupta M 2005 Biomaterials 26 3995

Google Scholar

Google Scholar

[7] Sun C, Lee J S H, Zhang M 2008 Adv. Drug. Deliv. Rev. 60 1252

Google Scholar

Google Scholar

[8] Pankhurst Q A, Connolly J, Jones S K, Dobson J 2003 J. Phys. D: Appl. Phys. 36 R167

Google Scholar

Google Scholar

[9] Laurent S, Forge D, Port M, Roch A, Robic C, Vander Elst L, Muller R N 2008 Chem. Rev. 108 2064

Google Scholar

Google Scholar

[10] Colombo M, Carregal-Romero S, Casula M F, Gutiérrez L, Morales M P, Böhm I B, Heverhagen J T, Prosperi D, Parak W J 2012 Chem. Soc. Rev. 41 4306

Google Scholar

Google Scholar

[11] Mitchell M J, Billingsley M M, Haley R M, Wechsler M E, Peppas N A, Langer R 2021 Nat. Rev. Drug Discov. 20 101

Google Scholar

Google Scholar

[12] Dilnawaz F, Singh A, Mohanty C, Sahoo S K 2010 Biomaterials 31 3694

Google Scholar

Google Scholar

[13] Wang Y, Zhao R B, Wang S B, Liu Z M, Tang R K 2016 Biomaterials 75 71

Google Scholar

Google Scholar

[14] Liao S H, Liu C H, Bastakoti B P, Suzuki N, Chang Y, Yamauchi Y, Lin F H, Wu K C 2015 Int. J. Nanomed. 10 3315

[15] Rajan A, Sharma M, Sahu N K 2020 Sci. Rep. 10 15045

Google Scholar

Google Scholar

[16] Sun S, Zeng H 2002 J. Am. Chem. Soc. 124 8204

Google Scholar

Google Scholar

[17] Hou Y, Yu J, Gao S 2003 J. Mater. Chem. 13 1983

Google Scholar

Google Scholar

[18] Sun S, Zeng H, Robinson D B, Raoux S, Rice P M, Wang S X, Li G 2004 J. Am. Chem. Soc. 126 273

Google Scholar

Google Scholar

[19] Park J, An K, Hwang Y, Park J G, Noh H J, Kim J Y, Park J H, Hwang N M, Hyeon T 2004 Nat. Mater. 3 891

Google Scholar

Google Scholar

[20] Tian Y, Yu B B, Li X, Li K 2011 J. Mater. Chem. 21 2476

Google Scholar

Google Scholar

[21] Kovalenko M V, Bodnarchuk M I, Lechner R T, Hesser G, Schäffler F, Heiss W 2007 J. Am. Chem. Soc. 129 6352

Google Scholar

Google Scholar

[22] Yang H, Ogawa T, Hasegawa D, Takahashi M 2008 J. Appl. Phys. 103 07D526

Google Scholar

Google Scholar

[23] Kim D, Lee N, Park M, Kim B H, An K, Hyeon T 2009 J. Am. Chem. Soc. 131 454

Google Scholar

Google Scholar

[24] Zhao L, Duan L 2010 Eur. J. Inorg. Chem. 2010 5635

Google Scholar

Google Scholar

[25] Zhang L H, Wu J J, Liao H B, Hou Y L, Gao S 2009 Chem. Commun. 29 4378

[26] Li X, Liu D, Song S, Wang X, Ge X, Zhang H 2011 CrystEngComm 13 6017

[27] Cheng X L, Jiang J S, Jiang D M, Zhao Z J 2014 J. Phys. Chem. C 118 12588

Google Scholar

Google Scholar

[28] Zheng R K, Gu H, Xu B, Fung K K, Zhang X X, Ringer S P 2006 Adv. Mater. 18 2418

Google Scholar

Google Scholar

[29] Zhao L J, Zhang H J, Xing Y, Song S Y, Yu S Y, Shi W D, Guo X M, Yang J H, Lei Y Q, Cao F 2008 Chem. Mat. 20 198

Google Scholar

Google Scholar

[30] Woo K, Hong J, Choi S, Lee H W, Ahn J P, Kim C S, Lee S W 2004 Chem. Mat. 16 2814

Google Scholar

Google Scholar

[31] Li Q, Kartikowati C W, Horie S, Ogi T, Iwaki T, Okuyama K 2017 Sci. Rep. 7 9894

Google Scholar

Google Scholar

[32] Liu J, Bin Y, Matsuo M 2012 J. Phys. Chem. C 116 134

Google Scholar

Google Scholar

[33] Ahghari M R, Amiri-khamakani Z, Maleki A 2023 Sci. Rep. 13 1007

Google Scholar

Google Scholar

[34] Qi Z L, Joshi T P, Liu R P, Liu H J, Qu J H 2017 J. Hazard. Mater. 329 193

Google Scholar

Google Scholar

[35] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[36] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[37] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[38] Liu H, Di Valentin C 2017 J. Phys. Chem. C 121 25736

Google Scholar

Google Scholar

[39] Dovesi R, Orlando R, Erba A, Zicovich-Wilson C M, Civalleri B, Casassa S, Maschio L, Ferrabone M, De La Pierre M, D'Arco P, Noël Y, Causà M, Rérat M, Kirtman B 2014 Int. J. Quantum Chem. 114 1287

Google Scholar

Google Scholar

[40] Krukau A V, Vydrov O A, Izmaylov A F, Scuseria G E 2006 J. Chem. Phys. 125 224106

Google Scholar

Google Scholar

[41] Liu H, Di Valentin C 2018 Nanoscale 10 11021

[42] Liu H, Di Valentin C 2019 Phys. Rev. Lett. 123 186101

Google Scholar

Google Scholar

[43] Hay P J, Wadt W R 1985 J. Chem. Phys. 82 299

Google Scholar

Google Scholar

[44] Durand P, Barthelat J C 1975 Theor. Chim. Acta 38 283

Google Scholar

Google Scholar

-

图 3 本征和掺杂的 Fe3O4 的磁各向异性, 图中横坐标为不同的磁化方向, 磁化轴从[001]方向开始沿着(1, –1, 0)面旋转到[111]方向, 中间均匀取7个数据点, 再从[111]方向沿着(1, –1, 0)面旋转到[110]方向, 中间也均匀取7个数据点(数据来源于VASP的PBE + U计算)

Fig. 3. Magnetic anisotropy of Fe3O4 with and without doping. The abscissas in the figure represent different magnetization directions. The magnetization axis starts from the [001] direction and rotates along the (1, –1, 0) plane to the [111] direction. Seven data points are evenly taken in the middle, and then the magnetization axis rotates from the [111] direction along the (1, –1, 0) plane to the [110] direction, and 7data points are evenly taken in the middle (data is from PBE + U calculation with VASP).

图 4 (a) 未掺杂的完美 Fe3O4, (b) Zn0.125Fe2.875O4, (c) Cd0.125Fe2.875O4 的投影态密度, 费米能级归零, 如黑色虚线所示(数据来源于CRYSTAL17的杂化泛函计算)

Fig. 4. Projected density of states of (a) perfect Fe3O4 without doping, (b) Zn0.125Fe2.875O4, (c) Cd0.125Fe2.875O4. The legend of colors is on the top, the Fermi level is scaled to zero as indicated by the dashed black lines (data is from HSE calculation with CRYSTAL17).

表 1 过渡金属掺杂Fe3O4的能量差ΔE = ET – EO, 其中ET和EO分别表示掺杂剂取代四面体 Fe 和八面体 Fe 的掺杂 Fe3O4 的总能量(数据来源于CRYSTAL17的杂化泛函计算)

Table 1. Energy difference ΔE = ET – EO for transition metal doped Fe3O4, where ET and EO represent the total energy of doped Fe3O4 with the dopant replacing tetrahedral Fe and octahedral Fe, respectively (data is from HSE calculation with CRYSTAL17).

杂质 Sc Ti V Cr Mn Co Ni Cu Zn ΔE /eV 0.70 0.10 0.37 1.48 0.10 0.13 0.95 0.19 –0.14 杂质 Y Zr Nb Mo Tc Ru Rh Pd Ag Cd ΔE /eV 4.23 0.13 0.01 0.72 2.14 2.27 1.31 0.96 –0.29 –0.32 表 2 过渡金属掺杂 Fe3O4 的形成能 Ef (数据来源于VASP的PBE + U计算)

Table 2. Formation energy Ef of transition metal doped Fe3O4 (data is from PBE + U calculation with VASP).

杂质 Sc Ti V Cr Mn Co Ni Cu Zn Ef /eV –6.45 –5.75 –4.94 –4.97 –3.72 –2.09 –1.69 0.21 –1.93 杂质 Y Zr Nb Mo Tc Ru Rh Pd Ag Cd Ef /eV –5.42 –6.09 –5.23 –2.60 –2.18 –1.00 –0.62 0.54 1.12 –0.61 表 3 Fe3O4掺杂时3d和4d过渡金属原子的原子磁矩(m)(数据来源于CRYSTAL17的杂化泛函计算)

Table 3. Atomic magnetic moment (m) of 3d and 4d transition metal atoms when doped in Fe3O4 (data is from HSE calculation with CRYSTAL17).

杂质 Sc Ti V Cr Mn Co Ni Cu Zn m/μB –0.06 –0.12 –2.02 –3.05 –4.76 –2.76 –1.78 0.01 0.07 杂质 Y Zr Nb Mo Tc Ru Rh Pd Ag Cd m/μB –0.09 –0.22 –0.52 –2.66 –1.91 0.11 –0.09 1.30 0.12 0.07 -

[1] Perez J M, Josephson L, O'Loughlin T, Högemann D, Weissleder R 2002 Nat. Biotechnol. 20 816

Google Scholar

Google Scholar

[2] Liu J, Sun Z, Deng Y, Zou Y, Li C, Guo X, Xiong L, Gao Y, Li F, Zhao D 2009 Angew. Chem. Int. Ed. 48 5875

Google Scholar

Google Scholar

[3] Wu W, Wu Z, Yu T, Jiang C, Kim W S 2015 Sci. Technol. Adv. Mater. 16 023501

Google Scholar

Google Scholar

[4] Martinkova P, Brtnicky M, Kynicky J, Pohanka M 2018 Adv. Healthc. Mater. 7 1700932

Google Scholar

Google Scholar

[5] Pankhurst Q A, Thanh N T K, Jones S K, Dobson J 2009 J. Phys. D: Appl. Phys. 42 224001

Google Scholar

Google Scholar

[6] Gupta A K, Gupta M 2005 Biomaterials 26 3995

Google Scholar

Google Scholar

[7] Sun C, Lee J S H, Zhang M 2008 Adv. Drug. Deliv. Rev. 60 1252

Google Scholar

Google Scholar

[8] Pankhurst Q A, Connolly J, Jones S K, Dobson J 2003 J. Phys. D: Appl. Phys. 36 R167

Google Scholar

Google Scholar

[9] Laurent S, Forge D, Port M, Roch A, Robic C, Vander Elst L, Muller R N 2008 Chem. Rev. 108 2064

Google Scholar

Google Scholar

[10] Colombo M, Carregal-Romero S, Casula M F, Gutiérrez L, Morales M P, Böhm I B, Heverhagen J T, Prosperi D, Parak W J 2012 Chem. Soc. Rev. 41 4306

Google Scholar

Google Scholar

[11] Mitchell M J, Billingsley M M, Haley R M, Wechsler M E, Peppas N A, Langer R 2021 Nat. Rev. Drug Discov. 20 101

Google Scholar

Google Scholar

[12] Dilnawaz F, Singh A, Mohanty C, Sahoo S K 2010 Biomaterials 31 3694

Google Scholar

Google Scholar

[13] Wang Y, Zhao R B, Wang S B, Liu Z M, Tang R K 2016 Biomaterials 75 71

Google Scholar

Google Scholar

[14] Liao S H, Liu C H, Bastakoti B P, Suzuki N, Chang Y, Yamauchi Y, Lin F H, Wu K C 2015 Int. J. Nanomed. 10 3315

[15] Rajan A, Sharma M, Sahu N K 2020 Sci. Rep. 10 15045

Google Scholar

Google Scholar

[16] Sun S, Zeng H 2002 J. Am. Chem. Soc. 124 8204

Google Scholar

Google Scholar

[17] Hou Y, Yu J, Gao S 2003 J. Mater. Chem. 13 1983

Google Scholar

Google Scholar

[18] Sun S, Zeng H, Robinson D B, Raoux S, Rice P M, Wang S X, Li G 2004 J. Am. Chem. Soc. 126 273

Google Scholar

Google Scholar

[19] Park J, An K, Hwang Y, Park J G, Noh H J, Kim J Y, Park J H, Hwang N M, Hyeon T 2004 Nat. Mater. 3 891

Google Scholar

Google Scholar

[20] Tian Y, Yu B B, Li X, Li K 2011 J. Mater. Chem. 21 2476

Google Scholar

Google Scholar

[21] Kovalenko M V, Bodnarchuk M I, Lechner R T, Hesser G, Schäffler F, Heiss W 2007 J. Am. Chem. Soc. 129 6352

Google Scholar

Google Scholar

[22] Yang H, Ogawa T, Hasegawa D, Takahashi M 2008 J. Appl. Phys. 103 07D526

Google Scholar

Google Scholar

[23] Kim D, Lee N, Park M, Kim B H, An K, Hyeon T 2009 J. Am. Chem. Soc. 131 454

Google Scholar

Google Scholar

[24] Zhao L, Duan L 2010 Eur. J. Inorg. Chem. 2010 5635

Google Scholar

Google Scholar

[25] Zhang L H, Wu J J, Liao H B, Hou Y L, Gao S 2009 Chem. Commun. 29 4378

[26] Li X, Liu D, Song S, Wang X, Ge X, Zhang H 2011 CrystEngComm 13 6017

[27] Cheng X L, Jiang J S, Jiang D M, Zhao Z J 2014 J. Phys. Chem. C 118 12588

Google Scholar

Google Scholar

[28] Zheng R K, Gu H, Xu B, Fung K K, Zhang X X, Ringer S P 2006 Adv. Mater. 18 2418

Google Scholar

Google Scholar

[29] Zhao L J, Zhang H J, Xing Y, Song S Y, Yu S Y, Shi W D, Guo X M, Yang J H, Lei Y Q, Cao F 2008 Chem. Mat. 20 198

Google Scholar

Google Scholar

[30] Woo K, Hong J, Choi S, Lee H W, Ahn J P, Kim C S, Lee S W 2004 Chem. Mat. 16 2814

Google Scholar

Google Scholar

[31] Li Q, Kartikowati C W, Horie S, Ogi T, Iwaki T, Okuyama K 2017 Sci. Rep. 7 9894

Google Scholar

Google Scholar

[32] Liu J, Bin Y, Matsuo M 2012 J. Phys. Chem. C 116 134

Google Scholar

Google Scholar

[33] Ahghari M R, Amiri-khamakani Z, Maleki A 2023 Sci. Rep. 13 1007

Google Scholar

Google Scholar

[34] Qi Z L, Joshi T P, Liu R P, Liu H J, Qu J H 2017 J. Hazard. Mater. 329 193

Google Scholar

Google Scholar

[35] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[36] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[37] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[38] Liu H, Di Valentin C 2017 J. Phys. Chem. C 121 25736

Google Scholar

Google Scholar

[39] Dovesi R, Orlando R, Erba A, Zicovich-Wilson C M, Civalleri B, Casassa S, Maschio L, Ferrabone M, De La Pierre M, D'Arco P, Noël Y, Causà M, Rérat M, Kirtman B 2014 Int. J. Quantum Chem. 114 1287

Google Scholar

Google Scholar

[40] Krukau A V, Vydrov O A, Izmaylov A F, Scuseria G E 2006 J. Chem. Phys. 125 224106

Google Scholar

Google Scholar

[41] Liu H, Di Valentin C 2018 Nanoscale 10 11021

[42] Liu H, Di Valentin C 2019 Phys. Rev. Lett. 123 186101

Google Scholar

Google Scholar

[43] Hay P J, Wadt W R 1985 J. Chem. Phys. 82 299

Google Scholar

Google Scholar

[44] Durand P, Barthelat J C 1975 Theor. Chim. Acta 38 283

Google Scholar

Google Scholar

计量

- 文章访问数: 3383

- PDF下载量: 114

- 被引次数: 0

下载:

下载: