-

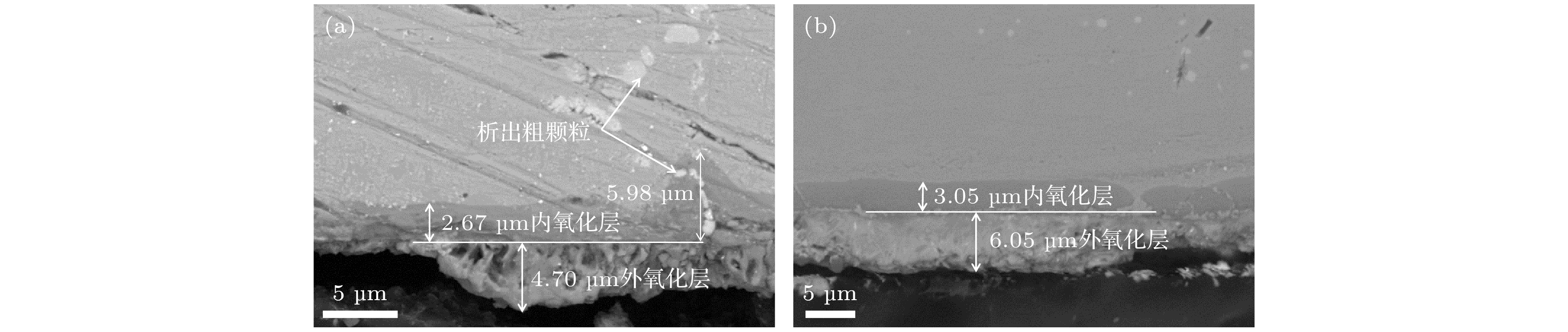

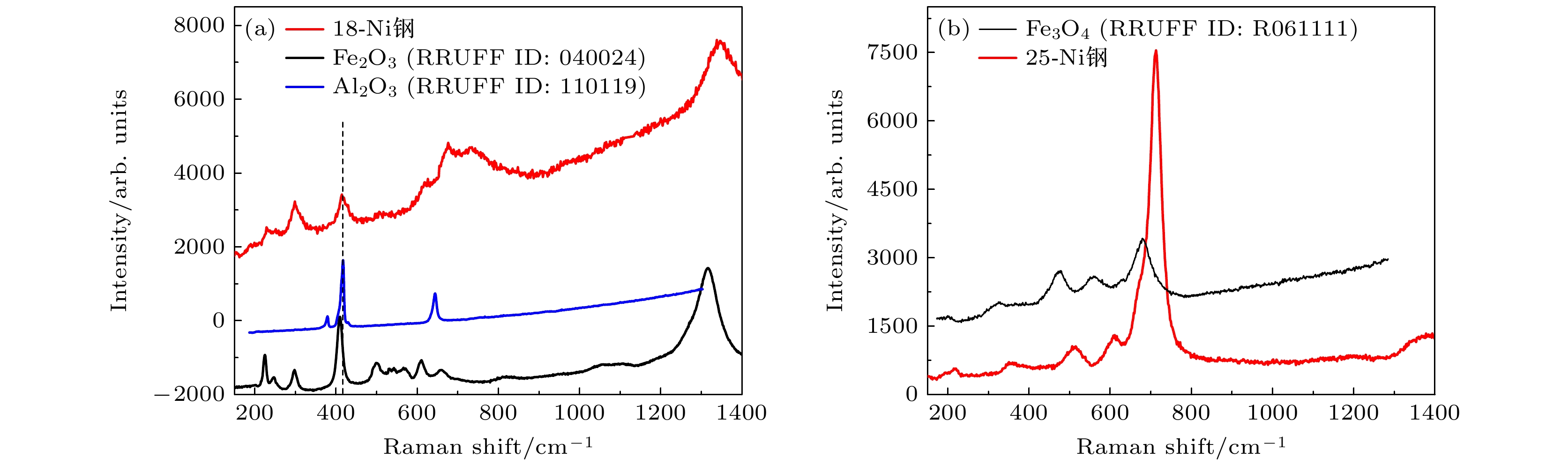

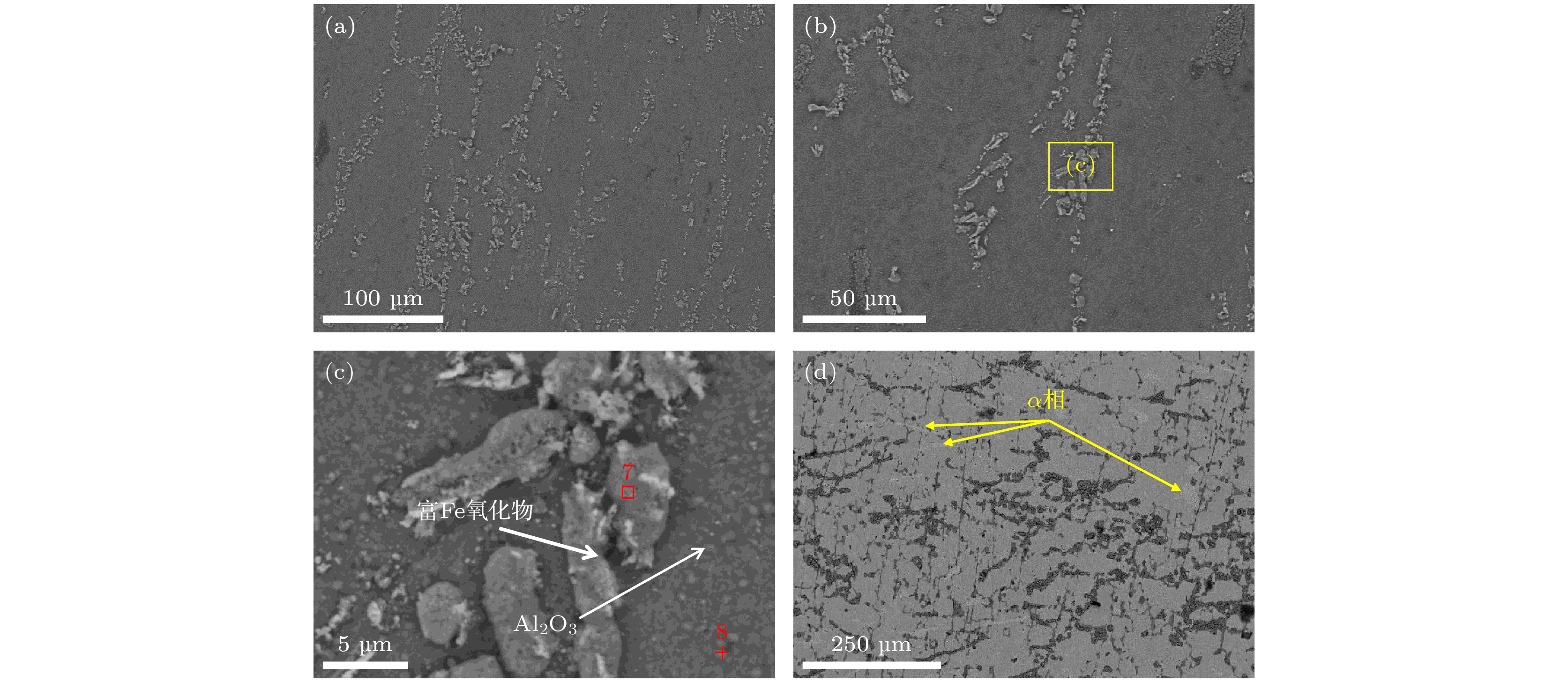

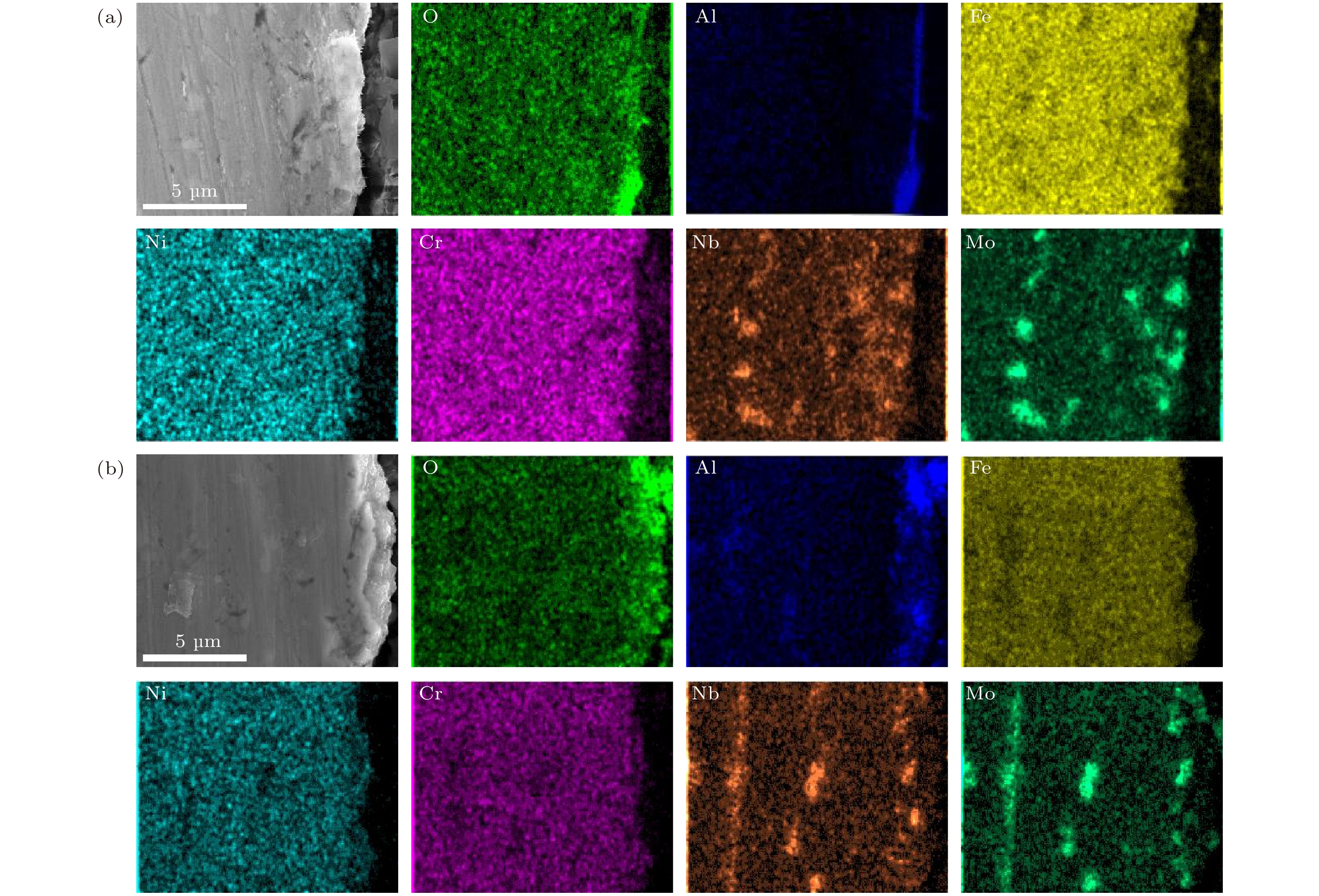

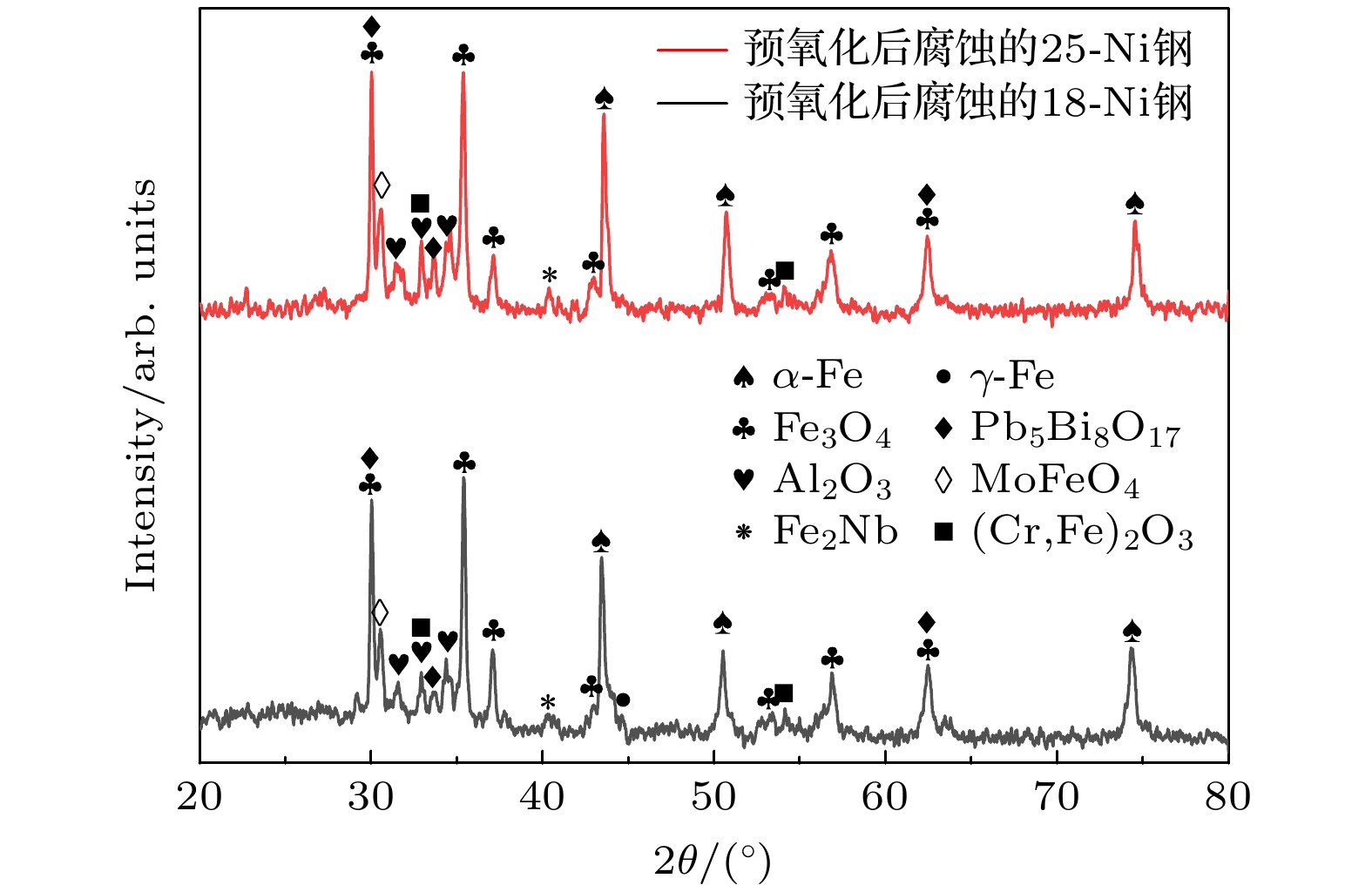

先进铅冷快堆和加速器驱动次临界系统商业化的关键材料问题是结构材料与铅基冷却剂之间的相容性问题, 结构钢材料需要在高温液态铅铋共晶中具有优异的抗腐蚀能力. 含铝强化奥氏体钢(alumina-forming austenite steel, AFA钢)因其表面可以形成Al2O3膜而在极端环境中具有良好的耐蚀性能. 本文研究了降低Ni元素成分和高温预氧化对AFA钢耐铅铋腐蚀性能的影响, 利用扫描电子显微镜、能量色散X射线光谱仪、X射线衍射技术, 对AFA钢在550 ℃液态铅铋饱和溶氧条件下腐蚀600 h的氧化层形貌及结构进行表征. 结果表明: 降低合金中Ni含量和高温预氧化处理都会促进样品表面形成保护性Al2O3氧化膜, 进而降低腐蚀层厚度, 提升材料耐铅铋腐蚀性能.The key material issue for the commercialization of advanced lead cooled fast reactors and accelerator driven subcritical systems is the compatibility between structural materials and lead based coolants. Structural steel materials require excellent corrosion resistance in high-temperature liquid lead bismuth eutectic (LBE) alloy. Aluminum forming austenitic steel (AFA steel) has excellent corrosion resistance in extreme environments due to its ability to form an Al2O3 film on its surface. However, excessively high Ni elements are more easily dissolved or oxidized in LBE than Fe and Cr elements. Therefore, this work investigates the effect of reducing Ni element composition (25-Ni steel and 18-Ni steel) on the corrosion resistance of steel in LBE. Surface treatment can protect the substrate from corrosion to some extent, so herein we explore whether it has a protective effect on AFA steel in LBE by generating Al2O3 through high-temperature pre oxidation. The morphology and structure of the oxide layer of AFA steel corroded for 600 h in LBE with saturated dissolved oxygen at 550 ℃ are characterized by scanning electron microscope (SEM), energy dispersive spectrometer (EDS), X-ray diffraction (XRD), and other technologies. The results indicate that the oxide film formed after corrosion of 18-Ni steel is thinner than that after corrosion of 25-Ni steel. Performing high-temperature pre oxidation is beneficial to forming a protective Al2O3 oxide film on the surface of the sample, thereby reducing the thickness of the oxide layer and improving the material’s LBE corrosion resistance. The reduction in thickness of the oxide layer generated after pre oxidation of 18-Ni steel is greater than that of 25-Ni steel, so the anti-corrosion effect of 18-Ni steel after pre oxidation is better than that of 25-Ni steel.

-

Keywords:

- aluminum forming austenitic steel /

- oxide layer /

- lead bismuth eutectic /

- high temperature pre oxidation

[1] Lu Y H, Song Y Y, Chen S H, Rong L J 2016 Acta Met. Sin. 52 298

[2] Schroer C, Wedemeyer O, Novotny J, Skrypnik A, Konys J 2014 Corros. Sci. 84 113

Google Scholar

Google Scholar

[3] Yamaki E, Ginestar K , Martinelli L 2011 Corros. Sci. 53 3075

[4] Sapundjiev D, Dyck V S, Bogaerts W 2006 Corros. Sci. 48 577

Google Scholar

Google Scholar

[5] Kurata Y, Futakawa M, Saito S 2005 J. Nucl. Mater. 343 333

Google Scholar

Google Scholar

[6] Anderoglu O, Byun T S, Toloczko M, Maloy S A 2012 Metall. Mater. Trans. A 44 70

[7] 陈灵芝, 周张健, Schroer C 2020 材料导报 34 05098

Google Scholar

Google Scholar

Chen L Z, Zhou Z J, Schroer C 2020 Mater. Rep. 34 05098

Google Scholar

Google Scholar

[8] Gong X, Marmy P, Qin L, Verlinden B, Wevers M, Seefeldt M 2014 Mater. Sci. Eng. A 618 406

Google Scholar

Google Scholar

[9] Vogt J , Proriol-Serre I 2013 Procedia Eng. 55 814

[10] Gong X, Li R, Sun M Z, Ren Q S, Liu T, Short M P 2016 J. Nucl. Mater. 482 225

[11] 梁娜, 姚存峰, 龙斌, 付晓钢 2022 材料导报 36 21090168

Google Scholar

Google Scholar

Liang N, Yao C F, Long B, Fu X G 2022 Mater. Rep. 36 21090168

Google Scholar

Google Scholar

[12] Kurata Y, Futakawa M, Saito S 2008 J. Nucl. Mater. 373 167

[13] 鞠娜, 雷玉成, 陈钢, 朱强, 李天庆, 王丹 2019 原子能科学技术 53 432

Google Scholar

Google Scholar

Ju N, Lei Y C, Chen G, Zhu Q, Li T Q 2019 Atomic Energy Sci. Techno. 53 432

Google Scholar

Google Scholar

[14] Brady M P, Yamamoto Y, Santella M L, Pint B A 2007 Scripta Mater. 57 1119

[15] Yamamoto Y, Takeyama M, Lu Z P, Liu C T, Evans N D, Maziasz P J, Brady M P 2008 Nature 30 191

[16] Lutz B S, Yanar N M, Holcomb G R, Meier G H 2017 Oxid. Met. 87 587

[17] Gao Q Z, Liu Z Y, Li H J, Zhang H L, Jiang C C, Hao A M, Qu F, Lin X P 2021 J. Mater. Sci. Technol. 68 99

[18] Meng H J, Wang J, Wang L, Fang X D, Dong N, Zhang C L, Han P D 2020 Mater. Charact. 163 110233

Google Scholar

Google Scholar

[19] Shi H, Tang C C, Jianu A, Fetzer R, Weisenburger A, Steinbrueck M, Grosse M, Stieglitz R, Müller G 2020 Corros. Sci. 170 108654

Google Scholar

Google Scholar

[20] Shen L, Wu B J, Zhao K, Peng H B Wen Y H 2021 Corros. Sci. 191 109754

Google Scholar

Google Scholar

[21] Yamamoto Y, Brady M P, Ren Q Q, Poplawsky J D, Hoelzer D T, Lance M J 2022 JOM 74 1462

[22] Yamamoto Y, Ren Q Q, Brady M P 2022 Metals 12 717-7

Google Scholar

Google Scholar

[23] Zhao W X, Jiang S H, Liu W H, Peng X Y, Wang H, Wu Y, Liu X J, Lu Z P 2022 Mater. Sci. Eng. A 857 143995

Google Scholar

Google Scholar

[24] 经济合作与发展组织/核能署 著 (戎利建, 张玉妥, 陆善平, 陈星秋, 王培, 熊超, 叶中飞, 李依依 译) 2007 铅与铅铋共晶合金手册 (北京: 科学出版社)第72—73页

OECD/NEA (translated by Rong L J, Zhang Y T, Lu S P, Chen X Q, Wang P, Xiong C, Ye Z F, Li Y Y) 2007 Handbook on Lead–Bismuth Eutectic Alloy and Lead (Beijing: Science Press) pp72–73

[25] Brady M P, Yamamoto Y, Santella M L, Maziasz P J, Pint B A, Liu C T, Lu Z P, Bei H 2008 JOM 60 12

[26] Yamamoto Y, Takeyama M, Lu Z P, Liu C T, Evans N D, Maziasz P J, Brady M P 2008 Intermetallics 16 458

[27] 程晓农, 姚永泉, 李冬升, 罗锐, 郑琦, 唐桢丁 2017 金属热处理 42 75

Chen X N, Yao Y Q, Li D S, Luo R, Zheng Q, Tang Z D 2017 Heat Treat. Met. 42 75

[28] Hosemann P, Bai S, Bickel J, Qiu J 2021 JOM 73 4014

[29] Liu Y C, Chen S M, Ouyang F Y, Kai J J 2018 J. Nucl. Mater. 505 13

[30] Chen L Z, Tsisar V, Wang M, Schroer C, Zhou Z J 2021 Corros. Sci. 189 109591

Google Scholar

Google Scholar

[31] 陈灵芝 2021 博士学位论文 (北京: 北京科技大学)

Chen L Z 2021 Ph. D. Dissertation (Beijing: University of Science and Technology

[32] Wang M, Sun Y D, Feng J K , Zhang R Q, Tang R, Zhou Z J 2016 Int. J. Min. Met. Mater. 23 316

[33] 周德强 2014 博士学位论文 (北京: 北京科技大学)

Zhou D Q 2014 Ph. D. Dissertation (Beijing: University of Science and Technology

[34] Ejenstam J, Szakálos P 2015 J. Nucl. Mater. 461 164

Google Scholar

Google Scholar

[35] Muller G, Heinzel A, Konys J, Schumacher G, Weisenburger A, Zimmermann F, Engelko V, Rusanov A, Markov V 2002 J. Nucl. Mater. 301 42

[36] 熊静, 邓平, 高军, 赵永福 2022 科学技术创新 10 55

Xiong J, Deng P, Gao J, Zhao Y F 2022 Sci. Technol. Inno. 10 55

[37] 王军健, 李华鑫, 李红菊, 郑文健, 闾川阳, 马英鹤, 任森栋, 包士毅, 贺艳明, 杨建国 2023 强激光与粒子束 35 056001

Wang J J, Li H X, Li H J, Zheng W J, Lv C Y, Ma Y H, Ren S D, Bao S Y, He Y M, Yang J G 2023 High Power Laser Part. Beams 35 056001

[38] 吴欣强, 戎利建, 谭季波, 陈胜虎, 胡小锋, 张洋鹏, 张兹瑜 2023 金属学报 59 504

Wu X Q, Rong L J, Tan J B, Chen S H, Hu X F, Zhang Y P, Zhang Z Y 2023 Acta Metall. Sin. 59 504

[39] Bischoff J, Motta A T 2012 J. Nucl. Mater. 424 261

Google Scholar

Google Scholar

[40] Bischoff J, Motta A T, Eichfeld C, Comstock R J, Cao G P, Allen T R 2013 J. Nucl. Mater. 441 604

Google Scholar

Google Scholar

[41] Tan L, Ren X, Allen T R 2010 Corros. Sci. 52 1520

Google Scholar

Google Scholar

[42] 肖纪美, 曹楚南 2002 材料腐蚀学原理 (北京: 化学工业出版社) 第96—99页

Xiao J M, Cao C N 2002 Principles of Material Corrosion (Beijing: Chemical Industry Press) pp96–99

[43] Xu S, Long F, Persaud S Y, Guo N, Yao Z W, Daymond M R, Gao W H, Zhang L F, Zhou Z J 2020 Corros. Sci. 165 108380

Google Scholar

Google Scholar

[44] 刘培生 2003 稀有金属材料与工程 32 684

Liu P S 2023 Rare Metal Mat. Eng. 32 684

[45] Boggs W E 1971 J. Electrochem. Soc. 118 906

Google Scholar

Google Scholar

[46] 李美栓, 周延春 2005 腐蚀科学与防护技术 17 409

Li M S, Zhou Y C 2005 Corros. Sci. Prot. Technol. 17 409

[47] Stott F H, Wei F I, 1989 Oxid. Met. 31 386

[48] 李铁藩 2003 金属高温氧化和热腐蚀 (北京: 化学工业出版社) 第31—35页

Li T F 2003 High Temperature Oxidation and Hot Corrosion of Metals (Beijing: Chemical Industry Press) pp31–35

[49] Ellingham H J T 1944 J. Soc. Chem. Ind. 63 125

Google Scholar

Google Scholar

[50] 康新婷, 杨坤, 迟煜頔, 王建, 王辉, 李亚宁, 王建永 2012 稀有金属材料与工程 41 822

Kang X T, Yang K, Chi Y D, Wang J, Wang H, Li Y N, Wang J Y 2012 Rare Metal Mat. Eng. 41 822

-

图 1 锻造态钢的EBSD图和SEM图 (a) 18-Ni钢EBSD图; (b) 基于图(a)的18-Ni钢相分布图; (c) 18-Ni钢SEM图, 右上角图像放大了α相区域; (d) 25-Ni钢EBSD图; (e) 基于图(d)的25-Ni钢相分布图; (f) 25-Ni钢SEM图

Fig. 1. EBSD and SEM images of steels: (a) EBSD images of 18-Ni steel; (b) phase distribution of 18-Ni steel; (c) SEM image of 18-Ni steel, the upper right corner picture magnifies the of α phase area; (d) 25-Ni steel EBSD image; (e) phase distribution of 25-Ni steel; (f) 25-Ni steel SEM image.

表 1 18-Ni钢和25-Ni钢的实际化学成分(质量分数, %)

Table 1. The actual chemical composition of 18-Ni steel and 25-Ni steel (mass percentage, %).

Ni Cr Al Mo Nb Fe 18-Ni 19.25 14.21 2.66 3.62 1.8 Bal. 25-Ni 26.67 14.11 2.76 3.55 1.81 Bal. 区域 Cr Al Fe Nb O 点1 0.3 0 43.3 2.7 53.6 点2 2.2 13.6 10.6 12.4 47.0 点3 1.9 16.6 7.3 2.0 48.2 点4 1.3 0.5 58.9 0.7 35.5 点5 18.8 1.9 36.4 2.2 37.0 点6 8.6 8.6 34.0 17.5 7.9 区域 Cr Al Fe O 点7 3.28 1.51 50.12 38.59 点8 9.94 14.24 44.26 9.46 点9 7.56 2.18 51.11 36.15 点10 25.00 5.88 38.62 22.34 点11 15.42 0.69 75.67 5.20 区域 Cr Al Fe Ni O 点12 9.2 4.4 49.5 4.2 30.9 点13 1.5 39.7 2.6 2.1 53.5 点14 1.1 1.1 85.7 0.0 10.9 点15 2.1 17.8 7.4 20.9 5.20 -

[1] Lu Y H, Song Y Y, Chen S H, Rong L J 2016 Acta Met. Sin. 52 298

[2] Schroer C, Wedemeyer O, Novotny J, Skrypnik A, Konys J 2014 Corros. Sci. 84 113

Google Scholar

Google Scholar

[3] Yamaki E, Ginestar K , Martinelli L 2011 Corros. Sci. 53 3075

[4] Sapundjiev D, Dyck V S, Bogaerts W 2006 Corros. Sci. 48 577

Google Scholar

Google Scholar

[5] Kurata Y, Futakawa M, Saito S 2005 J. Nucl. Mater. 343 333

Google Scholar

Google Scholar

[6] Anderoglu O, Byun T S, Toloczko M, Maloy S A 2012 Metall. Mater. Trans. A 44 70

[7] 陈灵芝, 周张健, Schroer C 2020 材料导报 34 05098

Google Scholar

Google Scholar

Chen L Z, Zhou Z J, Schroer C 2020 Mater. Rep. 34 05098

Google Scholar

Google Scholar

[8] Gong X, Marmy P, Qin L, Verlinden B, Wevers M, Seefeldt M 2014 Mater. Sci. Eng. A 618 406

Google Scholar

Google Scholar

[9] Vogt J , Proriol-Serre I 2013 Procedia Eng. 55 814

[10] Gong X, Li R, Sun M Z, Ren Q S, Liu T, Short M P 2016 J. Nucl. Mater. 482 225

[11] 梁娜, 姚存峰, 龙斌, 付晓钢 2022 材料导报 36 21090168

Google Scholar

Google Scholar

Liang N, Yao C F, Long B, Fu X G 2022 Mater. Rep. 36 21090168

Google Scholar

Google Scholar

[12] Kurata Y, Futakawa M, Saito S 2008 J. Nucl. Mater. 373 167

[13] 鞠娜, 雷玉成, 陈钢, 朱强, 李天庆, 王丹 2019 原子能科学技术 53 432

Google Scholar

Google Scholar

Ju N, Lei Y C, Chen G, Zhu Q, Li T Q 2019 Atomic Energy Sci. Techno. 53 432

Google Scholar

Google Scholar

[14] Brady M P, Yamamoto Y, Santella M L, Pint B A 2007 Scripta Mater. 57 1119

[15] Yamamoto Y, Takeyama M, Lu Z P, Liu C T, Evans N D, Maziasz P J, Brady M P 2008 Nature 30 191

[16] Lutz B S, Yanar N M, Holcomb G R, Meier G H 2017 Oxid. Met. 87 587

[17] Gao Q Z, Liu Z Y, Li H J, Zhang H L, Jiang C C, Hao A M, Qu F, Lin X P 2021 J. Mater. Sci. Technol. 68 99

[18] Meng H J, Wang J, Wang L, Fang X D, Dong N, Zhang C L, Han P D 2020 Mater. Charact. 163 110233

Google Scholar

Google Scholar

[19] Shi H, Tang C C, Jianu A, Fetzer R, Weisenburger A, Steinbrueck M, Grosse M, Stieglitz R, Müller G 2020 Corros. Sci. 170 108654

Google Scholar

Google Scholar

[20] Shen L, Wu B J, Zhao K, Peng H B Wen Y H 2021 Corros. Sci. 191 109754

Google Scholar

Google Scholar

[21] Yamamoto Y, Brady M P, Ren Q Q, Poplawsky J D, Hoelzer D T, Lance M J 2022 JOM 74 1462

[22] Yamamoto Y, Ren Q Q, Brady M P 2022 Metals 12 717-7

Google Scholar

Google Scholar

[23] Zhao W X, Jiang S H, Liu W H, Peng X Y, Wang H, Wu Y, Liu X J, Lu Z P 2022 Mater. Sci. Eng. A 857 143995

Google Scholar

Google Scholar

[24] 经济合作与发展组织/核能署 著 (戎利建, 张玉妥, 陆善平, 陈星秋, 王培, 熊超, 叶中飞, 李依依 译) 2007 铅与铅铋共晶合金手册 (北京: 科学出版社)第72—73页

OECD/NEA (translated by Rong L J, Zhang Y T, Lu S P, Chen X Q, Wang P, Xiong C, Ye Z F, Li Y Y) 2007 Handbook on Lead–Bismuth Eutectic Alloy and Lead (Beijing: Science Press) pp72–73

[25] Brady M P, Yamamoto Y, Santella M L, Maziasz P J, Pint B A, Liu C T, Lu Z P, Bei H 2008 JOM 60 12

[26] Yamamoto Y, Takeyama M, Lu Z P, Liu C T, Evans N D, Maziasz P J, Brady M P 2008 Intermetallics 16 458

[27] 程晓农, 姚永泉, 李冬升, 罗锐, 郑琦, 唐桢丁 2017 金属热处理 42 75

Chen X N, Yao Y Q, Li D S, Luo R, Zheng Q, Tang Z D 2017 Heat Treat. Met. 42 75

[28] Hosemann P, Bai S, Bickel J, Qiu J 2021 JOM 73 4014

[29] Liu Y C, Chen S M, Ouyang F Y, Kai J J 2018 J. Nucl. Mater. 505 13

[30] Chen L Z, Tsisar V, Wang M, Schroer C, Zhou Z J 2021 Corros. Sci. 189 109591

Google Scholar

Google Scholar

[31] 陈灵芝 2021 博士学位论文 (北京: 北京科技大学)

Chen L Z 2021 Ph. D. Dissertation (Beijing: University of Science and Technology

[32] Wang M, Sun Y D, Feng J K , Zhang R Q, Tang R, Zhou Z J 2016 Int. J. Min. Met. Mater. 23 316

[33] 周德强 2014 博士学位论文 (北京: 北京科技大学)

Zhou D Q 2014 Ph. D. Dissertation (Beijing: University of Science and Technology

[34] Ejenstam J, Szakálos P 2015 J. Nucl. Mater. 461 164

Google Scholar

Google Scholar

[35] Muller G, Heinzel A, Konys J, Schumacher G, Weisenburger A, Zimmermann F, Engelko V, Rusanov A, Markov V 2002 J. Nucl. Mater. 301 42

[36] 熊静, 邓平, 高军, 赵永福 2022 科学技术创新 10 55

Xiong J, Deng P, Gao J, Zhao Y F 2022 Sci. Technol. Inno. 10 55

[37] 王军健, 李华鑫, 李红菊, 郑文健, 闾川阳, 马英鹤, 任森栋, 包士毅, 贺艳明, 杨建国 2023 强激光与粒子束 35 056001

Wang J J, Li H X, Li H J, Zheng W J, Lv C Y, Ma Y H, Ren S D, Bao S Y, He Y M, Yang J G 2023 High Power Laser Part. Beams 35 056001

[38] 吴欣强, 戎利建, 谭季波, 陈胜虎, 胡小锋, 张洋鹏, 张兹瑜 2023 金属学报 59 504

Wu X Q, Rong L J, Tan J B, Chen S H, Hu X F, Zhang Y P, Zhang Z Y 2023 Acta Metall. Sin. 59 504

[39] Bischoff J, Motta A T 2012 J. Nucl. Mater. 424 261

Google Scholar

Google Scholar

[40] Bischoff J, Motta A T, Eichfeld C, Comstock R J, Cao G P, Allen T R 2013 J. Nucl. Mater. 441 604

Google Scholar

Google Scholar

[41] Tan L, Ren X, Allen T R 2010 Corros. Sci. 52 1520

Google Scholar

Google Scholar

[42] 肖纪美, 曹楚南 2002 材料腐蚀学原理 (北京: 化学工业出版社) 第96—99页

Xiao J M, Cao C N 2002 Principles of Material Corrosion (Beijing: Chemical Industry Press) pp96–99

[43] Xu S, Long F, Persaud S Y, Guo N, Yao Z W, Daymond M R, Gao W H, Zhang L F, Zhou Z J 2020 Corros. Sci. 165 108380

Google Scholar

Google Scholar

[44] 刘培生 2003 稀有金属材料与工程 32 684

Liu P S 2023 Rare Metal Mat. Eng. 32 684

[45] Boggs W E 1971 J. Electrochem. Soc. 118 906

Google Scholar

Google Scholar

[46] 李美栓, 周延春 2005 腐蚀科学与防护技术 17 409

Li M S, Zhou Y C 2005 Corros. Sci. Prot. Technol. 17 409

[47] Stott F H, Wei F I, 1989 Oxid. Met. 31 386

[48] 李铁藩 2003 金属高温氧化和热腐蚀 (北京: 化学工业出版社) 第31—35页

Li T F 2003 High Temperature Oxidation and Hot Corrosion of Metals (Beijing: Chemical Industry Press) pp31–35

[49] Ellingham H J T 1944 J. Soc. Chem. Ind. 63 125

Google Scholar

Google Scholar

[50] 康新婷, 杨坤, 迟煜頔, 王建, 王辉, 李亚宁, 王建永 2012 稀有金属材料与工程 41 822

Kang X T, Yang K, Chi Y D, Wang J, Wang H, Li Y N, Wang J Y 2012 Rare Metal Mat. Eng. 41 822

计量

- 文章访问数: 4162

- PDF下载量: 86

- 被引次数: 0

下载:

下载: