-

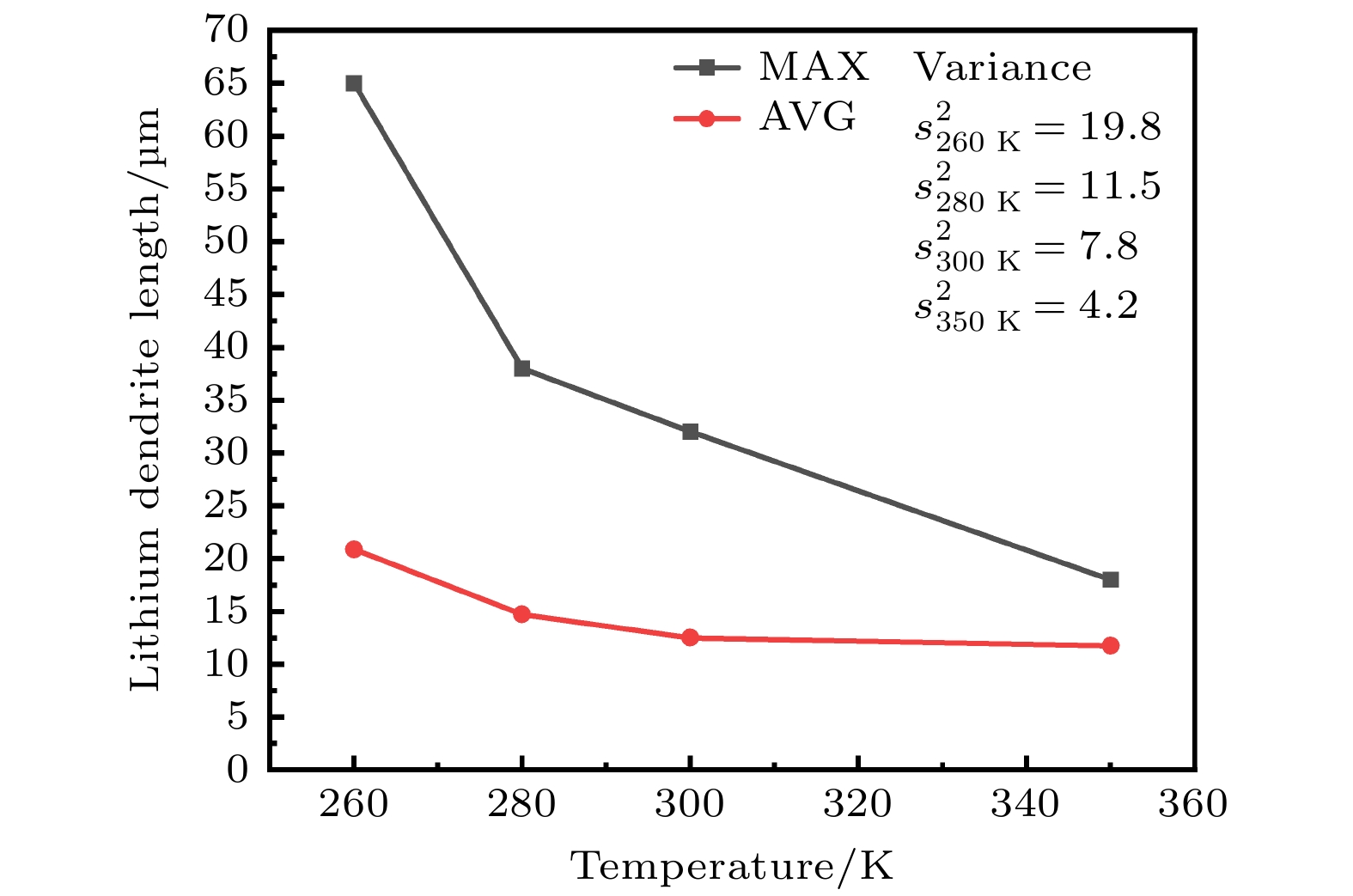

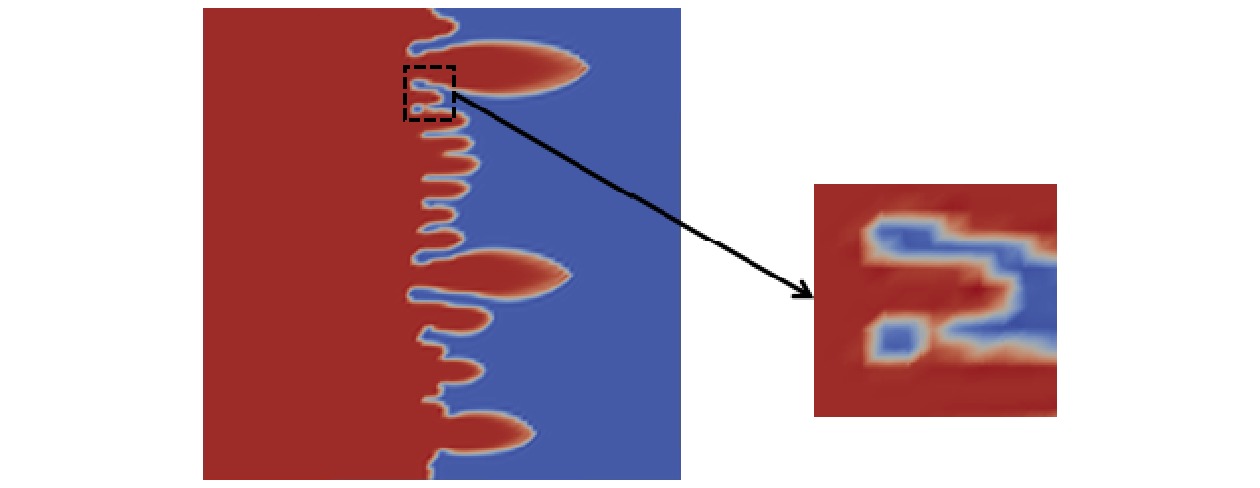

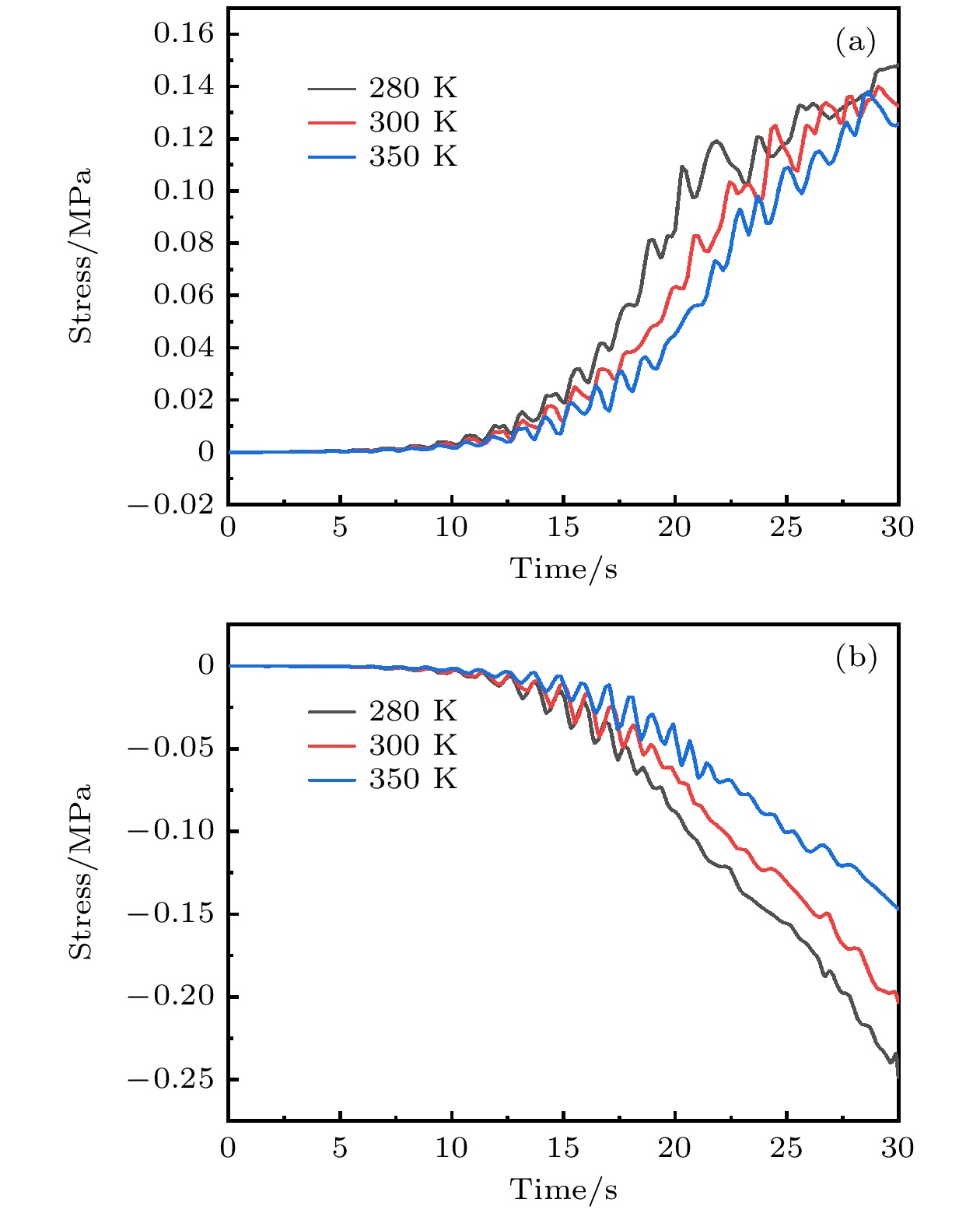

固态电池中的锂枝晶生长问题是困扰其进行商业化应用的重要因素, 锂枝晶在锂金属阳极界面的生长不仅会导致电池能量效率降低, 甚至会产生燃烧、爆炸等安全问题. 为了探究抑制锂枝晶生长的因素和方法, 本文针对聚合物固态电解质电池中锂枝晶的生长问题, 利用相场理论进行模拟研究, 建立了耦合机械应力和热力场的锂枝晶生长相场模型, 讨论分析了环境温度、固态电解质杨氏模量以及外应力等关键物理因素对枝晶生长的影响以及作用原理. 结果显示在高温、高固体电解质杨氏模量和外应力条件下锂枝晶生长缓慢, 长枝晶数量少, 电沉积较为均匀. 此外, 对比了常见范围内的固态电解质杨氏模量和环境温度对锂枝晶生长的影响, 发现固态电解质杨氏模量改变对于最大锂枝晶长度的抑制效果相对于改变环境温度要高出19%.Growth of lithium dendrites in solid state batteries is an important factor that disturbs their commercial applications. The growth of lithium dendrites at the interface of lithium metal anode will not only lead to the decrease of battery energy efficiency, but also cause combustion, explosion and other safety problems. In order to explore the factors and methods that inhibit the growth of lithium dendrites, the phase-field theory is used to simulate the growth of lithium dendrites in polymer solid electrolyte batteries, and a phase-field model of lithium dendrite growth coupled with mechanical stress and thermal field is established. The effects of key physical factors such as ambient temperature, solid electrolyte Young’s modulus and external stress on dendrite growth and their acting principles are discussed and analyzed. The results show that under the conditions of high temperature, high solid electrolyte Young’s modulus and external stress, the growth of lithium dendrites is slow, the number of long dendrites is small, and the electrodeposition is more uniform. In addition, the effects of Young’s modulus of solid electrolyte and ambient temperature on the growth of lithium dendrites in a common range are compared with each other. It is found that the inhibition effect of changing Young’s modulus of solid electrolyte on the maximum length of lithium dendrites is 19% higher than that caused by the change of ambient temperature.

-

Keywords:

- solid state battery /

- lithium dendrite /

- phase-field model /

- mechanical stress

[1] Krauskopf T, Dippel R, Hartmann H, Peppler K, Mogwitz B, Richter F H, Zeier W G, Janek J 2019 Joule 3 2030

Google Scholar

Google Scholar

[2] Steiger J, Kramer D, Mönig R 2014 Electrochim. Acta 136 529

Google Scholar

Google Scholar

[3] Porz L, Swamy T, Sheldon B W, Rettenwander D, Frömling T, Thaman H L, Berendts S, Uecker R, Carter W C, Chiang Y M 2017 Adv. Energy Mater. 7 1701003

Google Scholar

Google Scholar

[4] Li Y, Li Y, Pei A, Yan K, Sun Y, Wu C L, Joubert L M, Chin R, Koh A L, Yu Y, Perrino J, Butz B, Chu S, Cui Y 2017 Science 358 506

Google Scholar

Google Scholar

[5] Monroe C, Newman J 2003 J. Electrochem. Soc. 150 A1377

Google Scholar

Google Scholar

[6] Akolkar R 2013 J. Power Sources 232 23

Google Scholar

Google Scholar

[7] Hong Z, Viswanathan V 2018 ACS Energy Lett. 3 1737

Google Scholar

Google Scholar

[8] Chen L, Zhang H W, Liang L Y, Liu Z, Qi Y, Lu P, Chen J, Chen L Q 2015 J. Power Sources 300 376

Google Scholar

Google Scholar

[9] Ely D R, Jana A, García R E 2014 J. Power Sources 272 581

Google Scholar

Google Scholar

[10] Yurkiv V, Foroozan T, Ramasubramanian A, Shahbazian-Yassar R, Mashayek F 2018 Electrochim. Acta 265 609

Google Scholar

Google Scholar

[11] Yan H H, Bie Y H, Cui X Y, Xiong G P, Chen L 2018 Energy Convers. Manage. 161 193

Google Scholar

Google Scholar

[12] Jeon J, Yoon G H, Vegge T, Chang J H 2022 ACS Appl. Mater. Interfaces 14 15275

Google Scholar

Google Scholar

[13] 张更, 王巧, 沙立婷, 李亚捷, 王达, 施思齐 2020 69 226401

Google Scholar

Google Scholar

Zhang G, Wang Q, Sha L T, Li Y J, Wang D, Shi S Q 2020 Acta Phys. Sin. 69 226401

Google Scholar

Google Scholar

[14] Hong Z, Ahmad Z, Viswanathan V 2020 ACS Energy Lett. 5 2466

Google Scholar

Google Scholar

[15] Hong Z, Viswanathan V 2019 ACS Energy Lett. 4 1012

Google Scholar

Google Scholar

[16] Zhang J, Liu Y P, Wang C G, Tan H F 2021 J. Electrochem. Soc. 168 090522

Google Scholar

Google Scholar

[17] Ren Y, Zhou Y, Cao Y 2020 J. Phys. Chem. C 124 12195

Google Scholar

Google Scholar

[18] Lee J, Howell T, Rottmayer M, Boeckl J, Huang H 2019 J. Electrochem. Soc. 166 A416

Google Scholar

Google Scholar

[19] Bryden T S, Dimitrov B, Hilton G, Bugryniec P, Brown S, Cumming D, Cruden A 2018 J. Power Sources 395 369

Google Scholar

Google Scholar

[20] Li L, Basu S, Wang Y, Chen Z Z, Hundekar P, Wang B W, Shi J, Shi Y F, Narayanan, S, Koratkar N 2018 Science 359 1513

Google Scholar

Google Scholar

[21] Ichikawa K, Nozaki H, Komazawa N, Tachibana A 2012 AIP Adv. 2 042195

Google Scholar

Google Scholar

[22] Love C T, Baturina O A, Swider-Lyons K E 2015 ECS Electrochem. Lett. 4 A24

Google Scholar

Google Scholar

-

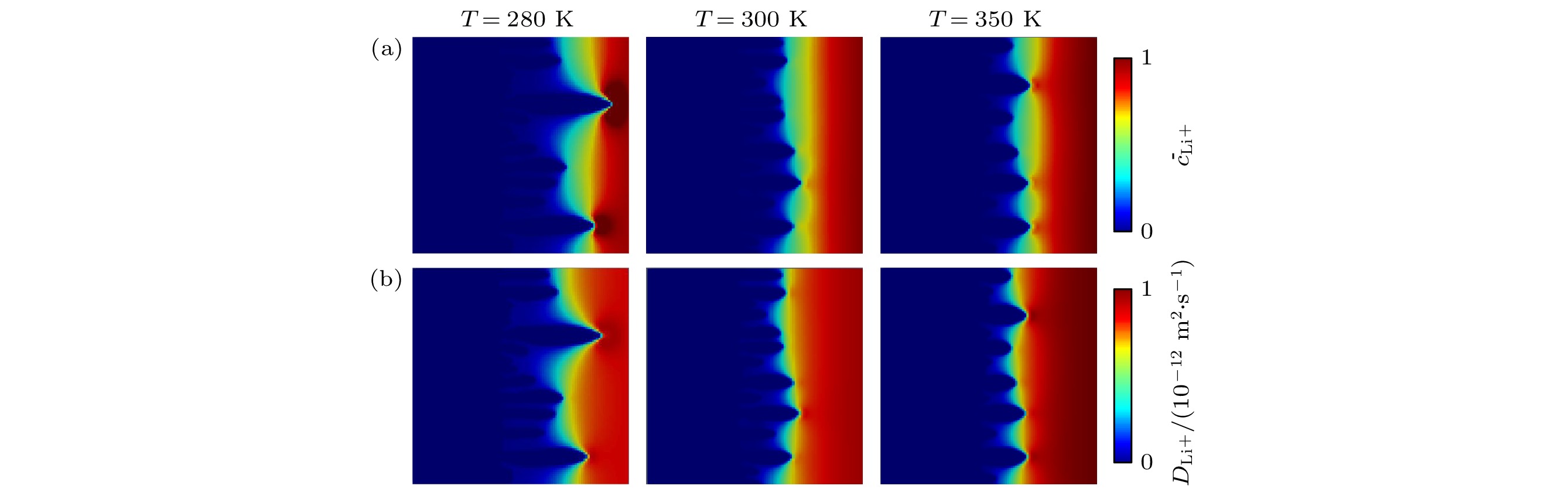

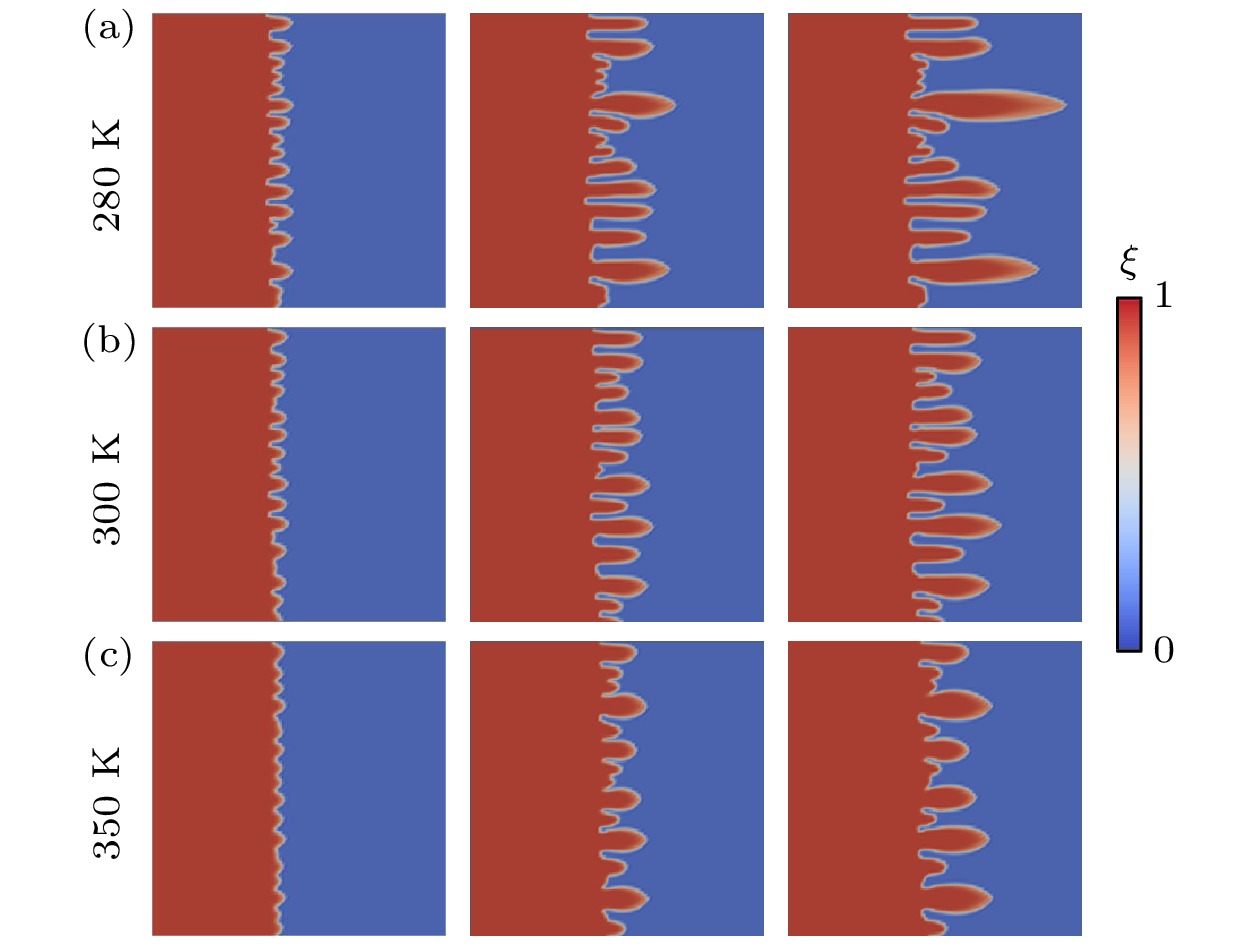

图 4 不同环境温度同一时刻机械-热耦合模型锂枝晶生长模型 (a) 锂枝晶生长形貌; (b) 锂离子浓度分布; (c) 锂枝晶X轴方向机械应力分布

Fig. 4. Lithium dendrite growth model with different environmental temperatures and same time mechanical thermal coupling model: (a) Growth morphology of lithium dendrite; (b) lithium ion concentration distribution; (c) mechanical stress distribution in the X-axis direction of lithium dendrite.

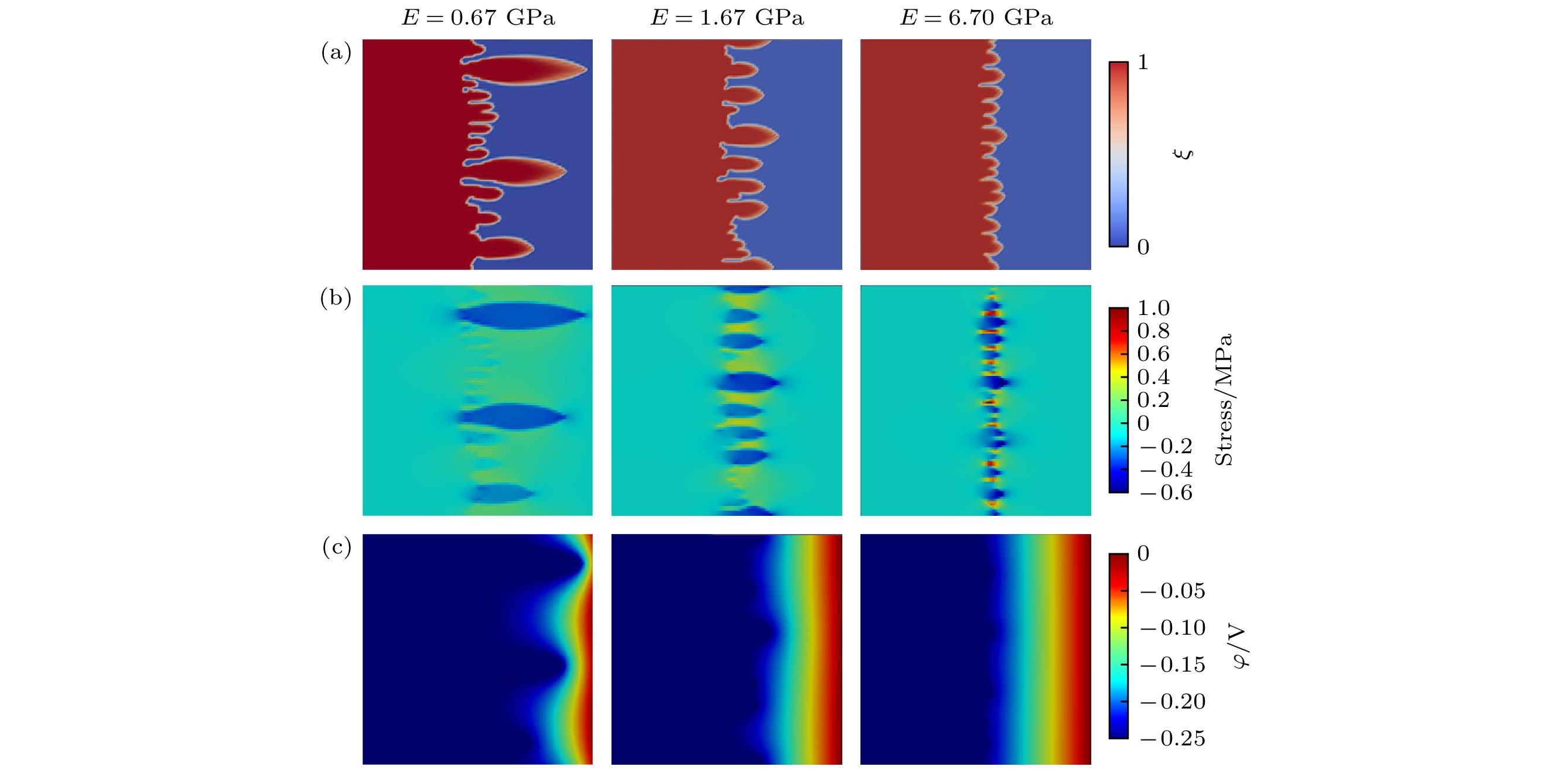

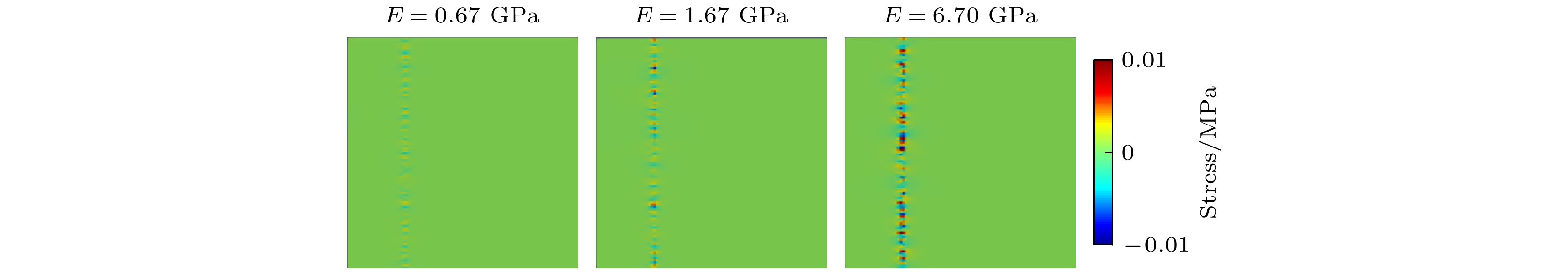

图 8 不同杨氏模量聚合物固态电解质中锂枝晶模型 (a) 锂枝晶生长形貌; (b) 锂枝晶X方向机械应力分布; (c) 锂枝晶所在电场电压分布

Fig. 8. Lithium dendrite model in solid polymer electrolytes with different Young’s modulus: (a) Morphology of lithium dendrite growth; (b) mechanical stress distribution in X direction of lithium dendrite; (c) electric field and voltage distribution of lithium dendrite.

表 1 相场模拟参数

Table 1. Phase field simulation parameters.

参数名称 值 文献 界面迁移率${L_\sigma}$/(10–6 m3·J–1·s–1) 2.5 [7] 动力学系数$ {L_\eta } $/s–1 0.1 [15] 梯度能量系数$ {\kappa _0} $/(10–5 J·m–1) 1.5 [16] 锂离子标准扩散系数$ {D_0}$/(10–12 m2·s–1) 2.5 [17] 电极的电导率$ {\sigma _{\rm{s}}} $/(107 S·m–1) 1.0 [8] 电解质的电导率$ {\sigma _{{\mathrm{l}}}} $/(10–2 S·m–1) 3.5 [18] 电荷转移数$ \alpha $ 0.5 [8] 对流换热系数h /(W·m–2·K–1) 10 [11] 热辐射系数$ {\varepsilon _{\text{R}}} $ 0.49 [11] 电极比热容$ {C_{{\text{ps}}}} $/(J·g–1·K–1) 3.55 [19] 电解质比热容$ {C_{{\text{pl}}}} $/(J·g–1·K–1) 1.76 [18] 电极导热系数$ {\kappa ^{\mathrm{s}}} $/(W·m–1·K–1) 84.8 [20] 电解质导热系数$ {\kappa ^{\mathrm{l}}} $/(W·m–1·K–1) 0.45 [18] 电极杨氏模量$ {E^{\mathrm{s}}} $/GPa 4.9 [21] 聚合物电解质杨氏模量$ {E^{\mathrm{l}}} $/GPa 0.07 [18] 纳米填料杨氏模量$ {E^{\mathrm{f}}} $/GPa 300 [17] 泊松比$ \upsilon $ 0.36 [10] -

[1] Krauskopf T, Dippel R, Hartmann H, Peppler K, Mogwitz B, Richter F H, Zeier W G, Janek J 2019 Joule 3 2030

Google Scholar

Google Scholar

[2] Steiger J, Kramer D, Mönig R 2014 Electrochim. Acta 136 529

Google Scholar

Google Scholar

[3] Porz L, Swamy T, Sheldon B W, Rettenwander D, Frömling T, Thaman H L, Berendts S, Uecker R, Carter W C, Chiang Y M 2017 Adv. Energy Mater. 7 1701003

Google Scholar

Google Scholar

[4] Li Y, Li Y, Pei A, Yan K, Sun Y, Wu C L, Joubert L M, Chin R, Koh A L, Yu Y, Perrino J, Butz B, Chu S, Cui Y 2017 Science 358 506

Google Scholar

Google Scholar

[5] Monroe C, Newman J 2003 J. Electrochem. Soc. 150 A1377

Google Scholar

Google Scholar

[6] Akolkar R 2013 J. Power Sources 232 23

Google Scholar

Google Scholar

[7] Hong Z, Viswanathan V 2018 ACS Energy Lett. 3 1737

Google Scholar

Google Scholar

[8] Chen L, Zhang H W, Liang L Y, Liu Z, Qi Y, Lu P, Chen J, Chen L Q 2015 J. Power Sources 300 376

Google Scholar

Google Scholar

[9] Ely D R, Jana A, García R E 2014 J. Power Sources 272 581

Google Scholar

Google Scholar

[10] Yurkiv V, Foroozan T, Ramasubramanian A, Shahbazian-Yassar R, Mashayek F 2018 Electrochim. Acta 265 609

Google Scholar

Google Scholar

[11] Yan H H, Bie Y H, Cui X Y, Xiong G P, Chen L 2018 Energy Convers. Manage. 161 193

Google Scholar

Google Scholar

[12] Jeon J, Yoon G H, Vegge T, Chang J H 2022 ACS Appl. Mater. Interfaces 14 15275

Google Scholar

Google Scholar

[13] 张更, 王巧, 沙立婷, 李亚捷, 王达, 施思齐 2020 69 226401

Google Scholar

Google Scholar

Zhang G, Wang Q, Sha L T, Li Y J, Wang D, Shi S Q 2020 Acta Phys. Sin. 69 226401

Google Scholar

Google Scholar

[14] Hong Z, Ahmad Z, Viswanathan V 2020 ACS Energy Lett. 5 2466

Google Scholar

Google Scholar

[15] Hong Z, Viswanathan V 2019 ACS Energy Lett. 4 1012

Google Scholar

Google Scholar

[16] Zhang J, Liu Y P, Wang C G, Tan H F 2021 J. Electrochem. Soc. 168 090522

Google Scholar

Google Scholar

[17] Ren Y, Zhou Y, Cao Y 2020 J. Phys. Chem. C 124 12195

Google Scholar

Google Scholar

[18] Lee J, Howell T, Rottmayer M, Boeckl J, Huang H 2019 J. Electrochem. Soc. 166 A416

Google Scholar

Google Scholar

[19] Bryden T S, Dimitrov B, Hilton G, Bugryniec P, Brown S, Cumming D, Cruden A 2018 J. Power Sources 395 369

Google Scholar

Google Scholar

[20] Li L, Basu S, Wang Y, Chen Z Z, Hundekar P, Wang B W, Shi J, Shi Y F, Narayanan, S, Koratkar N 2018 Science 359 1513

Google Scholar

Google Scholar

[21] Ichikawa K, Nozaki H, Komazawa N, Tachibana A 2012 AIP Adv. 2 042195

Google Scholar

Google Scholar

[22] Love C T, Baturina O A, Swider-Lyons K E 2015 ECS Electrochem. Lett. 4 A24

Google Scholar

Google Scholar

计量

- 文章访问数: 9773

- PDF下载量: 469

- 被引次数: 0

下载:

下载: