-

晶粒细化是提高Bi2Te3基热电材料力学性能的重要方法, 但晶粒细化过程中伴随的类施主效应严重劣化了材料的热电性能, 并且一旦产生类施主效应, 就很难通过简单的热处理等工艺消除. 本文系统研究n型Bi2Te3基化合物烧结前粉体颗粒尺寸对材料类施主效应和热电性能的影响规律. 随着颗粒尺寸减小, 氧诱导的类施主效应明显增强, 载流子浓度从10 M烧结样品的3.36×1019 cm–3急剧增加到120 M烧结样品的7.33×1019 cm–3, 严重偏离最佳载流子浓度2.51×1019 cm–3, 热电性能严重劣化. 当粉体颗粒尺寸为1—2 mm时, 烧结样品的Seebeck系数为–195 μV/K, 载流子浓度为3.36×1019 cm–3, 与区熔样品沿着ab面方向的Seebeck系数为–203 μV/K和载流子浓度为2.51×1019 cm–3相近, 未表现出明显的类施主效应, 可作为粉末冶金工艺的优质原料. 18 M烧结样品获得最大ZT值为0.75, 进一步增强织构有望获得优异的热电性能. 本研究为调控和有效抑制类施主效应的产生提供了新方法和途径, 为采用粉末冶金工艺制备具有优异热电性能和力学性能材料提供了重要指导.

-

关键词:

- Bi2Te3基化合物 /

- 颗粒尺寸 /

- 类施主效应 /

- 热电性能

Grain size refinement is the vital stratagem for improving mechanical properties of Bi2Te3-based thermoelectric material. However, the donor-like effect induced by grain size refinement seriously deteriorates the thermoelectric properties especially near room temperature. Once the donor-like effect is generated, it is very difficult to eliminate the donor-like effect by the simple heat treatment process and other processes. In this study, the influences of particle size on the donor-like effect and thermoelectric properties are systematically studied for Bi2Te3-based compounds. As the particle size decreases, the donor-like effect is enhanced significantly. The oxygen-induced donor-like effect dramatically increases the carrier concentration from 3.36× 1019 cm–3 for 10 M sintered sample to 7.33×1019 cm–3 for 120 M sintered sample, which is largely beyond the optimal carrier concentration of 2.51×1019 cm–3 and seriously deteriorates the thermoelectric properties. However, when the particle size of the powder is 1–2 mm, the Seebeck coefficient of –195 μV/K and the carrier concentration of 3.36×1019 cm–3 near room temperature are achieved, which are similar to those of the ZM sample with the Seebeck coefficient of –203 μV/K and the carrier concentration of 2.51×1019 cm–3. The powders without the obvious donor-like effect can be used as the excellent raw material for powder metallurgy process. A maximum ZT value of 0.75 is achieved for the 18 M sintered sample. The excellent thermoelectric properties are expected to be obtained by enhancing the texture further. This study provides a new way to regulate and effectively suppress the generation of the donor-like effect, and provides an important guidance for the preparation of materials with excellent thermoelectric and mechanical properties by powder metallurgy process.-

Keywords:

- Bi2Te3-based compound /

- particle size /

- donor-like effect /

- thermoelectric properties

[1] Wang Y, Liu W D, Shi X L, Hong M, Wang L J, Li M, Wang H, Zou J, Chen Z G 2020 Chem. Eng. J. 391 123513

Google Scholar

Google Scholar

[2] Deng R G, Su X L, Zheng Z, Liu W, Yan Y G, Zhang Q, Dravid V P, Uher C, Kanatzidis M G, Tang X F 2018 Sci. Adv. 4 5606

Google Scholar

Google Scholar

[3] Liu W S, Zhang Q, Lan Y, Chen S, Yan X, Zhang Q, Wang H, Wang D, Chen G, Ren Z 2011 Adv. Energy Mater. 1 577

Google Scholar

Google Scholar

[4] Sun M, Tang G W, Wang H F, Zhang T, Zhang P Y, Han B, Yang M, Zhang H, Chen Y C, Chen J, Chen D D, Gan J L, Qian Q, Yang Z M 2022 Adv. Mater. 34 2202942

Google Scholar

Google Scholar

[5] Hu L P, Zhu T J, Liu X H, Zhao X B 2014 Adv. Funct. Mater. 24 5211

Google Scholar

Google Scholar

[6] Tao Q R, Deng R G, Li J, Yan Y G, Su X L, Poudeu P F P, Tang X F 2020 ACS Appl. Mater. Interfaces 12 26330

Google Scholar

Google Scholar

[7] Hu L P, Wu H J, Zhu T J, Fu C G, He J Q, Ying P J, Zhao X B 2015 Adv. Energy Mater. 5 1500411

Google Scholar

Google Scholar

[8] Zhao L D, Zhang B P, Li J F, Zhang H L, Liu W S 2008 Solid State Sci. 10 651

Google Scholar

Google Scholar

[9] Liu Y, Zhang Y, Lim K H, Ibáñez M, Ortega S, Li M, David J, Martí-Sánchez S, Ng K M, Arbiol J, Kovalenko M V, Cadavid D, Cabot A 2018 ACS Nano 12 7174

Google Scholar

Google Scholar

[10] Jariwala B, Shah D V 2011 J. Cryst. Growth 318 1179

Google Scholar

Google Scholar

[11] Tang X F, Li Z W, Liu W, Zhang Q J, Uher C 2022 Inter. Mater. 1 88

Google Scholar

Google Scholar

[12] Tao Q R, Wu H J, Pan W F, Zhang Z K, Tang Y F, Wu Y T, Fan Y J, Chen Z Q, Wu J S, Su X L, Tang X F 2021 ACS Appl. Mater. Interfaces 13 60216

Google Scholar

Google Scholar

[13] Zheng Y, Zhang Q, Su X L, Xie H, Shu S, Chen T, Tan G J, Yan Y G, Tang X F, Uher C, Snyder G J 2015 Adv. Energy Mater. 5 1401391

Google Scholar

Google Scholar

[14] Zheng G, Su X L, Liang T, Lu Q B, Yan Y G, Uher C, Tang X F 2015 J. Mater. Chem. A 3 6603

Google Scholar

Google Scholar

[15] Lavrentev M G, Osvenskii V B, Parkhomenko Y N, Pivovarov G I, Sorokin A I, Bulat L P, Kim H S, Witting I T, Snyder G J, Bublik V T, Tabachkova N Y 2016 APL Mater. 4 104807

Google Scholar

Google Scholar

[16] Chen B, Li J Q, Wu M N, Hu L P, Liu F S, Ao W Q, Li Y, Xie H P, Zhang C H 2019 ACS Appl. Mater. Interfaces 11 45746

Google Scholar

Google Scholar

[17] Zhang C, Geng X, Chen B, Li J, Meledin A, Hu L, Liu F, Shi J, Mayer J, Wuttig M, Cojocaru-Mirédin O, Yu Y 2021 Small 17 2104067

Google Scholar

Google Scholar

[18] Deng R G, Su X L, Hao S, Zheng Z, Zhang M, Xie H Y, Liu W, Yan Y G, Wolverton C, Uher C, Kanatzidis M G, Tang X F 2018 Energy Environ. Sci 11 1520

Google Scholar

Google Scholar

[19] Tao Q R, Meng F C, Zhang Z K, Cao Y, Tang Y F, Zhao J G, Su X L, Uher C, Tang X F 2021 Mater. Today Phys. 20 100472

Google Scholar

Google Scholar

[20] 訾鹏, 白辉, 汪聪, 武煜天, 任培安, 陶奇睿, 吴劲松, 苏贤礼, 唐新峰 2022 71 117101

Google Scholar

Google Scholar

Zi P, Bai H, Wang C, Wu Y T, Ren P A, Tao Q R, Wu J S, Su X L, Tang X F 2022 Acta Phys. Sin. 71 117101

Google Scholar

Google Scholar

[21] 杨枭, 苏贤礼, 鄢永高, 唐新峰 2021 无机材料学报 36 75

Google Scholar

Google Scholar

Yang X, Su X L, Yan Y G, Tang X F 2021 J. Inorg. Mater. 36 75

Google Scholar

Google Scholar

[22] Zhang Z K, Tao Q R, Bai H, Tang H, Cao Y, Shi Y X, Wu J S, Su X L, Tang X F 2021 J. Eur. Ceram. Soc. 41 7703

Google Scholar

Google Scholar

[23] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[24] Du B S, Lai X F, Liu Q L, Liu H T, Wu J, Liu J, Zhang Z H, Pei Y Z, Zhao H Z, Jian J K 2019 ACS Appl. Mater. Interfaces 11 31816

Google Scholar

Google Scholar

[25] Su X L, Wei P, Li H, Liu W, Yan Y G, Li P, Su C Q, Xie C J, Zhao W Y, Zhai P C, Zhang Q J, Tang X F, Uher C 2017 Adv. Mater. 29 23

Google Scholar

Google Scholar

[26] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, Wang B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[27] 杨东旺, 罗婷婷, 苏贤礼, 吴劲松, 唐新峰 2021 无机材料学报 36 991

Google Scholar

Google Scholar

Yang D W, Luo T T, Su X L, Wu J S, Tang X F 2021 J. Inorg. Mater. 36 991

Google Scholar

Google Scholar

[28] Zhao L D, Hao S, Lo S H, Wu C I, Zhou X, Lee Y, Li H, Biswas K, Hogan T P, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2013 J. Am. Chem. Soc 135 7364

Google Scholar

Google Scholar

[29] Li J F, Liu W S, Zhao L D, Zhou M 2010 NPG Asia Mater. 2 152

Google Scholar

Google Scholar

[30] Cao Y Q, Zhao X B, Zhu T J, Zhang X B, Tu J P 2008 Appl. Phys. Lett. 92 143106

Google Scholar

Google Scholar

[31] Zhu T J, Hu L P, Zhao X B, He J 2016 Adv. Sci. 3 1600004

Google Scholar

Google Scholar

[32] Hu L P, Liu X H, Xie H H, Shen J J, Zhu T J, Zhao X B 2012 Acta Mater. 60 4431

Google Scholar

Google Scholar

[33] Zhang C, Fan X A, Hu J, Jiang C, Xiang Q, Li G, Li Y, He Z 2017 Adv. Eng. Mater. 19 1600696

Google Scholar

Google Scholar

[34] Zhang Q, Gu B C, Wu Y H, Zhu T J, Fang T, Yang Y X, Liu J D, Ye B J, Zhao X B 2019 ACS Appl. Mater. Interfaces 11 41424

Google Scholar

Google Scholar

[35] Liu X S, Xing T, Qiu P F, Deng T T, Li P, Li X W, Li X Y, Shi X 2023 J. Materiomics 9 345

Google Scholar

Google Scholar

[36] Lin S S, Liao C N 2011 J. Appl. Phys 110 093707

Google Scholar

Google Scholar

[37] Wang Y C, Shi Y G, Mei D Q, Chen Z C 2017 Appl. Energy 205 710

Google Scholar

Google Scholar

[38] Qin B, Wang D, Liu X, Qin Y, Dong J F, Luo J, Li J W, Liu W, Tan G J, Tang X F, Li J F, He J, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[39] Ma S F, Li C C, Wei P, Zhu W T, Nie X L, Sang X H, Zhang Q J, Zhao W Y 2020 J. Mater. Chem. A 8 4816

Google Scholar

Google Scholar

[40] Wu Y H, Yu Y, Zhang Q, Zhu T J, Zhai R S, Zhao X B 2019 Adv. Sci. 6 1901702

Google Scholar

Google Scholar

[41] Zhu B, Liu X X, Wang Q, Qiu Y, Shu Z, Guo Z T, Tong Y, Cui J, Gu M, He J Q 2020 Energy Environ. Sci. 13 2106

Google Scholar

Google Scholar

[42] 任培安, 汪聪, 訾鹏, 陶奇睿, 苏贤礼, 唐新峰 2022 无机材料学报 37 1079

Google Scholar

Google Scholar

Ren P A, Wang C, Zi P, Tao Q R, Su X L, Tang X F 2022 J. Inorg. Mater. 37 1079

Google Scholar

Google Scholar

[43] 胡威威, 孙进昌, 张玗, 龚悦, 范玉婷, 唐新峰, 谭刚健 2022 71 047101

Google Scholar

Google Scholar

Hu W W, Sun J C, Zhang Y, Gong Y, Fan Y T, Tang X F, Tan G J 2022 Acta Phys. Sin. 71 047101

Google Scholar

Google Scholar

-

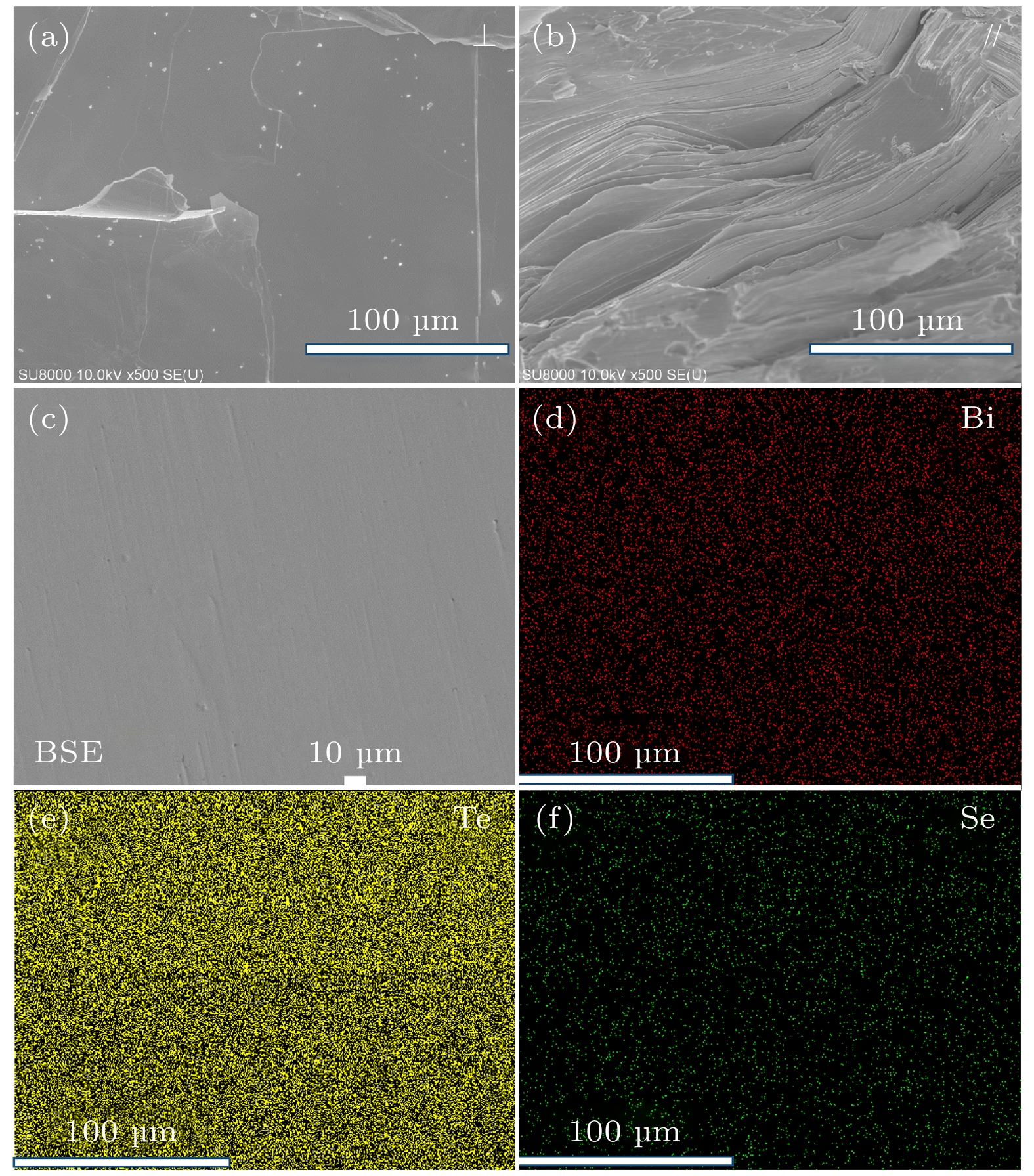

图 2 (a), (b) 10 M样品沿着垂直和平行于烧结压力方向断裂截面的场发射扫描电子显微镜图像(FESEM); (c) 10 M样品抛光表面的背散射电子图像; (d)—(f) 图(c)中Bi-Te-Se元素的能谱面扫描图(EDS-Map)

Fig. 2. (a), (b) Field emission scanning electron microscope images of fractured surfaces of the 10 M sample measured perpendicular to and parallel to the pressing direction; (c) backscattered electron images of polished surfaces of the 10 M sample; (d)–(f) EDS elemental mapping of Bi, Te, and Se of Fig. 2 (c).

图 3 区熔锭体沿ab面方向和Bi2Te2.79Se0.21烧结样品沿着(a), (c), (e)垂直和(b), (d), (f)平行于压力方向的电输运性能与温度的关系曲线 (a), (b) 电导率; (c), (d) Seebeck系数; (e), (f) 功率因子

Fig. 3. Temperature dependence of (a), (b) the electrical conductivity, (c), (d) Seebeck coefficient, and (e), (f) power factor for the zone melt (ZM) sample measured along the ab-plane and Bi2Te2.79Se0.21 sintered samples measured (a), (c), (e) perpendicular to and (b), (d), (f) parallel to the pressing direction, respectively.

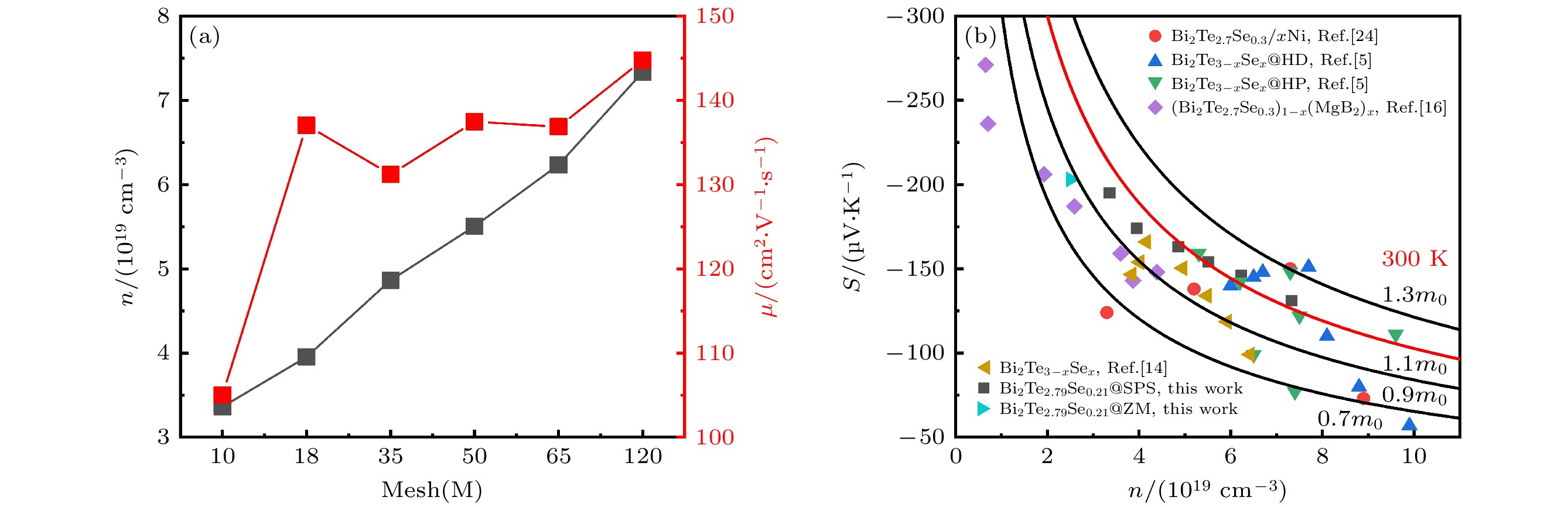

图 4 室温下Bi2Te2.79Se0.21烧结样品沿垂直于烧结压力方向的性质 (a)载流子浓度n和迁移率μ与颗粒尺寸的关系; (b)样品Seebeck系数与载流子浓度的关系曲线, 以及单抛带模型计算载流子有效质量

Fig. 4. Properties for Bi2Te2.79Se0.21 sintered samples measured perpendicular to the pressing direction at room temperature: (a) The relationship of carrier concentration n and carrier mobility μ to the size of powder; (b) Seebeck coefficients as a function of the charge carrier concentration, where the solid lines are Pisarenko plots based on the single parabolic band model.

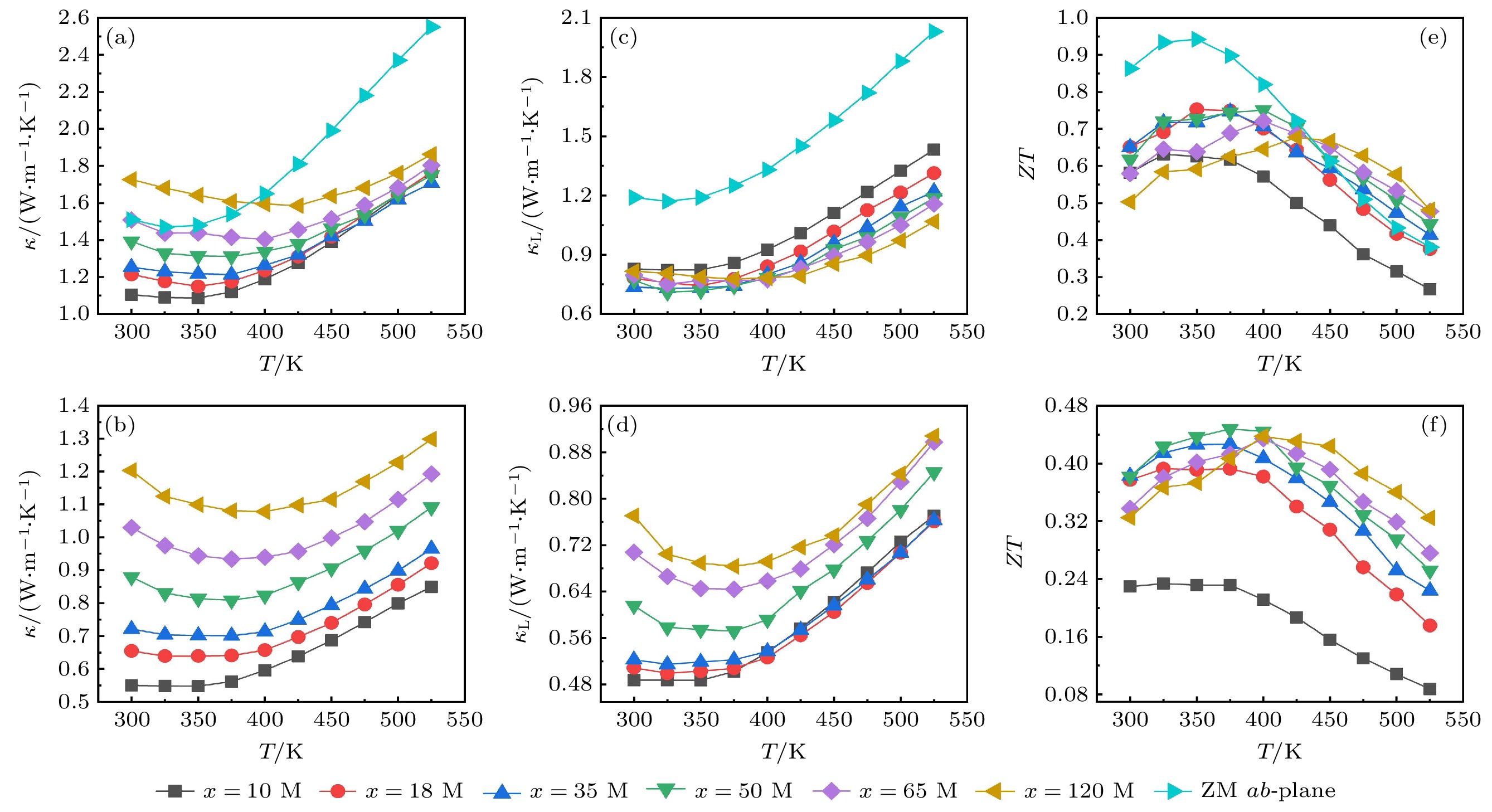

图 5 区熔锭体沿着ab面方向和Bi2Te2.79Se0.21烧结样品沿着(a), (c), (e)垂直和(b), (d), (f)平行于烧结压力方向的热输运性能和热电优值与温度的关系曲线 (a), (b) 总热导率; (c), (d) 晶格热导率; (e), (f) 无量纲热电优值ZT

Fig. 5. Temperature dependence of (a), (b) total thermal conductivity, (c), (d) lattice thermal conductivity, and (e), (f) dimensionless thermoelectric figure of merit ZT value for the ZM sample measured along the ab-plane and Bi2Te2.79Se0.21 sintered samples measured (a), (c), (e) perpendicular to and (b), (d), (f) parallel to the pressing direction, respectively.

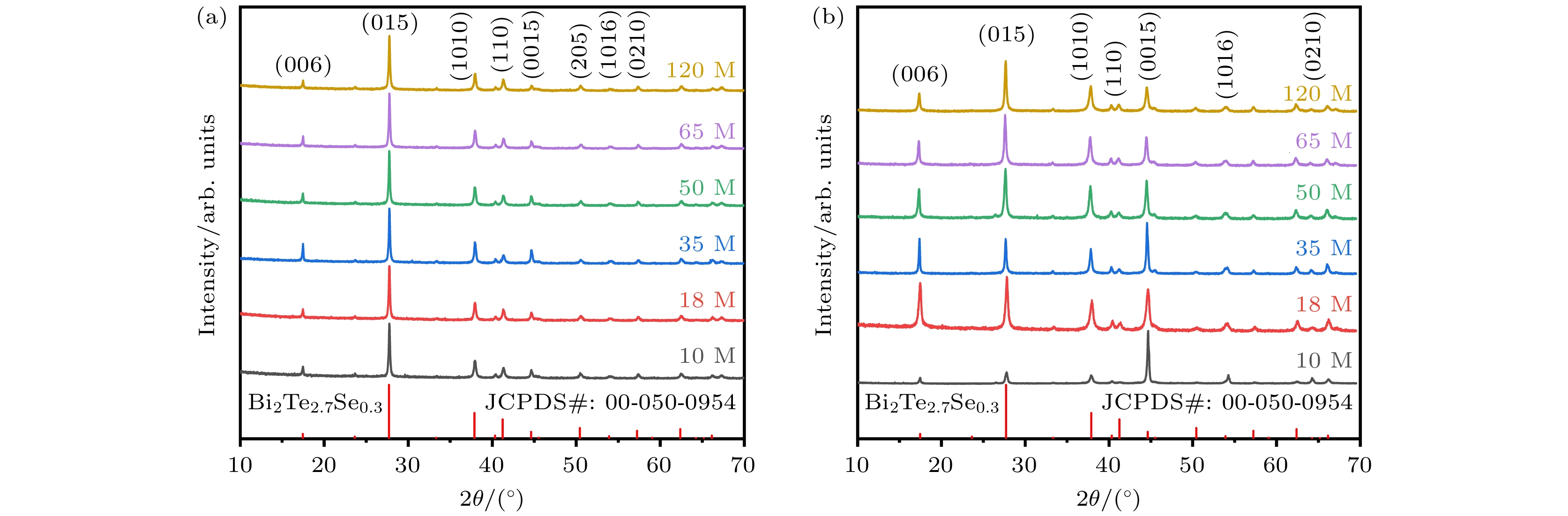

表 1 烧结块体样品垂直于压力方向的取向因子、密度和致密度

Table 1. Orientation factor F value, density, and relative density of sintered bulk samples perpendicular to the pressing direction.

目数 10 M 18 M 35 M 50 M 65 M 120 M F(0 0 l) 0.43 0.36 0.39 0.30 0.25 0.20 密度 6.98 7.06 7.13 7.27 7.42 7.69 致密度/% 89.2 90.3 91.2 93.0 94.9 98.3 -

[1] Wang Y, Liu W D, Shi X L, Hong M, Wang L J, Li M, Wang H, Zou J, Chen Z G 2020 Chem. Eng. J. 391 123513

Google Scholar

Google Scholar

[2] Deng R G, Su X L, Zheng Z, Liu W, Yan Y G, Zhang Q, Dravid V P, Uher C, Kanatzidis M G, Tang X F 2018 Sci. Adv. 4 5606

Google Scholar

Google Scholar

[3] Liu W S, Zhang Q, Lan Y, Chen S, Yan X, Zhang Q, Wang H, Wang D, Chen G, Ren Z 2011 Adv. Energy Mater. 1 577

Google Scholar

Google Scholar

[4] Sun M, Tang G W, Wang H F, Zhang T, Zhang P Y, Han B, Yang M, Zhang H, Chen Y C, Chen J, Chen D D, Gan J L, Qian Q, Yang Z M 2022 Adv. Mater. 34 2202942

Google Scholar

Google Scholar

[5] Hu L P, Zhu T J, Liu X H, Zhao X B 2014 Adv. Funct. Mater. 24 5211

Google Scholar

Google Scholar

[6] Tao Q R, Deng R G, Li J, Yan Y G, Su X L, Poudeu P F P, Tang X F 2020 ACS Appl. Mater. Interfaces 12 26330

Google Scholar

Google Scholar

[7] Hu L P, Wu H J, Zhu T J, Fu C G, He J Q, Ying P J, Zhao X B 2015 Adv. Energy Mater. 5 1500411

Google Scholar

Google Scholar

[8] Zhao L D, Zhang B P, Li J F, Zhang H L, Liu W S 2008 Solid State Sci. 10 651

Google Scholar

Google Scholar

[9] Liu Y, Zhang Y, Lim K H, Ibáñez M, Ortega S, Li M, David J, Martí-Sánchez S, Ng K M, Arbiol J, Kovalenko M V, Cadavid D, Cabot A 2018 ACS Nano 12 7174

Google Scholar

Google Scholar

[10] Jariwala B, Shah D V 2011 J. Cryst. Growth 318 1179

Google Scholar

Google Scholar

[11] Tang X F, Li Z W, Liu W, Zhang Q J, Uher C 2022 Inter. Mater. 1 88

Google Scholar

Google Scholar

[12] Tao Q R, Wu H J, Pan W F, Zhang Z K, Tang Y F, Wu Y T, Fan Y J, Chen Z Q, Wu J S, Su X L, Tang X F 2021 ACS Appl. Mater. Interfaces 13 60216

Google Scholar

Google Scholar

[13] Zheng Y, Zhang Q, Su X L, Xie H, Shu S, Chen T, Tan G J, Yan Y G, Tang X F, Uher C, Snyder G J 2015 Adv. Energy Mater. 5 1401391

Google Scholar

Google Scholar

[14] Zheng G, Su X L, Liang T, Lu Q B, Yan Y G, Uher C, Tang X F 2015 J. Mater. Chem. A 3 6603

Google Scholar

Google Scholar

[15] Lavrentev M G, Osvenskii V B, Parkhomenko Y N, Pivovarov G I, Sorokin A I, Bulat L P, Kim H S, Witting I T, Snyder G J, Bublik V T, Tabachkova N Y 2016 APL Mater. 4 104807

Google Scholar

Google Scholar

[16] Chen B, Li J Q, Wu M N, Hu L P, Liu F S, Ao W Q, Li Y, Xie H P, Zhang C H 2019 ACS Appl. Mater. Interfaces 11 45746

Google Scholar

Google Scholar

[17] Zhang C, Geng X, Chen B, Li J, Meledin A, Hu L, Liu F, Shi J, Mayer J, Wuttig M, Cojocaru-Mirédin O, Yu Y 2021 Small 17 2104067

Google Scholar

Google Scholar

[18] Deng R G, Su X L, Hao S, Zheng Z, Zhang M, Xie H Y, Liu W, Yan Y G, Wolverton C, Uher C, Kanatzidis M G, Tang X F 2018 Energy Environ. Sci 11 1520

Google Scholar

Google Scholar

[19] Tao Q R, Meng F C, Zhang Z K, Cao Y, Tang Y F, Zhao J G, Su X L, Uher C, Tang X F 2021 Mater. Today Phys. 20 100472

Google Scholar

Google Scholar

[20] 訾鹏, 白辉, 汪聪, 武煜天, 任培安, 陶奇睿, 吴劲松, 苏贤礼, 唐新峰 2022 71 117101

Google Scholar

Google Scholar

Zi P, Bai H, Wang C, Wu Y T, Ren P A, Tao Q R, Wu J S, Su X L, Tang X F 2022 Acta Phys. Sin. 71 117101

Google Scholar

Google Scholar

[21] 杨枭, 苏贤礼, 鄢永高, 唐新峰 2021 无机材料学报 36 75

Google Scholar

Google Scholar

Yang X, Su X L, Yan Y G, Tang X F 2021 J. Inorg. Mater. 36 75

Google Scholar

Google Scholar

[22] Zhang Z K, Tao Q R, Bai H, Tang H, Cao Y, Shi Y X, Wu J S, Su X L, Tang X F 2021 J. Eur. Ceram. Soc. 41 7703

Google Scholar

Google Scholar

[23] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[24] Du B S, Lai X F, Liu Q L, Liu H T, Wu J, Liu J, Zhang Z H, Pei Y Z, Zhao H Z, Jian J K 2019 ACS Appl. Mater. Interfaces 11 31816

Google Scholar

Google Scholar

[25] Su X L, Wei P, Li H, Liu W, Yan Y G, Li P, Su C Q, Xie C J, Zhao W Y, Zhai P C, Zhang Q J, Tang X F, Uher C 2017 Adv. Mater. 29 23

Google Scholar

Google Scholar

[26] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, Wang B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[27] 杨东旺, 罗婷婷, 苏贤礼, 吴劲松, 唐新峰 2021 无机材料学报 36 991

Google Scholar

Google Scholar

Yang D W, Luo T T, Su X L, Wu J S, Tang X F 2021 J. Inorg. Mater. 36 991

Google Scholar

Google Scholar

[28] Zhao L D, Hao S, Lo S H, Wu C I, Zhou X, Lee Y, Li H, Biswas K, Hogan T P, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2013 J. Am. Chem. Soc 135 7364

Google Scholar

Google Scholar

[29] Li J F, Liu W S, Zhao L D, Zhou M 2010 NPG Asia Mater. 2 152

Google Scholar

Google Scholar

[30] Cao Y Q, Zhao X B, Zhu T J, Zhang X B, Tu J P 2008 Appl. Phys. Lett. 92 143106

Google Scholar

Google Scholar

[31] Zhu T J, Hu L P, Zhao X B, He J 2016 Adv. Sci. 3 1600004

Google Scholar

Google Scholar

[32] Hu L P, Liu X H, Xie H H, Shen J J, Zhu T J, Zhao X B 2012 Acta Mater. 60 4431

Google Scholar

Google Scholar

[33] Zhang C, Fan X A, Hu J, Jiang C, Xiang Q, Li G, Li Y, He Z 2017 Adv. Eng. Mater. 19 1600696

Google Scholar

Google Scholar

[34] Zhang Q, Gu B C, Wu Y H, Zhu T J, Fang T, Yang Y X, Liu J D, Ye B J, Zhao X B 2019 ACS Appl. Mater. Interfaces 11 41424

Google Scholar

Google Scholar

[35] Liu X S, Xing T, Qiu P F, Deng T T, Li P, Li X W, Li X Y, Shi X 2023 J. Materiomics 9 345

Google Scholar

Google Scholar

[36] Lin S S, Liao C N 2011 J. Appl. Phys 110 093707

Google Scholar

Google Scholar

[37] Wang Y C, Shi Y G, Mei D Q, Chen Z C 2017 Appl. Energy 205 710

Google Scholar

Google Scholar

[38] Qin B, Wang D, Liu X, Qin Y, Dong J F, Luo J, Li J W, Liu W, Tan G J, Tang X F, Li J F, He J, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[39] Ma S F, Li C C, Wei P, Zhu W T, Nie X L, Sang X H, Zhang Q J, Zhao W Y 2020 J. Mater. Chem. A 8 4816

Google Scholar

Google Scholar

[40] Wu Y H, Yu Y, Zhang Q, Zhu T J, Zhai R S, Zhao X B 2019 Adv. Sci. 6 1901702

Google Scholar

Google Scholar

[41] Zhu B, Liu X X, Wang Q, Qiu Y, Shu Z, Guo Z T, Tong Y, Cui J, Gu M, He J Q 2020 Energy Environ. Sci. 13 2106

Google Scholar

Google Scholar

[42] 任培安, 汪聪, 訾鹏, 陶奇睿, 苏贤礼, 唐新峰 2022 无机材料学报 37 1079

Google Scholar

Google Scholar

Ren P A, Wang C, Zi P, Tao Q R, Su X L, Tang X F 2022 J. Inorg. Mater. 37 1079

Google Scholar

Google Scholar

[43] 胡威威, 孙进昌, 张玗, 龚悦, 范玉婷, 唐新峰, 谭刚健 2022 71 047101

Google Scholar

Google Scholar

Hu W W, Sun J C, Zhang Y, Gong Y, Fan Y T, Tang X F, Tan G J 2022 Acta Phys. Sin. 71 047101

Google Scholar

Google Scholar

计量

- 文章访问数: 8055

- PDF下载量: 131

- 被引次数: 0

下载:

下载: