-

外加声场激励下固体细颗粒的声凝并在燃烧污染物超低排放中具有应用潜力, 添加大粒径液滴有望提高细颗粒声凝并效果. 本文从颗粒运动、碰撞、凝并与反弹的动力学过程出发, 基于直接模拟蒙特卡罗方法, 建立气相中液滴与固体颗粒共存的气-液-固三相体系的声凝并模型, 对外加液滴条件下固体细颗粒声凝并的过程和效果开展数值模拟. 将模拟结果与实验相对比, 验证模型可靠性. 在此基础上, 探究外加液滴条件下细颗粒声凝并动力学行为, 考察外加液滴直径和数目浓度对细颗粒声凝并效果的影响规律. 结果表明, 外加液滴条件下, 固体细颗粒迅速与大粒径液滴凝并, 形成液-固混合相颗粒, 细颗粒凝并效率显著提升. 外加液滴直径和数目浓度是影响细颗粒声凝并的重要因素, 随着直径的增大或数目浓度的提高, 细颗粒凝并效率增大, 而增幅趋于减小. 研究结果可为复杂颗粒系统凝并模型的建立提供理论基础, 并可为燃烧源细颗粒超低排放提供方法指导.Agglomeration of fine solid particles under the excitation of external acoustic field has potential applications in the field of ultra-low emission of combustion pollutants. It is expected that the performance of particle agglomeration can be improved by adding large sized liquid droplets. According to the dynamic process of acoustic agglomeration, including the particle motion, collision, agglomeration and rebound, a model of acoustic agglomeration for gas-liquid-solid three phase system with coexistence of liquid droplets and solid particles in gas phase is developed by using the direct simulation Monte Carlo (DSMC) method. Using this model, numerical simulations are performed to investigate the process and performance of acoustic agglomeration of fine solid particles under the effect of additional droplets. The numerical results are compared with experimental data, and the proposed model is validated. On this basis, the dynamic behaviors of acoustic agglomeration of fine particles in the case with additional droplets are explored. Furthermore, the influences of the diameter and number concentration of additional droplets on the performance of acoustic agglomeration of fine particles are examined. The results show that rapid agglomeration among the solid fine particles and additional droplets can be achieved by adding droplets into the acoustic field, yielding large sized liquid-solid mixed-phase particles. In this process, the agglomeration efficiency of fine particles increases significantly. It is also found that the diameter and number concentration of additional droplets are important factors that affect the acoustic agglomeration of fine particles. The agglomeration efficiency of fine particles rises, while the magnitude of increase tends to decrease with the droplet diameter and number concentration increasing. The research results can provide both theoretical basis for modeling the agglomeration process of complex particle systems and method guidance for achieving the ultra-low emission of fine particles from combustion sources.

-

Keywords:

- fine particles /

- acoustic agglomeration /

- additional droplets /

- numerical simulation

[1] Zhou D, Luo Z, Jiang J, Chen H, Lu M, Fang M 2016 Powder Technol. 289 52

Google Scholar

Google Scholar

[2] Shang X P, Ng B F, Wan M P, Xiong J W, Arikrishnan S 2018 Aerosol Sci. Technol. 52 872

Google Scholar

Google Scholar

[3] Zhang G X, Ma Z F, Shen J, Zhang K, Wang J Q, Chi Z H 2020 J. Hazard. Maters. 382 121089

Google Scholar

Google Scholar

[4] 屈广宁, 凡凤仙, 张斯宏, 苏明旭 2020 69 064704

Google Scholar

Google Scholar

Qu G N, Fan F X, Zhang S H, Su M X 2020 Acta Phys. Sin. 69 064704

Google Scholar

Google Scholar

[5] Wu Z H, Fan F X, Yan J P, Chen H T, Hu X H, Su M X 2022 Chem. Eng. Sci. 249 117298

Google Scholar

Google Scholar

[6] Liu J Z, Zhang G X, Zhou J H, Zhao W D, Cen K F 2009 Powder Technol. 193 20

Google Scholar

Google Scholar

[7] Fan F X, Zhang M J, Peng Z B, Chen J, Su M X, Moghtaderi B, Doroodchi E 2017 Aerosol Air Qual. Res. 17 1073

Google Scholar

Google Scholar

[8] Yan J P, Chen L Q, Li Z 2016 Fuel. 165 316

Google Scholar

Google Scholar

[9] Zhang G X, Zhang L L, Wang J, Hu E 2017 Powder Technol. 317 181

Google Scholar

Google Scholar

[10] Wang J, Liu J Z, Zhang G X, Zhou J H, Cen K F 2011 Powder Technol. 210 315

Google Scholar

Google Scholar

[11] Yang N N, Fan F X, Hu X H, Su M X 2022 J. Aerosol Sci. 165 106018

Google Scholar

Google Scholar

[12] Yan J P, Chen L Q, Lin Q 2017 Powder Technol. 315 106

Google Scholar

Google Scholar

[13] Chen H, Wang T, Luo Z Y, Zhou D, Lu M S, He M C, Fang M X, Cen K F 2017 Aerosol Air Qual. Res. 17 857

Google Scholar

Google Scholar

[14] Yan J P, Lin Q, Zhao S H, Chen L Q 2018 Powder Technol. 340 8

Google Scholar

Google Scholar

[15] Zhang G X, Wang J Q, Chi Z H, Hu E 2018 Chem. Eng. Sci. 187 342

Google Scholar

Google Scholar

[16] Shang X P, Wan M P, Ng B F, Ding S R 2020 Powder Technol. 362 111

Google Scholar

Google Scholar

[17] Crowe C T, Schwarzkopf J D, Scommerfeld M, Tsuij Y 2012 Multiphase Flows with Droplets and Particles (2nd Ed.) (New York: CRC Press) pp119–137

[18] Higashitani K, Makino H, Matsusaka S 2020 Powder Technology Handbook (4th Ed.) (New York: CRC Press) p60

[19] Tsuji Y, Tanaka T, Yonemura S 1998 Powder Technol. 95 254

Google Scholar

Google Scholar

[20] Zhang G X, Liu J Z, Wang J, Zhou J H, Cen K F 2012 Chin. Sci. Bull. 57 2404

Google Scholar

Google Scholar

[21] Song L 1990 Ph. D. Dissertation (State College: Pennsylvania State University)

[22] Sgrott O L, Sommerfeld M 2019 Can. J. Chem. Eng. 97 511

[23] Ennis B J 1991 Powder Technol. 65 257

Google Scholar

Google Scholar

[24] He Y X, Zhao H B 2016 Int. J. Multiphase Flow. 83 12

Google Scholar

Google Scholar

[25] Kleinhans U, Wieland C, Frandsen F J, Spliethoff H 2018 Prog. Energy Combust. Sci. 68 65

Google Scholar

Google Scholar

-

图 1 碰撞颗粒对类型 (a) 固体颗粒与固体颗粒; (b) 固体颗粒与液滴; (c) 固体颗粒与混合相颗粒; (d) 液滴与液滴; (e) 液滴与混合相颗粒; (f) 混合相颗粒与混合相颗粒

Fig. 1. Types of collision particle pair: (a) Solid particle and solid particle; (b) solid particle and droplet; (c) solid particle and mixed-phase particle; (d) droplet and droplet; (e) droplet and mixed-phase particle; (f) mixed-phase particle and mixed-phase particle.

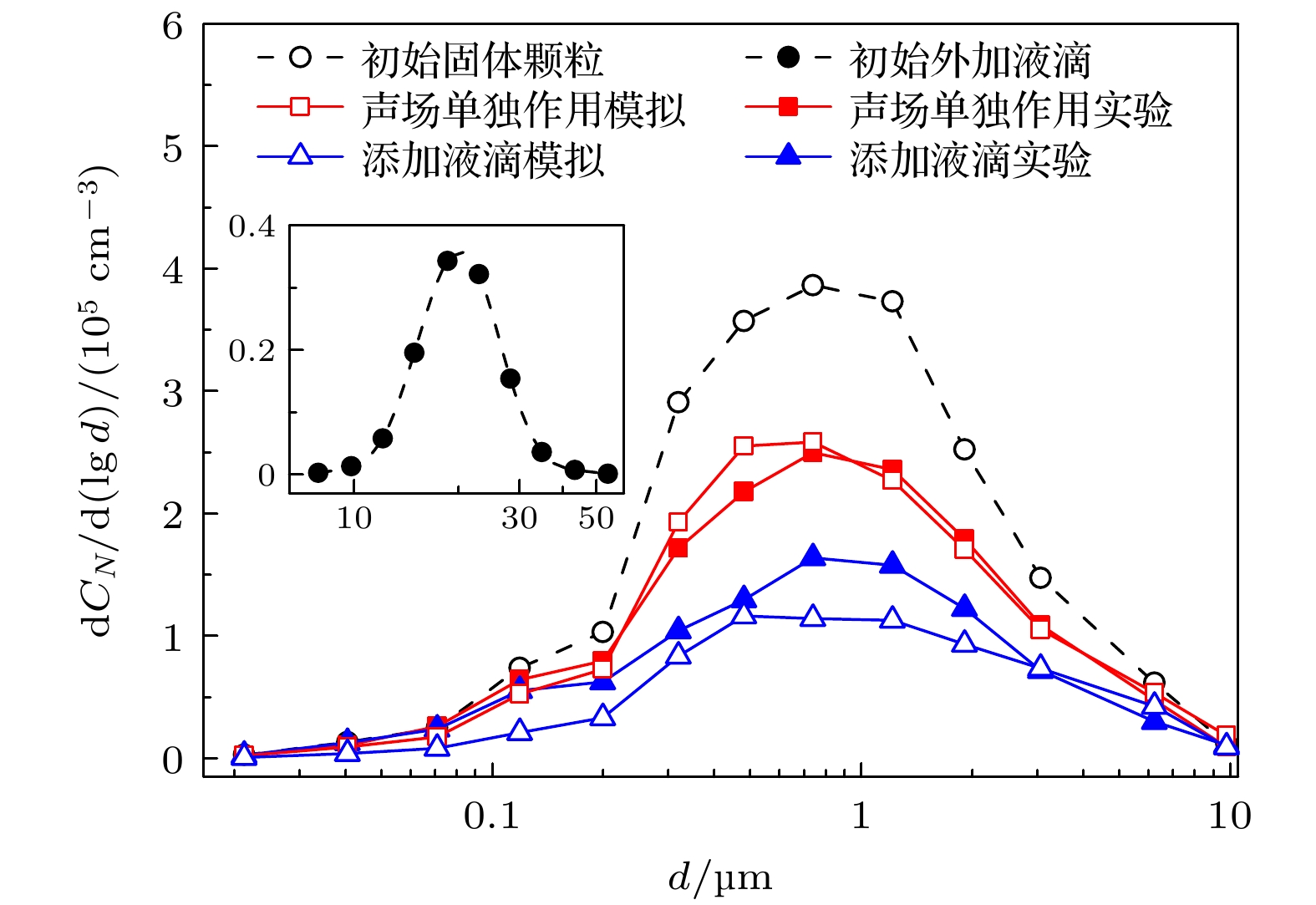

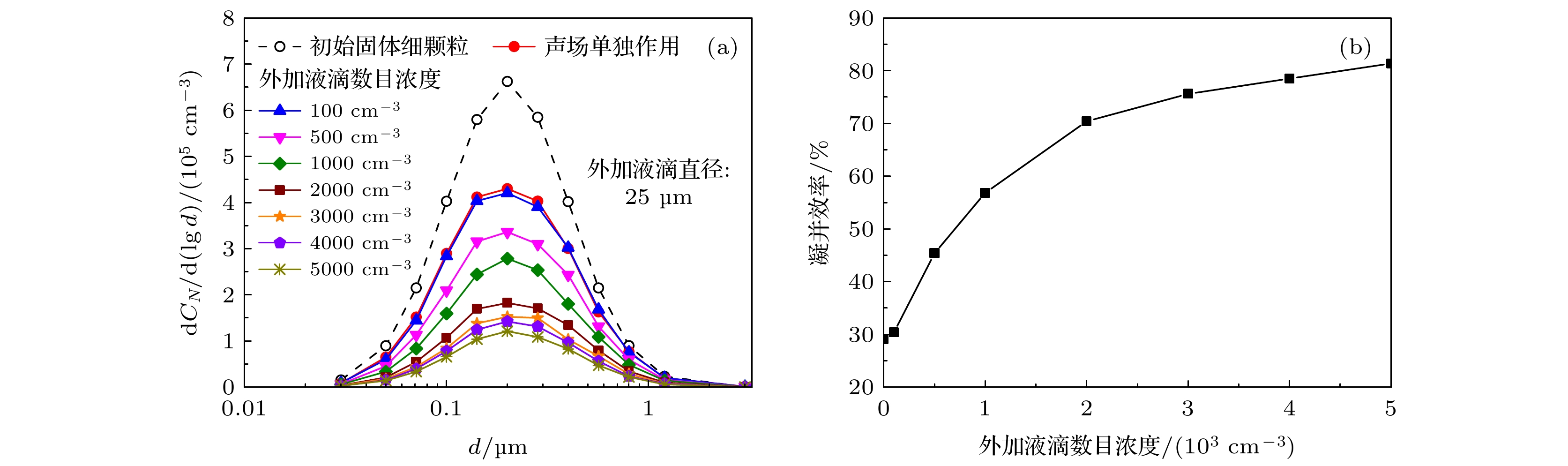

图 4 声凝并动力学行为 (a) 粒径分布; (b) 细颗粒凝并效率; (c) 凝并过程快照 (0 ≤ x ≤ 0.25λ, 液相放大40倍, 固相放大120倍)

Fig. 4. Dynamic behavior of acoustic agglomeration: (a) Particle size distribution; (b) agglomeration efficiency of fine particles; (c) snapshots of agglomeration process (0 ≤ x ≤ 0.25λ, liquid phase at 40× magnification and solid phase at 120× magnification).

表 1 模型验证采用的参数

Table 1. Parameters used for model validation.

P/Pa T/K L/dB f/Hz t/s ρs/(kg·m–3) ρl/(kg·m–3) e fp 数值 101325 298.15 144 1400 4 2500 1000 0.6 0.2 表 2 数值模拟参数

Table 2. Parameters used in numerical simulation.

P/Pa T/K L/dB f/Hz t/s ρs/(kg·m–3) ρl/(kg·m–3) e fp 数值 101325 298.15 140 2000 4 2500 1000 0.6 0.2 -

[1] Zhou D, Luo Z, Jiang J, Chen H, Lu M, Fang M 2016 Powder Technol. 289 52

Google Scholar

Google Scholar

[2] Shang X P, Ng B F, Wan M P, Xiong J W, Arikrishnan S 2018 Aerosol Sci. Technol. 52 872

Google Scholar

Google Scholar

[3] Zhang G X, Ma Z F, Shen J, Zhang K, Wang J Q, Chi Z H 2020 J. Hazard. Maters. 382 121089

Google Scholar

Google Scholar

[4] 屈广宁, 凡凤仙, 张斯宏, 苏明旭 2020 69 064704

Google Scholar

Google Scholar

Qu G N, Fan F X, Zhang S H, Su M X 2020 Acta Phys. Sin. 69 064704

Google Scholar

Google Scholar

[5] Wu Z H, Fan F X, Yan J P, Chen H T, Hu X H, Su M X 2022 Chem. Eng. Sci. 249 117298

Google Scholar

Google Scholar

[6] Liu J Z, Zhang G X, Zhou J H, Zhao W D, Cen K F 2009 Powder Technol. 193 20

Google Scholar

Google Scholar

[7] Fan F X, Zhang M J, Peng Z B, Chen J, Su M X, Moghtaderi B, Doroodchi E 2017 Aerosol Air Qual. Res. 17 1073

Google Scholar

Google Scholar

[8] Yan J P, Chen L Q, Li Z 2016 Fuel. 165 316

Google Scholar

Google Scholar

[9] Zhang G X, Zhang L L, Wang J, Hu E 2017 Powder Technol. 317 181

Google Scholar

Google Scholar

[10] Wang J, Liu J Z, Zhang G X, Zhou J H, Cen K F 2011 Powder Technol. 210 315

Google Scholar

Google Scholar

[11] Yang N N, Fan F X, Hu X H, Su M X 2022 J. Aerosol Sci. 165 106018

Google Scholar

Google Scholar

[12] Yan J P, Chen L Q, Lin Q 2017 Powder Technol. 315 106

Google Scholar

Google Scholar

[13] Chen H, Wang T, Luo Z Y, Zhou D, Lu M S, He M C, Fang M X, Cen K F 2017 Aerosol Air Qual. Res. 17 857

Google Scholar

Google Scholar

[14] Yan J P, Lin Q, Zhao S H, Chen L Q 2018 Powder Technol. 340 8

Google Scholar

Google Scholar

[15] Zhang G X, Wang J Q, Chi Z H, Hu E 2018 Chem. Eng. Sci. 187 342

Google Scholar

Google Scholar

[16] Shang X P, Wan M P, Ng B F, Ding S R 2020 Powder Technol. 362 111

Google Scholar

Google Scholar

[17] Crowe C T, Schwarzkopf J D, Scommerfeld M, Tsuij Y 2012 Multiphase Flows with Droplets and Particles (2nd Ed.) (New York: CRC Press) pp119–137

[18] Higashitani K, Makino H, Matsusaka S 2020 Powder Technology Handbook (4th Ed.) (New York: CRC Press) p60

[19] Tsuji Y, Tanaka T, Yonemura S 1998 Powder Technol. 95 254

Google Scholar

Google Scholar

[20] Zhang G X, Liu J Z, Wang J, Zhou J H, Cen K F 2012 Chin. Sci. Bull. 57 2404

Google Scholar

Google Scholar

[21] Song L 1990 Ph. D. Dissertation (State College: Pennsylvania State University)

[22] Sgrott O L, Sommerfeld M 2019 Can. J. Chem. Eng. 97 511

[23] Ennis B J 1991 Powder Technol. 65 257

Google Scholar

Google Scholar

[24] He Y X, Zhao H B 2016 Int. J. Multiphase Flow. 83 12

Google Scholar

Google Scholar

[25] Kleinhans U, Wieland C, Frandsen F J, Spliethoff H 2018 Prog. Energy Combust. Sci. 68 65

Google Scholar

Google Scholar

计量

- 文章访问数: 6115

- PDF下载量: 94

- 被引次数: 0

下载:

下载: