-

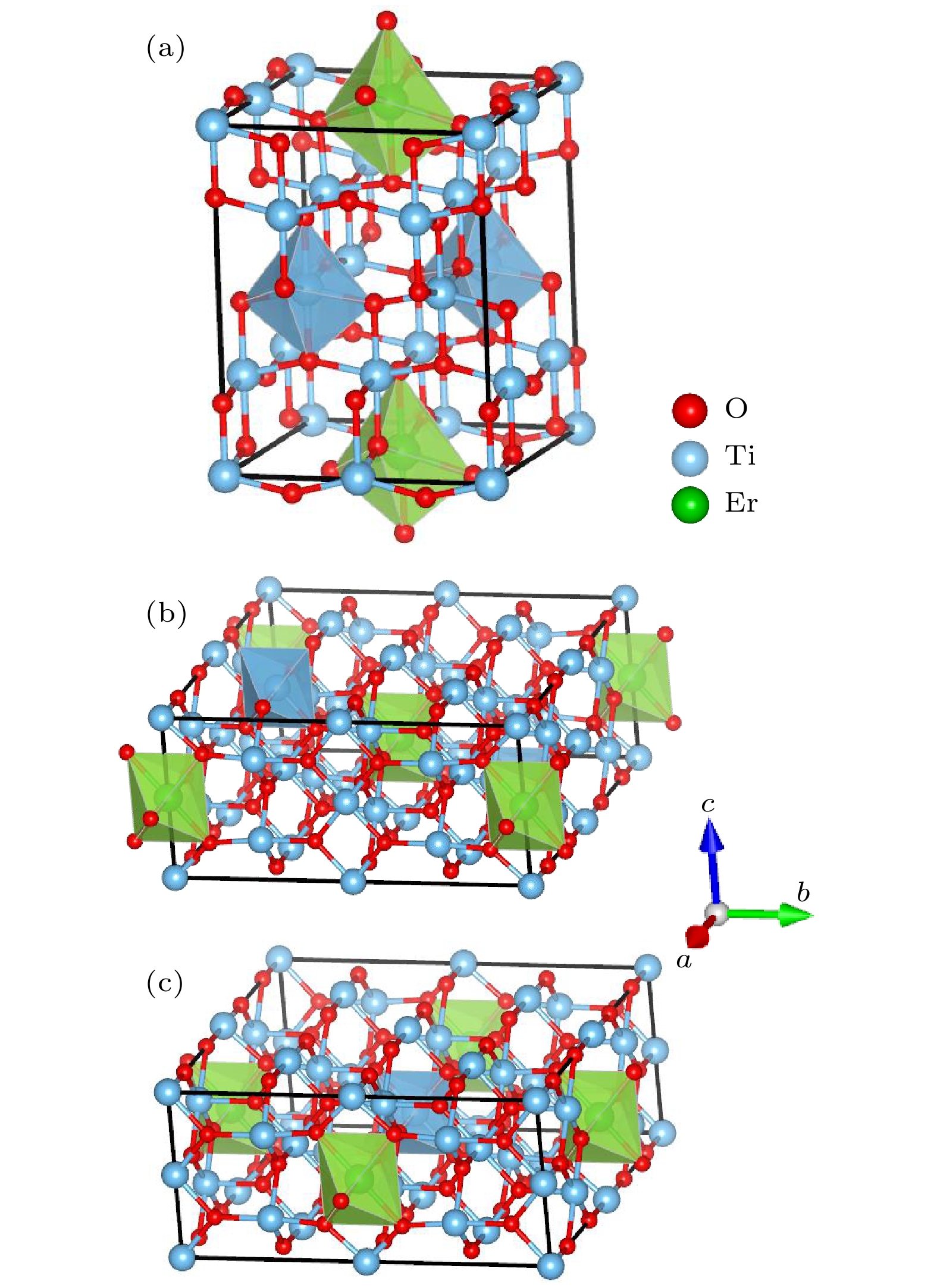

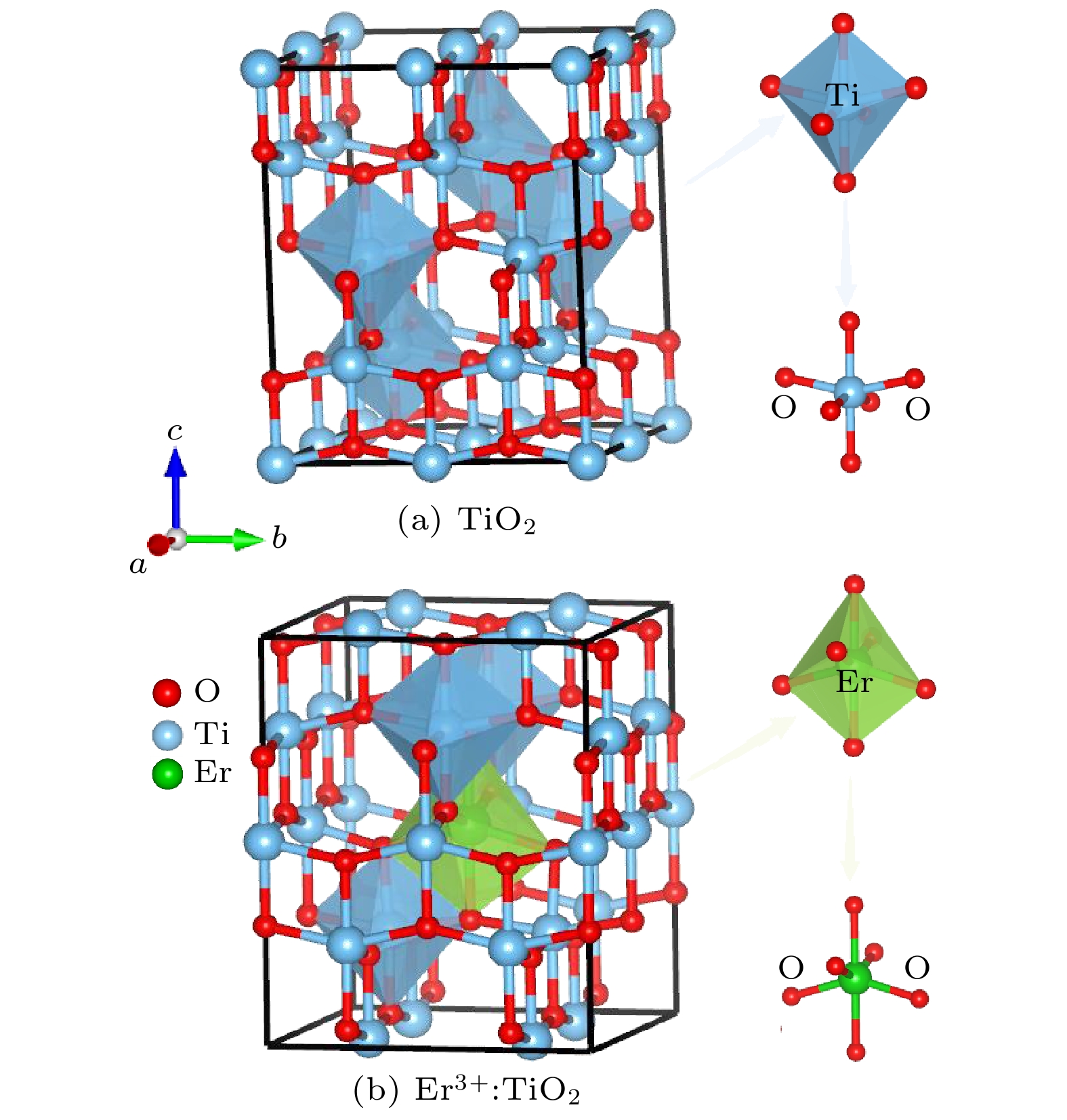

三价稀土铒离子(Er3+)掺杂二氧化钛(TiO2)因其优异的光电性能, 在众多稀土掺杂发光晶体材料中脱颖而出, 具有非常广泛的应用前景. 利用CALYPSO (Crystal structure AnaLYsis by Particle Swarm Optimization)结构搜索方法和第一性原理计算, 成功地预测和探究了三价铒离子掺杂二氧化钛(Er3+:TiO2)晶体的基态结构. 首次报道Er3+掺杂TiO2的最低能量结构具有

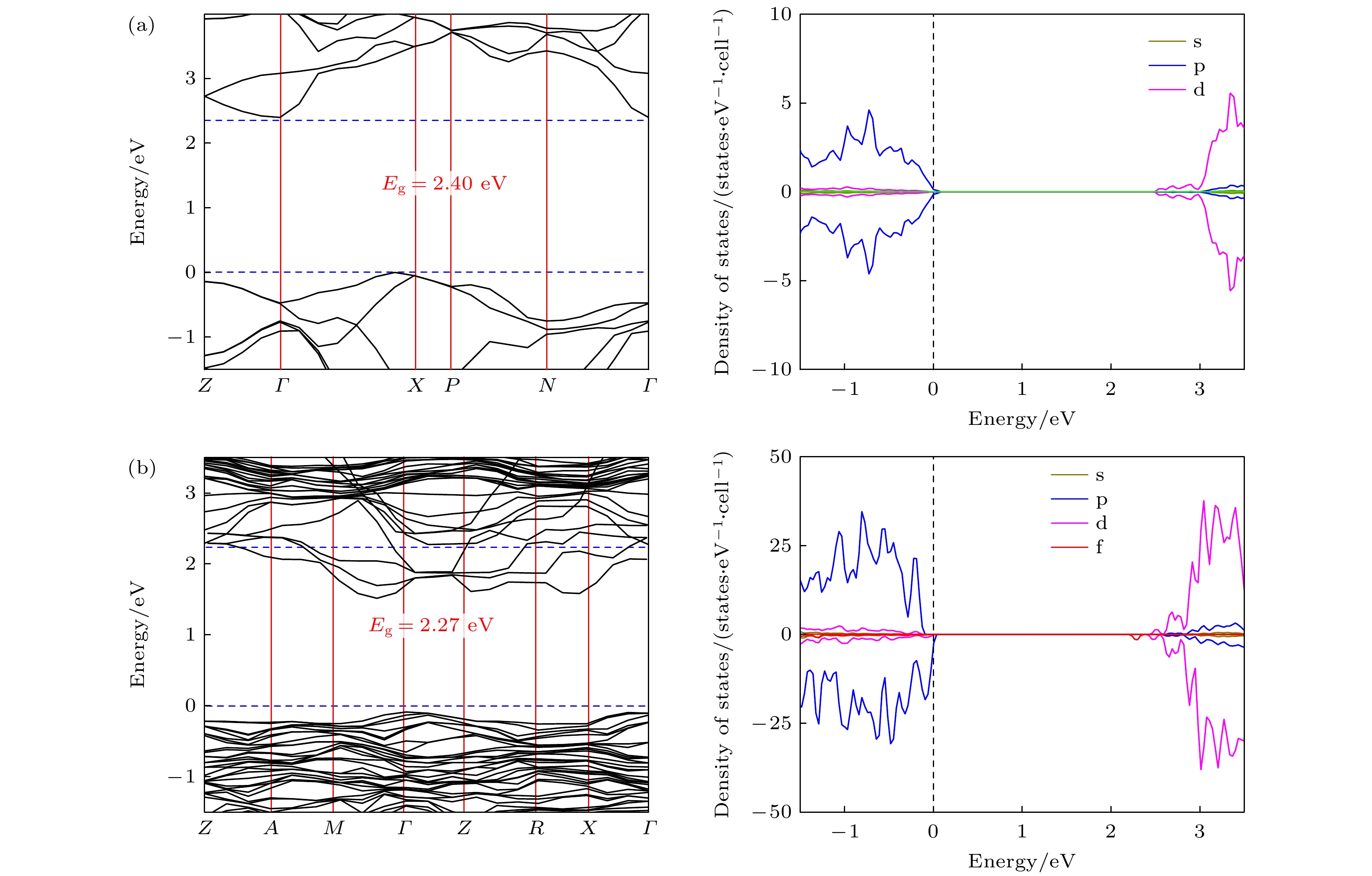

$P\overline 4 m2$ 空间对称性. 当Er3+离子掺杂基质晶体时, Er3+离子占据Ti4+离子的位置, 并造成结构畸变, 最终使得Er3+离子的局域对称性由D2d降低为C2v. 通过电子结构计算发现Er3+掺杂TiO2的能带隙值约为2.27 eV, 这表明Er3+离子的掺杂会导致体系的带隙值降低, 但没有改变其半导体性质, 从而在光伏电池和半导体激光器等领域具有更广泛的应用. 这些发现不仅为进一步探索Er3+:TiO2晶体的性质和应用提供了数据参考, 也为探究其他稀土掺杂晶体材料提供了最新的方法.-

关键词:

- CALYPSO /

- Er3+掺杂TiO2 /

- 局域结构 /

- 第一性原理计算

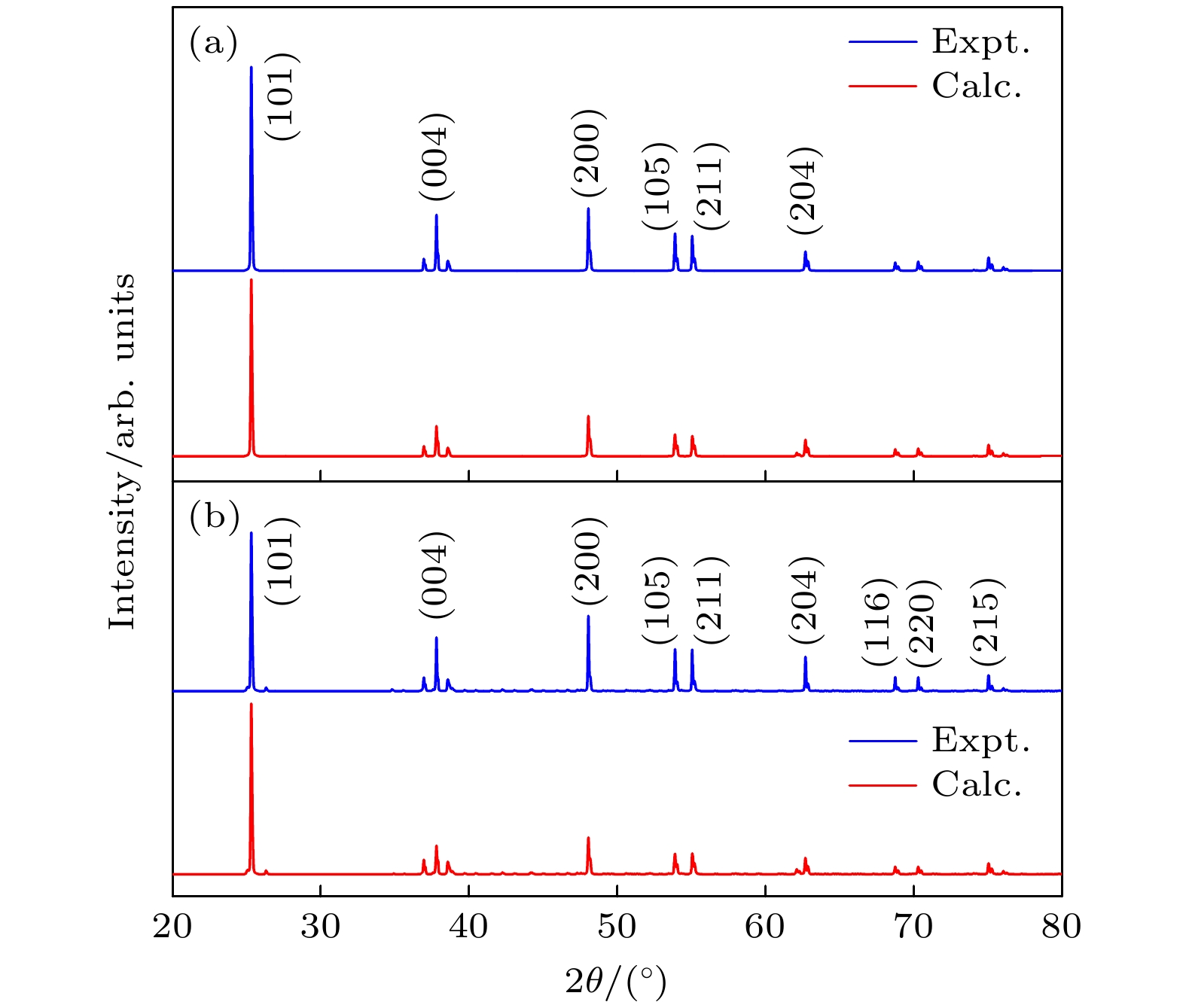

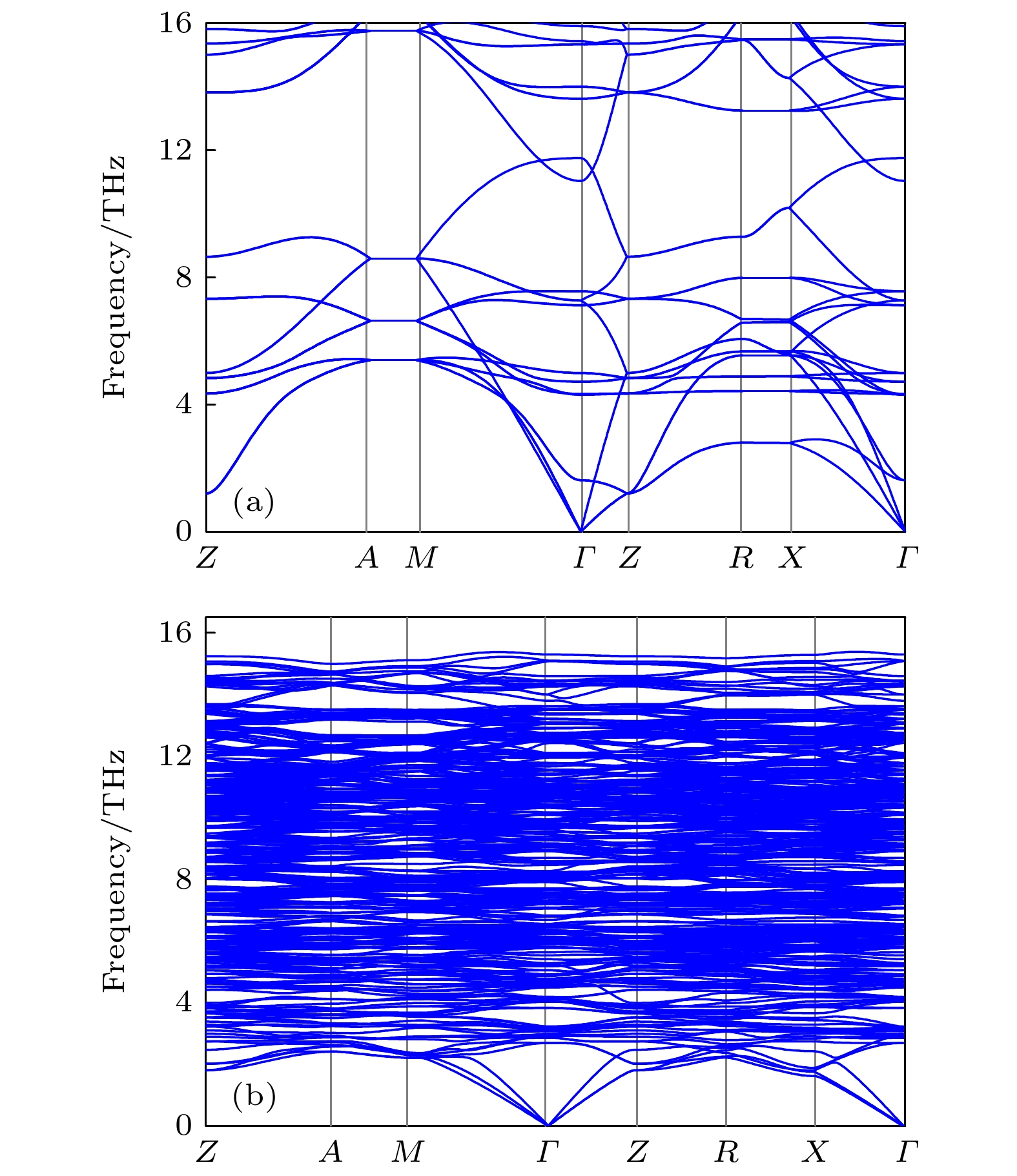

Trivalent rare earth erbium ion (Er3+) doped titanium oxide (TiO2) can possess a very wide range of applications due to its excellent optoelectronic properties, thus standing out among many rare-earth-doped luminescent crystals. However, the issues regarding local structure and electronic properties have not been finalized. To address these problems, the CALYPSO (Crystal structure AnaLYsis by Particle Swarm Optimization) method combined with the first-principles calculations is employed, and many converged structures of Er3+-doped TiO2 are successfully obtained. Further structural optimization is performed by using the VASP (Vienna ab initio simulation package) software package, and we report for the first time that the lowest energy structure of Er3+-doped TiO2 has the$ P\overline 4 $ m2 symmetry. It can be observed that the doped Er3+ ions enter into the host crystal and occupy the positions of Ti4+ ions, resulting in structural distortion, which eventually leads the local Er3+ coordination site symmetry to reduce from D2d into C2v. We speculate that there are two reasons: 1) the difference in charge between Er3+ ions and Ti4+ ions leads to charge compensation; 2) the difference between their electron radii is obvious: the radius is 0.0881 for Er3+ ion and 0.0881 for Ti4+ ion. In addition, during the structural search, we also find many metastable structures that may exist at a special temperature or pressure, which play an important role in the studying of structural evolution. When the electronic band structure of the Er3+-doped TiO2 system is calculated, we adopt the method of local density approximation (LDA) combined with the on-site Coulomb repulsion parameter U to accurately describe the strongly correlated system. For the specific value of U, we adopt 3.5 eV and 7.6 eV to describe the strong correlation of 3d electrons of Ti4+ ions and 4f electrons of Er3+ ions, respectively. According to the calculation of electronic properties, the band gap value of Er3+ doped TiO2 is about 2.27 eV, which is lower than that of the host crystal (Eg = 2.40 eV). The results show that the reduction in the band gap is mainly caused by the f state of Er3+ ions. The doping of Er ion does reduce the band gap value, but it does not change the conductivity of the system, which have great application prospect in diode-pumped laser. These findings not only provide the data for further exploring the properties and applications of Er3+:TiO2 crystals, but also present an approach to studying other rare-earth-doped crystalline materials.-

Keywords:

- CALYPSO /

- Er3+-doped TiO2 /

- local structure /

- first-principles calculations

[1] 钟淑琳, 仇家豪, 罗文崴, 吴木生 2021 70 158203

Google Scholar

Google Scholar

Zhong S L, Qiu J H, Luo W W, Wu M S 2021 Acta Phys. Sin. 70 158203

Google Scholar

Google Scholar

[2] 孟勇军, 李洪, 唐建伟, 陈学文 2022 71 027801

Google Scholar

Google Scholar

Meng Y J, Li H, Tang J W, Chen X W 2022 Acta Phys. Sin. 71 027801

Google Scholar

Google Scholar

[3] Wu B, Zhao L, Wang Y, Dong H, Yu H 2019 RSC Adv. 9 42228

Google Scholar

Google Scholar

[4] Menezes L D S, Araújo C B D 2015 J. Braz. Chem. Soc. 26 2405

[5] Stengl V, Bakardjieva S, Murafa N 2009 Mater. Chem. Phys. 114 217

Google Scholar

Google Scholar

[6] Hassan M S, Amna T, Yang O B, Kim H C, Khil M S 2012 Ceram. Int. 38 5925

Google Scholar

Google Scholar

[7] Borlaf M, Colomer M T, Moreno R, Ortiz A L 2014 J. Eur. Ceram. Soc. 34 4457

Google Scholar

Google Scholar

[8] Bao R, Li R, Chen C, Wu H, Xia J, Long C, Li H 2019 J. Phys. Chem. Solid. 126 78

Google Scholar

Google Scholar

[9] Li J G, Wang X H, Kamiyama H, Ishigaki T, Sekiguchi T 2006 Thin Solid Films 506 292

[10] Agrios A G, Pochat P 2005 J. Appl. Electrochem. 35 655

Google Scholar

Google Scholar

[11] Camps I, Borlaf M, Toudert J, Andres A D, Colomer M T, Moreno R, Serna R 2018 J. Alloys Compd. 735 2267

Google Scholar

Google Scholar

[12] Talane T E 2018 M. S. Thesis (Gauteng Province: University of South Africa)

[13] Pablo L I, Laeticia P, Jonathan M, Davide J, Nadia G B, Diego P, Sonia F, Chiara N, Fabrizio G, Daniel M 2017 J. Non-Cryst. Solids 460 161

Google Scholar

Google Scholar

[14] Mignotte C 2004 Appl. Surf. Sci. 226 355

Google Scholar

Google Scholar

[15] Talane T E, Mbule P S, Noto L L, Shingange K, Mhlongo G H, Mothudi B M, Dhlamini M S 2018 Mater. Res. Bull. 108 234

Google Scholar

Google Scholar

[16] Wild J D, Meijerink A, Rath J K, van Sark W G J H M, Schropp R E I 2011 Energy Environ. Sci. 4 4835

Google Scholar

Google Scholar

[17] Pablo L I, Diego P, Nadia G B, Davide J, Giovanni B, Laeticia P, Daniel M 2018 Nanomaterials 8 20

Google Scholar

Google Scholar

[18] van den Hoven G N, Koper R J I M, Polman A, Dam C V, Uffelen J W M V, Smit M K 1996 Appl. Phys. Lett. 68 1886

Google Scholar

Google Scholar

[19] Jia C W, Zhao J G, Duan H G, Xie E Q 2007 Mater. Lett. 61 4389

Google Scholar

Google Scholar

[20] Fu C Y, Liao J S, Luo W Q, Li R F, Chen X Y 2008 Opt. Lett. 33 953

Google Scholar

Google Scholar

[21] Luo W Q, Fu C Y, Li R F, Liu Y S, Zhu H M, Chen X Y 2011 Small 7 3046

Google Scholar

Google Scholar

[22] Ren Z, Wu J, Wang N, Li X 2018 J. Mater. Chem. A 6 15348

Google Scholar

Google Scholar

[23] Mazierski P, Mikolajczyk A, Grzybd T, Caicedo P N A, Wei Z, Kowalska E, Henry P P, Adriana Z M, Nadolna J 2020 Appl. Surf. Sci. 527 146815

Google Scholar

Google Scholar

[24] Wang Y C, Lv J, Zhu L, Ma Y M 2012 Comput. Phys. Commun. 183 2063

Google Scholar

Google Scholar

[25] Wang Y C, Lv J, Zhu L, Lu S H, Yin K T, Li Q, Wang H, Zhang L J, Ma Y M 2015 J. Phys. Condens. Matter. 27 203203

Google Scholar

Google Scholar

[26] Wang H, Wang Y C, Lv J, Li Q, Zhang L J, Ma Y M 2016 Comput. Mater. Sci. 112 406

Google Scholar

Google Scholar

[27] Wang Y C, Lv J, Zhu L, Ma Y M 2010 Phys. Rev. B 82 094116

Google Scholar

Google Scholar

[28] Gao B, Gao P, Lu S, Lv J, Wang Y, Ma Y 2019 Sci. Bull. 64 301

Google Scholar

Google Scholar

[29] Wang Y, Miao M, Lv J, Zhu L, Yin K, Liu H, Ma Y 2012 J. Chem. Phys. 137 224108

Google Scholar

Google Scholar

[30] Hafner J 2008 J. Comput. Chem. 29 2044

Google Scholar

Google Scholar

[31] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[32] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[33] Sanna S, Schmidt W G, Frauenheim T, Gerstmann U 2009 Phys. Rev. B 80 104120

Google Scholar

Google Scholar

[34] Xiao Y, Ju M, Yuan H K, Yeung Y Y 2021 J. Phys. Chem. C 125 18015

Google Scholar

Google Scholar

[35] Togo A, Tanaka I 2015 Scr. Mater. 108 1

Google Scholar

Google Scholar

[36] Phenicie C M, Stevenson P, Welinski S, Rose B C, Asfaw A T, Cava R J, Lyon S A, de Leon N P, Thompson J D 2019 Nano Lett. 19 8928

Google Scholar

Google Scholar

[37] Mills A, Hunte S L 1997 J. Photochem. Photobiol. A 108 1

Google Scholar

Google Scholar

[38] Yang J, Hu Y, Jin C, Zhuge L, Wu X 2017 Thin Solid Films 637 9

Google Scholar

Google Scholar

[39] Pan L, Xiao Y, Kuang X Y, Ju M 2021 Mater. Chem. Phys. 257 123824

Google Scholar

Google Scholar

[40] Savin A, Nesper R, Wengert S, Fässler T F 1997 Angew. Chem. Int. Ed. Engl. 36 1808

Google Scholar

Google Scholar

[41] Lu T, Chen F 2011 Acta Phys. Chim. Sin. 27 2786

Google Scholar

Google Scholar

[42] Fuentealba P, Chamorro E, Santos J C 2007 Theoretical Aspects of Chemical Reactivity 19 57

-

表 1 Er3+:TiO2能量最低结构中所有原子的坐标

Table 1. Coordinates of all atoms for the low-energy structure of Er3+:TiO2.

Atom x y z Wyckoff site

symmetryO(1) 0.247 0.249 0.204 4j O(2) 0.753 0.751 0.204 4k O(3) 0.249 0.753 0.796 2g O(4) 0.751 0.247 0.796 8l O(6) 0.753 0.249 0.204 2g O(7) 0.250 0.247 0.796 4k O(8) 0.751 0.753 0.796 4j O(11) 0.250 0.000 0.545 2f O(19) 0.500 0.753 0.036 2e Ti(1) 0.000 0.250 0.251 4j Ti(2) 0.000 0.750 0.251 4k Ti(3) 0.250 0.000 0.749 2g Ti(4) 0.750 0.000 0.749 4h Ti(10) 0.500 0.000 0.495 1d Er(1) 0.500 0.500 0.500 1c 表 2 Er3+:TiO2的基态结构以及亚稳态结构的晶格参数a, b, c, 原胞体积V, 相对能量∆E

Table 2. Structural parameters a, b and c, unit-cell volume, relative energies for the optimized TiO2 and metastable Er3+:TiO2

Space group a/Å b/Å c/Å V/Å3 ∆E/eV TiO2 I41/amd 7.568 7.568 9.515 545.003 — Er3+:TiO2 $ P\overline 4 $m2 7.682 7.682 9.798 578.193 0 Isomer (a) $ P\overline 4 $m2 7.681 7.681 9.799 578.213 0.051 Isomer (b) Cmmm 13.258 13.258 6.013 1051.764 0.853 Isomer (c) Cmmm 13.261 13.261 6.009 1051.988 0.975 -

[1] 钟淑琳, 仇家豪, 罗文崴, 吴木生 2021 70 158203

Google Scholar

Google Scholar

Zhong S L, Qiu J H, Luo W W, Wu M S 2021 Acta Phys. Sin. 70 158203

Google Scholar

Google Scholar

[2] 孟勇军, 李洪, 唐建伟, 陈学文 2022 71 027801

Google Scholar

Google Scholar

Meng Y J, Li H, Tang J W, Chen X W 2022 Acta Phys. Sin. 71 027801

Google Scholar

Google Scholar

[3] Wu B, Zhao L, Wang Y, Dong H, Yu H 2019 RSC Adv. 9 42228

Google Scholar

Google Scholar

[4] Menezes L D S, Araújo C B D 2015 J. Braz. Chem. Soc. 26 2405

[5] Stengl V, Bakardjieva S, Murafa N 2009 Mater. Chem. Phys. 114 217

Google Scholar

Google Scholar

[6] Hassan M S, Amna T, Yang O B, Kim H C, Khil M S 2012 Ceram. Int. 38 5925

Google Scholar

Google Scholar

[7] Borlaf M, Colomer M T, Moreno R, Ortiz A L 2014 J. Eur. Ceram. Soc. 34 4457

Google Scholar

Google Scholar

[8] Bao R, Li R, Chen C, Wu H, Xia J, Long C, Li H 2019 J. Phys. Chem. Solid. 126 78

Google Scholar

Google Scholar

[9] Li J G, Wang X H, Kamiyama H, Ishigaki T, Sekiguchi T 2006 Thin Solid Films 506 292

[10] Agrios A G, Pochat P 2005 J. Appl. Electrochem. 35 655

Google Scholar

Google Scholar

[11] Camps I, Borlaf M, Toudert J, Andres A D, Colomer M T, Moreno R, Serna R 2018 J. Alloys Compd. 735 2267

Google Scholar

Google Scholar

[12] Talane T E 2018 M. S. Thesis (Gauteng Province: University of South Africa)

[13] Pablo L I, Laeticia P, Jonathan M, Davide J, Nadia G B, Diego P, Sonia F, Chiara N, Fabrizio G, Daniel M 2017 J. Non-Cryst. Solids 460 161

Google Scholar

Google Scholar

[14] Mignotte C 2004 Appl. Surf. Sci. 226 355

Google Scholar

Google Scholar

[15] Talane T E, Mbule P S, Noto L L, Shingange K, Mhlongo G H, Mothudi B M, Dhlamini M S 2018 Mater. Res. Bull. 108 234

Google Scholar

Google Scholar

[16] Wild J D, Meijerink A, Rath J K, van Sark W G J H M, Schropp R E I 2011 Energy Environ. Sci. 4 4835

Google Scholar

Google Scholar

[17] Pablo L I, Diego P, Nadia G B, Davide J, Giovanni B, Laeticia P, Daniel M 2018 Nanomaterials 8 20

Google Scholar

Google Scholar

[18] van den Hoven G N, Koper R J I M, Polman A, Dam C V, Uffelen J W M V, Smit M K 1996 Appl. Phys. Lett. 68 1886

Google Scholar

Google Scholar

[19] Jia C W, Zhao J G, Duan H G, Xie E Q 2007 Mater. Lett. 61 4389

Google Scholar

Google Scholar

[20] Fu C Y, Liao J S, Luo W Q, Li R F, Chen X Y 2008 Opt. Lett. 33 953

Google Scholar

Google Scholar

[21] Luo W Q, Fu C Y, Li R F, Liu Y S, Zhu H M, Chen X Y 2011 Small 7 3046

Google Scholar

Google Scholar

[22] Ren Z, Wu J, Wang N, Li X 2018 J. Mater. Chem. A 6 15348

Google Scholar

Google Scholar

[23] Mazierski P, Mikolajczyk A, Grzybd T, Caicedo P N A, Wei Z, Kowalska E, Henry P P, Adriana Z M, Nadolna J 2020 Appl. Surf. Sci. 527 146815

Google Scholar

Google Scholar

[24] Wang Y C, Lv J, Zhu L, Ma Y M 2012 Comput. Phys. Commun. 183 2063

Google Scholar

Google Scholar

[25] Wang Y C, Lv J, Zhu L, Lu S H, Yin K T, Li Q, Wang H, Zhang L J, Ma Y M 2015 J. Phys. Condens. Matter. 27 203203

Google Scholar

Google Scholar

[26] Wang H, Wang Y C, Lv J, Li Q, Zhang L J, Ma Y M 2016 Comput. Mater. Sci. 112 406

Google Scholar

Google Scholar

[27] Wang Y C, Lv J, Zhu L, Ma Y M 2010 Phys. Rev. B 82 094116

Google Scholar

Google Scholar

[28] Gao B, Gao P, Lu S, Lv J, Wang Y, Ma Y 2019 Sci. Bull. 64 301

Google Scholar

Google Scholar

[29] Wang Y, Miao M, Lv J, Zhu L, Yin K, Liu H, Ma Y 2012 J. Chem. Phys. 137 224108

Google Scholar

Google Scholar

[30] Hafner J 2008 J. Comput. Chem. 29 2044

Google Scholar

Google Scholar

[31] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[32] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[33] Sanna S, Schmidt W G, Frauenheim T, Gerstmann U 2009 Phys. Rev. B 80 104120

Google Scholar

Google Scholar

[34] Xiao Y, Ju M, Yuan H K, Yeung Y Y 2021 J. Phys. Chem. C 125 18015

Google Scholar

Google Scholar

[35] Togo A, Tanaka I 2015 Scr. Mater. 108 1

Google Scholar

Google Scholar

[36] Phenicie C M, Stevenson P, Welinski S, Rose B C, Asfaw A T, Cava R J, Lyon S A, de Leon N P, Thompson J D 2019 Nano Lett. 19 8928

Google Scholar

Google Scholar

[37] Mills A, Hunte S L 1997 J. Photochem. Photobiol. A 108 1

Google Scholar

Google Scholar

[38] Yang J, Hu Y, Jin C, Zhuge L, Wu X 2017 Thin Solid Films 637 9

Google Scholar

Google Scholar

[39] Pan L, Xiao Y, Kuang X Y, Ju M 2021 Mater. Chem. Phys. 257 123824

Google Scholar

Google Scholar

[40] Savin A, Nesper R, Wengert S, Fässler T F 1997 Angew. Chem. Int. Ed. Engl. 36 1808

Google Scholar

Google Scholar

[41] Lu T, Chen F 2011 Acta Phys. Chim. Sin. 27 2786

Google Scholar

Google Scholar

[42] Fuentealba P, Chamorro E, Santos J C 2007 Theoretical Aspects of Chemical Reactivity 19 57

计量

- 文章访问数: 9393

- PDF下载量: 169

- 被引次数: 0

下载:

下载: