-

由于具有适合的带隙和较高的稳定性, CsPbIBr2无机钙钛矿被认为是一种较有前景的太阳能电池光吸收材料. 但是目前报道的CsPbIBr2钙钛矿太阳能电池效率还偏低, 主要原因是制备的CsPbIBr2钙钛矿膜质量差、缺陷多. 本文通过将醋酸纤维素(CA)加入CsPbIBr2钙钛矿前驱体溶液中改善CsPbIBr2钙钛矿结晶过程, 从而制备高质量的CsPbIBr2钙钛矿膜. 实验结果表明, CA中的C=O基团与前驱体溶液中的Pb2+间存在明显的相互作用, 这种相互作用结合CA加入引起的前驱体溶液粘度增加, 使CsPbIBr2钙钛矿的结晶速率明显降低, 从而制备了致密、结晶度高、晶粒尺寸大、晶界和缺陷少的高质量CsPbIBr2钙钛矿膜. 同时, CA的保护作用显著提高了CsPbIBr2钙钛矿膜的稳定性. 用碳材料层作为空穴传输层和背电极, 制备结构为FTO/TiO2/CsPbIBr2钙钛矿膜/碳层的碳基CsPbIBr2钙钛矿太阳能电池. 在100 mW/cm2光照下, CA-CsPbIBr2钙钛矿太阳能电池的效率达到7.52%, 比未加CA的CsPbIBr2钙钛矿电池提高了40%. 同时, 将CA-CsPbIBr2钙钛矿太阳能电池在空气环境中贮存800 h, 其效率仍保持初始值的90%以上, 表明具有较高的长期稳定性.

-

关键词:

- 醋酸纤维素 /

- CsPbIBr2钙钛矿 /

- 稳定性 /

- 钙钛矿太阳能电池

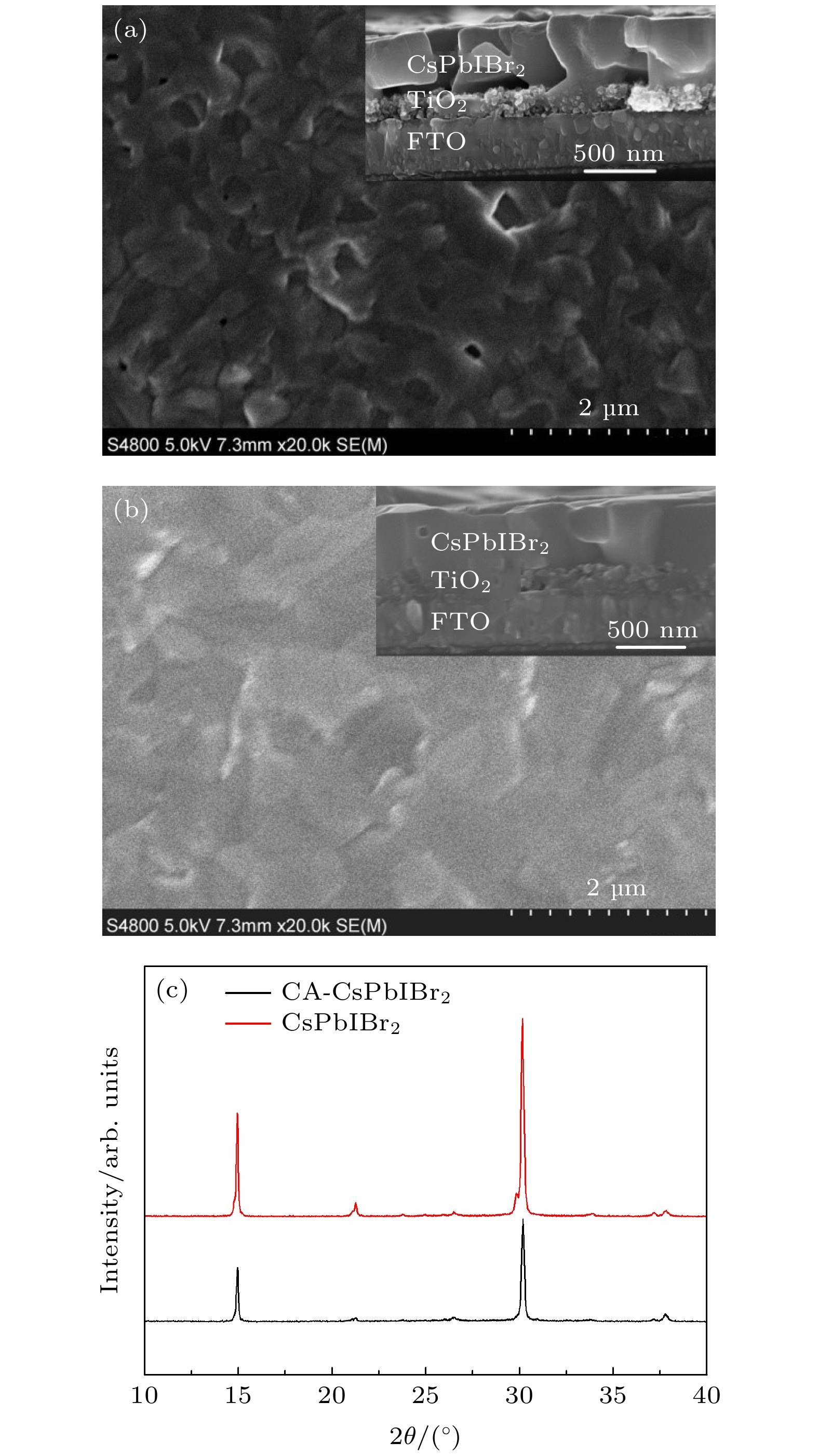

CsPbIBr2 perovskite has been considered as a promising candidate for the light-harvesting material of perovskite solar cells (PSCs) due to its acceptable band gap and high stability. Nevertheless, the efficiency of CsPbIBr2-based PSC still lags behind that of its homologs and is far away from the theoretical value. This can be attributed to the poor quality of CsPbIBr2 perovskite film. Therefore, it is highly desirable to improve the quality of CsPbIBr2 perovskite film for enhancing the photovoltaic performance of CsPbIBr2 PSCs. In this work, cellulose acetate (CA) is used as a polymer additive that is introduced into CsPbIBr2 precursor solution for improving the quality of CsPbIBr2 perovskite film via controlling crystallization process. The interaction between the C=O group of CA and Pb2+ in the precursor solution and the enhanced viscosity of precursor solution induced by CA addition reduce the crystallization rate of CsPbIBr2 perovskite. As a result, a compact CsPbIBr2 perovskite film with high crystallinity, large grain size, and low density of defect is prepared. The remarkably improved quality of CsPbIBr2 perovskite film upon CA addition can be attributed to the relatively slow crystallization rate. The slow crystallization rate allows the perovskite film to have enough time to form perfect perovskite crystal structure with large-size crystal grain and low density of defects. Furthermore, the oxygen functional groups of CA can passivate the undercoordinated Pb2+, which effectively suppresses the defects and traps induced by Pb2+ in CsPbIBr2 perovskite film. The stability of CsPbIBr2 perovskite film is also greatly improved by CA addition. The added CA does not participate into the CsPbIBr2 perovskite crystal but distributes at the grain boundaries and, or, interfaces area and forms a moisture barrier around perovskite grains, which obviously enhances the stability of CsPbIBr2 perovskite film in the ambient air. The carbon-based CsPbIBr2 perovskite solar cells with a configuration of FTO/TiO2/perovskite film/ carbon are fabricated by using the carbon layer as both the hole-transport layer and the back electrode. Under the illumination of 100 mW/cm2, the PSC based on CA-CsPbIBr2 perovskite film delivers a high conversion efficiency of 7.52%, which is increased by 40% compared with the efficiency of the device based on the pure CsPbIBr2 perovskite film. In addition, the PSC based on CA-CsPbIBr2 perovskite film shows a hysteresis index (HI) of 7%, while the device based on pure CsPbIBr2 film displays a higher HI of 22%. This result demonstrates that the CA addition can effectively suppress the hysteresis effect of inorganic PSCs. The stability of the PSC based on CA-CsPbIBr2 perovskite film is investigated by tracking the variation of the efficiency with time in the ambient condition. The fabricated PSCs without any encapsulation are stored in the air. The photovoltaic performance is measured once a day. The efficiency of the PSC based on CA-CsPbIBr2 perovskite remains more than 90% of its initial value after being stored in the air for 800 h, showing an excellent long-term stability. Therefore, this work provides a facile and effective method of improving the quality of CsPbIBr2 perovskite films, which is expected to be helpful in developing high-efficiency and stable carbon-based inorganic PSCs. -

Keywords:

- cellulose acetate /

- CsPbIBr2 perovskite /

- stability /

- perovskite solar cells

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Ono L K, Qi Y 2016 J. Phys. Chem. Lett. 7 4764

Google Scholar

Google Scholar

[3] 姚鑫, 丁艳丽, 张晓丹, 赵颖 2015 64 038805

Google Scholar

Google Scholar

Yao X, Ding Y L, Zhang X D, Zhao Y 2015 Acta Phys. Sin. 64 038805

Google Scholar

Google Scholar

[4] Deng X, Xie L, Wang S 2020 Chem. Eng. J. 398 125594

Google Scholar

Google Scholar

[5] Huang Y, Liu T, Liang C 2020 Adv. Funct. Mater. 30 2000863

Google Scholar

Google Scholar

[6] Jia X, Zho C, Tao S 2019 Sci. Bull. 64 1532

Google Scholar

Google Scholar

[7] Tai Q, Tang K, Yan F 2019 Energy Environ. Sci. 12 2375

Google Scholar

Google Scholar

[8] Li B, Fu L, Li S, Pan L, Wang L, Yin L 2019 J. Mater. Chem. A 7 20494

Google Scholar

Google Scholar

[9] Wang G, Lei M, Liu J, Zhang W, He Q 2020 Solar RRL 4 2000528

Google Scholar

Google Scholar

[10] Duan J, Xu H, Sha W, Tang Q 2019 J. Mater. Chem. A 7 21036

Google Scholar

Google Scholar

[11] Wang Y, Liu X, Zhang T, Wang X, J. Shi, Zhao Y 2019 Angew. Chem. Int. Ed. 58 16691

Google Scholar

Google Scholar

[12] Li Z, Zhou F, Wang Q 2020 Nano Energy 71 104634

Google Scholar

Google Scholar

[13] Duan J, Zhao Y, He B, Tang Q 2018 Angew. Chem. Int. Ed. 57 3787

Google Scholar

Google Scholar

[14] Chang X, Li W, Zhu L 2016 ACS Appl. Mater. Interfaces 8 33649

Google Scholar

Google Scholar

[15] Liu X, Tan X, Liu Z, Sun B, Tan Z, Liao G 2019 Nano Energy 56 184

Google Scholar

Google Scholar

[16] Guo Y, Yin X, Liu J 2019 Solar RRL 3 1900135

Google Scholar

Google Scholar

[17] Guo Z, Teo S, Xu Z, S. Hayase, Ma T 2019 J. Mater. Chem. A 7 1227

Google Scholar

Google Scholar

[18] Ma Q, Huang S, Wen X 2016 Adv. Energy Mater. 6 1502202

Google Scholar

Google Scholar

[19] Subhani W, Wang K, Du M 2019 Adv. Energy Mater. 9 1803785

Google Scholar

Google Scholar

[20] Ren Y, Hao Y, Zhang N, Cai M, Dai S 2020 Chem. Eng. J. 392 123805

Google Scholar

Google Scholar

[21] Li B, Zhang Y, Fu L 2018 Nat. Commun. 9 1076

Google Scholar

Google Scholar

[22] Peng H, Cai M, Zhou J, Ding X, Pan J, Dai S 2020 Solar RRL 4 2000216

Google Scholar

Google Scholar

[23] Xu W, Zhu T, Wu H 2020 ACS Appl. Mater. Interfaces 12 45045

Google Scholar

Google Scholar

[24] Zhao Y C, Wei J, Li H, Yan Y, Zhou W, Yu D, Zhao Q 2016 Nat. Commun. 7 10228

Google Scholar

Google Scholar

[25] Wu W, Zhong J, Liao J 2020 Nano Energy 75 104929

Google Scholar

Google Scholar

[26] Yang J, Liu C, Cai C 2019 Adv. Energy Mater. 9 1900198

Google Scholar

Google Scholar

[27] Yin G, Zhao H, Jiang H, Liu Z, Liu S 2018 Adv. Funct Mater. 28 1803269

Google Scholar

Google Scholar

[28] Du J, Duan J, Yang X, Duan Y, Zhou Q, Tang Q 2021 Angew. Chem. Int. Ed. 60 1

Google Scholar

Google Scholar

[29] Wang Z, BaranwalA K, Kamarudin M A, Ng C, Pandey M, Ma T, Hayase S 2019 Nano Energy 59 258

Google Scholar

Google Scholar

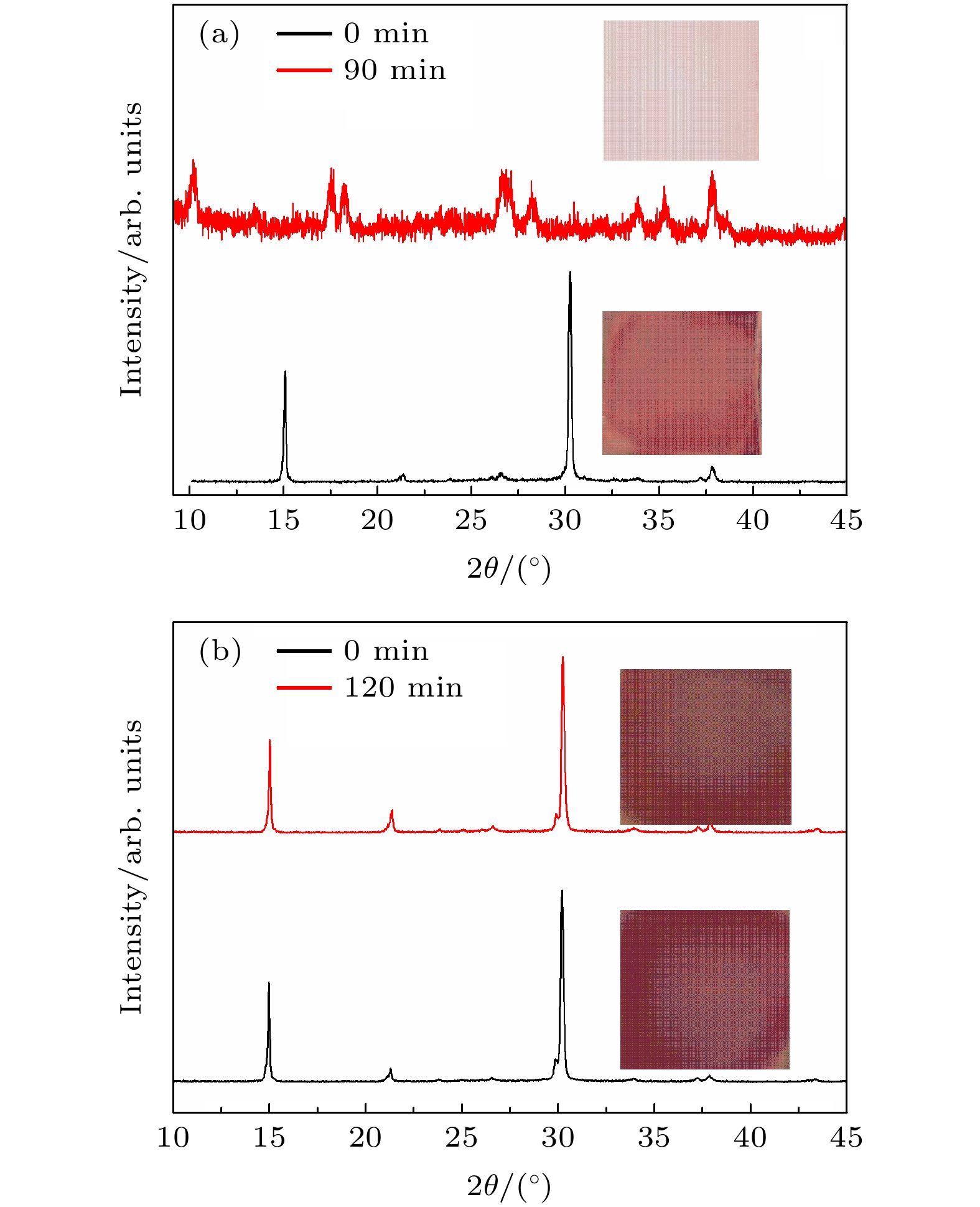

-

图 4 贮存在温度为30 ℃、相对湿度为85%的空气环境中不同时间点的(a) CsPbIBr2和(b) CA-CsPbIBr2钙钛矿膜的XRD曲线(插图为对应的CsPbIBr2和CA- CsPbIBr2照片)

Fig. 4. XRD curves of (a) CsPbIBr2 and (b) CA-CsPbIBr2 perovskite films stored in the air with a temperature of 30 ℃ and a relative humidity of 85% (the insets are the photos of CsPbIBr2 and CA-CsPbIBr2 perovskite films).

图 7 (a) CsPbIBr2和CA-CsPbIBr2钙钛矿太阳能电池在正向和反向扫描条件下测得的光电流密度-电压(J-V)曲线; (b) CsPbIBr2和CA-CsPbIBr2钙钛矿太阳能电池Nyquist曲线; (c) 空气环境中, 未密封CsPbIBr2和CA-CsPbIBr2钙钛矿太阳能电池的光电转换效率随时间的变化趋势

Fig. 7. (a) Photocurrent density-voltage (J-V) curves of perovskite solar cells based on CsPbIBr2 and CA-CsPbIBr2 perovskite films measured under forward and reverse scans; (b) Nyquist plots of CsPbIBr2 and CA-CsPbIBr2 perovskite solar cells; (c) variation of PCE of perovskite solar cells based on CsPbIBr2 and CA-CsPbIBr2 perovskite films stored in ambient air.

表 1 CsPbIBr2和CA-CsPbIBr2钙钛矿太阳能电池界面电荷复合电阻及正向和反向扫描测得的光电参数

Table 1. The recombination resistances (Rrec) and photovoltaic parameters of perovskite solar cells based on CsPbIBr2 and CA-CsPbIBr2 perovskite films measured under forward and reverse scans.

电池 扫描方向 Voc/V Jsc/(mA·cm2) FF PCE/% HIa Rrec/Ω CsPbIBr2 正向 平均 0.96 ± 0.05 9.89 ± 0.39 0.33 ± 0.4 3.13 ± 0.72 22% 1448 最高 1.03 10.35 0.39 4.16 反向 平均 1.01 ± 0.03 10.21 ± 0.42 0.45 ± 0.02 4.64 ± 0.56 最高 1.07 10.62 0.47 5.34 CA

-CsPbIBr2正向 平均 1.02 ± 0.03 10.52 ± 0.37 0.57 ± 0.02 6.12 ± 0.67 7% 2269 最高 1.06 10.91 0.60 6.94 反向 平均 1.05 ± 0.03 10.55 ± 0.27 0.62 ± 0.02 6.87 ± 0.38 最高 1.08 10.88 0.64 7.52 a HI = (PCE反向–PCE正向)/PCE反向 -

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Ono L K, Qi Y 2016 J. Phys. Chem. Lett. 7 4764

Google Scholar

Google Scholar

[3] 姚鑫, 丁艳丽, 张晓丹, 赵颖 2015 64 038805

Google Scholar

Google Scholar

Yao X, Ding Y L, Zhang X D, Zhao Y 2015 Acta Phys. Sin. 64 038805

Google Scholar

Google Scholar

[4] Deng X, Xie L, Wang S 2020 Chem. Eng. J. 398 125594

Google Scholar

Google Scholar

[5] Huang Y, Liu T, Liang C 2020 Adv. Funct. Mater. 30 2000863

Google Scholar

Google Scholar

[6] Jia X, Zho C, Tao S 2019 Sci. Bull. 64 1532

Google Scholar

Google Scholar

[7] Tai Q, Tang K, Yan F 2019 Energy Environ. Sci. 12 2375

Google Scholar

Google Scholar

[8] Li B, Fu L, Li S, Pan L, Wang L, Yin L 2019 J. Mater. Chem. A 7 20494

Google Scholar

Google Scholar

[9] Wang G, Lei M, Liu J, Zhang W, He Q 2020 Solar RRL 4 2000528

Google Scholar

Google Scholar

[10] Duan J, Xu H, Sha W, Tang Q 2019 J. Mater. Chem. A 7 21036

Google Scholar

Google Scholar

[11] Wang Y, Liu X, Zhang T, Wang X, J. Shi, Zhao Y 2019 Angew. Chem. Int. Ed. 58 16691

Google Scholar

Google Scholar

[12] Li Z, Zhou F, Wang Q 2020 Nano Energy 71 104634

Google Scholar

Google Scholar

[13] Duan J, Zhao Y, He B, Tang Q 2018 Angew. Chem. Int. Ed. 57 3787

Google Scholar

Google Scholar

[14] Chang X, Li W, Zhu L 2016 ACS Appl. Mater. Interfaces 8 33649

Google Scholar

Google Scholar

[15] Liu X, Tan X, Liu Z, Sun B, Tan Z, Liao G 2019 Nano Energy 56 184

Google Scholar

Google Scholar

[16] Guo Y, Yin X, Liu J 2019 Solar RRL 3 1900135

Google Scholar

Google Scholar

[17] Guo Z, Teo S, Xu Z, S. Hayase, Ma T 2019 J. Mater. Chem. A 7 1227

Google Scholar

Google Scholar

[18] Ma Q, Huang S, Wen X 2016 Adv. Energy Mater. 6 1502202

Google Scholar

Google Scholar

[19] Subhani W, Wang K, Du M 2019 Adv. Energy Mater. 9 1803785

Google Scholar

Google Scholar

[20] Ren Y, Hao Y, Zhang N, Cai M, Dai S 2020 Chem. Eng. J. 392 123805

Google Scholar

Google Scholar

[21] Li B, Zhang Y, Fu L 2018 Nat. Commun. 9 1076

Google Scholar

Google Scholar

[22] Peng H, Cai M, Zhou J, Ding X, Pan J, Dai S 2020 Solar RRL 4 2000216

Google Scholar

Google Scholar

[23] Xu W, Zhu T, Wu H 2020 ACS Appl. Mater. Interfaces 12 45045

Google Scholar

Google Scholar

[24] Zhao Y C, Wei J, Li H, Yan Y, Zhou W, Yu D, Zhao Q 2016 Nat. Commun. 7 10228

Google Scholar

Google Scholar

[25] Wu W, Zhong J, Liao J 2020 Nano Energy 75 104929

Google Scholar

Google Scholar

[26] Yang J, Liu C, Cai C 2019 Adv. Energy Mater. 9 1900198

Google Scholar

Google Scholar

[27] Yin G, Zhao H, Jiang H, Liu Z, Liu S 2018 Adv. Funct Mater. 28 1803269

Google Scholar

Google Scholar

[28] Du J, Duan J, Yang X, Duan Y, Zhou Q, Tang Q 2021 Angew. Chem. Int. Ed. 60 1

Google Scholar

Google Scholar

[29] Wang Z, BaranwalA K, Kamarudin M A, Ng C, Pandey M, Ma T, Hayase S 2019 Nano Energy 59 258

Google Scholar

Google Scholar

计量

- 文章访问数: 9298

- PDF下载量: 176

- 被引次数: 0

下载:

下载: