-

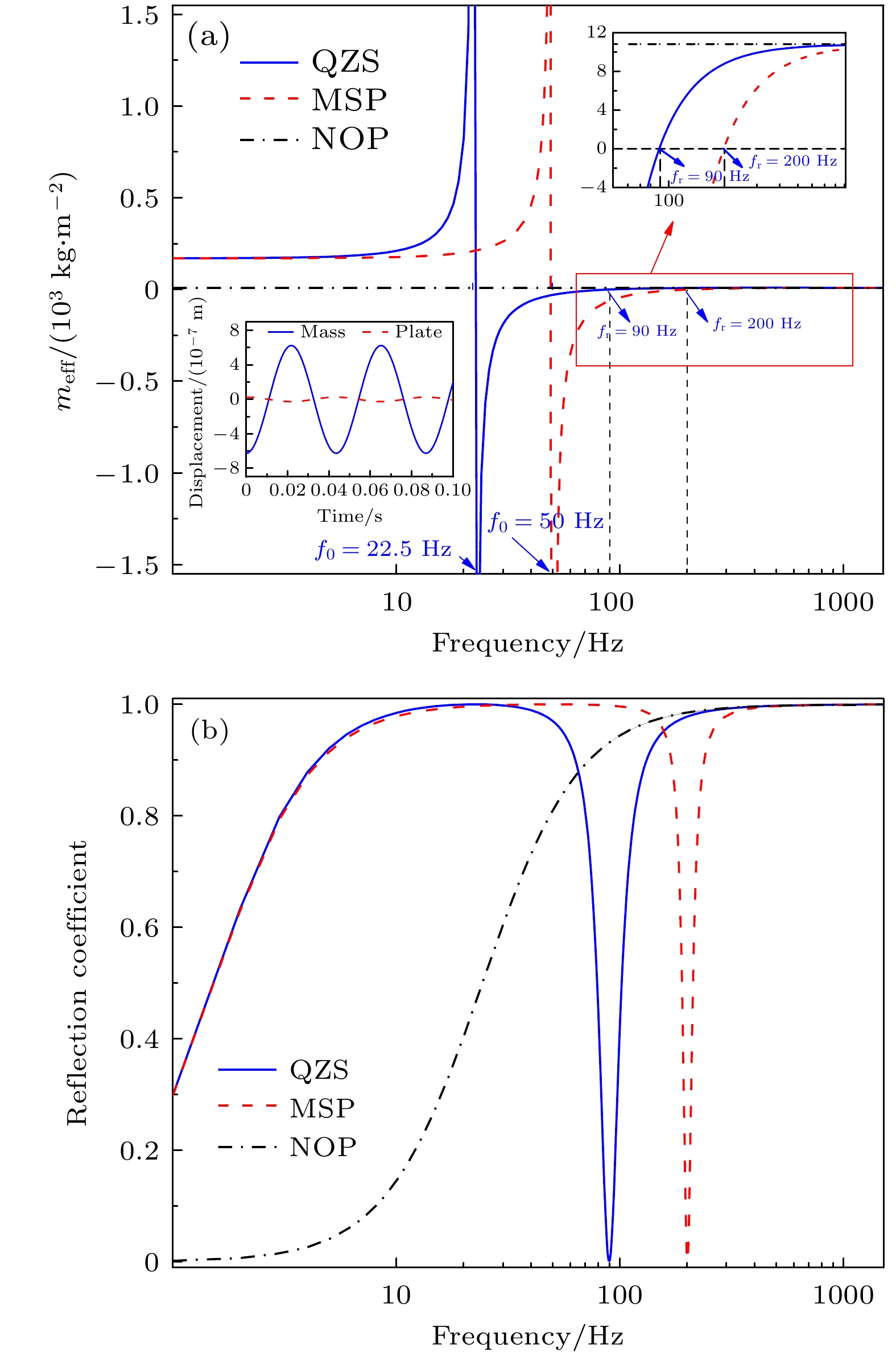

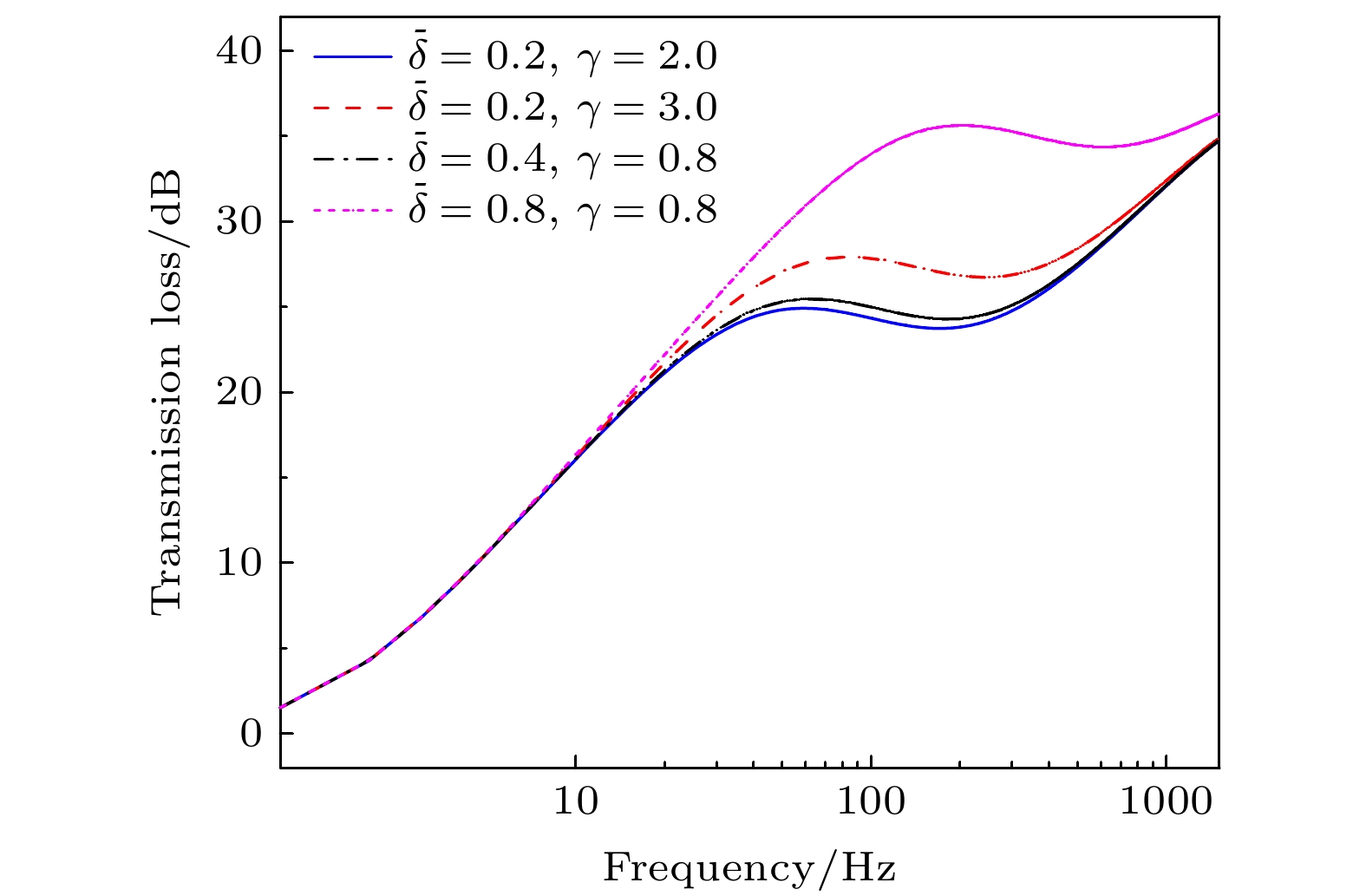

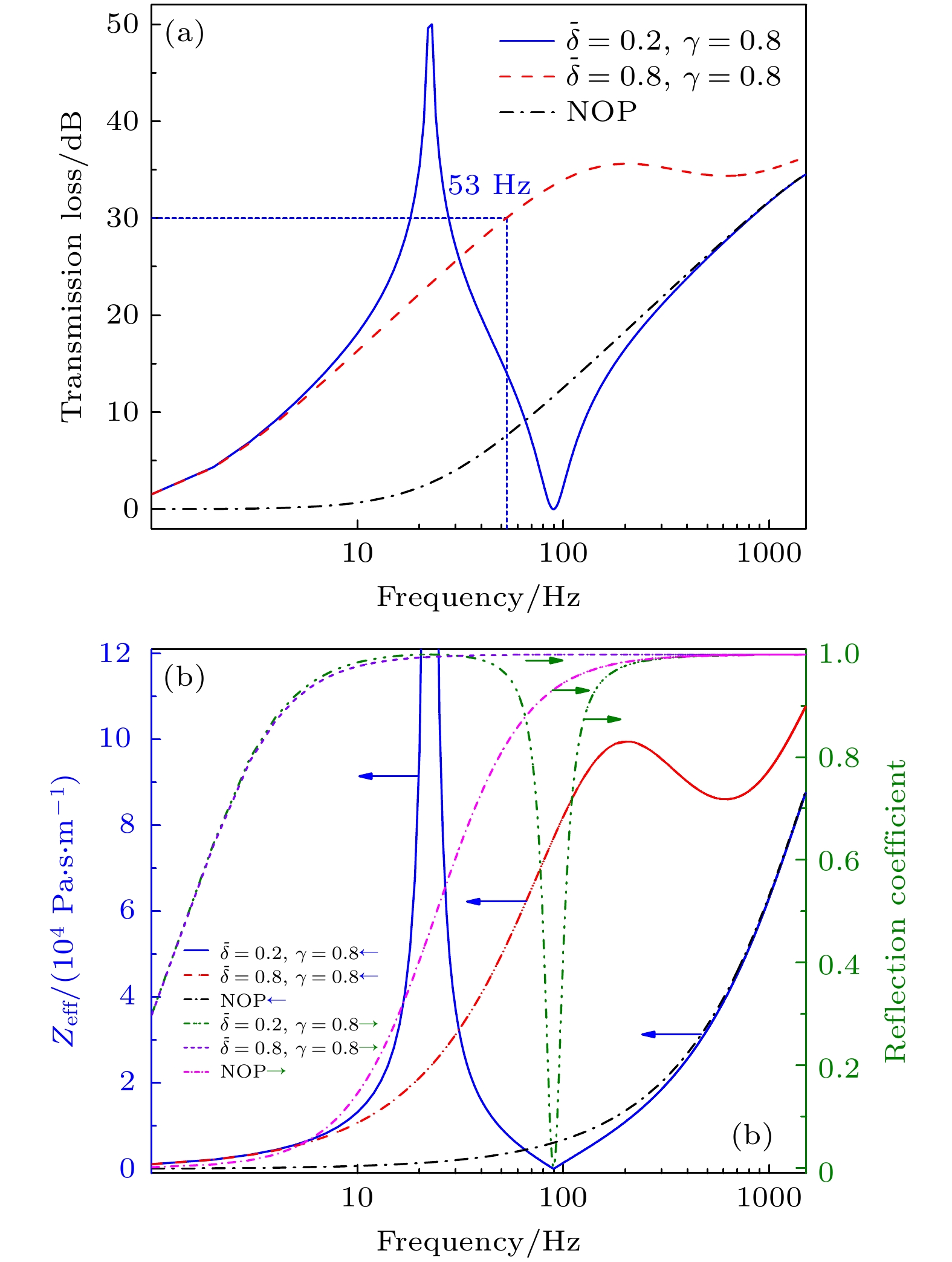

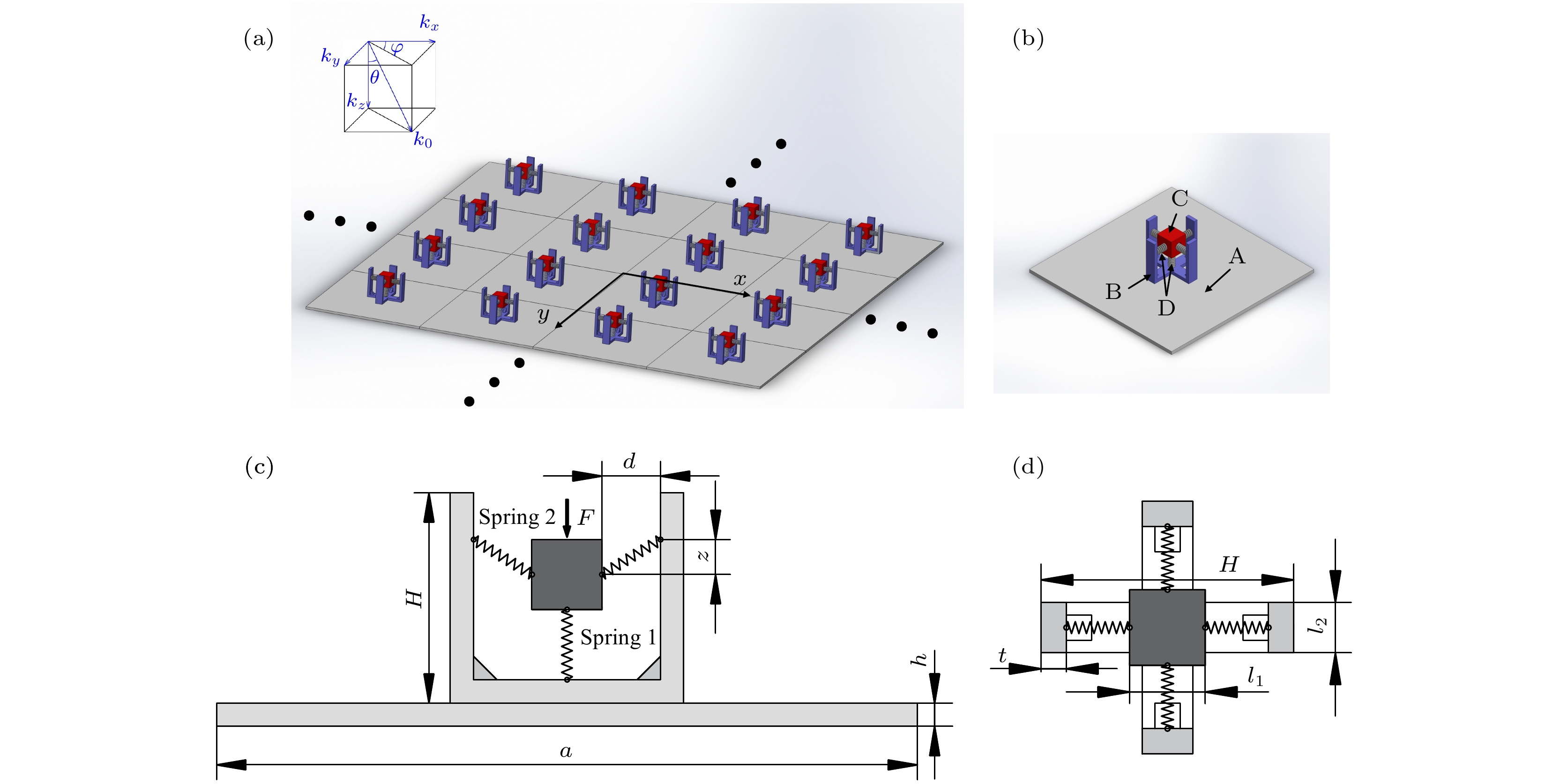

在传统弹簧-振子局域共振基础上, 本文并联倾斜弹簧负刚度机构, 提出一种新型的准零刚度局域共振型声学超材料板, 以实现低频宽频带有效隔声. 首先, 从动力学角度推导准零刚度结构的归一化等效刚度; 然后, 基于等效介质法建立声学超材料板的隔声理论模型, 并通过理论分析和数值模拟(有限元)结果, 讨论其在正负等效刚度区的隔声效果; 最后, 为验证理论预测的准确性, 制备准零刚度超材料板样件并采用阻抗管对其进行测试. 结果表明: 在正刚度区, 增大弹簧的刚度比或预压缩量可显著降低超材料板的局域共振频率, 如在10 Hz附近获得30 dB的传输损失, 实现了超低频隔声. 在负刚度区, 超材料板不产生局域共振现象, 且可避免“吻合效应”引起的隔声低谷现象, 故可在53—1500 Hz宽频段内实现大宽带隔声(大于30 dB), 相较传统材料或类似的超材料具有显著优势. 进一步利用理论模型, 从等效质量面密度、反射系数和声阻抗率等多个角度, 分析了超材料板的隔声机理, 在隔声峰处发现了负的等效质量密度, 且隔声谷处产生了低频“吻合效应”. 本文提出利用准零刚度局域共振思想实现低频宽带隔声的方法, 克服了传统超材料需减小刚度或增大附加质量的不利特性, 对低频隔声结构的设计具有重要的理论指导意义.For realizing the effective broadband insulation of sound at low frequencies, a novel local resonant acoustic metamaterial plate having quasi-zero stiffness is proposed. Based on the classical mass-spring local resonance model, a metastructure is constructed by introducing additional inclined springs with negative stiffness. First, the normalized equivalent stiffness of the quasi-zero stiffness structure is derived from the perspective of dynamics. Then, by employing the method of equivalent medium, a sound insulation model of the metastructure is established theoretically. For validation, numerical simulations as well as experimental measurements are carried out. It is demonstrated that in the positive (equivalent) stiffness regime, increasing either the stiffness ratio or pre-compression can significantly reduce the local resonance frequency of the metastructure, which exhibits the great insulation performance around the local resonance frequency. For a typical example, the proposed metastructure can achieve a transmission loss of 30 dB around 10 Hz. In contrast, within the negative stiffness regime, the metastructure does not exhibit local resonance, thus avoiding sound insulation valley caused by the “coincidence effect”. Compared with traditional materials or similar metamaterials, the proposed metastructure has significant advantages in sound insulation (e.g. more than 30 dB drop over a wide frequency band of 53-1500 Hz). By analyzing the equivalent mass density, reflection coefficient, and acoustic impedance ratio of the metastructure, the physical mechanism behind its superior insulation performance is further explored. The equivalent mass density changes from positive to negative and tends to infinity at the insulation peak. The insulation peak is attributed to a nearly perfect total reflection of sound wave caused by impedance mismatch, while the insulation valley is caused by low-frequency “coincidence effect” originating from the local resonance band gap. The using of the quasi-zero stiffness local resonance to achieve low-frequency broadband sound insulation overcomes the disadvantages of traditional metamaterials such as reduced stiffness or additional mass, thus becoming vastly attractive for constructing low-frequency broad band sound insulation structures.

-

Keywords:

- metamaterial /

- local resonance /

- quasi-zero stiffness /

- low frequency range /

- sound insulation

[1] 田源, 葛浩, 卢明辉, 陈延锋 2019 68 194301

Google Scholar

Google Scholar

Tian Y, Ge H, Lu M H, Chen Y F 2019 Acta Phys. Sin. 68 194301

Google Scholar

Google Scholar

[2] Ma G C, Sheng P 2016 Sci. Adv. 2 e1501595

Google Scholar

Google Scholar

[3] 丁昌林, 董仪宝, 赵晓鹏 2018 67 194301

Google Scholar

Google Scholar

Ding C L, Dong Y B, Zhao X P 2018 Acta Phys. Sin. 67 194301

Google Scholar

Google Scholar

[4] Liu Z Y, Chan C T, Sheng P 2005 Phys. Rev. B 71 014103

Google Scholar

Google Scholar

[5] Fang N, Xi D J, Xu J Y, Ambati M, Srituravanich W, Sun C, Zhang X 2006 Nat. Mater. 5 452

Google Scholar

Google Scholar

[6] Deng K, Ding Y Q, He Z J, Zhao H P, Shi J, Liu Z Y 2009 J. Appl. Phys. 105 188505

Google Scholar

Google Scholar

[7] Zhu X F, Liang B, Kan W W, Zou X Y, Cheng J C 2011 Phys. Rev. Lett. 106 014301

Google Scholar

Google Scholar

[8] Peng S S, He Z J, Jia H, Zhang A Q, Qiu C Y, Ke M Z, Liu Z Y 2010 Appl. Phys. Lett. 96 263502

Google Scholar

Google Scholar

[9] Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Sheng P 2012 Nat. Commun. 3 756

Google Scholar

Google Scholar

[10] Kushwaha M S, Halevi P, Dobrzynski L, Djafari-Rouhani B 1993 Phys. Rev. Lett. 71 2022

Google Scholar

Google Scholar

[11] Liu Z Y, Zhang X, Mao Y, Zhu Y Y, Yang Z, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[12] 张佳龙, 姚宏, 杜军, 赵静波, 董亚科, 祁鹏山 2016 硅酸盐学报 44 1440

Google Scholar

Google Scholar

Zhang J L, Yao H, Du J, Zhao J B, Dong Y K, Qi P S 2016 J. Chin. Ceramic Soc. 44 1440

Google Scholar

Google Scholar

[13] 张思文, 吴九汇 2013 62 134302

Google Scholar

Google Scholar

Zhang S W, Wu J H 2013 Acta Phys. Sin. 62 134302

Google Scholar

Google Scholar

[14] 张永燕, 吴九汇, 钟宏民 2017 66 094301

Google Scholar

Google Scholar

Zhang Y Y, Wu J H, Zhong H M 2017 Acta Phys. Sin. 66 094301

Google Scholar

Google Scholar

[15] 张若军, 肖勇, 温激鸿, 郁殿龙 2016 振动工程学报 29 905

Google Scholar

Google Scholar

Zhang R J, Xiao Y, Wen J H, Yu D L 2016 J. Vib. Eng. 29 905

Google Scholar

Google Scholar

[16] 乔厚, 何锃, 张恒堃, 彭伟才, 江雯 2019 68 128101

Google Scholar

Google Scholar

Qiao H, He Z, Zhang H K, Peng W C, Jiang W 2019 Acta Phys. Sin. 68 128101

Google Scholar

Google Scholar

[17] 梅军, 杨旻, 杨志宇, 陈傲轩, 沈平 2010 物理 39 243

Mei J, Yang M, Yang Z Y, Chen A X, Shen P 2010 Physics 39 243

[18] 贺子厚, 赵静波, 姚宏, 陈鑫 2019 68 214302

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Chen X 2019 Acta Phys. Sin. 68 214302

Google Scholar

Google Scholar

[19] 贺子厚, 赵静波, 姚宏, 蒋娟娜, 陈鑫 2019 68 134302

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Jiang J N, Chen X 2019 Acta Phys. Sin. 68 134302

Google Scholar

Google Scholar

[20] Xiao Y, Wen J H, Wen X S 2012 J. Phys. D:Appl. Phys. 45 195401

Google Scholar

Google Scholar

[21] Xiao Y, Wen J H, Wen X S 2012 J. Sound Vib. 331 5408

Google Scholar

Google Scholar

[22] Huang X C, Liu X T, Sun J Y, Zhang Z Y, Hua H X 2014 J. Sound Vib. 333 1132

Google Scholar

Google Scholar

[23] Carrella A, Brennan M J, Waters T P 2007 J. Sound Vib. 301 678

Google Scholar

Google Scholar

[24] Zheng Y S, Zhang X N, Luo Y J, Zhang Y H, Xie S L 2018 Mech. Syst. Sig. Process. 100 135

Google Scholar

Google Scholar

[25] Wang K, Zhou J X, Cai C Q, Xu D L, Ouyang H J 2019 Appl. Math. Modell. 73 581

Google Scholar

Google Scholar

[26] 张浩 2016 博士学位论文 (长沙: 国防科技大学)

Zhang H 2016 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[27] 杜功焕, 朱哲民, 龚秀芬 2012 声学基础 (南京: 南京大学出版社) 第71页

Du G H, Zhu Z M, Gong X F 2012 Acoustic Basis (Nanjing: Nanjing University Press) p71 (in Chinese)

[28] 李佩 2014 博士学位论文 (北京: 北京理工大学)

Li P 2014 Ph. D. Dissertation (Beijing: Beijing Institute of Technology) (in Chinese)

[29] 何琳, 朱海潮, 邱小军, 杜功焕 2006 声学理论与工程应用 (北京: 科学出版社) 第177页

He L, Zhu H C, Qiu X J, Du G H 2006 Acoustic Theory and Engineering Application (Beijing: Science Press) p177 (in Chinese)

-

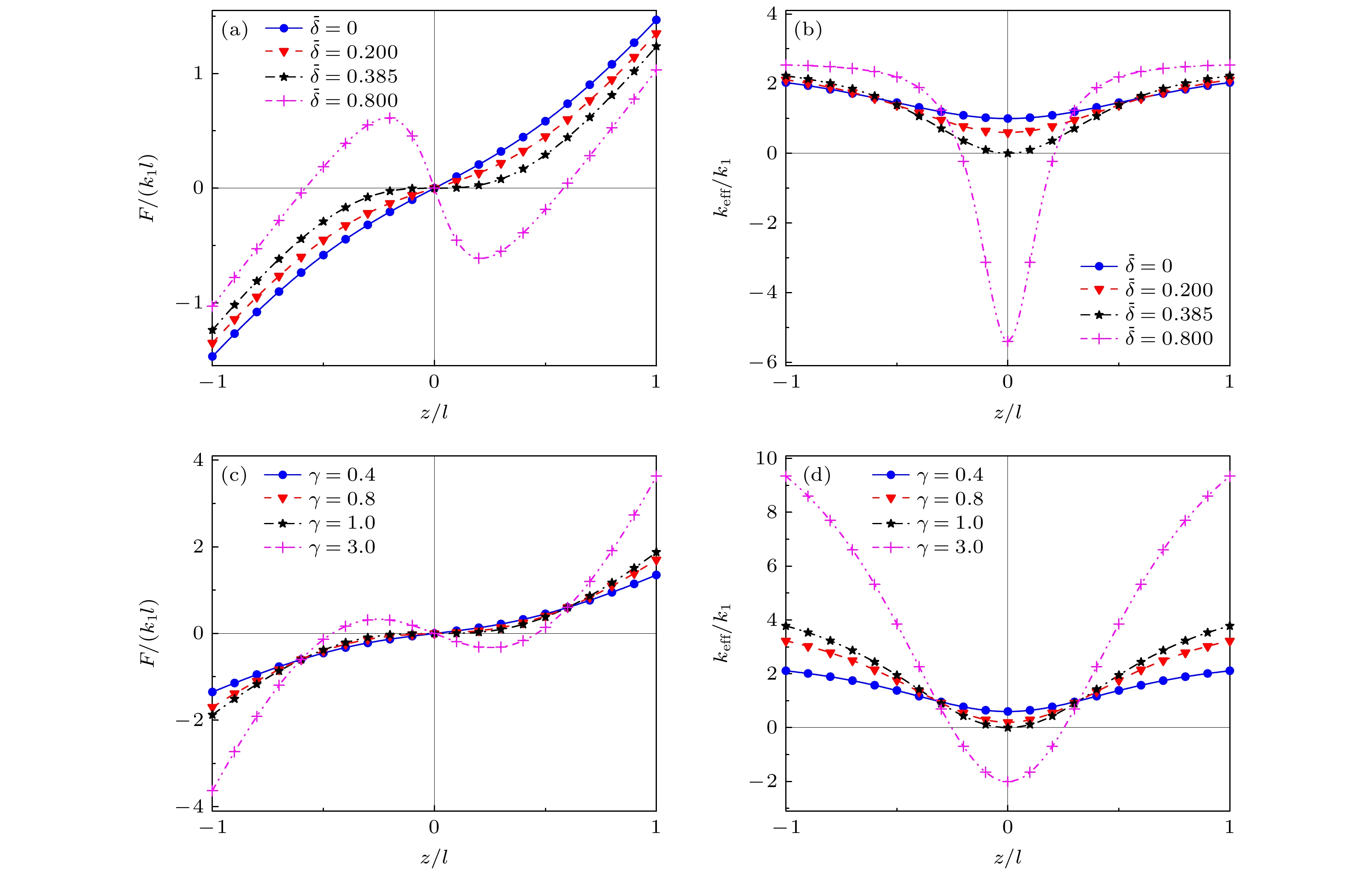

图 2 弹簧刚度比保持不变(

$\gamma = 0.4$ ), (a)归一化恢复力和(b)等效刚度随弹簧预压缩量的变化趋势; 弹簧预压缩量保持不变($\bar \delta = 0.2$ ), (c)归一化恢复力和(d)等效刚度随弹簧刚度比的变化趋势Fig. 2. (a) Normalized reacting force and (b) equivalent stiffness plotted as functions of pre-compression of springs for

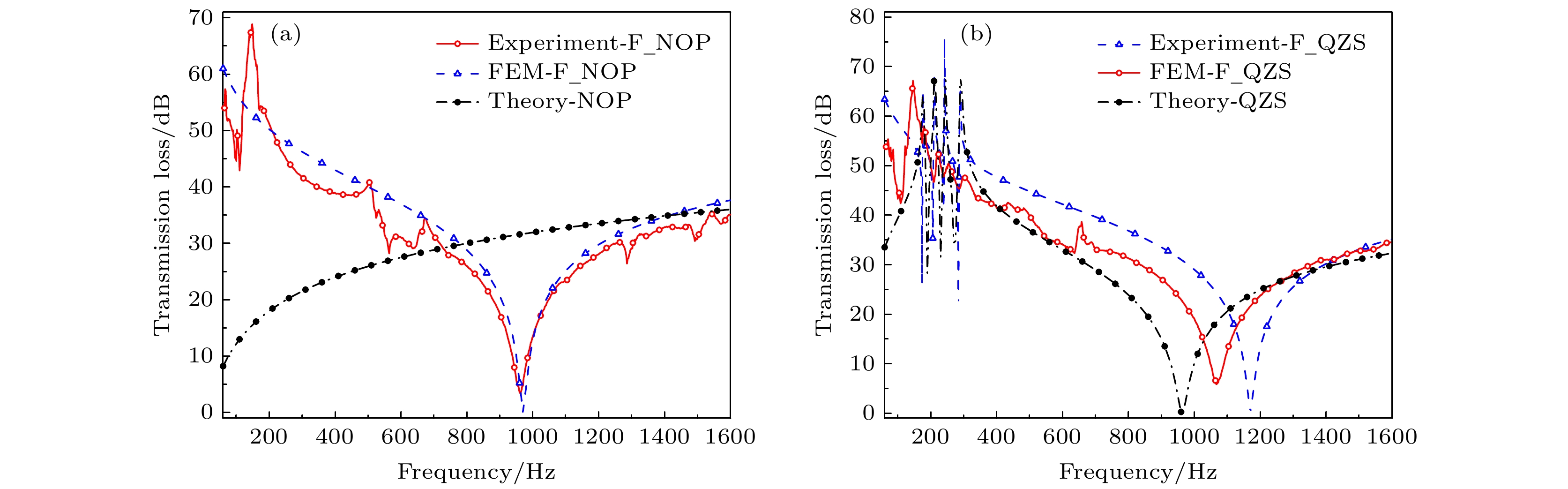

$\gamma = 0.4$ ; (c) normalized reacting force and (d) equivalent stiffness plotted as functions of spring stiffness ratio for$\bar \delta = 0.2$ .图 9 正/负等效刚度区超材料板和无振子板对比 (a)传输损失; (b)等效阻抗和反射系数

Fig. 9. Metamaterial plate compared with non-oscillator plate in both positive regime (

$\bar \delta = 0.2$ and$\gamma = 0.8$ ) and negative regime ($\bar \delta = 0.8$ and$\gamma = 0.8$ ) of equivalent stiffness: (a) Transmission loss; (b) equivalent impedance and reflection coefficient.表 1 材料参数

Table 1. Material parameters.

Material $\rho $/(kg⋅m–3) E /(1010 Pa) Possion ratio Aluminum 2700 7 0.33 Steel 7780 21.06 0.3 Epoxy resin 1150 0.435 0.38 Plumbum 11600 40.8 0.369 表 2 三种声学板结构的结构参数

Table 2. Structural parameters of the three structures.

Model a/mm h/mm k1/(N⋅m–1) Stiffness ratio Pre-compression m/kg QZS 25 4 10000 0.8 0.2 0.1 MSP 25 4 10000 0 0 0.1 NOP 25 4 0 0 0 0 表 3 准零刚度单元在正等效刚度区的调节参数

Table 3. Selected values of spring stiffness and pre-compression in the regime of positive equivalent stiffness.

Group k1 /(N⋅m–1) Stiffness ratio Pre-compression Case1 10000 0.4 0.2 Case2 10000 0.6 0.2 Case3 10000 0.8 0.2 Case4

Case510000

100000.4

0.40.3

0.376表 4 准零刚度单元在负等效刚度区的调节参数

Table 4. Selected values of spring stiffness and pre-compression in the regime of negative equivalent stiffness.

Group k1/(N⋅m–1) Stiffness ratio Pre-compression Case1 10000 2.0 0.2 Case2 10000 3.0 0.2 Case3

Case410000

100000.8

0.80.4

0.8表 5 有限大四振子超材料板的力学参数及局域共振频率

Table 5. Mechanical parameters and local resonance frequencies of finite four-oscillator metamaterial plate.

k1/(N·m–1) k2/(N·m–1) Pre-compression m/g Experiment f0/Hz FEM f0/ Hz A 35137.8 11322.1 0.2 19.14 178 176 B 35137.8 1093.16 0.2 19.14 211 210 C 35137.8 11322.1 0.2 10.17 254 242 D 35137.8 11322.1 0.02 10.17 300 289 -

[1] 田源, 葛浩, 卢明辉, 陈延锋 2019 68 194301

Google Scholar

Google Scholar

Tian Y, Ge H, Lu M H, Chen Y F 2019 Acta Phys. Sin. 68 194301

Google Scholar

Google Scholar

[2] Ma G C, Sheng P 2016 Sci. Adv. 2 e1501595

Google Scholar

Google Scholar

[3] 丁昌林, 董仪宝, 赵晓鹏 2018 67 194301

Google Scholar

Google Scholar

Ding C L, Dong Y B, Zhao X P 2018 Acta Phys. Sin. 67 194301

Google Scholar

Google Scholar

[4] Liu Z Y, Chan C T, Sheng P 2005 Phys. Rev. B 71 014103

Google Scholar

Google Scholar

[5] Fang N, Xi D J, Xu J Y, Ambati M, Srituravanich W, Sun C, Zhang X 2006 Nat. Mater. 5 452

Google Scholar

Google Scholar

[6] Deng K, Ding Y Q, He Z J, Zhao H P, Shi J, Liu Z Y 2009 J. Appl. Phys. 105 188505

Google Scholar

Google Scholar

[7] Zhu X F, Liang B, Kan W W, Zou X Y, Cheng J C 2011 Phys. Rev. Lett. 106 014301

Google Scholar

Google Scholar

[8] Peng S S, He Z J, Jia H, Zhang A Q, Qiu C Y, Ke M Z, Liu Z Y 2010 Appl. Phys. Lett. 96 263502

Google Scholar

Google Scholar

[9] Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Sheng P 2012 Nat. Commun. 3 756

Google Scholar

Google Scholar

[10] Kushwaha M S, Halevi P, Dobrzynski L, Djafari-Rouhani B 1993 Phys. Rev. Lett. 71 2022

Google Scholar

Google Scholar

[11] Liu Z Y, Zhang X, Mao Y, Zhu Y Y, Yang Z, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[12] 张佳龙, 姚宏, 杜军, 赵静波, 董亚科, 祁鹏山 2016 硅酸盐学报 44 1440

Google Scholar

Google Scholar

Zhang J L, Yao H, Du J, Zhao J B, Dong Y K, Qi P S 2016 J. Chin. Ceramic Soc. 44 1440

Google Scholar

Google Scholar

[13] 张思文, 吴九汇 2013 62 134302

Google Scholar

Google Scholar

Zhang S W, Wu J H 2013 Acta Phys. Sin. 62 134302

Google Scholar

Google Scholar

[14] 张永燕, 吴九汇, 钟宏民 2017 66 094301

Google Scholar

Google Scholar

Zhang Y Y, Wu J H, Zhong H M 2017 Acta Phys. Sin. 66 094301

Google Scholar

Google Scholar

[15] 张若军, 肖勇, 温激鸿, 郁殿龙 2016 振动工程学报 29 905

Google Scholar

Google Scholar

Zhang R J, Xiao Y, Wen J H, Yu D L 2016 J. Vib. Eng. 29 905

Google Scholar

Google Scholar

[16] 乔厚, 何锃, 张恒堃, 彭伟才, 江雯 2019 68 128101

Google Scholar

Google Scholar

Qiao H, He Z, Zhang H K, Peng W C, Jiang W 2019 Acta Phys. Sin. 68 128101

Google Scholar

Google Scholar

[17] 梅军, 杨旻, 杨志宇, 陈傲轩, 沈平 2010 物理 39 243

Mei J, Yang M, Yang Z Y, Chen A X, Shen P 2010 Physics 39 243

[18] 贺子厚, 赵静波, 姚宏, 陈鑫 2019 68 214302

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Chen X 2019 Acta Phys. Sin. 68 214302

Google Scholar

Google Scholar

[19] 贺子厚, 赵静波, 姚宏, 蒋娟娜, 陈鑫 2019 68 134302

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Jiang J N, Chen X 2019 Acta Phys. Sin. 68 134302

Google Scholar

Google Scholar

[20] Xiao Y, Wen J H, Wen X S 2012 J. Phys. D:Appl. Phys. 45 195401

Google Scholar

Google Scholar

[21] Xiao Y, Wen J H, Wen X S 2012 J. Sound Vib. 331 5408

Google Scholar

Google Scholar

[22] Huang X C, Liu X T, Sun J Y, Zhang Z Y, Hua H X 2014 J. Sound Vib. 333 1132

Google Scholar

Google Scholar

[23] Carrella A, Brennan M J, Waters T P 2007 J. Sound Vib. 301 678

Google Scholar

Google Scholar

[24] Zheng Y S, Zhang X N, Luo Y J, Zhang Y H, Xie S L 2018 Mech. Syst. Sig. Process. 100 135

Google Scholar

Google Scholar

[25] Wang K, Zhou J X, Cai C Q, Xu D L, Ouyang H J 2019 Appl. Math. Modell. 73 581

Google Scholar

Google Scholar

[26] 张浩 2016 博士学位论文 (长沙: 国防科技大学)

Zhang H 2016 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[27] 杜功焕, 朱哲民, 龚秀芬 2012 声学基础 (南京: 南京大学出版社) 第71页

Du G H, Zhu Z M, Gong X F 2012 Acoustic Basis (Nanjing: Nanjing University Press) p71 (in Chinese)

[28] 李佩 2014 博士学位论文 (北京: 北京理工大学)

Li P 2014 Ph. D. Dissertation (Beijing: Beijing Institute of Technology) (in Chinese)

[29] 何琳, 朱海潮, 邱小军, 杜功焕 2006 声学理论与工程应用 (北京: 科学出版社) 第177页

He L, Zhu H C, Qiu X J, Du G H 2006 Acoustic Theory and Engineering Application (Beijing: Science Press) p177 (in Chinese)

计量

- 文章访问数: 13064

- PDF下载量: 383

- 被引次数: 0

下载:

下载: