-

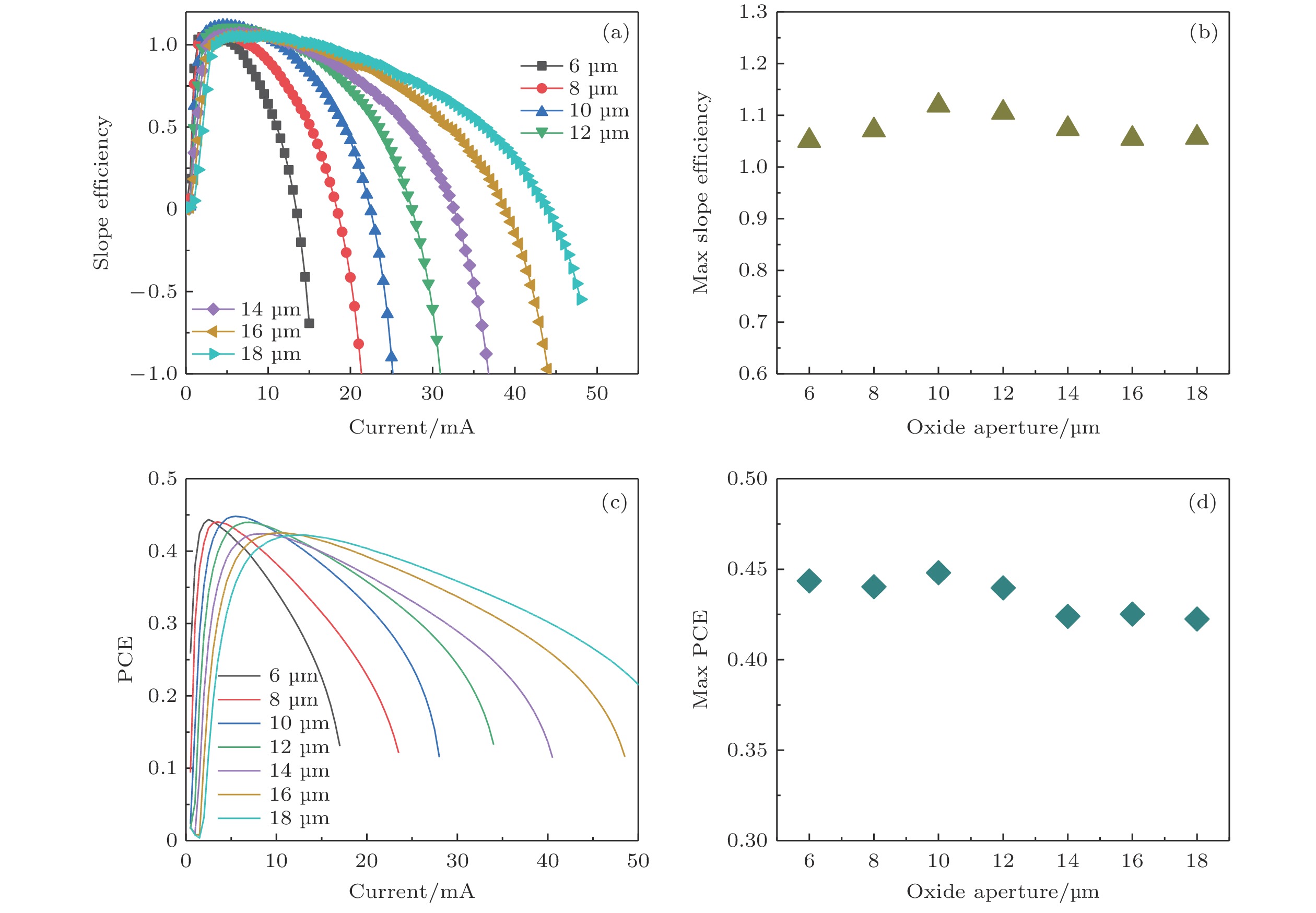

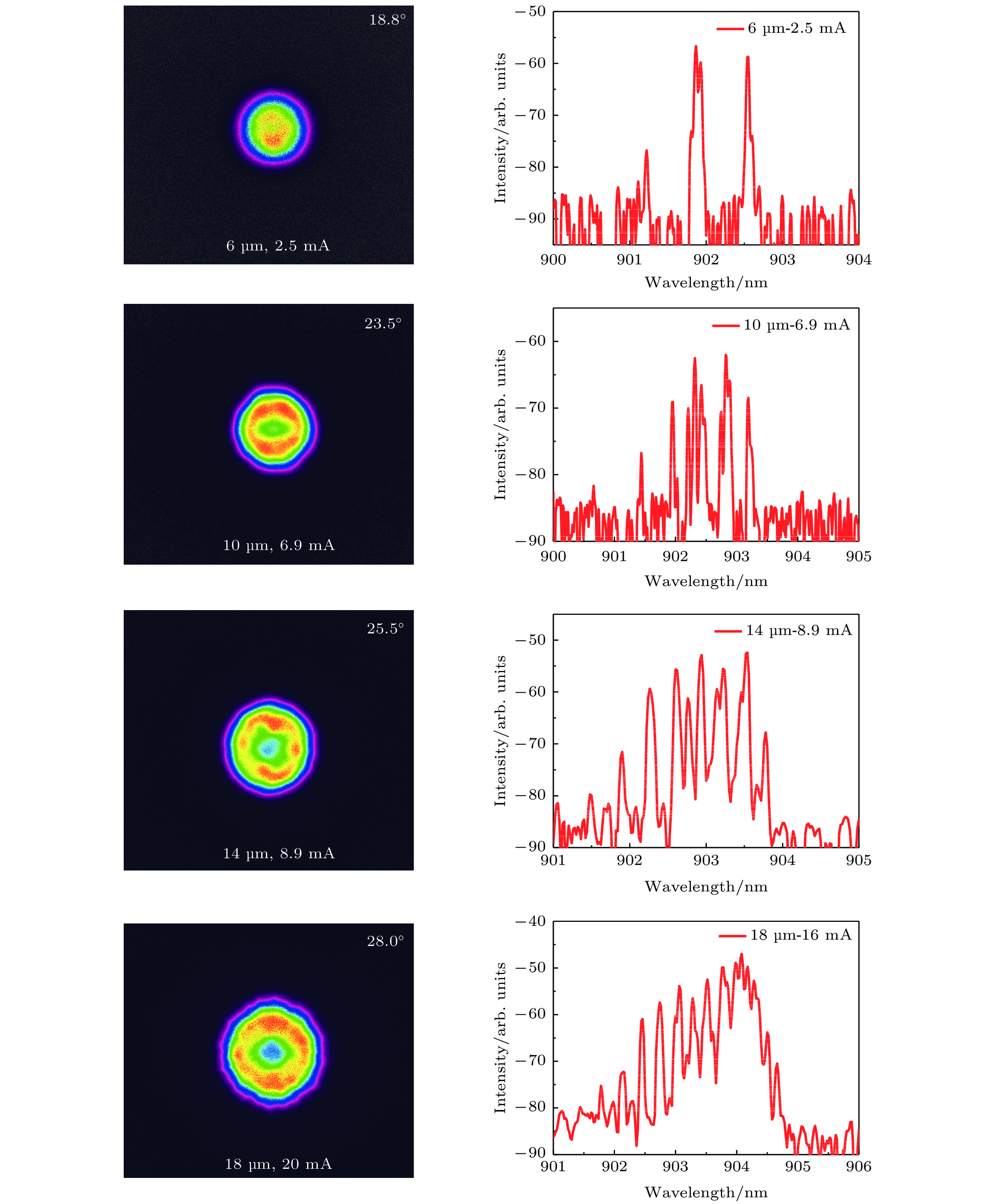

通过对影响垂直腔面发射激光器(vertical cavity surface emitting laser, VCSEL)的功率转换效率的因素进行理论分析, 得出斜率效率是影响功率转换效率的主要因素的结论. 为获得高功率转换效率, 通过对有源区量子阱、P型和N型分布布拉格反射镜(DBR)等进行优化, 设计出了905 nm VCSEL的外延结构并进行了高质量外延生长. 成功制备出了不同氧化孔径的905 nm VCSEL器件, 获得的最大斜率效率为1.12 W/A, 最大转换效率为44.8%. 此外, 探究了氧化孔径对VCSEL的远场和光谱特性的影响. 这种具有高功率转换效率的905 nm VCSEL器件为激光雷达的小型化、低成本化提供了良好的基础数据.

-

关键词:

- 905 nm垂直腔面发射激光器 /

- 高功率转换效率 /

- 外延结构设计 /

- 器件制备

Vertical cavity surface emitting lasers (VCSELs) have lots of excellent properties, such as circular beam, low threshold, single longitudinal mode, high speed modulation and monolithic array fabrication capability. The VCSELs have been widely used in data communication and short-distance optical interconnection. In the fields of distance detection and automatic driving, high accuracy lidars have become an indispensable component. In practical applications, 905 nm laser exhibits little absorption by the water vapor in the air. In addition, the 905 nm laser can match with both inexpensive Si detector and high response avalanche photodiode (APD). Therefore, the 905 nm semiconductor laser has become a key light source of lidar. This paper presents the design and fabrication of 905 nm VCSEL with high power conversion efficiency. First, the main factors influencing the power conversion efficiency (PCE) of VCSEL are analyzed theoretically. It is concluded that the slope efficiency contributes to the PCE most. In order to achieve a high slope efficiency, strained InGaAs is used as a quantum well material. Due to the wavelength redshift caused by the thermal effect, the lasing peak wavelength of the multiple quantum well (MQW) is designed to be about 892 nm by optimizing the In composition. The active region consists of three pairs of In0.123Ga0.88As/Al0.3Ga0.7 MQWs. The N-distributed Bragg reflectors (DBRs) are designed to have 40 pairs of Al0.9Ga0.1As/Al0.12Ga0.88As, and the P-DBRs are designed to have 20 pairs of Al0.9Ga0.1As/Al0.12Ga0.88As. The epitaxial structure is designed and grown by metal organic chemical vapor deposition (MOCVD). The cavity mode of the epitaxial wafer is around 903.7 nm. The photoluminescence (PL) spectrum is also measured. The peak wavelength is approximately 893.7 nm, and the full width at half maximum is 21.6 nm. Then, the 905 nm VCSELs with different apertures (6–18 μm) are fabricated via semiconductor technologies such as photolithography, evaporation, inductively coupled plasma (ICP), wet oxidation, electroplating, etc. Finally, the L-I-V characteristics and spectra of VCSELs with different apertures are tested. The obtained maximum slope efficiency and PCE of the devices are 1.12 W/A and 44.8%, respectively. In addition, the influences of aperture size on the far-field profiles and spectra of the devices are investigated. These 905 nm VCSELs with high PCE are potential for the miniaturization and lowing the cost of LiDAR.-

Keywords:

- 905 nm vertical cavity surface emitting laser /

- high power conversion efficiency /

- epitaxial structure design /

- device fabrication

[1] Huffaker D L, Deppe D G 1994 Appl. Phys. Lett. 65 97

Google Scholar

Google Scholar

[2] 张星, 张奕, 张建伟, 张建, 钟础宇, 黄佑文, 宁永强, 顾思洪, 王立军 2016 65 134204

Google Scholar

Google Scholar

Zhang X, Zhang Y, Zhang J W, Zhang J, Zhong C Y, Huang Y W, Ning Y Q, Gu S H, Wang L J 2016 Acta Phy. Sin. 65 134204

Google Scholar

Google Scholar

[3] Larisch G, Moser P, Lott J A, Bimberg D 2016 IEEE Photonic Technol. Lett. 28 2327

Google Scholar

Google Scholar

[4] Jaeger, R, Grabherr, M, Jung, C, Michalzik, Reiner, G, Weigl 1997 Electron. Lett. 33 330

Google Scholar

Google Scholar

[5] Yang X, Li M X, Zhao G, Freisem S, Deppe D G 2014 Electron. Lett. 50 1864

Google Scholar

Google Scholar

[6] Mukoyama N, Otoma H, Sakurai J, Ueki N, Nakayama H 2008 Proc. SPIE 6908 690815

[7] Seurin J F, Zhou D, Xu G, Miglo A, Ghosh C 2016 Proc. SPIE 9766 97660D

Google Scholar

Google Scholar

[8] Larsson A 2011 IEEE J. Sel.Top. Quantum Electron. 17 1552

Google Scholar

Google Scholar

[9] Harris J S, Sullivan T O, Sarmiento T, Lee M M, Vo S 2010 Semicond. Sci. Technol. 26 14010

[10] Zhou D, Seurin J F, Xu G, Leeuwen R V, Miglo A, Wang Q, Kovsh A, Ghosh C 2017 Proc. SPIE 10122 1012206

Google Scholar

Google Scholar

[11] Hao Y Q, Ma J L, Yan C L, Liu G J, Zhao Y J 2013 Laser Physics Letters 10 527

[12] Pan G Z, Xie Y, Xu C, Xun M, Dong Y, Deng J, Chen H, Sun J 2018 IEEE J. Quantum Electron. 54 1

[13] Zhong C, Zhang X, Hofmann W H E, Ning Y Q, Wang L J 2018 IEEE Photonics J. 10 1

[14] Huang C Y, Wang H Y, Wu C H, Lo W C, Lin G R 2020 J. Lightwave Technol. 38 573

Google Scholar

Google Scholar

[15] Xun M, Xu C, Xie Y, Deng J, Xu K, Chen H 2014 IEEE J. Quantum Electron. 51 1

[16] 郝永芹, 冯源, 王菲, 晏长岭, 赵英杰, 王晓华, 王玉霞, 姜会林, 高欣 2011 60 064201

Google Scholar

Google Scholar

Hao Y Q, Feng Y, Wang F, Yan C L, Zhao Y J, Wang X H, Wang Y X, Jiang H L, Gao X 2011 Acta Phy. Sin. 60 064201

Google Scholar

Google Scholar

[17] 周广正, 尧舜, 于洪岩, 吕朝晨, 王青, 周天宝, 李颖, 兰天, 夏宇, 郎陆广, 程立文, 董国亮, 康联鸿, 王智勇 2018 67 104205

Google Scholar

Google Scholar

Zhou G Z, Rao S, Yu H Y, Lv C C, Wang Q, Zhou T B, Li Y, Lan T, Xia Y, Lang L G, Cheng L W, Dong G L, Kang L H, Wang Z Y 2018 Acta Phy. Sin. 67 104205

Google Scholar

Google Scholar

[18] Warren M E, Carson R F, Joseph J R, Wilcox T, Dacha P, D. Abell J, Otis K J 2015 Proc. SPIE 9381 93810C

Google Scholar

Google Scholar

[19] Zhang J W, Ning Y Q, Zhang X, Qiu J, Zeng Y G, Fu X H, Zhang J Y, Qin L, Wang L J 2018 Jpn. J. Appl. Phys. 57 100302

Google Scholar

Google Scholar

[20] Chen X N, Shi J W, Chi K L, Y J L, Chen Jaso 2017 J. Lightwave Technol. 35 3242

Google Scholar

Google Scholar

[21] Nanni J, Fernandez L, Hadi M U, Viana C, Tartarini G 2020 Electron. Lett. 56 385

Google Scholar

Google Scholar

[22] Caliman A, Mereuta A, Wolf P, Sirbu A, Iakovlev V, Bimberg D, Kapon E 2016 Opt. Express 24 16329

Google Scholar

Google Scholar

[23] Chase C, Yi R, Hofmann W, Chang-Hasnain C J 2010 Opt. Express 15 15461

[24] Li X P, Peng Q J, Xu Z Y, Zhang X D, Wang X J 2020 IEEE Photonics Technol. Lett. 32 434

Google Scholar

Google Scholar

[25] Seurin J F, Ghosh C L, Khalfin V, Miglo A, Xu G, Wynn J D, Pradhan P, D'Asaro L A 2008 Proc. SPIE 6908 690808

Google Scholar

Google Scholar

[26] Kressel, Henry 1977 Semiconductor Lasers and Heterojunction LEDs (New York: Academic) pp459−465

[27] Coldren, Larry A 1995 Opt. Eng. 36 616

[28] 于洪岩, 尧舜, 张红梅, 王青, 张杨, 周广正, 吕朝晨, 程立文, 郎陆广, 夏宇 2019 68 064207

Google Scholar

Google Scholar

Yu H Y, Yao S, Zhang H M, Wang Q, Zhang Y, Zhou G Z, Lv Z C, Cheng L W, Lang L G, Xia Y 2019 Acta Phy. Sin. 68 064207

Google Scholar

Google Scholar

[29] Fujisawa T, Sato T, Mitsuhara M, Kakitsuka T, Yamanaka T, Kondo Y, Kano F 2009 IEEE J. Quantum Electron. 45 1183

Google Scholar

Google Scholar

[30] 周梅, 赵德刚 2016 65 077802

Google Scholar

Google Scholar

Zhou M, Zhao D G 2016 Acta Phy. Sin. 65 077802

Google Scholar

Google Scholar

-

-

[1] Huffaker D L, Deppe D G 1994 Appl. Phys. Lett. 65 97

Google Scholar

Google Scholar

[2] 张星, 张奕, 张建伟, 张建, 钟础宇, 黄佑文, 宁永强, 顾思洪, 王立军 2016 65 134204

Google Scholar

Google Scholar

Zhang X, Zhang Y, Zhang J W, Zhang J, Zhong C Y, Huang Y W, Ning Y Q, Gu S H, Wang L J 2016 Acta Phy. Sin. 65 134204

Google Scholar

Google Scholar

[3] Larisch G, Moser P, Lott J A, Bimberg D 2016 IEEE Photonic Technol. Lett. 28 2327

Google Scholar

Google Scholar

[4] Jaeger, R, Grabherr, M, Jung, C, Michalzik, Reiner, G, Weigl 1997 Electron. Lett. 33 330

Google Scholar

Google Scholar

[5] Yang X, Li M X, Zhao G, Freisem S, Deppe D G 2014 Electron. Lett. 50 1864

Google Scholar

Google Scholar

[6] Mukoyama N, Otoma H, Sakurai J, Ueki N, Nakayama H 2008 Proc. SPIE 6908 690815

[7] Seurin J F, Zhou D, Xu G, Miglo A, Ghosh C 2016 Proc. SPIE 9766 97660D

Google Scholar

Google Scholar

[8] Larsson A 2011 IEEE J. Sel.Top. Quantum Electron. 17 1552

Google Scholar

Google Scholar

[9] Harris J S, Sullivan T O, Sarmiento T, Lee M M, Vo S 2010 Semicond. Sci. Technol. 26 14010

[10] Zhou D, Seurin J F, Xu G, Leeuwen R V, Miglo A, Wang Q, Kovsh A, Ghosh C 2017 Proc. SPIE 10122 1012206

Google Scholar

Google Scholar

[11] Hao Y Q, Ma J L, Yan C L, Liu G J, Zhao Y J 2013 Laser Physics Letters 10 527

[12] Pan G Z, Xie Y, Xu C, Xun M, Dong Y, Deng J, Chen H, Sun J 2018 IEEE J. Quantum Electron. 54 1

[13] Zhong C, Zhang X, Hofmann W H E, Ning Y Q, Wang L J 2018 IEEE Photonics J. 10 1

[14] Huang C Y, Wang H Y, Wu C H, Lo W C, Lin G R 2020 J. Lightwave Technol. 38 573

Google Scholar

Google Scholar

[15] Xun M, Xu C, Xie Y, Deng J, Xu K, Chen H 2014 IEEE J. Quantum Electron. 51 1

[16] 郝永芹, 冯源, 王菲, 晏长岭, 赵英杰, 王晓华, 王玉霞, 姜会林, 高欣 2011 60 064201

Google Scholar

Google Scholar

Hao Y Q, Feng Y, Wang F, Yan C L, Zhao Y J, Wang X H, Wang Y X, Jiang H L, Gao X 2011 Acta Phy. Sin. 60 064201

Google Scholar

Google Scholar

[17] 周广正, 尧舜, 于洪岩, 吕朝晨, 王青, 周天宝, 李颖, 兰天, 夏宇, 郎陆广, 程立文, 董国亮, 康联鸿, 王智勇 2018 67 104205

Google Scholar

Google Scholar

Zhou G Z, Rao S, Yu H Y, Lv C C, Wang Q, Zhou T B, Li Y, Lan T, Xia Y, Lang L G, Cheng L W, Dong G L, Kang L H, Wang Z Y 2018 Acta Phy. Sin. 67 104205

Google Scholar

Google Scholar

[18] Warren M E, Carson R F, Joseph J R, Wilcox T, Dacha P, D. Abell J, Otis K J 2015 Proc. SPIE 9381 93810C

Google Scholar

Google Scholar

[19] Zhang J W, Ning Y Q, Zhang X, Qiu J, Zeng Y G, Fu X H, Zhang J Y, Qin L, Wang L J 2018 Jpn. J. Appl. Phys. 57 100302

Google Scholar

Google Scholar

[20] Chen X N, Shi J W, Chi K L, Y J L, Chen Jaso 2017 J. Lightwave Technol. 35 3242

Google Scholar

Google Scholar

[21] Nanni J, Fernandez L, Hadi M U, Viana C, Tartarini G 2020 Electron. Lett. 56 385

Google Scholar

Google Scholar

[22] Caliman A, Mereuta A, Wolf P, Sirbu A, Iakovlev V, Bimberg D, Kapon E 2016 Opt. Express 24 16329

Google Scholar

Google Scholar

[23] Chase C, Yi R, Hofmann W, Chang-Hasnain C J 2010 Opt. Express 15 15461

[24] Li X P, Peng Q J, Xu Z Y, Zhang X D, Wang X J 2020 IEEE Photonics Technol. Lett. 32 434

Google Scholar

Google Scholar

[25] Seurin J F, Ghosh C L, Khalfin V, Miglo A, Xu G, Wynn J D, Pradhan P, D'Asaro L A 2008 Proc. SPIE 6908 690808

Google Scholar

Google Scholar

[26] Kressel, Henry 1977 Semiconductor Lasers and Heterojunction LEDs (New York: Academic) pp459−465

[27] Coldren, Larry A 1995 Opt. Eng. 36 616

[28] 于洪岩, 尧舜, 张红梅, 王青, 张杨, 周广正, 吕朝晨, 程立文, 郎陆广, 夏宇 2019 68 064207

Google Scholar

Google Scholar

Yu H Y, Yao S, Zhang H M, Wang Q, Zhang Y, Zhou G Z, Lv Z C, Cheng L W, Lang L G, Xia Y 2019 Acta Phy. Sin. 68 064207

Google Scholar

Google Scholar

[29] Fujisawa T, Sato T, Mitsuhara M, Kakitsuka T, Yamanaka T, Kondo Y, Kano F 2009 IEEE J. Quantum Electron. 45 1183

Google Scholar

Google Scholar

[30] 周梅, 赵德刚 2016 65 077802

Google Scholar

Google Scholar

Zhou M, Zhao D G 2016 Acta Phy. Sin. 65 077802

Google Scholar

Google Scholar

计量

- 文章访问数: 9039

- PDF下载量: 288

- 被引次数: 0

下载:

下载: