-

等离子密度及金属离化率是影响高功率脉冲磁控溅射沉积薄膜质量的关键因素, 高功率脉冲磁控溅射参数(如电压、脉宽、沉积气压及峰值电流等)影响着等离子密度和金属离化率. 本文利用MATLAB/SIMULINK建立等效电路模型, 对高功率脉冲磁控溅射钛(Ti)靶材的放电电流曲线进行模拟, 利用鞘层电阻计算Ti靶材鞘层处的等离子密度, 并采用半圆柱体-整体模型理论计算Ti的离化率. 研究发现: 采用由电容、电感和电阻组成的等效电路模型, 可以模拟Ti靶材的放电电流; 在不同高功率脉冲溅射电压、脉冲宽度和不同沉积气压下, 真空室等离子密度在2 × 1017—9 × 1017 m–3范围内, 随着溅射电压、脉冲宽度及沉积气压的增加, 鞘层处的平均等离子密度增大; 在不同沉积气压下, Ti的离化率值在31%—38%之间, 随着气压增加, Ti的离化率增加.

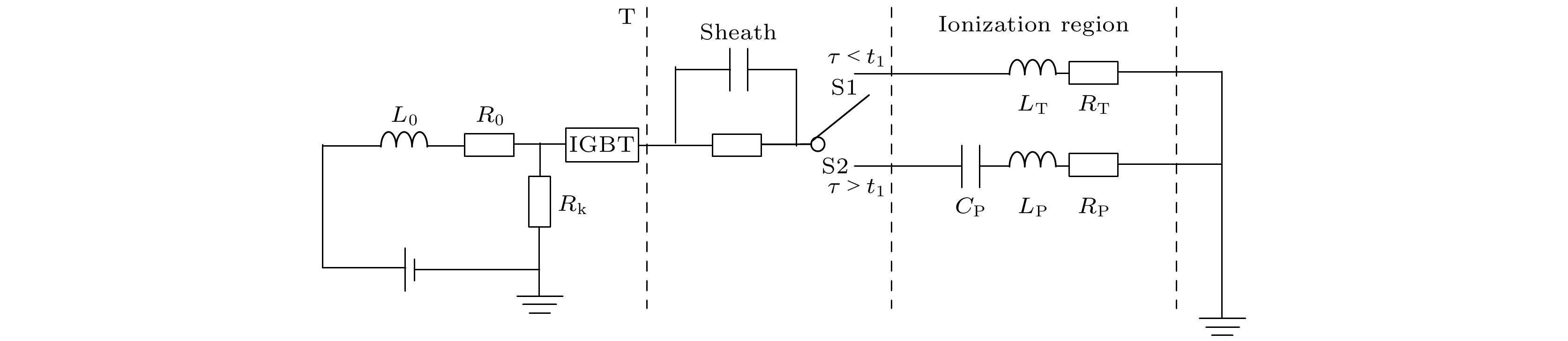

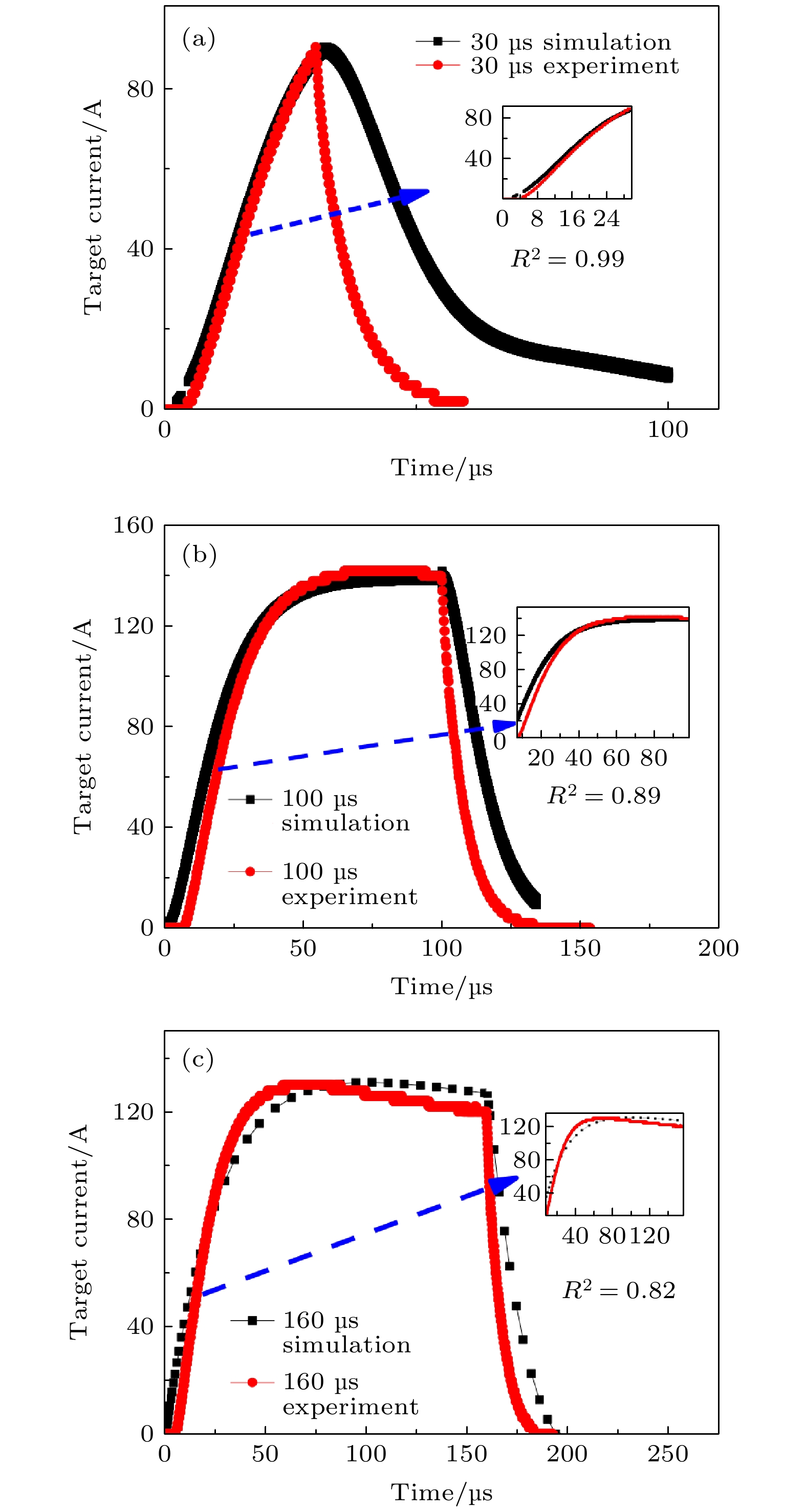

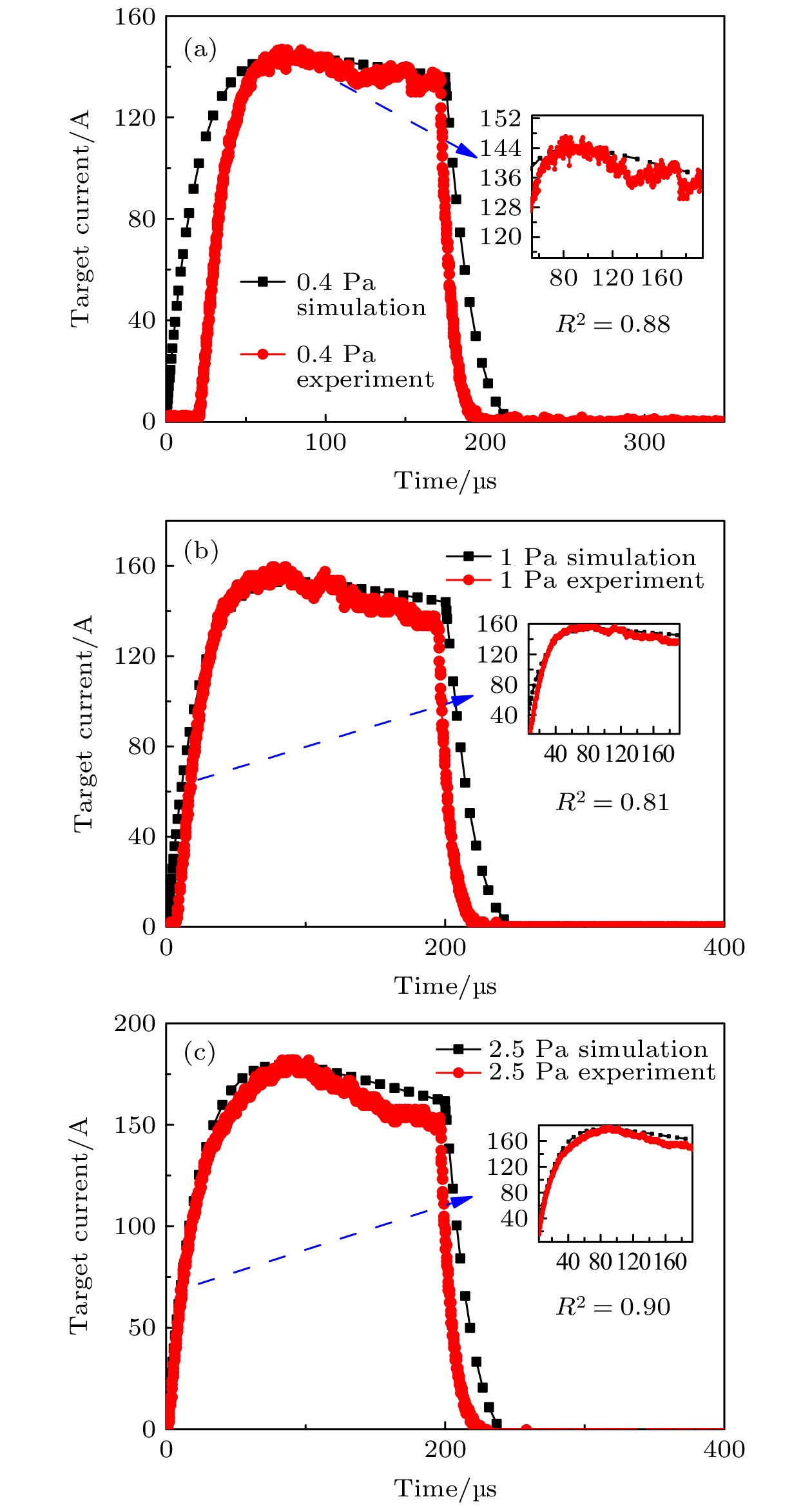

High-power pulsed magnetron sputtering has become a popular research tool in surface technology industry because it can prepare the films with excellent surface quality. The plasma density and metal ionization rate are the key factors affecting the quality of the film deposited by high-power pulsed magnetron sputtering. The parameters of high-power pulsed magnetron sputtering (such as applied voltage, pulse width, deposition pressure and peak current) affect the plasma density and metal ionization rate. In this paper, in order to more easily understand the plasma densities and metal ionization rates at the different process parameters, the plasma densities and ionization rates are calculated numerically. An equivalent circuit model established by MATLAB/Simulink software is used to obtain the discharge current curve of high-power pulsed magnetron sputtering titanium (Ti) target. The plasma density near the plasma sheath is calculated by the sheath resistance in the equivalent circuit model. The ionization rate of Ti is calculated by using the semi-cylinder global model theory combined with the discharge current simulated by equivalent circuit model. It is found that under the different high power pulse sputtering voltages, pulse widths and different deposition pressures, the discharge modes are of gas discharge and metal ion discharge, and the gas discharge interacts with metal ion discharge. The equivalent circuit model is produced by the main discharge mode, and the equivalent circuit model composed of capacitor, inductor and resistors in series and in parallel can be used to simulate the discharge current of Ti target. The result shows that the simulated discharge current is accurate in the rising edge and peak value in comparison with experimental data. The value of electron component in the model is related to the saturation ion current. According to the sheath resistance in the model, the average plasma density in the vacuum chamber increases with increasing sputtering voltage, pulse width and deposition pressure. And the plasma density in the vacuum chamber lies in a range of (2–9) × 1017 m–3. The particle equilibrium equation is established by using the semi-cylinder global model theory. The electron temperature (5 eV) and discharge current are used as boundary conditions to calculate the ionization rate of Ti. The value of the ionization rate of Ti is in a range of 31%–38% at different deposition pressures, and the ionization rate of Ti increases with the increase of deposition pressure. -

Keywords:

- high power pulsed magnetron sputtering /

- equivalent circuit /

- global model /

- ionization rate

[1] 崔岁寒, 吴忠振, 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Chen L, Li T J, Liu L L, Fu R K Y, Tian X B, Chu P K, Tan W C 2019 Acta Phys. Sin. 68 195204

Google Scholar

Google Scholar

[2] Bobzin K, Brgelmann T, Kruppe N C, Carlet M 2020 Surf. Coat. Technol. 385 125370

Google Scholar

Google Scholar

[3] Jing P P, Ma D L, Gong Y L, Luo X Y, Leng Y X 2020 Surf. Coat. Technol. 405 126542

Google Scholar

Google Scholar

[4] Alami J, Sarakinos K, Uslu F, Wuttig M 2009 J. Phys. D: Appl. Phys. 42 015304

Google Scholar

Google Scholar

[5] 王愉, 陈畅子, 吴艳萍, 冷永祥 2017 表面技术 46 15

Google Scholar

Google Scholar

Wang Y, Chen C Z, Wu Y P, Leng Y X 2017 Surface Technology 46 15

Google Scholar

Google Scholar

[6] Bohlmark J, Lattemann M, Gudmundsson J T, Ehiasarian A P, Helmersson U 2006 Thin Solid Films 515 1522

Google Scholar

Google Scholar

[7] Konstantinidis S, Dauchot J P, Ganciu M, Ricard A, Hecq M 2006 J. Appl. Phys. 99 013307

Google Scholar

Google Scholar

[8] Yu H, Sporre J R, Liang M, McLain J T, Ruzic D N, Szott M M, Raman P 2015 J. Vac. Sci. Technol. A 33 031301

Google Scholar

Google Scholar

[9] Bohlmark J, Helmersson U, Van Zeeland M, Axnis I, Alami J, Brenning N 2004 Plasma Sources Sci. Technol. 13 654

Google Scholar

Google Scholar

[10] Gahan D, Dolinaj B, Hopkinsl M 2008 Rev. Sci. Instrum. 79 3455

Google Scholar

Google Scholar

[11] Kirkpatrick S 2009 Ph. D. Dissertations (Nebraska: University of Nebraska)

[12] Ken Y, Ryosuke M, Kingo A, Hiroshi T, Tadao O 2009 Nuclear Inst & Methods in Physics Research B 267 1692

Google Scholar

Google Scholar

[13] Chen C Z, Ma D L, Huang N, Leng Y X 2019 Int. J. Mod. Phys. B 33 290

Google Scholar

Google Scholar

[14] Zheng B C, Meng D, Che H L, Lei M K 2015 J. Appl. Phys. 117 290

Google Scholar

Google Scholar

[15] Gudmundsson J T 2008 J. Phys. Conf. Ser. 100 082013

Google Scholar

Google Scholar

[16] Hopwood J 1998 Phys. Plasmas 5 1624

Google Scholar

Google Scholar

[17] Kozak T, Pajdarova A D 2011 J. Appl. Phys. 110 1661

Google Scholar

Google Scholar

[18] Minea T M, Costin C, Revel A, Lundin D, Caillault L 2014 Surf. Coat. Technol. 255 52

Google Scholar

Google Scholar

[19] Wu Z Z, Xiao S, Ma Z Y, Cui S H, Ji S P, Tian X B, Fu Ricky K Y, Chu P K, Pan F 2015 AIP Adv. 5 097178

Google Scholar

Google Scholar

[20] Wu Z Z, Xiao S, Ma Z Y, Cui S H, Pan F, Tian X B, Fu R K Y, Chu P K 2016 Surf. Coat. Technol. 306 319

Google Scholar

Google Scholar

[21] Liang M, Yu H, Szott M M, McLain J T, Ruzic D N 2014 J. Appl. Phys. 115 290

Google Scholar

Google Scholar

[22] Ross A E, Ganesan R, Bilek M M M, McKenzie D R 2015 Plasma Sources Sci. Technol. 24 025018

Google Scholar

Google Scholar

[23] Jing F J, Yin T L, K Yukimura, Sun H, Leng Y X, Huang N 2012 Vacuum 86 2114

Google Scholar

Google Scholar

[24] Wu B H, Wu J, Jiang F, Ma D L, Chen C Z, Sun H, Leng Y X, Huang N 2017 Vacuum 135 93

Google Scholar

Google Scholar

[25] Ma D L, Wu B H, Deng Q Y, Leng Y X, Huang N 2019 Vacuum 160 226

Google Scholar

Google Scholar

[26] Raman P, Shchelkanov I, McLain J, Cheng M, Ruzic D, Haehnlein I, Jurczyk B, Stubbers R, Armstrong S 2016 Surf. Coat. Technol. 293 10

Google Scholar

Google Scholar

[27] 迈克尔 A 力伯曼, 阿伦 J 里登伯格 著 (蒲以康等 译) 2007 等离子体放电原理与材料处理 (北京: 科学出版社) 第293页

Lieberman M A, Lichtenberg A J (translated by Pu Y K) 2007 Principles of Plasma Discharges and Materials Processing (Beijing: Science Press) p293 (in Chinese)

[28] André A 2010 Surf. Coat. Technol. 204 2864

Google Scholar

Google Scholar

[29] André A, Joakim A, David H, Arutiun E 2011 Surf. Coat. Technol. 205 S1

Google Scholar

Google Scholar

[30] André A, Joakim A, Arutiun E 2007 J. Appl. Phys. 102 113303

Google Scholar

Google Scholar

[31] Brenning N, Axnas I, Raadu M A, Lundin D, Helmerson U 2008 Plasma Sources Sci. Technol. 17 045009

Google Scholar

Google Scholar

[32] Ku V P T, Annaratone B M, Allen J E 1998 J. Appl. Phys. 84 6536

Google Scholar

Google Scholar

[33] Bohlmark J, Alami J, Christou C 2005 J. Vac. Sci. Technol. A 23 18

Google Scholar

Google Scholar

[34] Horwat D, Anders A 2008 J. Phys. D: Appl. Phys. 41 135210

Google Scholar

Google Scholar

[35] 林浩 2014 硕士学位论文 (西安: 西安电子科技大学)

Lin H 2014 M. S. Thesis (Xi’an: Xidian University) (in Chinese)

[36] 吴忠振, 田修波, 李春伟, 傅劲裕, 潘锋, 朱剑豪 2014 63 175201

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Li C W, Fu R K Y, Pan F, Chu P K 2014 Acta Phys. Sin. 63 175201

Google Scholar

Google Scholar

[37] Yushkov G Y, Anders A 2010 IEEE Trans. Plasma Sci. 38 3028

Google Scholar

Google Scholar

[38] Ehiasarian A P, Vetushka A, Hecimovic A 2008 J. Appl. Phys. 104 267

Google Scholar

Google Scholar

[39] 吴保华, 冷永祥, 黄楠, 杨文茂, 李雪源 2018 表面技术 47 245

Google Scholar

Google Scholar

Wu B H, Leng Y X, Huang N, Yang W M, Li X Y 2018 Surf. Technol. 47 245

Google Scholar

Google Scholar

-

图 7 不同高功率脉冲磁控溅射工艺参数下的等离子密度 (a) 不同脉宽30, 100, 160 μs; (b) 不同电压700, 800, 900 V; (c)不同靶电流 113, 150, 185 A

Fig. 7. Comparison of plasma density calculated by equivalent circuit (simulation) under different HPPMS process parameters: (a) Different pulse width (30, 100, 160 μs); (b) different sputtering voltages (700, 800, 900 V); (c) different target currents (113, 150, 185 A)

-

[1] 崔岁寒, 吴忠振, 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Chen L, Li T J, Liu L L, Fu R K Y, Tian X B, Chu P K, Tan W C 2019 Acta Phys. Sin. 68 195204

Google Scholar

Google Scholar

[2] Bobzin K, Brgelmann T, Kruppe N C, Carlet M 2020 Surf. Coat. Technol. 385 125370

Google Scholar

Google Scholar

[3] Jing P P, Ma D L, Gong Y L, Luo X Y, Leng Y X 2020 Surf. Coat. Technol. 405 126542

Google Scholar

Google Scholar

[4] Alami J, Sarakinos K, Uslu F, Wuttig M 2009 J. Phys. D: Appl. Phys. 42 015304

Google Scholar

Google Scholar

[5] 王愉, 陈畅子, 吴艳萍, 冷永祥 2017 表面技术 46 15

Google Scholar

Google Scholar

Wang Y, Chen C Z, Wu Y P, Leng Y X 2017 Surface Technology 46 15

Google Scholar

Google Scholar

[6] Bohlmark J, Lattemann M, Gudmundsson J T, Ehiasarian A P, Helmersson U 2006 Thin Solid Films 515 1522

Google Scholar

Google Scholar

[7] Konstantinidis S, Dauchot J P, Ganciu M, Ricard A, Hecq M 2006 J. Appl. Phys. 99 013307

Google Scholar

Google Scholar

[8] Yu H, Sporre J R, Liang M, McLain J T, Ruzic D N, Szott M M, Raman P 2015 J. Vac. Sci. Technol. A 33 031301

Google Scholar

Google Scholar

[9] Bohlmark J, Helmersson U, Van Zeeland M, Axnis I, Alami J, Brenning N 2004 Plasma Sources Sci. Technol. 13 654

Google Scholar

Google Scholar

[10] Gahan D, Dolinaj B, Hopkinsl M 2008 Rev. Sci. Instrum. 79 3455

Google Scholar

Google Scholar

[11] Kirkpatrick S 2009 Ph. D. Dissertations (Nebraska: University of Nebraska)

[12] Ken Y, Ryosuke M, Kingo A, Hiroshi T, Tadao O 2009 Nuclear Inst & Methods in Physics Research B 267 1692

Google Scholar

Google Scholar

[13] Chen C Z, Ma D L, Huang N, Leng Y X 2019 Int. J. Mod. Phys. B 33 290

Google Scholar

Google Scholar

[14] Zheng B C, Meng D, Che H L, Lei M K 2015 J. Appl. Phys. 117 290

Google Scholar

Google Scholar

[15] Gudmundsson J T 2008 J. Phys. Conf. Ser. 100 082013

Google Scholar

Google Scholar

[16] Hopwood J 1998 Phys. Plasmas 5 1624

Google Scholar

Google Scholar

[17] Kozak T, Pajdarova A D 2011 J. Appl. Phys. 110 1661

Google Scholar

Google Scholar

[18] Minea T M, Costin C, Revel A, Lundin D, Caillault L 2014 Surf. Coat. Technol. 255 52

Google Scholar

Google Scholar

[19] Wu Z Z, Xiao S, Ma Z Y, Cui S H, Ji S P, Tian X B, Fu Ricky K Y, Chu P K, Pan F 2015 AIP Adv. 5 097178

Google Scholar

Google Scholar

[20] Wu Z Z, Xiao S, Ma Z Y, Cui S H, Pan F, Tian X B, Fu R K Y, Chu P K 2016 Surf. Coat. Technol. 306 319

Google Scholar

Google Scholar

[21] Liang M, Yu H, Szott M M, McLain J T, Ruzic D N 2014 J. Appl. Phys. 115 290

Google Scholar

Google Scholar

[22] Ross A E, Ganesan R, Bilek M M M, McKenzie D R 2015 Plasma Sources Sci. Technol. 24 025018

Google Scholar

Google Scholar

[23] Jing F J, Yin T L, K Yukimura, Sun H, Leng Y X, Huang N 2012 Vacuum 86 2114

Google Scholar

Google Scholar

[24] Wu B H, Wu J, Jiang F, Ma D L, Chen C Z, Sun H, Leng Y X, Huang N 2017 Vacuum 135 93

Google Scholar

Google Scholar

[25] Ma D L, Wu B H, Deng Q Y, Leng Y X, Huang N 2019 Vacuum 160 226

Google Scholar

Google Scholar

[26] Raman P, Shchelkanov I, McLain J, Cheng M, Ruzic D, Haehnlein I, Jurczyk B, Stubbers R, Armstrong S 2016 Surf. Coat. Technol. 293 10

Google Scholar

Google Scholar

[27] 迈克尔 A 力伯曼, 阿伦 J 里登伯格 著 (蒲以康等 译) 2007 等离子体放电原理与材料处理 (北京: 科学出版社) 第293页

Lieberman M A, Lichtenberg A J (translated by Pu Y K) 2007 Principles of Plasma Discharges and Materials Processing (Beijing: Science Press) p293 (in Chinese)

[28] André A 2010 Surf. Coat. Technol. 204 2864

Google Scholar

Google Scholar

[29] André A, Joakim A, David H, Arutiun E 2011 Surf. Coat. Technol. 205 S1

Google Scholar

Google Scholar

[30] André A, Joakim A, Arutiun E 2007 J. Appl. Phys. 102 113303

Google Scholar

Google Scholar

[31] Brenning N, Axnas I, Raadu M A, Lundin D, Helmerson U 2008 Plasma Sources Sci. Technol. 17 045009

Google Scholar

Google Scholar

[32] Ku V P T, Annaratone B M, Allen J E 1998 J. Appl. Phys. 84 6536

Google Scholar

Google Scholar

[33] Bohlmark J, Alami J, Christou C 2005 J. Vac. Sci. Technol. A 23 18

Google Scholar

Google Scholar

[34] Horwat D, Anders A 2008 J. Phys. D: Appl. Phys. 41 135210

Google Scholar

Google Scholar

[35] 林浩 2014 硕士学位论文 (西安: 西安电子科技大学)

Lin H 2014 M. S. Thesis (Xi’an: Xidian University) (in Chinese)

[36] 吴忠振, 田修波, 李春伟, 傅劲裕, 潘锋, 朱剑豪 2014 63 175201

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Li C W, Fu R K Y, Pan F, Chu P K 2014 Acta Phys. Sin. 63 175201

Google Scholar

Google Scholar

[37] Yushkov G Y, Anders A 2010 IEEE Trans. Plasma Sci. 38 3028

Google Scholar

Google Scholar

[38] Ehiasarian A P, Vetushka A, Hecimovic A 2008 J. Appl. Phys. 104 267

Google Scholar

Google Scholar

[39] 吴保华, 冷永祥, 黄楠, 杨文茂, 李雪源 2018 表面技术 47 245

Google Scholar

Google Scholar

Wu B H, Leng Y X, Huang N, Yang W M, Li X Y 2018 Surf. Technol. 47 245

Google Scholar

Google Scholar

计量

- 文章访问数: 7926

- PDF下载量: 109

- 被引次数: 0

下载:

下载: