-

石墨烯因其优异的力学性能已成为增强金属基复合材料的理想增强体. 然而, 目前对石墨烯/金属基复合材料在纳米压痕过程中嵌入石墨烯与位错之间的相互作用仍不清晰. 本文采用分子动力学模拟方法, 对90°, 45°和0°位向的石墨烯/铝基复合材料进行了纳米压痕模拟, 研究了压痕加载和卸载过程中石墨烯/铝基复合材料的位错形核及演化, 以获取不同位向的石墨烯与位错的相互作用机制, 并分析其对塑性区的影响. 研究发现, 石墨烯可以有效阻碍位错运动, 并且石墨烯会沿着位错滑移方向发生弹性变形. 在纳米压痕过程中, 位错与不同位向石墨烯之间的相互作用差异导致塑性区的变化趋势不同. 研究结果表明, 在石墨烯/铝基复合材料中, 位向不同的石墨烯对位错阻碍强度和方式不同, 且石墨烯位向为45°的复合材料的硬度高于其他模型. 此外, 石墨烯/铝基复合材料的位错线总长度的演化规律与石墨烯位向紧密相关. 本文研究可为设计和制备高性能石墨烯/金属基复合材料提供一定的理论指导.

-

关键词:

- 分子动力学模拟 /

- 力学性质 /

- 纳米压痕 /

- 石墨烯/铝基复合材料

Graphene has been thought to be an ideal reinforcement material for metal matrix composite due to its superior mechanical properties and unique two-dimensional geometry. However, the deformation mechanism of graphene/aluminum matrix composite is still unclear. In this paper, molecular dynamics simulation is used to elucidate the evolution details of the dislocation microstructure and the underlying interaction behavior between dislocation and graphene during nanoindentation of the graphene/aluminum matrix composite with various graphene orientations. To this end, four different cases, i.e. the pure aluminum and the graphene/aluminum matrix composite with the graphene orientation of 90°, 45° and 0° are examined, respectively. Based on the force-indentation depth curve, the interaction behavior between dislocation and graphene and its effect on the plastic zone are analyzed. The results indicate that the graphene can act as an effective dislocation motion barrier, and the elastic deformation of graphene can occur locally along the direction of dislocation slip. Using the visualization technique of dislocation extraction algorithm, the nucleation and propagation of dislocation are investigated. The results show that the differences in interaction behavior between dislocation and graphene with various orientations affect the spreading trend of the plastic zone and the blocking strength of graphene to dislocation. For the composite with the graphene orientations of 45° and 0°, the interaction between graphene and dislocation causes the number of dislocations to increase. Additionally, the plastic zone of the composite with the graphene orientation of 45° is tangent to two symmetrical graphene sheets. For the composite with the graphene orientation of 90°, the interaction between graphene and dislocation shortens the total length of the dislocation line, and the volume shrinkage of plastic zone is most significant after indenter retraction. Here, the hardness is also calculated to quantitatively evaluate the influence of graphene orientation on the mechanical properties of graphene/aluminum matrix composite. The hardness of the composite with the graphene orientation of 45° is highest, which is due to the decrease of the volume of the plastic zone and the increase of dislocation number. The decrease of the hardness of the composite with the graphene orientation of 90° is attributed to the reduction of dislocation number in the plastic zone. However, for the composite with the graphene orientation of 0°, the interaction between graphene and dislocation results in the softening effect, because of a wide range of elastic deformation in the graphene plane. The study can provide a certain theoretical guidance for designing and preparing the high-performance graphene/metal matrix composites.-

Keywords:

- molecular dynamics simulation /

- mechanical property /

- nanoindentation /

- graphene/aluminum matrix composite

[1] Miracle D B 2005 Compos. Sci. Technol. 65 2526

Google Scholar

Google Scholar

[2] Tjong S C 2013 Mater. Sci. Eng., R 74 281

Google Scholar

Google Scholar

[3] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[4] 范冰冰, 郭焕焕, 李稳, 贾瑜, 张锐 2013 62 148101

Google Scholar

Google Scholar

Fan B B, Guo H H, Li W, Jia Y, Zhang R 2013 Acta Phys. Sin. 62 148101

Google Scholar

Google Scholar

[5] Zhong T, Li J, Zhang K 2019 J. Appl. Phys. 125 175110

Google Scholar

Google Scholar

[6] Kim Y, Lee J, Yeom M S, Shin J W, Kim H, Cui Y, Kysar J W, Hone J, Jung Y, Jeon S, Han S M 2013 Nat. Commun. 4 2114

Google Scholar

Google Scholar

[7] Bartolucci S F, Paras J, Rafiee M A, Rafiee J, Lee S, Kapoor D, Koratkar N 2011 Mater. Sci. Eng., A 528 7933

Google Scholar

Google Scholar

[8] Ovid’ko I A, Sheinerman A G 2014 J. Phys. D: Appl. Phys. 47 495302

Google Scholar

Google Scholar

[9] Li Z, Guo Q, Li Z, Fan G, Xiong D B, Su Y, Zhang J, Zhang D 2015 Nano Lett. 15 8077

Google Scholar

Google Scholar

[10] Zhao L, Guo Q, Li Z, Xiong D B, Osovski S, Su Y, Zhang D 2019 Int. J. Plast. 116 265

Google Scholar

Google Scholar

[11] 马通, 谢红献 2020 69 130202

Google Scholar

Google Scholar

Ma T, Xian H X 2020 Acta Phys. Sin. 69 130202

Google Scholar

Google Scholar

[12] Lyu G J, Qiao J C, Yao Y, Pelletier J M, Rodney D, Morthomas J, Fusco C 2020 Scr. Mater. 174 39

Google Scholar

Google Scholar

[13] Zhou X, Bu W, Song S, Sansoz F, Huang X 2019 Mater. Des. 182 108093

Google Scholar

Google Scholar

[14] Du Y, Zhou Q, Jia Q, Shi Y, Wang H, Wang J 2020 Mater. Res. Lett. 8 357

Google Scholar

Google Scholar

[15] Charleston J, Agrawal A, Mirzaeifar R 2020 Comput. Mater. Sci. 178 109621

Google Scholar

Google Scholar

[16] Weng S, Ning H, Fu T, Hu N, Zhao Y, Huang C, Peng X 2018 Sci. Rep. 8 3089

Google Scholar

Google Scholar

[17] Shuang F, Aifantis K E 2020 Scr. Mater. 181 70

Google Scholar

Google Scholar

[18] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[19] Zha X H, Zhang R Q, Lin Z 2014 J. Chem. Phys. 141 064705

Google Scholar

Google Scholar

[20] Lee Y, Park J Y, Kim S Y, Jun S, Im S 2005 Mech. Mater. 37 1035

Google Scholar

Google Scholar

[21] Mishin Y, Farkas D, Mehl M J, Papaconstantopoulos D A 1999 Phys. Rev. B 59 3393

Google Scholar

Google Scholar

[22] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[23] Silvestre N, Faria B, Canongia Lopes J N 2014 Compos. Sci. Technol. 90 16

Google Scholar

Google Scholar

[24] Zhou X, Liu X, Lei J, Yang Q 2020 Comput. Mater. Sci. 172 109342

Google Scholar

Google Scholar

[25] Stukowski A 2010 Model. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[26] Faken D, Jónsson H 1994 Comput. Mater. Sci. 2 279

Google Scholar

Google Scholar

[27] Stukowski A, Bulatov V V, Arsenlis A 2012 Model. Simul. Mater. Sci. Eng. 20 085007

Google Scholar

Google Scholar

[28] Remington T P, Ruestes C J, Bringa E M, Remington B A, Lu C H, Kad B, Meyers M A 2014 Acta Mater. 78 378

Google Scholar

Google Scholar

[29] Jiao S, Tu W, Zhang P, Zhang W, Qin L, Sun Z, Chen J 2018 Comput. Mater. Sci. 143 384

Google Scholar

Google Scholar

[30] Chang S W, Nair A K, Buehler M J 2013 Philos. Mag. Lett. 93 196

Google Scholar

Google Scholar

[31] Mortazavi B, Rémond Y, Ahzi S, Toniazzo V 2012 Comput. Mater. Sci. 53 298

Google Scholar

Google Scholar

[32] Gao Y, Ruestes C J, Tramontina D R, Urbassek H M 2015 J. Mech. Phys. Solids 75 58

Google Scholar

Google Scholar

[33] 李锐, 刘腾, 陈翔, 陈思聪, 符义红, 刘琳 2018 67 190202

Google Scholar

Google Scholar

Li R, Liu T, Chen X, Chen S C, Fu Y H, Liu L 2018 Acta Phys. Sin. 67 190202

Google Scholar

Google Scholar

[34] Taylor G I 1934 Proc. R. Soc. London, Ser. A 145 388

Google Scholar

Google Scholar

[35] Bagheripoor M, Klassen R 2020 Mech. Mater. 143 103311

Google Scholar

Google Scholar

[36] Vardanyan V H, Urbassek H M 2019 Comput. Mater. Sci. 170 109158

Google Scholar

Google Scholar

-

图 1 (a)纯铝的初始模型; 石墨烯的嵌入方位分别为(b) 90°, (c) 45°和(d) 0°的Gr/Al复合材料的初始模型, 其中蓝色原子为对称的石墨烯片, 绿色原子为铝基体

Fig. 1. (a) Initial model of the pure Al; initial model of the Gr/Al composites with graphene orientations of (b) 90°, (c) 45°, and (d) 0°, where blue atoms represent symmetrical graphene sheets and green atoms are Al matrix.

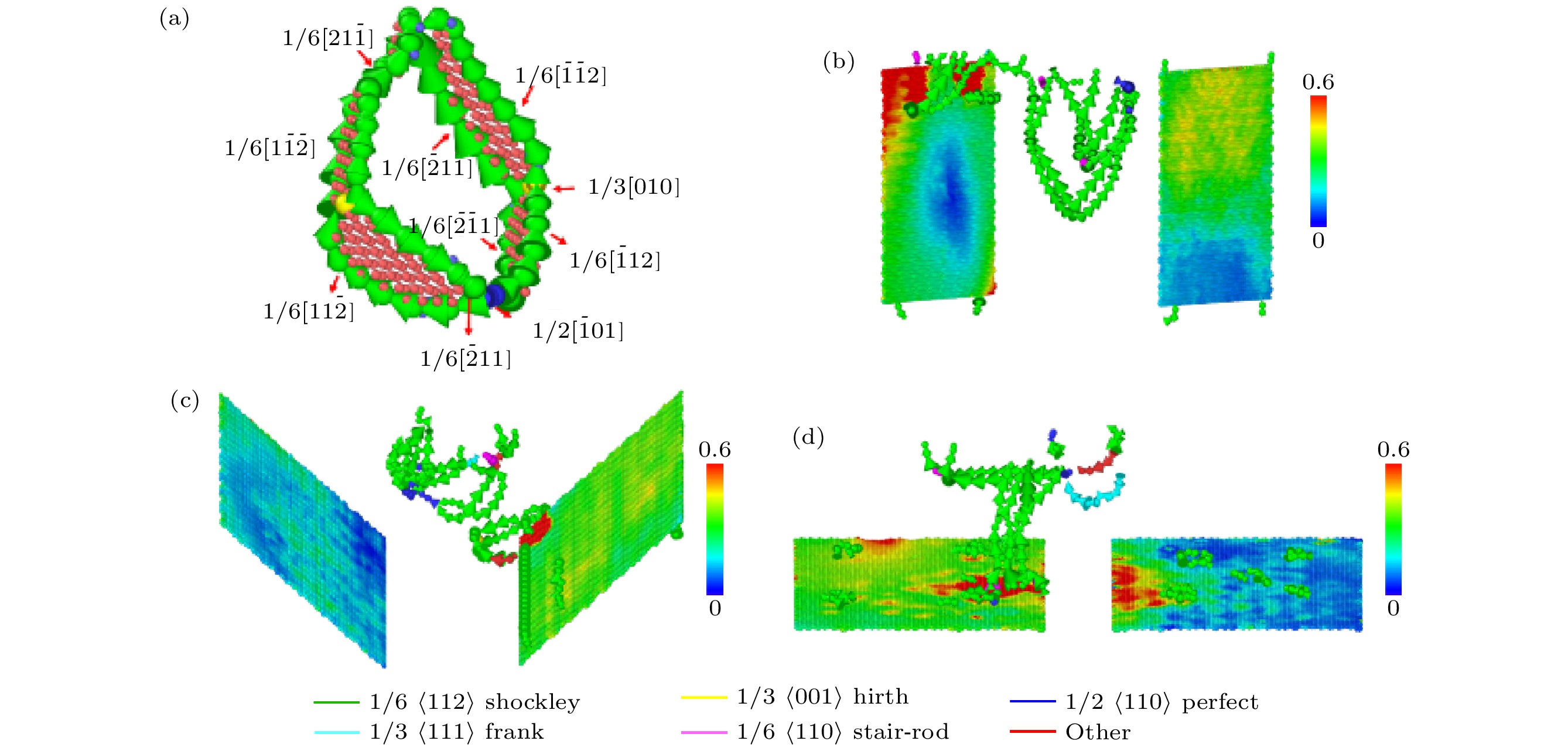

图 4 (a)棱柱形位错环的原子结构图; (b)—(d) Gr/Al复合材料在石墨烯嵌入位向分别为(b) 90°, (c) 45°和(d) 0°, 压痕深度分别为(b) 1.75 nm, (c) 1.59 nm和(d) 1.59 nm时的位错线分布和石墨烯的表面起伏情况

Fig. 4. (a) Atomic snapshot of prismatic dislocation loop; (b)–(d) dislocation line distribution of Gr/Al composites and in-plane height profile of graphene at the indentation depth of (b) 1.75 nm, (c) 1.59 nm, and (d) 1.59 nm, with graphene orientations of (b) 90°, (c) 45°, and (d) 0°.

图 5 (a)卸载过程中, 纯铝和Gr/Al复合材料的压痕力与压痕深度的关系; (b) 卸载过程中, 纯铝和Gr/Al复合材料的总位错线长度的演化

Fig. 5. (a) Relationship between indentation force and indentation depth of the pure Al and the Gr/Al composites during the unloading stage; (b) evolution of total dislocation length of the pure Al and the Gr/Al composites during the unloading stage.

-

[1] Miracle D B 2005 Compos. Sci. Technol. 65 2526

Google Scholar

Google Scholar

[2] Tjong S C 2013 Mater. Sci. Eng., R 74 281

Google Scholar

Google Scholar

[3] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[4] 范冰冰, 郭焕焕, 李稳, 贾瑜, 张锐 2013 62 148101

Google Scholar

Google Scholar

Fan B B, Guo H H, Li W, Jia Y, Zhang R 2013 Acta Phys. Sin. 62 148101

Google Scholar

Google Scholar

[5] Zhong T, Li J, Zhang K 2019 J. Appl. Phys. 125 175110

Google Scholar

Google Scholar

[6] Kim Y, Lee J, Yeom M S, Shin J W, Kim H, Cui Y, Kysar J W, Hone J, Jung Y, Jeon S, Han S M 2013 Nat. Commun. 4 2114

Google Scholar

Google Scholar

[7] Bartolucci S F, Paras J, Rafiee M A, Rafiee J, Lee S, Kapoor D, Koratkar N 2011 Mater. Sci. Eng., A 528 7933

Google Scholar

Google Scholar

[8] Ovid’ko I A, Sheinerman A G 2014 J. Phys. D: Appl. Phys. 47 495302

Google Scholar

Google Scholar

[9] Li Z, Guo Q, Li Z, Fan G, Xiong D B, Su Y, Zhang J, Zhang D 2015 Nano Lett. 15 8077

Google Scholar

Google Scholar

[10] Zhao L, Guo Q, Li Z, Xiong D B, Osovski S, Su Y, Zhang D 2019 Int. J. Plast. 116 265

Google Scholar

Google Scholar

[11] 马通, 谢红献 2020 69 130202

Google Scholar

Google Scholar

Ma T, Xian H X 2020 Acta Phys. Sin. 69 130202

Google Scholar

Google Scholar

[12] Lyu G J, Qiao J C, Yao Y, Pelletier J M, Rodney D, Morthomas J, Fusco C 2020 Scr. Mater. 174 39

Google Scholar

Google Scholar

[13] Zhou X, Bu W, Song S, Sansoz F, Huang X 2019 Mater. Des. 182 108093

Google Scholar

Google Scholar

[14] Du Y, Zhou Q, Jia Q, Shi Y, Wang H, Wang J 2020 Mater. Res. Lett. 8 357

Google Scholar

Google Scholar

[15] Charleston J, Agrawal A, Mirzaeifar R 2020 Comput. Mater. Sci. 178 109621

Google Scholar

Google Scholar

[16] Weng S, Ning H, Fu T, Hu N, Zhao Y, Huang C, Peng X 2018 Sci. Rep. 8 3089

Google Scholar

Google Scholar

[17] Shuang F, Aifantis K E 2020 Scr. Mater. 181 70

Google Scholar

Google Scholar

[18] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[19] Zha X H, Zhang R Q, Lin Z 2014 J. Chem. Phys. 141 064705

Google Scholar

Google Scholar

[20] Lee Y, Park J Y, Kim S Y, Jun S, Im S 2005 Mech. Mater. 37 1035

Google Scholar

Google Scholar

[21] Mishin Y, Farkas D, Mehl M J, Papaconstantopoulos D A 1999 Phys. Rev. B 59 3393

Google Scholar

Google Scholar

[22] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[23] Silvestre N, Faria B, Canongia Lopes J N 2014 Compos. Sci. Technol. 90 16

Google Scholar

Google Scholar

[24] Zhou X, Liu X, Lei J, Yang Q 2020 Comput. Mater. Sci. 172 109342

Google Scholar

Google Scholar

[25] Stukowski A 2010 Model. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[26] Faken D, Jónsson H 1994 Comput. Mater. Sci. 2 279

Google Scholar

Google Scholar

[27] Stukowski A, Bulatov V V, Arsenlis A 2012 Model. Simul. Mater. Sci. Eng. 20 085007

Google Scholar

Google Scholar

[28] Remington T P, Ruestes C J, Bringa E M, Remington B A, Lu C H, Kad B, Meyers M A 2014 Acta Mater. 78 378

Google Scholar

Google Scholar

[29] Jiao S, Tu W, Zhang P, Zhang W, Qin L, Sun Z, Chen J 2018 Comput. Mater. Sci. 143 384

Google Scholar

Google Scholar

[30] Chang S W, Nair A K, Buehler M J 2013 Philos. Mag. Lett. 93 196

Google Scholar

Google Scholar

[31] Mortazavi B, Rémond Y, Ahzi S, Toniazzo V 2012 Comput. Mater. Sci. 53 298

Google Scholar

Google Scholar

[32] Gao Y, Ruestes C J, Tramontina D R, Urbassek H M 2015 J. Mech. Phys. Solids 75 58

Google Scholar

Google Scholar

[33] 李锐, 刘腾, 陈翔, 陈思聪, 符义红, 刘琳 2018 67 190202

Google Scholar

Google Scholar

Li R, Liu T, Chen X, Chen S C, Fu Y H, Liu L 2018 Acta Phys. Sin. 67 190202

Google Scholar

Google Scholar

[34] Taylor G I 1934 Proc. R. Soc. London, Ser. A 145 388

Google Scholar

Google Scholar

[35] Bagheripoor M, Klassen R 2020 Mech. Mater. 143 103311

Google Scholar

Google Scholar

[36] Vardanyan V H, Urbassek H M 2019 Comput. Mater. Sci. 170 109158

Google Scholar

Google Scholar

计量

- 文章访问数: 10221

- PDF下载量: 192

- 被引次数: 0

下载:

下载: