-

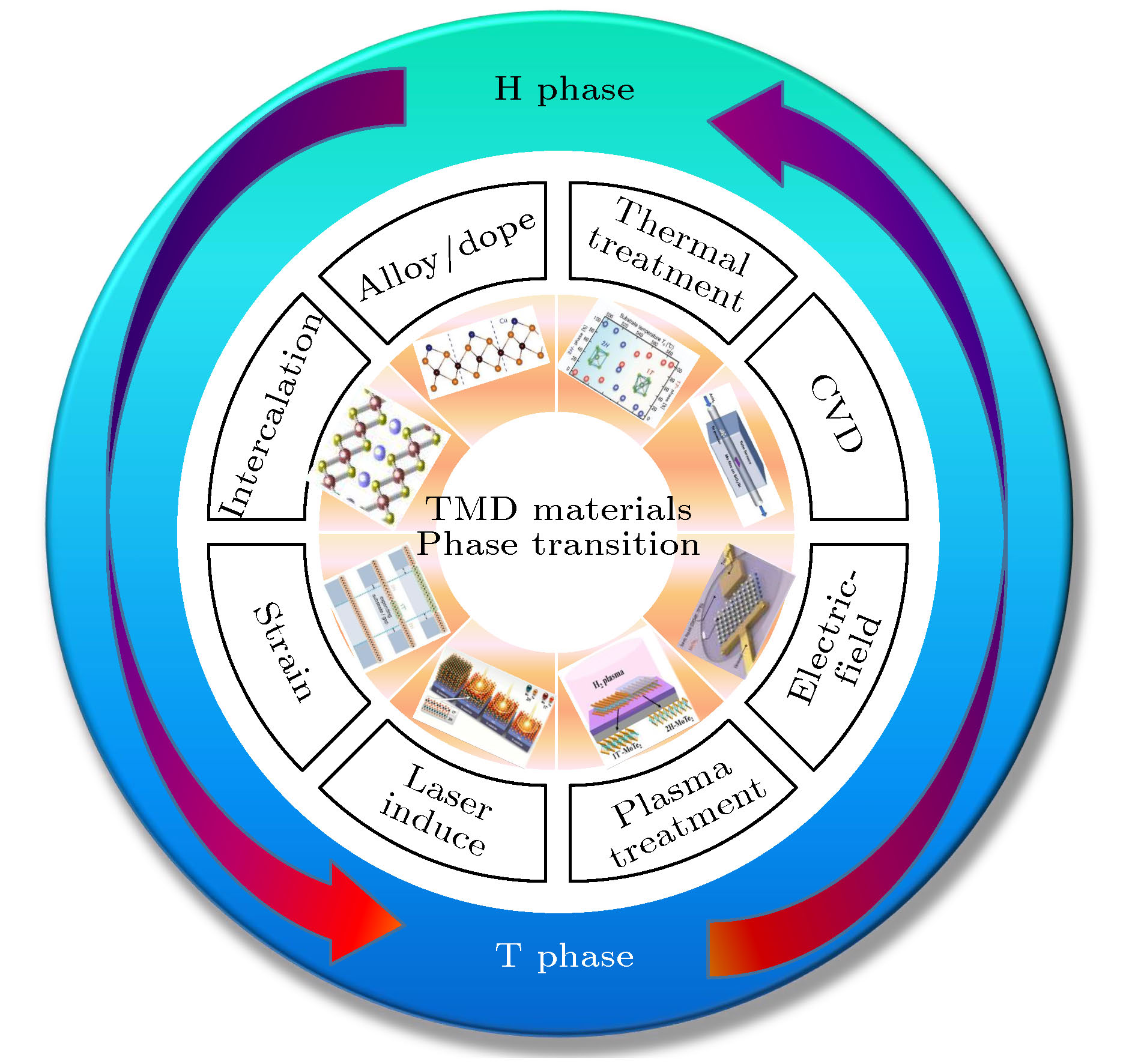

近些年来, 二维过渡金属硫属化合物因其具有独特的原子结构和能带特征而备受关注. 过渡金属硫属化合物不仅存在稳定相, 也存在一些亚稳相, 这些亚稳相因其独特的电学和光学特性逐渐成为研究的热点. 为了获得这些亚稳相, 一种能够使过渡金属硫属化合物在两种晶相之间可控相变的方法必不可少. 本文首先对过渡金属硫属化合物的电学、力学和光学特性进行了总结, 然后介绍了其不同的晶相结构特征, 接着列举了目前报道的过渡金属硫属化合物的八种相变方法: 化学气相沉积法、掺杂法、分子插层法、应力法、高温热处理法、激光引导法、等离子体处理法以及电场引导法, 并且介绍了各自的研究进展, 最后对本文涉及的相变方法进行了总结并列举了这些方法迄今为止所存在的一些问题. 该文详细阐述了过渡金属硫属化合物的相变方法, 为未来过渡金属硫属化合物的相变研究提供了一个很好的参考方向.Following traditional semiconductors such as silicon and GaAs, in recent years the two-dimensional materials have attracted attention in the field of optoelectronic devices, thermoelectric devices and energy storage and conversion due to their many peculiar properties. However, the normal two-dimensional materials such as graphene, cannot be well used in the field of optoelectronics due to the lack of a band gap, and the black phosphorus is also greatly limited in practical applications due to its instability in the air. The two-dimensional transition metal dichalcogenides have attracted more attention due to the different atomic structures, adjustable energy band and excellent photoelectric properties. There are different crystal phases in transition metal dichalcogenides, some of which are stable in the ground state, and others are instable. Different phases exhibit different characteristics, some of which have semiconductor properties and others have like metal in property. These stable and metastable phases of transition metal dichalcogenides can be transformed into each other under some conditions. In order to obtain these metastable phases, thereby modulating their photoelectric performance and improving the mobility of the devices, it is essential to obtain a phase transition method that enables the crystal phase transition of the transition metal dichalcogenides. In this article, first of all, we summarize the different crystal structures of transition metal dichalcogenides and their electrical, mechanical, and optical properties. Next, the eight phase transition methods of transition metal dichalcogenides are listed, these being chemical vapor deposition, doping, ion intercalation, strain, high temperature thermal treatment, laser inducing, plasma treatment, and electric field inducing. After that, the research progress of these phase transition methods and their advantages and disadvantages are introduced. Finally, we sum up all the phase transition methods mentioned in this article and then list some of the problems that have not been solved so far. This review elaborates all of the presently existing different phase transition methods of transition metal dichalcogenides in detail, which provides a good reference for studying the phase transition of transition metal dichalcogenides in the future, the electrical performance regulated by different phases, and the applications of memory devices and electrode manufacturing.

-

Keywords:

- two-dimensional transition metal dichalcogenides /

- crystal structure /

- phase transition method

[1] Novoselov K S, Jiang D, Schedin F, Booth T J, Khotkevich V V, Morozov S V, Geim A K 2005 Proc. Natl. Acad. Sci. U. S. A. 102 10451

Google Scholar

Google Scholar

[2] Allen M J, Tung V C, Kaner R B 2010 Chem. Rev. 110 132

Google Scholar

Google Scholar

[3] Fukuoka S, Taen T, Osada T 2015 J. Phys. Soc. Jpn. 84 121004

Google Scholar

Google Scholar

[4] Li P, Zhang D Z, Liu J J, Chang H Y, Sun Y, Yin N L 2015 ACS Appl. Mater. Interfaces 7 24396

Google Scholar

Google Scholar

[5] Xu M S, Liang T, Shi M M, Chen H Z 2013 Chem. Rev. 113 3766

Google Scholar

Google Scholar

[6] Xie L, Liao M Z, Wang S P, Yu H, Du L J, Tang J, Zhao J, Zhang J, Chen P, Lu X B, Wang G L, Xie G B, Yang R, Shi D X, Zhang G Y 2017 Adv. Mater. 29 1702522

Google Scholar

Google Scholar

[7] Liu H, Neal A T, Ye P D 2012 ACS Nano 6 8563

Google Scholar

Google Scholar

[8] Zhang F, Appenzeller J 2015 Nano Lett. 15 301

Google Scholar

Google Scholar

[9] Kappera R, Voiry D, Yalcin S E, Branch B, Gupta G, Mohite A D, Chhowalla M 2014 Nat. Mater. 13 1128

Google Scholar

Google Scholar

[10] Kuc A, Heine T 2015 Chem. Soc. Rev. 44 2603

Google Scholar

Google Scholar

[11] Zhang F, Zhang H R, Krylyuk S, Milligan C A, Zhu Y Q, Zemlyanov D Y, Bendersky L A, Burton B P, Davydov A V, Appenzeller J 2019 Nat. Mater. 18 55

Google Scholar

Google Scholar

[12] Splendiani A, Sun L, Zhang Y B, Li T S, Kim J, Chim C Y, Galli G, Wang F 2010 Nano Lett. 10 1271

Google Scholar

Google Scholar

[13] 苏向英 2017 低维过渡金属硫属化合物的电子性质及调控 (北京: 电子工业出版社) 第3页

Su X Y 2017 Electronic Properties and Control of Low-dimensional Transition Metal Chalcogenides (Beijing: Publishing House of Electronics Industry) p3 (in Chinese)

[14] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotechnol. 6 147

Google Scholar

Google Scholar

[15] Zhang Y J, Ye J T, Matsuhashi Y, Iwasa Y 2012 Nano Lett. 12 1136

Google Scholar

Google Scholar

[16] Agnihotri P, Dhakras P, Lee J U 2016 Nano Lett. 16 4355

Google Scholar

Google Scholar

[17] Lee Y T, Kang J H, Kwak K, Ahn J, Choi H T, Ju B K, Shokouh S H, Im S, Park M C, Hwang D K 2018 ACS Photonics 5 4745

Google Scholar

Google Scholar

[18] Bertolazzi S, Brivio J, Kis A 2011 ACS Nano 5 9703

Google Scholar

Google Scholar

[19] Castellanos-Gomez A, Poot M, Steele G A, van der Zant H S J, Agrait N, Rubio-Bollinger G 2012 Adv. Mater. 24 772

Google Scholar

Google Scholar

[20] 周愈之 2018 67 218102

Google Scholar

Google Scholar

Zhou Y Z 2018 Acta Phys. Sin. 67 218102

Google Scholar

Google Scholar

[21] Park J C, Yun S J, Kim H, Park J H, Chae S H, An S J, Kim J G, Kim S M, Kim K K, Lee Y H 2015 ACS Nano 9 6548

Google Scholar

Google Scholar

[22] Zhou L, Xu K, Zubair A, Liao A D, Fang W J, Ouyang F P, Lee Y H, Ueno K, Saito R, Palacios T, Kong J, Dresselhaus M S 2015 J. Am. Chem. Soc. 137 11892

Google Scholar

Google Scholar

[23] Naylor C H, Parkin W M, Ping J L, Gao Z L, Zhou Y R, Kim Y, Streller F, Carpick R W, Rappe A M, Drndic M, Kikkawa J M, Johnson A T C 2016 Nano Lett 16 4297

Google Scholar

Google Scholar

[24] Yang L, Zhang W F, Li J, Cheng S, Xie Z J, Chang H X 2017 ACS Nano 11 1964

Google Scholar

Google Scholar

[25] Zhu X K, Li A L, Wu D, Zhu P, Xiang H Y, Liu S, Sun J, Ouyang F P, Zhou Y, Xiong X 2019 J. Mater. Chem. C 7 10598

Google Scholar

Google Scholar

[26] Huang W J, G an, L, Li H Q, Ma Y, Zhai T Y 2018 Chem. – Eur. J. 24 15678

Google Scholar

Google Scholar

[27] Liu L N, Wu J X, Wu L Y, Ye M, Liu X Z, Wang Q, Hou S Y, Lu P F, Sun L F, Zheng J Y, Xing L, Gu L, Jiang X W, Xie L M, Jiao L Y 2018 Nat. Mater. 17 1108

Google Scholar

Google Scholar

[28] Wang Z Q, Shen Y H, Ito Y, Zheng Y Z, Du J, Fujita T, Hirata A, Tang Z, Chen M W 2018 ACS Nano 12 1571

Google Scholar

Google Scholar

[29] Wang Z, Sun J, Wang H L, Lei Y M, Xie Y, Wang G F, Zhao Y, Li X B, Xu H, Yang X B, Feng L P, Ma X H 2020 Appl. Surf. Sci. 504 144371

Google Scholar

Google Scholar

[30] Feng Q L, Mao N N, Wu J X, Xu H, Wang C M, Zhang J, Xie L M 2015 ACS Nano 9 7450

Google Scholar

Google Scholar

[31] Feng Q L, Zhu Y M, Hong J H, Zhang M, Duan W J, Mao N N, Wu J X, Xu H, Dong F L, Lin F, Jin C H, Wang C M, Zhang J, Xie L M 2014 Adv. Mater. 26 2648

Google Scholar

Google Scholar

[32] Tongay S, Narang D S, Kang J, Fan W, Ko C H, Luce A V, Wang K X, Suh J, Patel K D, Pathak V M, Li J B, Wu J Q 2014 Appl. Phys. Lett. 104 012101

Google Scholar

Google Scholar

[33] Li H L, Duan X D, Wu X P, Zhuang X J, Zhou H, Zhang Q L, Zhu X L, Hu W, Ren P Y, Guo P F, Ma L, Fan X P, Wang X X, Xu J Y, Pan A L, Duan X F 2014 J. Am. Chem. Soc. 136 3756

Google Scholar

Google Scholar

[34] Li H L, Zhang Q L, Duan X D, Wu X P, Fan X P, Zhu X L, Zhuang X J, Hu W, Zhou H, Pan A L, Duan X F 2015 J. Am. Chem. Soc. 137 5284

Google Scholar

Google Scholar

[35] Chen Y F, Dumcenco D O, Zhu Y M, Zhang X, Mao N N, Feng Q L, Zhang M, Zhang J, Tan P H, Huang Y S, Xie L M 2014 Nanoscale 6 2833

Google Scholar

Google Scholar

[36] Liu H F, Antwi K K A, Chua S, Chi D Z 2014 Nanoscale 6 624

Google Scholar

Google Scholar

[37] Chen Y F, Xi J Y, Dumcenco D O, Liu Z, Suenaga K, Wang D, Shuai Z G, Huang Y S, Xie L M 2013 ACS Nano 7 4610

Google Scholar

Google Scholar

[38] Liu S J, Huang L, Wu K D, Wei Z M, Huang B J, Meng X Q, Tongay S, Liu J, Li J B, Chen H D 2016 Appl. Phys. Lett. 109 112102

Google Scholar

Google Scholar

[39] Lin Y C, Dumcenco D O, Komsa H P, Niimi Y, Krasheninnikov A V, Huang Y S, Suenaga K 2014 Adv. Mater. 26 2857

Google Scholar

Google Scholar

[40] Zandalazini C I, Albanesi E A 2019 J. Magn. Magn. Mater. 484 146

Google Scholar

Google Scholar

[41] Fan S W, Yang L, Gao G Y 2019 Phys. Lett. A 383 3138

Google Scholar

Google Scholar

[42] Laroussi A, Berber M, Mokaddem A, Doumi B, Abid H, Boudali A 2019 Acta Phys. Pol. A 135 451

Google Scholar

Google Scholar

[43] Duerloo K N, Reed E J 2016 ACS Nano 10 289

Google Scholar

Google Scholar

[44] Kumar A, Strachan A, Onofrio N 2019 J. Appl. Phys. 125 204303

Google Scholar

Google Scholar

[45] Wang J Z, Yang T, Zhang Z D, Yang L 2018 Appl. Phys. Lett. 112 213104

Google Scholar

Google Scholar

[46] Young J, Reinecke T L 2017 Phys. Chem. Chem. Phys. 19 31874

Google Scholar

Google Scholar

[47] Huang H H, Fan X F, Singh D J, Zheng W T 2018 Phys. Chem. Chem. Phys. 20 26986

Google Scholar

Google Scholar

[48] Chen M W, Zhu L G, Chen Q F, Miao N H, Si C, Zhou J, Sun Z M 2020 J. Mater. Chem. C 8 721

Google Scholar

Google Scholar

[49] Koski K J, Wessells C D, Reed B W, Cha J J, Kong D S, Cui Y 2012 J. Am. Chem. Soc. 134 13773

Google Scholar

Google Scholar

[50] Gong Y J, Yuan H T, Wu C L, et al. 2018 Nat. Nanotechnol. 13 294

Google Scholar

Google Scholar

[51] Meng Y S, Elena Arroyo-de Dompablo M 2009 Energy Environ. Sci. 2 589

Google Scholar

Google Scholar

[52] Zhang Z X, Yang M Y, Zhao N, Wang L, Li Y Y 2019 Phys. Chem. Chem. Phys. 21 23441

Google Scholar

Google Scholar

[53] Py M A, Haering R R 1983 Can. J. Phys. 61 76

Google Scholar

Google Scholar

[54] Kan M, Wang J Y, Li X W, Zhang S H, Li Y W, Kawazoe Y, Sun Q, Jena P 2014 J. Phys. Chem. C 118 1515

Google Scholar

Google Scholar

[55] Tan S J R, Abdelwahab I, Ding Z J, Zhao X X, Yang T S, Loke G Z J, Lin H, Verzhbitskiy I, Poh S M, Xu H, Nai C T, Zhou W, Eda G, Jia B H, Loh K P 2017 J. Am. Chem. Soc. 139 2504

Google Scholar

Google Scholar

[56] Xia J, Wang J, Chao D L, Chen Z, Liu Z, Kuo J L, Yan J X, Shen Z X 2017 Nanoscale 9 7533

Google Scholar

Google Scholar

[57] Sun L F, Yan X X, Zheng J Y, Yu H D, Lu Z X, Gao S P, Liu L N, Pan X Q, Wang D, Wang Z G, Wang P, Jiao L Y 2018 Nano Lett. 18 3435

Google Scholar

Google Scholar

[58] Eshete Y A, Ling N, Kim S, Kim D, Hwang G, Cho S, Yang H 2019 Adv. Funct. Mater. 29 1904504

Google Scholar

Google Scholar

[59] Leng K, Chen Z X, Zhao X X, Tang W, Tian B B, Nai C T, Zhou W, Loh K P 2016 ACS Nano 10 9208

Google Scholar

Google Scholar

[60] Tan C L, Zhao W, Chaturvedi A, Fei Z, Zeng Z Y, Chen J Z, Huang Y, Ercius P, Luo Z M, Qi X Y, Chen B, Lai Z C, Li B, Zhang X, Yang J, Zong Y, Jin C H, Zheng H M, Kloc C, Zhang H 2016 Small 12 1866

Google Scholar

Google Scholar

[61] Wang X F, Shen X, Wang Z X, Yu R C, Chen L Q 2014 ACS Nano 8 11394

Google Scholar

Google Scholar

[62] Koley S, Basu S 2020 J. Magn. Magn. Mater. 499 166294

Google Scholar

Google Scholar

[63] Li P, Jeong J Y, Jin B J, Zhang K, Park J H 2020 Energy Storage Mater. 25 687

Google Scholar

Google Scholar

[64] Island J O, Kuc A, Diependaal E H, Bratschitsch R, van der Zant H S J, Heine T, Castellanos-Gomez A 2016 Nanoscale 8 2589

Google Scholar

Google Scholar

[65] Duerloo K N, Li Y, Reed E J 2014 Nat. Commun. 5 4214

Google Scholar

Google Scholar

[66] Song S, Keum D H, Cho S, Perello D, Kim Y, Lee Y H 2016 Nano Letters 16 188

Google Scholar

Google Scholar

[67] Huang H H, Fan X F, Singh D J, Chen H, Jiang Q, Zheng W T 2016 Phys. Chem. Chem. Phys. 18 4086

Google Scholar

Google Scholar

[68] Fan X F, Singh D J, Jiang Q, Zheng W T 2016 Phys. Chem. Chem. Phys. 18 12080

Google Scholar

Google Scholar

[69] Tang Q 2018 J. Mater. Chem. C 6 9561

Google Scholar

Google Scholar

[70] Johari P, Shenoy V B 2012 ACS Nano 6 5449

Google Scholar

Google Scholar

[71] Apte A, Kochat V, Rajak P, et al. 2018 ACS Nano 12 3468

Google Scholar

Google Scholar

[72] Keum D H, Cho S, Kim J H, et al. 2015 Nat. Phys. 11 482

Google Scholar

Google Scholar

[73] Wang Z Y, Sun Y Y, Abdelwahab I, et al. 2018 ACS Nano 12 12619

Google Scholar

Google Scholar

[74] Yin X M, Tang C S, Wu D, et al. 2019 Adv. Sci. 6 1802093

Google Scholar

Google Scholar

[75] Sung J H, Heo H, Si S, Kim Y H, Noh H R, Song K, Kim J, Lee C S, Seo S Y, Kim D H, Kim H K, Yeom H W, Kim T H, Choi S Y, Kim J S, Jo M H 2017 Nat. Nanotechnol. 12 1064

Google Scholar

Google Scholar

[76] Nakata Y, Sugawara K, Shimizu R, Okada Y, Han P, Hitosugi T, Ueno K, Sato T, Takahashi T 2016 NPG Asia Mater. 8 e231

Google Scholar

Google Scholar

[77] Chen J C, Feng Z H, Fan S Q, et al. 2017 ACS Appl. Mater. Interfaces 9 30107

Google Scholar

Google Scholar

[78] Cho S, Kim S, Kim J H, Zhao J, Seok J, Keum D H, Baik J, Choe D H, Chang K J, Suenaga K, Kim S W, Lee Y H, Yang H 2015 Science 349 625

Google Scholar

Google Scholar

[79] Yu Y F, Nam G H, He Q Y, et al. 2018 Nat. Chem. 10 638

Google Scholar

Google Scholar

[80] Chen Z R, Nan H Y, Liu Z, Wang X Y, Gu X F, Xiao S Q 2019 J. Raman Spectrosc. 50 755

Google Scholar

Google Scholar

[81] Si C, Choe D, Xie W Y, Wang H, Sun Z M, Bang J, Zhang S B 2019 Nano Lett. 19 3612

Google Scholar

Google Scholar

[82] Azcatl A, Qin X Y, Prakash A, et al. 2016 Nano Lett. 16 5437

Google Scholar

Google Scholar

[83] Cheng C C, Lu A Y, Tseng C C, Yang X L, Hedhili M N, Chen M C, Wei K H, Li L J 2016 Nano Energy 30 846

Google Scholar

Google Scholar

[84] O’Brien M, Lee K, Morrish R, Berner N C, McEvoy N, Wolden C A, Duesberg G S 2014 Chem. Phys. Lett. 615 6

Google Scholar

Google Scholar

[85] Jin J C, Zhang D P, Qin X N, Yang Y, Huang Y, Guan H, He Q C, Fan P, Lv W Z 2019 Nanomaterials 9 102

Google Scholar

Google Scholar

[86] Zhu J, Wang Z, Yu H 2017 J. Am. Chem. Soc. 139 10216

Google Scholar

Google Scholar

[87] Shawkat M S, Gil J, Han S S, et al. 2020 ACS Appl. Mater. Interfaces 12 14341

Google Scholar

Google Scholar

[88] Nan H Y, Jiang J, Xiao S Q, et al. 2018 Nanotechnology 30 034004

Google Scholar

Google Scholar

[89] Taniguchi K, Matsumoto A, Shimotani H, Takagi H 2012 Appl, . Phys. Lett. 101 042603

Google Scholar

Google Scholar

[90] Ye J T, Zhang Y J, Akashi R, Bahramy M S, Arita R, Iwasa Y 2012 Science 338 1193

Google Scholar

Google Scholar

[91] 何学侠, 刘富才, 曾庆圣, 刘政 2015 化学学报 73 924

Google Scholar

Google Scholar

He X X, Liu F C, Zeng Q S, Liu Z 2015 Acta Chim. Sin. 73 924

Google Scholar

Google Scholar

[92] Li Y, Duerloo K A N, Wauson K, Reed E J 2016 Nat. Commun. 7 10671

Google Scholar

Google Scholar

[93] Wang Y, Xiao J, Zhu H 2017 Nature 550 487

Google Scholar

Google Scholar

[94] Bischoff F, Auwarter W, Barth J V, Schiffrin A, Fuhrer M, Weber B 2017 Chem. Mater. 29 9907

Google Scholar

Google Scholar

-

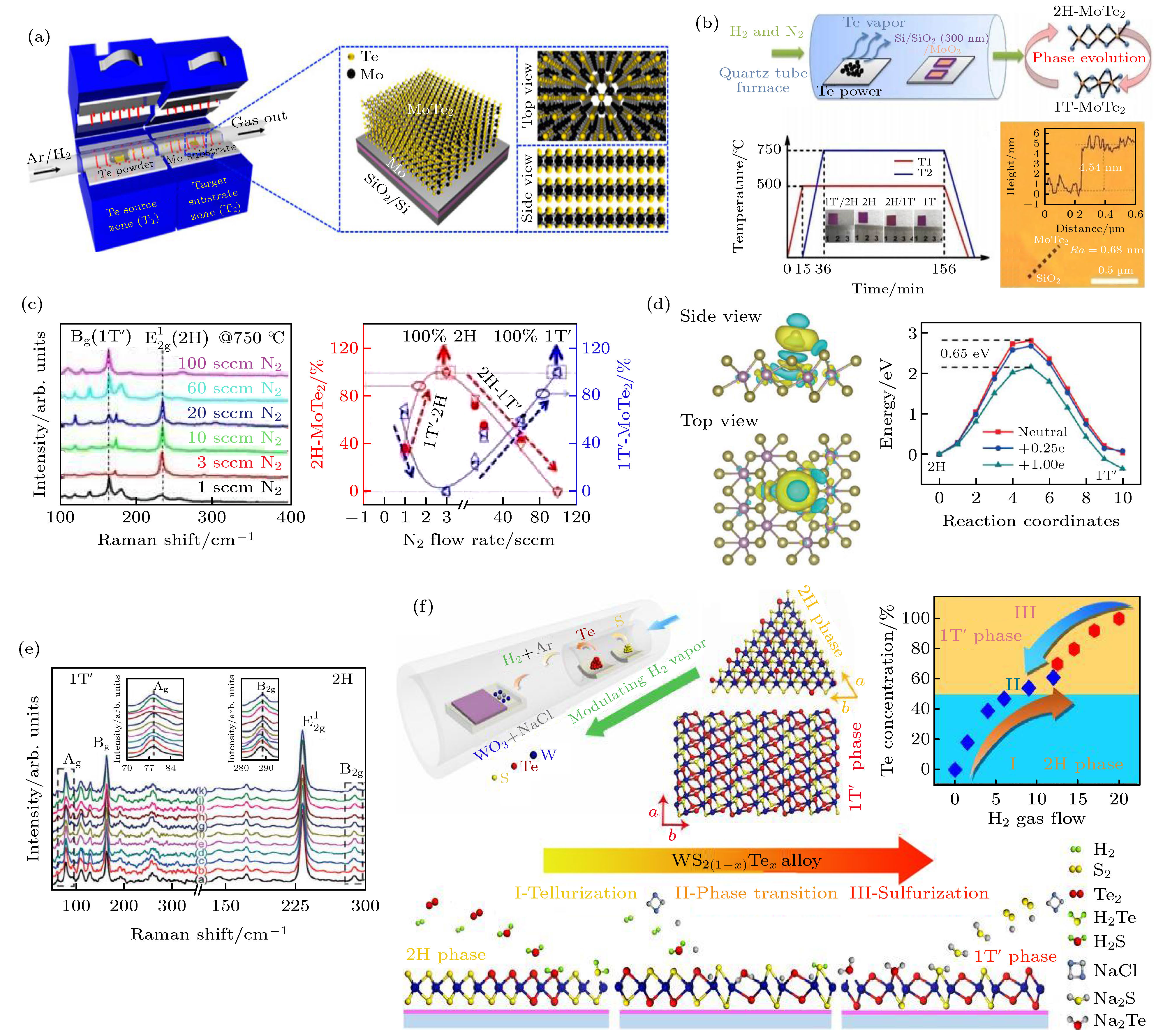

图 4 TMD的CVD法相变 (a) 通过CVD生长出1T' MoTe2的示意图[21]; (b), (c)大面积多层MoTe2的CVD过程中金属-半导体-金属相演化与前驱体的碲化速度的关系[24]; (d), (e) CVD法获得多层1T'-2H MoTe2横向同质结[25]; (f) 三元TMD的CVD法驱动2H到1T' 相变示意图[29]

Fig. 4. TMD phase transition induced by CVD method: (a) Schematic diagram of 1T' MoTe2 grown by CVD[21]; (b), (c) relationship between metal-semiconductor-metal phase evolution and telluride velocity of precursor during the CVD process of large-area multilayer MoTe2[24]; (d), (e) multilayer 1T' -2H MoTe2 transverse homogeneous junction was obtained by CVD[25]; (f) schematic diagram of ternary TMD 2H-1T' phase transition driven by the CVD method[29].

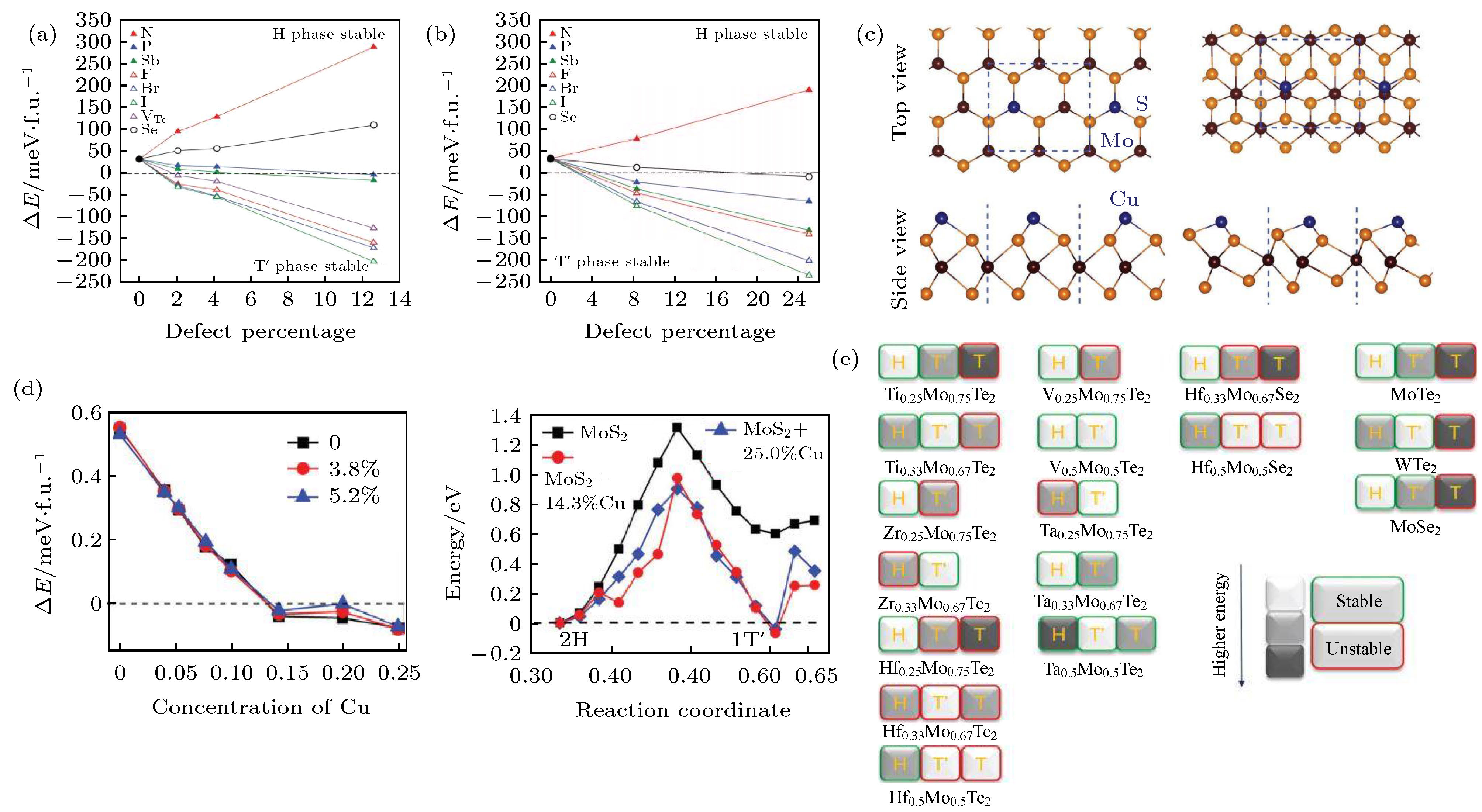

图 5 通过掺杂/合金化诱导TMD相变 (a), (b) MoTe2掺杂部分非金属元素后发生的相位改变[46]; (c), (d) MoS2掺杂Cu引发2H-1T' 相的改变[47]; (e) 过渡金属掺入MoSe2, MoTe2和WTe2形成合金的相位稳定性[48]

Fig. 5. TMD phase transition induced by doping/alloying: (a), (b) The phase transition of MoTe2 after doping part of nonmetallic elements[46]; (c), (d) the 2H-1T' phase transition of MoS2 induced by doping Cu[47]; (e) the phase stability of the alloy was obtained by mixing the transition metal with MoSe2, MoTe2 and WTe2[48].

图 6 分子插层和应力诱导TMD相变 (a) MoS2相变难度与其层数的关系[57]; (b) 电化学法诱导三元TMD相变示意图; (c) 相变前后三元TMD的STEM图像和XPS光谱; (d) 1T三元层状TMD的电学特性[60]; (e) 机械拉伸诱导MoTe2由2H-1T' 的转变[65]; (f) 在空位与拉伸条件下MoX2 TMD的相位稳定性[69]; (g) 三元TMD通过拉伸引发不可逆相变[71]

Fig. 6. TMD phase transition induced by intercalation and strain: (a) The relationship between the phase transition difficulty of MoS2 and the number of layers[57]; (b) schematic diagram of ternary TMD phase transition induced by electrochemical method; (c) STEM image and XPS spectrum of ternary TMD before and after phase transition; (d) electrical properties of 1T ternary layered TMD[60]; (e) mechanical tensile induced 2H-1T' transformation of MoTe2[65]; (f) phase stability of MoX2 TMD under vacancy and stretch conditions[69]; (g) irreversible phase transition of ternary TMD induced by stretching[71].

图 7 高温热处理、激光、等离子体诱导TMD相变 (a) MoTe2相变程度与温度及Te浓度的关系[72]; (b) 块状1T-TaS2的1T-2H相变示意图[73]; (c) NbSe2上1T和2H相的选择性合成[76]; (d) 激光灼烧诱导相变示意图[78]; (e) 激光引导MoTe2诱导相变的原理图[81]; (f) Ar等离子体引发MoS2相变的光学特性[86]; (g) 温和等离子体诱导MoTe2相变原理图; (h) 2H和1T' MoTe2的转移特性曲线[88]

Fig. 7. TMDs phase transition induced by thermal, laser and plasma treatment: (a) The relationship between MoTe2 phase transition and temperature and Te concentration[72]; (b) schematic diagram of 1T-2H phase transition on the bulk 1T-TaS2[73]; (c) selective synthesis of 1T and 2H phases on NbSe2[76]; (d) schematic diagram of the phase transition by laser irradiation[78]; (e) schematic diagram of laser-induced MoTe2 phase transition[81]; (f) optical properties of MoS2 phase transition induced by Ar plasma[86]; (g) schematic diagram of MoTe2 phase transition induced by soft plasma; (h) transfer characteristic curves of 2H and 1T' MoTe2[88].

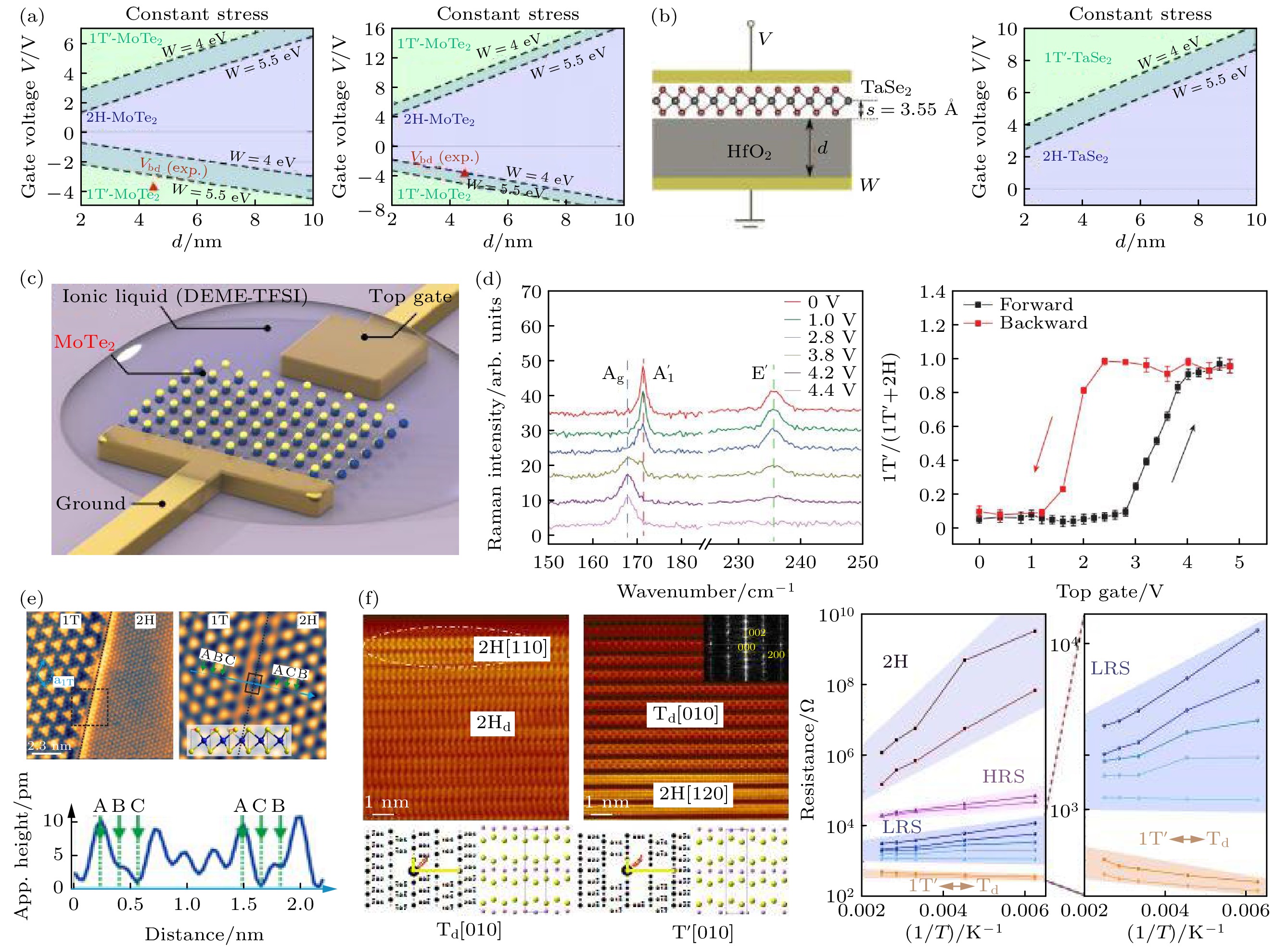

图 8 电场引导TMD相变 (a) MoTe2相变与门控电压的关系; (b) TaSe2电场相变示意图及其相变与门控电压的关系[92]; (c) 静电掺杂诱导MoTe2相变原理图; (d) MoTe2相变过程拉曼光谱及其相变程度与栅极电压的关系[93]; (e) STM尖端电压脉冲诱导NbSe2的相变[94]; (f) 施加电场对Mo1–xWxTe2的2H-2Hd相变[11]

Fig. 8. TMDs phase transition induced by electric-field: (a) Relationship between MoTe2 phase transition and gate voltage; (b) schematic diagram of TaSe2 electric-field phase transition and its relationship with gate voltage[92]; (c) schematic diagram of electrostatic doping induced MoTe2 phase transition; (d) Raman spectrum of MoTe2 phase transition and relationship between the phase transition and gate voltage[93]; (e) phase transition of NbSe2 induced by voltage pulses with an STM tip[94]; (f) the 2H-2Hd phase transition of Mo1–xWxTe2 by applying electric field[11].

表 1 TMD的相变方法及其特点

Table 1. Phase transition methods of TMDs and their properties.

相变方法 特点 优点 不足 化学气相沉积 可以通过改变温度、气流量以及源粉成分来实现

不同相的选择性生长或相变, 操作简单该方法受环境因素影响较大, 产物不稳定 掺杂/合金化 通过对TMD引入其他原子使其完成半导体到半金属

的转变, 生成产物性质稳定, 不易变质原有材料本身的化学性质容易发生改变,

一些原有的良好性能受到破坏分子插层 将离解出的原子或离子嵌入对象TMD材料

双层之间的空隙从而达到相变

的目的, 该方法因其操作简单,

现已成为TMD的常用相变方法相变产物中可能包含插层原子或离子 应力 通过机械拉伸可以实现薄层TMD的相变, 这种相变

通常不可逆, 所以可以保持产物的稳定性过度引入应力可能使材料开裂或变形 高温热处理 提高温度来实现TMD的相变, 是最为

直接的相变方法, 操作容易相变产物在长时间室温条件下

可以恢复为原来的晶相激光引导 使用激光照射TMD样品来实现其相变, 相变产物稳定,

不易恢复为原来的晶相, 有着广阔的应用前景相变往往具有不可逆性, 且激光功

率过大容易损坏样品等离子体处理 通过低温等离子体处理TMD材料实现其相变,

可实现大范围简易相位调控, 研究前景广阔相变产物不稳定, 高温下晶相容易恢复 电场引导 通过电场直接在TMD器件上实现相变, 避免了相变后的

TMD在制作器件时恢复为原来的晶相, 这种相变通常

可逆, 在电子器件制造上有着广泛的应用局限于电学器件制造, 很难在其他方面有所应用,

另外实验所需环境较为苛刻 -

[1] Novoselov K S, Jiang D, Schedin F, Booth T J, Khotkevich V V, Morozov S V, Geim A K 2005 Proc. Natl. Acad. Sci. U. S. A. 102 10451

Google Scholar

Google Scholar

[2] Allen M J, Tung V C, Kaner R B 2010 Chem. Rev. 110 132

Google Scholar

Google Scholar

[3] Fukuoka S, Taen T, Osada T 2015 J. Phys. Soc. Jpn. 84 121004

Google Scholar

Google Scholar

[4] Li P, Zhang D Z, Liu J J, Chang H Y, Sun Y, Yin N L 2015 ACS Appl. Mater. Interfaces 7 24396

Google Scholar

Google Scholar

[5] Xu M S, Liang T, Shi M M, Chen H Z 2013 Chem. Rev. 113 3766

Google Scholar

Google Scholar

[6] Xie L, Liao M Z, Wang S P, Yu H, Du L J, Tang J, Zhao J, Zhang J, Chen P, Lu X B, Wang G L, Xie G B, Yang R, Shi D X, Zhang G Y 2017 Adv. Mater. 29 1702522

Google Scholar

Google Scholar

[7] Liu H, Neal A T, Ye P D 2012 ACS Nano 6 8563

Google Scholar

Google Scholar

[8] Zhang F, Appenzeller J 2015 Nano Lett. 15 301

Google Scholar

Google Scholar

[9] Kappera R, Voiry D, Yalcin S E, Branch B, Gupta G, Mohite A D, Chhowalla M 2014 Nat. Mater. 13 1128

Google Scholar

Google Scholar

[10] Kuc A, Heine T 2015 Chem. Soc. Rev. 44 2603

Google Scholar

Google Scholar

[11] Zhang F, Zhang H R, Krylyuk S, Milligan C A, Zhu Y Q, Zemlyanov D Y, Bendersky L A, Burton B P, Davydov A V, Appenzeller J 2019 Nat. Mater. 18 55

Google Scholar

Google Scholar

[12] Splendiani A, Sun L, Zhang Y B, Li T S, Kim J, Chim C Y, Galli G, Wang F 2010 Nano Lett. 10 1271

Google Scholar

Google Scholar

[13] 苏向英 2017 低维过渡金属硫属化合物的电子性质及调控 (北京: 电子工业出版社) 第3页

Su X Y 2017 Electronic Properties and Control of Low-dimensional Transition Metal Chalcogenides (Beijing: Publishing House of Electronics Industry) p3 (in Chinese)

[14] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotechnol. 6 147

Google Scholar

Google Scholar

[15] Zhang Y J, Ye J T, Matsuhashi Y, Iwasa Y 2012 Nano Lett. 12 1136

Google Scholar

Google Scholar

[16] Agnihotri P, Dhakras P, Lee J U 2016 Nano Lett. 16 4355

Google Scholar

Google Scholar

[17] Lee Y T, Kang J H, Kwak K, Ahn J, Choi H T, Ju B K, Shokouh S H, Im S, Park M C, Hwang D K 2018 ACS Photonics 5 4745

Google Scholar

Google Scholar

[18] Bertolazzi S, Brivio J, Kis A 2011 ACS Nano 5 9703

Google Scholar

Google Scholar

[19] Castellanos-Gomez A, Poot M, Steele G A, van der Zant H S J, Agrait N, Rubio-Bollinger G 2012 Adv. Mater. 24 772

Google Scholar

Google Scholar

[20] 周愈之 2018 67 218102

Google Scholar

Google Scholar

Zhou Y Z 2018 Acta Phys. Sin. 67 218102

Google Scholar

Google Scholar

[21] Park J C, Yun S J, Kim H, Park J H, Chae S H, An S J, Kim J G, Kim S M, Kim K K, Lee Y H 2015 ACS Nano 9 6548

Google Scholar

Google Scholar

[22] Zhou L, Xu K, Zubair A, Liao A D, Fang W J, Ouyang F P, Lee Y H, Ueno K, Saito R, Palacios T, Kong J, Dresselhaus M S 2015 J. Am. Chem. Soc. 137 11892

Google Scholar

Google Scholar

[23] Naylor C H, Parkin W M, Ping J L, Gao Z L, Zhou Y R, Kim Y, Streller F, Carpick R W, Rappe A M, Drndic M, Kikkawa J M, Johnson A T C 2016 Nano Lett 16 4297

Google Scholar

Google Scholar

[24] Yang L, Zhang W F, Li J, Cheng S, Xie Z J, Chang H X 2017 ACS Nano 11 1964

Google Scholar

Google Scholar

[25] Zhu X K, Li A L, Wu D, Zhu P, Xiang H Y, Liu S, Sun J, Ouyang F P, Zhou Y, Xiong X 2019 J. Mater. Chem. C 7 10598

Google Scholar

Google Scholar

[26] Huang W J, G an, L, Li H Q, Ma Y, Zhai T Y 2018 Chem. – Eur. J. 24 15678

Google Scholar

Google Scholar

[27] Liu L N, Wu J X, Wu L Y, Ye M, Liu X Z, Wang Q, Hou S Y, Lu P F, Sun L F, Zheng J Y, Xing L, Gu L, Jiang X W, Xie L M, Jiao L Y 2018 Nat. Mater. 17 1108

Google Scholar

Google Scholar

[28] Wang Z Q, Shen Y H, Ito Y, Zheng Y Z, Du J, Fujita T, Hirata A, Tang Z, Chen M W 2018 ACS Nano 12 1571

Google Scholar

Google Scholar

[29] Wang Z, Sun J, Wang H L, Lei Y M, Xie Y, Wang G F, Zhao Y, Li X B, Xu H, Yang X B, Feng L P, Ma X H 2020 Appl. Surf. Sci. 504 144371

Google Scholar

Google Scholar

[30] Feng Q L, Mao N N, Wu J X, Xu H, Wang C M, Zhang J, Xie L M 2015 ACS Nano 9 7450

Google Scholar

Google Scholar

[31] Feng Q L, Zhu Y M, Hong J H, Zhang M, Duan W J, Mao N N, Wu J X, Xu H, Dong F L, Lin F, Jin C H, Wang C M, Zhang J, Xie L M 2014 Adv. Mater. 26 2648

Google Scholar

Google Scholar

[32] Tongay S, Narang D S, Kang J, Fan W, Ko C H, Luce A V, Wang K X, Suh J, Patel K D, Pathak V M, Li J B, Wu J Q 2014 Appl. Phys. Lett. 104 012101

Google Scholar

Google Scholar

[33] Li H L, Duan X D, Wu X P, Zhuang X J, Zhou H, Zhang Q L, Zhu X L, Hu W, Ren P Y, Guo P F, Ma L, Fan X P, Wang X X, Xu J Y, Pan A L, Duan X F 2014 J. Am. Chem. Soc. 136 3756

Google Scholar

Google Scholar

[34] Li H L, Zhang Q L, Duan X D, Wu X P, Fan X P, Zhu X L, Zhuang X J, Hu W, Zhou H, Pan A L, Duan X F 2015 J. Am. Chem. Soc. 137 5284

Google Scholar

Google Scholar

[35] Chen Y F, Dumcenco D O, Zhu Y M, Zhang X, Mao N N, Feng Q L, Zhang M, Zhang J, Tan P H, Huang Y S, Xie L M 2014 Nanoscale 6 2833

Google Scholar

Google Scholar

[36] Liu H F, Antwi K K A, Chua S, Chi D Z 2014 Nanoscale 6 624

Google Scholar

Google Scholar

[37] Chen Y F, Xi J Y, Dumcenco D O, Liu Z, Suenaga K, Wang D, Shuai Z G, Huang Y S, Xie L M 2013 ACS Nano 7 4610

Google Scholar

Google Scholar

[38] Liu S J, Huang L, Wu K D, Wei Z M, Huang B J, Meng X Q, Tongay S, Liu J, Li J B, Chen H D 2016 Appl. Phys. Lett. 109 112102

Google Scholar

Google Scholar

[39] Lin Y C, Dumcenco D O, Komsa H P, Niimi Y, Krasheninnikov A V, Huang Y S, Suenaga K 2014 Adv. Mater. 26 2857

Google Scholar

Google Scholar

[40] Zandalazini C I, Albanesi E A 2019 J. Magn. Magn. Mater. 484 146

Google Scholar

Google Scholar

[41] Fan S W, Yang L, Gao G Y 2019 Phys. Lett. A 383 3138

Google Scholar

Google Scholar

[42] Laroussi A, Berber M, Mokaddem A, Doumi B, Abid H, Boudali A 2019 Acta Phys. Pol. A 135 451

Google Scholar

Google Scholar

[43] Duerloo K N, Reed E J 2016 ACS Nano 10 289

Google Scholar

Google Scholar

[44] Kumar A, Strachan A, Onofrio N 2019 J. Appl. Phys. 125 204303

Google Scholar

Google Scholar

[45] Wang J Z, Yang T, Zhang Z D, Yang L 2018 Appl. Phys. Lett. 112 213104

Google Scholar

Google Scholar

[46] Young J, Reinecke T L 2017 Phys. Chem. Chem. Phys. 19 31874

Google Scholar

Google Scholar

[47] Huang H H, Fan X F, Singh D J, Zheng W T 2018 Phys. Chem. Chem. Phys. 20 26986

Google Scholar

Google Scholar

[48] Chen M W, Zhu L G, Chen Q F, Miao N H, Si C, Zhou J, Sun Z M 2020 J. Mater. Chem. C 8 721

Google Scholar

Google Scholar

[49] Koski K J, Wessells C D, Reed B W, Cha J J, Kong D S, Cui Y 2012 J. Am. Chem. Soc. 134 13773

Google Scholar

Google Scholar

[50] Gong Y J, Yuan H T, Wu C L, et al. 2018 Nat. Nanotechnol. 13 294

Google Scholar

Google Scholar

[51] Meng Y S, Elena Arroyo-de Dompablo M 2009 Energy Environ. Sci. 2 589

Google Scholar

Google Scholar

[52] Zhang Z X, Yang M Y, Zhao N, Wang L, Li Y Y 2019 Phys. Chem. Chem. Phys. 21 23441

Google Scholar

Google Scholar

[53] Py M A, Haering R R 1983 Can. J. Phys. 61 76

Google Scholar

Google Scholar

[54] Kan M, Wang J Y, Li X W, Zhang S H, Li Y W, Kawazoe Y, Sun Q, Jena P 2014 J. Phys. Chem. C 118 1515

Google Scholar

Google Scholar

[55] Tan S J R, Abdelwahab I, Ding Z J, Zhao X X, Yang T S, Loke G Z J, Lin H, Verzhbitskiy I, Poh S M, Xu H, Nai C T, Zhou W, Eda G, Jia B H, Loh K P 2017 J. Am. Chem. Soc. 139 2504

Google Scholar

Google Scholar

[56] Xia J, Wang J, Chao D L, Chen Z, Liu Z, Kuo J L, Yan J X, Shen Z X 2017 Nanoscale 9 7533

Google Scholar

Google Scholar

[57] Sun L F, Yan X X, Zheng J Y, Yu H D, Lu Z X, Gao S P, Liu L N, Pan X Q, Wang D, Wang Z G, Wang P, Jiao L Y 2018 Nano Lett. 18 3435

Google Scholar

Google Scholar

[58] Eshete Y A, Ling N, Kim S, Kim D, Hwang G, Cho S, Yang H 2019 Adv. Funct. Mater. 29 1904504

Google Scholar

Google Scholar

[59] Leng K, Chen Z X, Zhao X X, Tang W, Tian B B, Nai C T, Zhou W, Loh K P 2016 ACS Nano 10 9208

Google Scholar

Google Scholar

[60] Tan C L, Zhao W, Chaturvedi A, Fei Z, Zeng Z Y, Chen J Z, Huang Y, Ercius P, Luo Z M, Qi X Y, Chen B, Lai Z C, Li B, Zhang X, Yang J, Zong Y, Jin C H, Zheng H M, Kloc C, Zhang H 2016 Small 12 1866

Google Scholar

Google Scholar

[61] Wang X F, Shen X, Wang Z X, Yu R C, Chen L Q 2014 ACS Nano 8 11394

Google Scholar

Google Scholar

[62] Koley S, Basu S 2020 J. Magn. Magn. Mater. 499 166294

Google Scholar

Google Scholar

[63] Li P, Jeong J Y, Jin B J, Zhang K, Park J H 2020 Energy Storage Mater. 25 687

Google Scholar

Google Scholar

[64] Island J O, Kuc A, Diependaal E H, Bratschitsch R, van der Zant H S J, Heine T, Castellanos-Gomez A 2016 Nanoscale 8 2589

Google Scholar

Google Scholar

[65] Duerloo K N, Li Y, Reed E J 2014 Nat. Commun. 5 4214

Google Scholar

Google Scholar

[66] Song S, Keum D H, Cho S, Perello D, Kim Y, Lee Y H 2016 Nano Letters 16 188

Google Scholar

Google Scholar

[67] Huang H H, Fan X F, Singh D J, Chen H, Jiang Q, Zheng W T 2016 Phys. Chem. Chem. Phys. 18 4086

Google Scholar

Google Scholar

[68] Fan X F, Singh D J, Jiang Q, Zheng W T 2016 Phys. Chem. Chem. Phys. 18 12080

Google Scholar

Google Scholar

[69] Tang Q 2018 J. Mater. Chem. C 6 9561

Google Scholar

Google Scholar

[70] Johari P, Shenoy V B 2012 ACS Nano 6 5449

Google Scholar

Google Scholar

[71] Apte A, Kochat V, Rajak P, et al. 2018 ACS Nano 12 3468

Google Scholar

Google Scholar

[72] Keum D H, Cho S, Kim J H, et al. 2015 Nat. Phys. 11 482

Google Scholar

Google Scholar

[73] Wang Z Y, Sun Y Y, Abdelwahab I, et al. 2018 ACS Nano 12 12619

Google Scholar

Google Scholar

[74] Yin X M, Tang C S, Wu D, et al. 2019 Adv. Sci. 6 1802093

Google Scholar

Google Scholar

[75] Sung J H, Heo H, Si S, Kim Y H, Noh H R, Song K, Kim J, Lee C S, Seo S Y, Kim D H, Kim H K, Yeom H W, Kim T H, Choi S Y, Kim J S, Jo M H 2017 Nat. Nanotechnol. 12 1064

Google Scholar

Google Scholar

[76] Nakata Y, Sugawara K, Shimizu R, Okada Y, Han P, Hitosugi T, Ueno K, Sato T, Takahashi T 2016 NPG Asia Mater. 8 e231

Google Scholar

Google Scholar

[77] Chen J C, Feng Z H, Fan S Q, et al. 2017 ACS Appl. Mater. Interfaces 9 30107

Google Scholar

Google Scholar

[78] Cho S, Kim S, Kim J H, Zhao J, Seok J, Keum D H, Baik J, Choe D H, Chang K J, Suenaga K, Kim S W, Lee Y H, Yang H 2015 Science 349 625

Google Scholar

Google Scholar

[79] Yu Y F, Nam G H, He Q Y, et al. 2018 Nat. Chem. 10 638

Google Scholar

Google Scholar

[80] Chen Z R, Nan H Y, Liu Z, Wang X Y, Gu X F, Xiao S Q 2019 J. Raman Spectrosc. 50 755

Google Scholar

Google Scholar

[81] Si C, Choe D, Xie W Y, Wang H, Sun Z M, Bang J, Zhang S B 2019 Nano Lett. 19 3612

Google Scholar

Google Scholar

[82] Azcatl A, Qin X Y, Prakash A, et al. 2016 Nano Lett. 16 5437

Google Scholar

Google Scholar

[83] Cheng C C, Lu A Y, Tseng C C, Yang X L, Hedhili M N, Chen M C, Wei K H, Li L J 2016 Nano Energy 30 846

Google Scholar

Google Scholar

[84] O’Brien M, Lee K, Morrish R, Berner N C, McEvoy N, Wolden C A, Duesberg G S 2014 Chem. Phys. Lett. 615 6

Google Scholar

Google Scholar

[85] Jin J C, Zhang D P, Qin X N, Yang Y, Huang Y, Guan H, He Q C, Fan P, Lv W Z 2019 Nanomaterials 9 102

Google Scholar

Google Scholar

[86] Zhu J, Wang Z, Yu H 2017 J. Am. Chem. Soc. 139 10216

Google Scholar

Google Scholar

[87] Shawkat M S, Gil J, Han S S, et al. 2020 ACS Appl. Mater. Interfaces 12 14341

Google Scholar

Google Scholar

[88] Nan H Y, Jiang J, Xiao S Q, et al. 2018 Nanotechnology 30 034004

Google Scholar

Google Scholar

[89] Taniguchi K, Matsumoto A, Shimotani H, Takagi H 2012 Appl, . Phys. Lett. 101 042603

Google Scholar

Google Scholar

[90] Ye J T, Zhang Y J, Akashi R, Bahramy M S, Arita R, Iwasa Y 2012 Science 338 1193

Google Scholar

Google Scholar

[91] 何学侠, 刘富才, 曾庆圣, 刘政 2015 化学学报 73 924

Google Scholar

Google Scholar

He X X, Liu F C, Zeng Q S, Liu Z 2015 Acta Chim. Sin. 73 924

Google Scholar

Google Scholar

[92] Li Y, Duerloo K A N, Wauson K, Reed E J 2016 Nat. Commun. 7 10671

Google Scholar

Google Scholar

[93] Wang Y, Xiao J, Zhu H 2017 Nature 550 487

Google Scholar

Google Scholar

[94] Bischoff F, Auwarter W, Barth J V, Schiffrin A, Fuhrer M, Weber B 2017 Chem. Mater. 29 9907

Google Scholar

Google Scholar

计量

- 文章访问数: 19126

- PDF下载量: 695

- 被引次数: 0

下载:

下载: