-

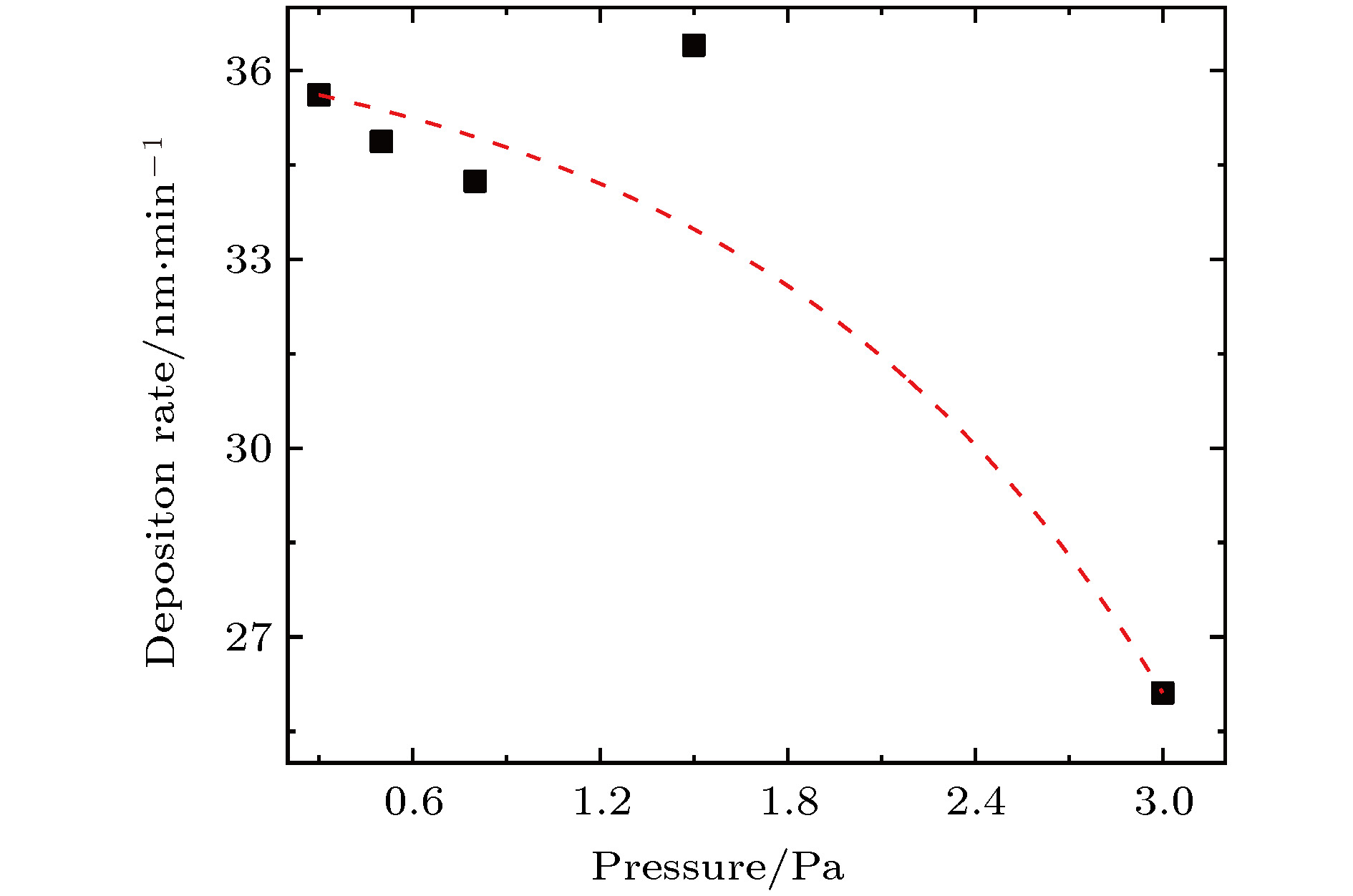

本文采用磁控溅射技术, 对F和Al共掺杂ZnO (FAZO)薄膜进行研究, 系统地研究了溅射气压对薄膜结构、形貌、光电等特性的影响. 实验研究结果表明: F, Al共掺入并未改变ZnO的生长方式, 所制备的薄膜都呈(002)择优生长; 随着溅射气压增加, FAZO薄膜的沉积速率降低, 结晶质量恶化, 表面形貌由“弹坑状”逐渐变为“弹坑状”与“颗粒状”并存的形貌特性, 表面粗糙度增加. 在0.5 Pa时制备的FAZO薄膜性能最优, 迁移率40.03 cm2/(V·s), 载流子浓度3.92 × 1020 cm–3, 电阻率最低, 为3.98 × 10–4 Ω·cm, 380—1200 nm平均透过率约90%. 理论模拟结果表明: F和Al的共掺杂兼顾了F, Al单独掺杂的优点, 克服了以往金属元素掺杂仅依靠金属元素轨道提供导电电子的不足, 实现了既增加载流子浓度又减少了掺入原子各轨道间相互作用对载流子散射的影响. 掺入的F 2p电子轨道对O 2p及Zn 4s电子轨道产生排斥, 使它们分别下移, 提供导电电子; 同时掺入的Al的3s和3p电子轨道也为导电电子提供了贡献. F和Al共掺之后载流子浓度提升更加显著, 导电性能增强.

-

关键词:

- F和Al共掺杂ZnO薄膜 /

- 磁控溅射 /

- 第一性原理计算 /

- 太阳电池

Transparent conductive oxide (TCO) films, as transparent electrodes, are widely used in thin-film solar cells. The performance of TCO film has a significant influence on the conversion efficiency of the film solar cell fabricated byusing it. Although the conductivity can be improved by increasing the carrier concentration, the transmittance in the long wave will be sacrificed. Therefore, the only feasible method is to increase the carrier mobility within a certain carrier concentration range, rather than increase the mobility by reducing carrier concentration. In this paper, the F and Al co-doped ZnO (FAZO) films are deposited on glass substrates (Corning XG) by an RF magnetron sputtering technique with using a small amount of ZnF2 (1 wt.%) and Al2O3 (1 wt.%) dopant. The influences of sputtering pressure on the structure, morphology and photoelectric characteristics of the films are respectively investigated by X-ray diffraction analysis, scanning electron microscope, Hall effect measurement, and ultraviolet–visible–near infrared spectrophotometry. All the thin films show typical wurtzite structure with the c axis preferentially oriented perpendicular to the substrate. With the increase of sputtering pressure, the deposition rate of FAZO film decreases, the crystallization quality is deteriorated, surface topography changes gradually from “crater-like” to co-existent “crater-like” and “granular-like”, and the surface roughness increases. The FAZO film deposited at 0.5 Pa presents the optimal performance with a mobility of 40.03 cm2/V·s, carrier concentration of 3.92 × 1020 cm–3, resistivity of 3.98 × 10–4 Ω·cm, and about 90% average transmittance in a range of 380-1200 nm. The theoretical result shows that the co-doping of F and Al takes the advantages of single F and Al doped ZnO films, and overcomes the shortcoming of metal elements doping, which donates the carriers just from doped metal elements. Furthermore, the co-doping of F and Al not only increases the carriers but also reduces the scatterings caused by the inter-orbital interaction of doped atoms. The doped F 2p electron orbitals repel the O 2p and Zn 4s electron orbitals, making them move down and donate electrons. At the same time, the orbitals of Al 3s and Al 3p also make a contribution to the conductivity. After co-doping of F and Al, both the carrier concentration and conductivity increase significantly.-

Keywords:

- F and Al co-doped ZnO film /

- magnetron sputtering /

- first principle calculations /

- solar cells

[1] Gordon R G 2000 MRS Bull. 25 52

[2] Minami T 2000 MRS Bull. 25 38

[3] Moulin E, Bittkau K, Ghosh M, Bugnon G, Stuckelberger M, Meier M, Haug F J, Hüpkes J, Ballif C 2016 Sol. Energy Mater. Sol. Cells 145 185

Google Scholar

Google Scholar

[4] Jost G, Merdzhanova T, Zimmermann T, Hüpkes J 2013 Thin Solid Films 532 66

Google Scholar

Google Scholar

[5] Tao K, Sun Y, Cai H K, Zhang D X, Xie K, Wang Y 2012 Appl. Surf. Sci. 258 5943

Google Scholar

Google Scholar

[6] Warasawa M, Kaijo A, Sugiyama M 2012 Thin Solid Films 520 2119

Google Scholar

Google Scholar

[7] Wang Y F, Song J M, Bai L S, Yang F, Han B, Guo Y J, Dai B T, Zhao Y, Zhang X D 2018 Sol. Energy Mater. Sol. Cells 179 401

Google Scholar

Google Scholar

[8] Liu B F, Bai L S, Li T T, Wei C C, Li B Z, Huang Q, Zhang D K, Wang G C, Zhao Y, Zhang X D 2017 Energy Environ. Sci. 10 1134

Google Scholar

Google Scholar

[9] Zhang L, Huang J, Yang J, Tang K, Ren B, Zhang S W, Wang L J 2016 Surf. Coat. Technol. 307 1129

Google Scholar

Google Scholar

[10] Tsay C Y, Pai K C 2018 Thin Solid Films 654 11

Google Scholar

Google Scholar

[11] Kirby S D, van Dover R B 2009 Thin Solid Films 517 1958

Google Scholar

Google Scholar

[12] Li Q, Zhu L P, Li Y G, Zhang X Y, Niu W Z, Guo Y M, Ye Z Z 2017 J. Alloys Compd. 697 156

Google Scholar

Google Scholar

[13] Mallick A, Basak D 2017 Appl. Surf. Sci. 410 540

Google Scholar

Google Scholar

[14] Shi Q, Zhou K S, Dai M J, Lin S S, Hou H J, Wei C B, Hu F 2014 Ceram. Int. 40 211

Google Scholar

Google Scholar

[15] Ji X Z, Song J M, Wu T T, Tian Y, Han B, Liu X N, Wang H W, Gui Y B, Ding Y, Wang Y F 2019 Sol. Energy Mater. Sol. Cells 190 6

Google Scholar

Google Scholar

[16] Wang Y F, Song J M, Song W Y, Tian Y, Han B, Meng X D, Yang F, Ding Y, Li J J 2019 Sol. Energy 186 126

Google Scholar

Google Scholar

[17] Zheng G X, Song J M, Zhang J, Li J J, Han B, Meng X D, Yang F, Zhao Y, Wang Y F 2020 Mater. Sci. Semicond. Process. 112 105016

Google Scholar

Google Scholar

[18] 王延峰, 黄茜, 宋庆功, 刘阳, 魏长春, 赵颖, 张晓丹 2012 61 137801

Google Scholar

Google Scholar

Wang Y F, Huang Q, Song Q G, Liu Y, Wei C C, Zhao Y, Zhang X D 2012 Acta Phys. Sin. 61 137801

Google Scholar

Google Scholar

[19] 王延峰, 张晓丹, 黄茜, 杨富, 孟旭东, 宋庆功, 赵颖 2013 62 247802

Google Scholar

Google Scholar

Wang Y F, Zhang X D, Huang Q, Yang F, Meng X D, Song Q G, Zhao Y 2013 Acta Phys. Sin. 62 247802

Google Scholar

Google Scholar

[20] Segall M D, Lindan P J D, Probert M J, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys. Condens. Matter 14 2717

Google Scholar

Google Scholar

[21] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[22] Vanderbilt D 1990 Phys. Rev. B 41 7892

Google Scholar

Google Scholar

[23] Sheetz R M, Ponomareva I, Richter E, Andriotis A N, Menon M 2009 Phys. Rev. B 80 195314

Google Scholar

Google Scholar

[24] 王延峰, 孟旭东, 郑伟, 宋庆功, 翟昌鑫, 郭兵, 张越, 杨富, 南景宇 2016 65 087802

Google Scholar

Google Scholar

Wang Y F, Meng X D, Zheng W, Song Q G, Zhai C X, Guo B, Zhang Y, Yang F, Nan J Y 2016 Acta Phys. Sin. 65 087802

Google Scholar

Google Scholar

[25] Hsu F H, Wang N F, Tsai Y Z, Chuang M C, Cheng Y S, Houng M P 2013 Appl. Surf. Sci. 280 104

Google Scholar

Google Scholar

[26] Yue H, Wu A, Feng Y, Zhang X, Li T 2011 Thin Solid Films 519 5577

Google Scholar

Google Scholar

[27] Kluth O, Schöpe G, Hüpkes J, Agashe C, Müller J, Rech B 2003 Thin Solid Films 442 80

Google Scholar

Google Scholar

[28] Assunção V, Fortunato E, Marques A, Águas H, Ferreira I, Costa M E V, Martins R 2003 Thin Solid Films 427 401

Google Scholar

Google Scholar

[29] Maccoa B, Knoops H C M, Verheijen M A, Beyer W, Creatore M, Kessels W M M 2017 Sol. Energy Mater. Sol. Cells 173 111

Google Scholar

Google Scholar

[30] Pei Z L, Sun C, Tan M H, Xiao J Q, Guan D H, Huang R F, Wen L S 2001 J. Appl. Phys. 90 3432

Google Scholar

Google Scholar

[31] Sreedhar A, Kwon J H, Yi J, Gwag J S 2016 Ceram. Int. 42 14456

Google Scholar

Google Scholar

[32] Cao L, Zhu LvP, Jiang J, Zhao R, Ye Z Z, Zhao B H 2011 Sol. Energy Mater. Sol. Cells 95 894

Google Scholar

Google Scholar

[33] Xu H Y, Liu Y C, Mu R, Shao C L, Lu Y M, Shen D Z, Fan X W 2005 Appl. Phys. Lett. 86 123107

[34] Burstein E 1954 Phys. Rev. 93 632

Google Scholar

Google Scholar

[35] Moss T S 1954 Proc. Phys. Soc. London, Sect. B 67 775

Google Scholar

Google Scholar

[36] Slassi A 2015 Opt. Quantum Electron. 47 2465

Google Scholar

Google Scholar

[37] 张富春, 张志勇, 张威虎, 阎军峰, 贠江妮 2009 光学学报 29 2015

Zhang F C, Zhang Z Y, Zhang W H, Yan J F, Yun J N 2009 Acta Opt. Sin. 29 2015

[38] Wang Y F, Zhang X D, Meng X D, Cao Y, Yang F, Nan J Y, Song Q G, Huang Q, Wei C C, Zhang J J, Zhao Y 2016 Sol. Energy Mater. Sol. Cells 145 171

Google Scholar

Google Scholar

-

-

[1] Gordon R G 2000 MRS Bull. 25 52

[2] Minami T 2000 MRS Bull. 25 38

[3] Moulin E, Bittkau K, Ghosh M, Bugnon G, Stuckelberger M, Meier M, Haug F J, Hüpkes J, Ballif C 2016 Sol. Energy Mater. Sol. Cells 145 185

Google Scholar

Google Scholar

[4] Jost G, Merdzhanova T, Zimmermann T, Hüpkes J 2013 Thin Solid Films 532 66

Google Scholar

Google Scholar

[5] Tao K, Sun Y, Cai H K, Zhang D X, Xie K, Wang Y 2012 Appl. Surf. Sci. 258 5943

Google Scholar

Google Scholar

[6] Warasawa M, Kaijo A, Sugiyama M 2012 Thin Solid Films 520 2119

Google Scholar

Google Scholar

[7] Wang Y F, Song J M, Bai L S, Yang F, Han B, Guo Y J, Dai B T, Zhao Y, Zhang X D 2018 Sol. Energy Mater. Sol. Cells 179 401

Google Scholar

Google Scholar

[8] Liu B F, Bai L S, Li T T, Wei C C, Li B Z, Huang Q, Zhang D K, Wang G C, Zhao Y, Zhang X D 2017 Energy Environ. Sci. 10 1134

Google Scholar

Google Scholar

[9] Zhang L, Huang J, Yang J, Tang K, Ren B, Zhang S W, Wang L J 2016 Surf. Coat. Technol. 307 1129

Google Scholar

Google Scholar

[10] Tsay C Y, Pai K C 2018 Thin Solid Films 654 11

Google Scholar

Google Scholar

[11] Kirby S D, van Dover R B 2009 Thin Solid Films 517 1958

Google Scholar

Google Scholar

[12] Li Q, Zhu L P, Li Y G, Zhang X Y, Niu W Z, Guo Y M, Ye Z Z 2017 J. Alloys Compd. 697 156

Google Scholar

Google Scholar

[13] Mallick A, Basak D 2017 Appl. Surf. Sci. 410 540

Google Scholar

Google Scholar

[14] Shi Q, Zhou K S, Dai M J, Lin S S, Hou H J, Wei C B, Hu F 2014 Ceram. Int. 40 211

Google Scholar

Google Scholar

[15] Ji X Z, Song J M, Wu T T, Tian Y, Han B, Liu X N, Wang H W, Gui Y B, Ding Y, Wang Y F 2019 Sol. Energy Mater. Sol. Cells 190 6

Google Scholar

Google Scholar

[16] Wang Y F, Song J M, Song W Y, Tian Y, Han B, Meng X D, Yang F, Ding Y, Li J J 2019 Sol. Energy 186 126

Google Scholar

Google Scholar

[17] Zheng G X, Song J M, Zhang J, Li J J, Han B, Meng X D, Yang F, Zhao Y, Wang Y F 2020 Mater. Sci. Semicond. Process. 112 105016

Google Scholar

Google Scholar

[18] 王延峰, 黄茜, 宋庆功, 刘阳, 魏长春, 赵颖, 张晓丹 2012 61 137801

Google Scholar

Google Scholar

Wang Y F, Huang Q, Song Q G, Liu Y, Wei C C, Zhao Y, Zhang X D 2012 Acta Phys. Sin. 61 137801

Google Scholar

Google Scholar

[19] 王延峰, 张晓丹, 黄茜, 杨富, 孟旭东, 宋庆功, 赵颖 2013 62 247802

Google Scholar

Google Scholar

Wang Y F, Zhang X D, Huang Q, Yang F, Meng X D, Song Q G, Zhao Y 2013 Acta Phys. Sin. 62 247802

Google Scholar

Google Scholar

[20] Segall M D, Lindan P J D, Probert M J, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys. Condens. Matter 14 2717

Google Scholar

Google Scholar

[21] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[22] Vanderbilt D 1990 Phys. Rev. B 41 7892

Google Scholar

Google Scholar

[23] Sheetz R M, Ponomareva I, Richter E, Andriotis A N, Menon M 2009 Phys. Rev. B 80 195314

Google Scholar

Google Scholar

[24] 王延峰, 孟旭东, 郑伟, 宋庆功, 翟昌鑫, 郭兵, 张越, 杨富, 南景宇 2016 65 087802

Google Scholar

Google Scholar

Wang Y F, Meng X D, Zheng W, Song Q G, Zhai C X, Guo B, Zhang Y, Yang F, Nan J Y 2016 Acta Phys. Sin. 65 087802

Google Scholar

Google Scholar

[25] Hsu F H, Wang N F, Tsai Y Z, Chuang M C, Cheng Y S, Houng M P 2013 Appl. Surf. Sci. 280 104

Google Scholar

Google Scholar

[26] Yue H, Wu A, Feng Y, Zhang X, Li T 2011 Thin Solid Films 519 5577

Google Scholar

Google Scholar

[27] Kluth O, Schöpe G, Hüpkes J, Agashe C, Müller J, Rech B 2003 Thin Solid Films 442 80

Google Scholar

Google Scholar

[28] Assunção V, Fortunato E, Marques A, Águas H, Ferreira I, Costa M E V, Martins R 2003 Thin Solid Films 427 401

Google Scholar

Google Scholar

[29] Maccoa B, Knoops H C M, Verheijen M A, Beyer W, Creatore M, Kessels W M M 2017 Sol. Energy Mater. Sol. Cells 173 111

Google Scholar

Google Scholar

[30] Pei Z L, Sun C, Tan M H, Xiao J Q, Guan D H, Huang R F, Wen L S 2001 J. Appl. Phys. 90 3432

Google Scholar

Google Scholar

[31] Sreedhar A, Kwon J H, Yi J, Gwag J S 2016 Ceram. Int. 42 14456

Google Scholar

Google Scholar

[32] Cao L, Zhu LvP, Jiang J, Zhao R, Ye Z Z, Zhao B H 2011 Sol. Energy Mater. Sol. Cells 95 894

Google Scholar

Google Scholar

[33] Xu H Y, Liu Y C, Mu R, Shao C L, Lu Y M, Shen D Z, Fan X W 2005 Appl. Phys. Lett. 86 123107

[34] Burstein E 1954 Phys. Rev. 93 632

Google Scholar

Google Scholar

[35] Moss T S 1954 Proc. Phys. Soc. London, Sect. B 67 775

Google Scholar

Google Scholar

[36] Slassi A 2015 Opt. Quantum Electron. 47 2465

Google Scholar

Google Scholar

[37] 张富春, 张志勇, 张威虎, 阎军峰, 贠江妮 2009 光学学报 29 2015

Zhang F C, Zhang Z Y, Zhang W H, Yan J F, Yun J N 2009 Acta Opt. Sin. 29 2015

[38] Wang Y F, Zhang X D, Meng X D, Cao Y, Yang F, Nan J Y, Song Q G, Huang Q, Wei C C, Zhang J J, Zhao Y 2016 Sol. Energy Mater. Sol. Cells 145 171

Google Scholar

Google Scholar

计量

- 文章访问数: 10521

- PDF下载量: 141

- 被引次数: 0

下载:

下载: