-

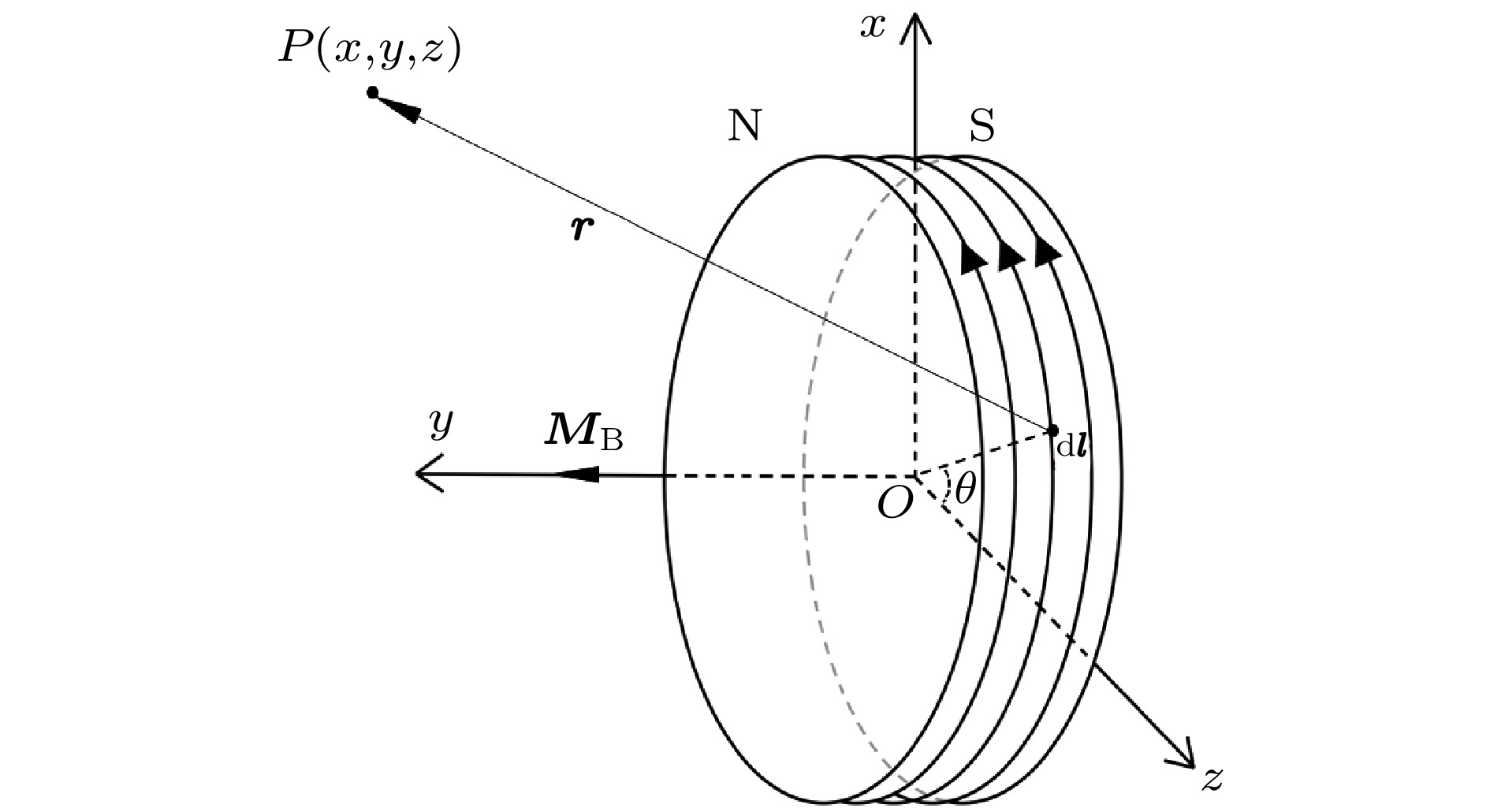

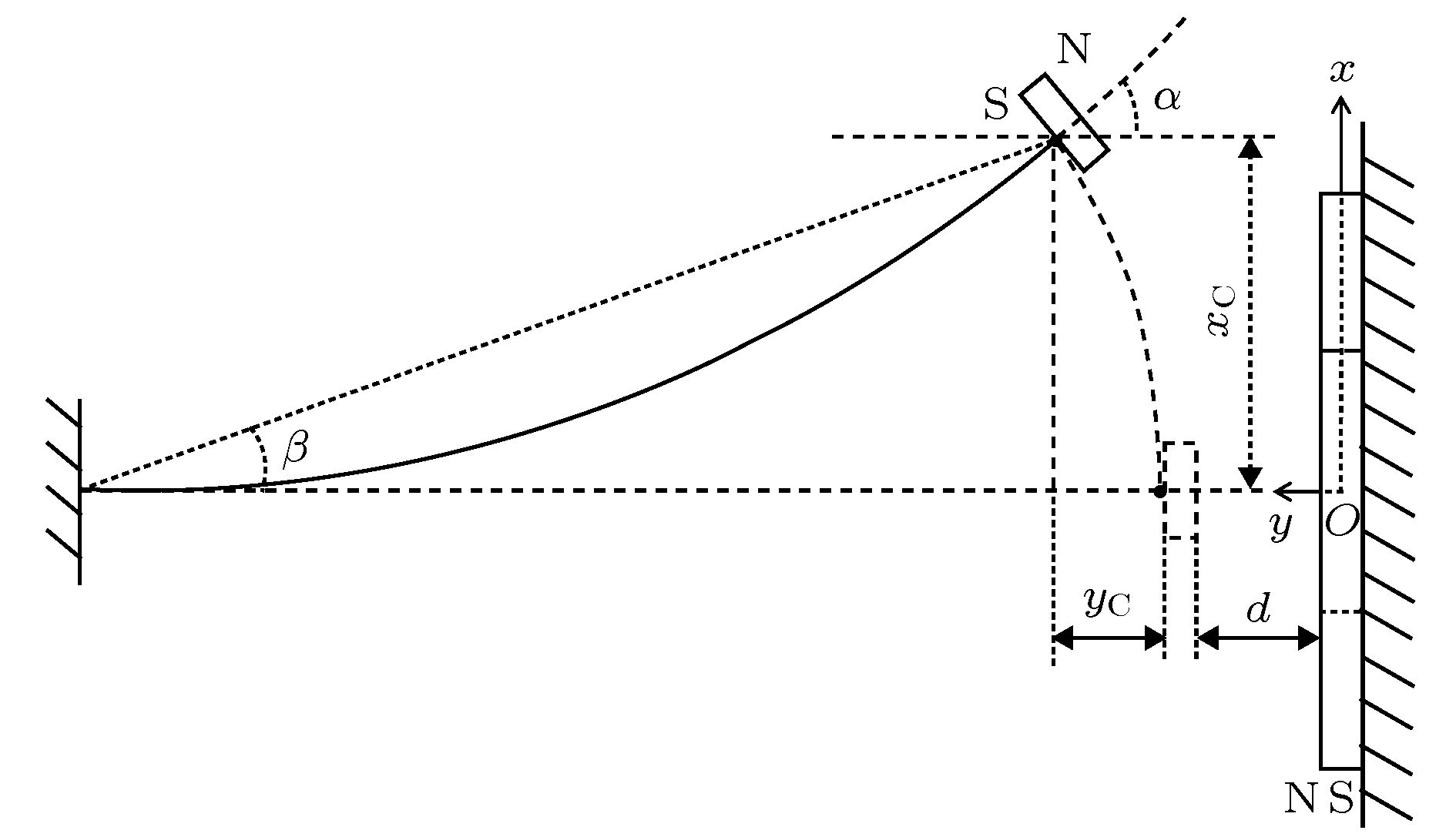

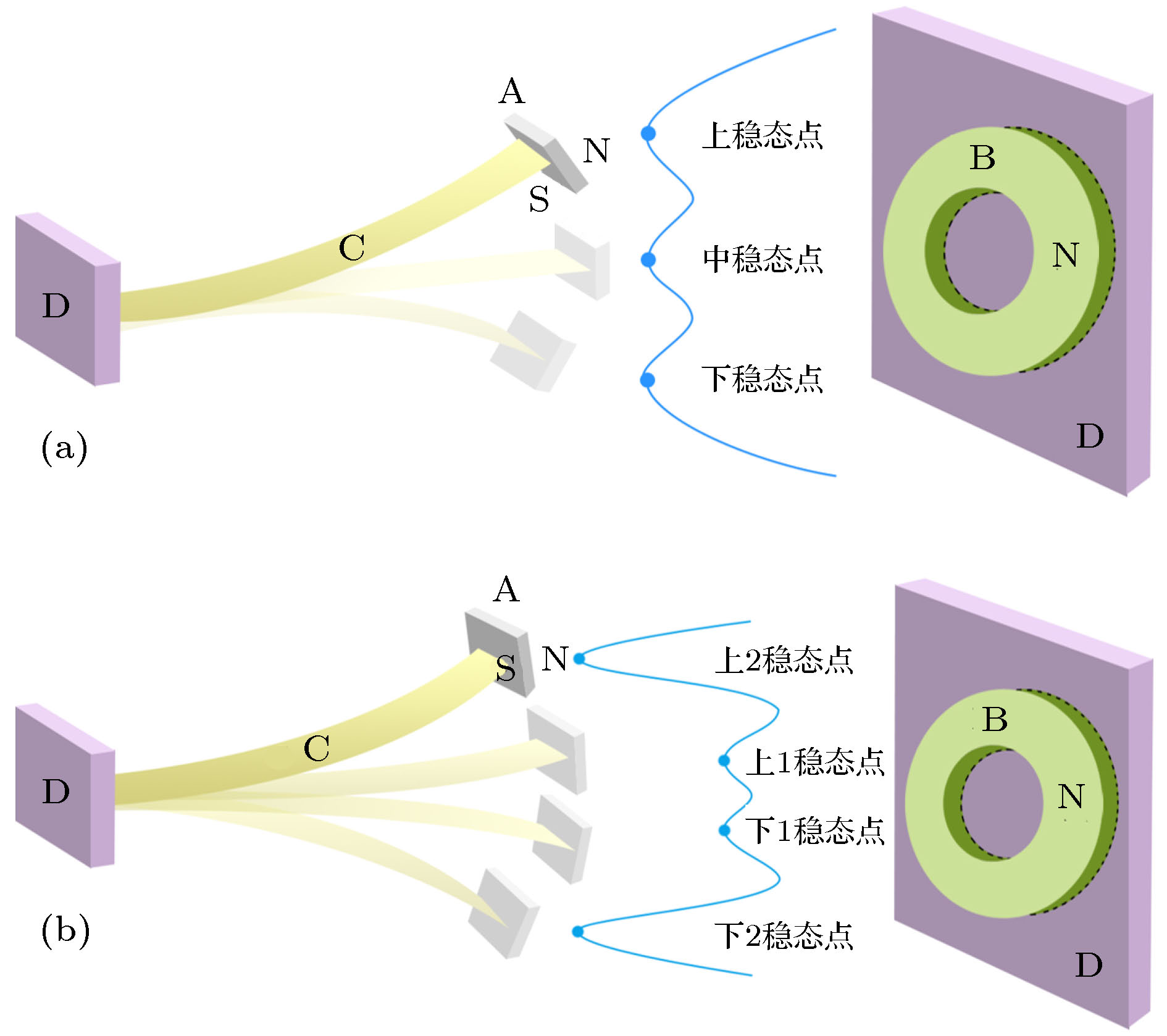

Multi-stable structures are deformable structures that can have large deformations under external excitation. Generally, multi-stable structures have at least two stable points and can jump from one to another. Because multi-stable structures have excellent nonlinear characteristics, they are widely used in many fields. In the field of energy harvesting, multi-stable structures are often obtained by means of cantilever beams. This is because the cantilever beam is simple to make, low in stiffness, and high in sensitivity, and can undergo large deformations under small excitation forces. Besides, by simply sticking magnets on its free end and its outside, various kinds of multi-stable characteristics can be constructed, such as bi-stable characteristics, tri-stable characteristics, quad-stable characteristics, etc. Furthermore, the cantilever beam and the magnet at its end can generally be simplified into an equivalent mass-spring-damping mechanical model, which is convenient for the analysis of system potential function and dynamics. In recent years, many vibration energy harvesters proposed by researchers have adopted the conventional multi-stable cantilever beams, which involve many bi-stable cantilever beams and tri-stable cantilever beams. However, if the cantilever beams need to introduce more stable points, the number of magnets required will also increase accordingly. As a result, the adjustable parameters are continuously increasing, which increases the complexity of structural optimization and the tediousness of dynamic analysis. In order to make up for the shortcomings of conventional multi-stable cantilever beams, in this paper we present a multi-stable cantilever beam with only two magnets, a ring magnet and a rectangular magnet. By changing the size of the rectangular magnet and the distance between the two magnets, this cantilever beam can have mono-stable, bi-stable, tri-stable or quad-stable characteristics. This multi-stable cantilever beam greatly simplifies the complexity of the system design, dynamic analysis, debugging and installation, and provides new ideas and technical methods for the design and application of the vibration energy harvester realized by the multi-stable cantilever beam. In this paper, firstly, the magnetizing current method is used to analyze the magnetic induction intensity of the ring magnet at any point in the three-dimensional coordinate system, and the simulation and experimental results prove its correctness. Secondly, two methods of calculating the position of the rectangular magnet at the free end of the cantilever beam are compared. Thirdly, the magnetic force between the ring magnet and the rectangular magnet is calculated and verified in experiment. Fourthly, the system potential functions under different structural parameters are analyzed and it is found that the change of the number of the stable points of the system is caused by the change of the magnetic force between the two magnets. Finally, the correctness of the number of stable points of the system under different parameters is verified in experiment and by dynamic simulations. -

Keywords:

- two magnets /

- multi-stable cantilever beam /

- magnetic force /

- potential function

[1] Daynes S, Weaver P M 2012 Smart Mater. Struct. 21 105019

Google Scholar

Google Scholar

[2] Barbarino S, Bilgen O, Ajaj R M, Friswell M I, Inman D J 2011 J. Intel. Mat. Syst. Str. 22 823

Google Scholar

Google Scholar

[3] 姜伟红 2018 硕士学位论文(哈尔滨: 哈尔滨工业大学)

Jiang W H 2018 M. S. Thesis (Harbin: Harbin Institute of Technology) (in Chinese)

[4] Diaconu C G, Weaver P M, Mattioni F 2008 Thin Wall. Struct. 46 689

Google Scholar

Google Scholar

[5] Daynes S, Nall S J, Weaver P M, Potter K D, Margaris P, Mellor P H 2010 J. Aircraft 47 334

Google Scholar

Google Scholar

[6] 沙山克·普利亚, 丹尼尔·茵曼(黄见秋, 黄庆安, 译) 2010 能量收集技术 (南京: 东南大学出版社) 第 1—4 页

Priya S, Inman D J (Translated by Huang J Q, Huang Q A) 2010 Energy Harvesting Technologies (Nanjing: Southeast University Press) pp1–4 (in Chinese)

[7] 卢有为, 单小彪, 袁江波, 谢涛 2010 机械设计与制造 5 118

Google Scholar

Google Scholar

Lu Y W, Shan X B, Yuan J B, Xie T 2010 Machinery Design & Manufacture 5 118

Google Scholar

Google Scholar

[8] 王治平, 刘俊标, 姜楠, 李博 2010 压电与声光 32 763

Wang Z P, Liu J B, Jiang N, Li B 2010 Piezoelectrics & Acoustooptics 32 763

[9] Challa V R, Prasad M G, Fisher F T 2009 Smart Mater. Struct. 18 095029

Google Scholar

Google Scholar

[10] 陈仲生, 杨拥民 2011 60 074301

Google Scholar

Google Scholar

Chen Z S, Yang Y M 2011 Acta Phys. Sin. 60 074301

Google Scholar

Google Scholar

[11] Podder P, Amann A, Roy S 2015 Sensor Actuat. A-Phys. 227 39

Google Scholar

Google Scholar

[12] Gao Y J, Leng Y G, Fan S B, Lai Z H 2014 Smart Mater. Struct. 23 095003

Google Scholar

Google Scholar

[13] Leng Y G, Tan D, Liu J J, Zhang Y Y, Fan S B 2017 J. Sound Vib. 406 146

Google Scholar

Google Scholar

[14] Zhou S X, Cao J Y, Inman D J, Lin J, Liu S S, Wang Z Z 2014 Appl. Energy 133 33

Google Scholar

Google Scholar

[15] Deng W, Wang Y 2017 Mech. Syst. Signal Pr. 85 591

Google Scholar

Google Scholar

[16] Roundy S, Wright P K, Rabaey J 2003 Comput. Commun. 26 1131

Google Scholar

Google Scholar

[17] DuToit N E, Wardle B L 2005 Integr. Ferroelectri. 45 1126

[18] Roundy S, Wright P K 2004 Smart Mater. Struct. 13 1131

Google Scholar

Google Scholar

[19] Agashe J S, Arnold D P 2008 J. Phys. D: Appl. Phys. 41 105001

Google Scholar

Google Scholar

[20] 张雨阳, 冷永刚, 谭丹, 刘进军, 范胜波 2017 66 220502

Google Scholar

Google Scholar

Zhang Y Y, Leng Y G, Tan D, Liu J J, Fan S B 2017 Acta Phys. Sin. 66 220502

Google Scholar

Google Scholar

[21] 谭丹, 冷永刚, 范胜波, 高毓璣 2015 64 060502

Google Scholar

Google Scholar

Tan D, Leng Y G, Fan S B, Gao Y J 2015 Acta Phys. Sin. 64 060502

Google Scholar

Google Scholar

[22] Tan D, Leng Y G, Gao Y J 2015 Eur. Phys. J.: Spec. Top. 224 2839

Google Scholar

Google Scholar

-

图 3 磁感应强度Bi, Bj随x的变化关系 (a) Bi随x的变化, y = 6.0 mm; (b) Bj随x的变化, y = 6.0 mm; (c) Bi随x的变化, y = 10.0 mm; (d) Bj随x的变化, y = 10.0 mm

Fig. 3. The curves of Bi and Bj varying with x: (a) The curves of Bi varying with x, y = 6.0 mm; (b) the curves of Bj varying with x, y = 6.0 mm; (c) the curves of Bi varying with x, y = 10.0 mm; (d) the curves of Bj varying with x, y = 10.0 mm.

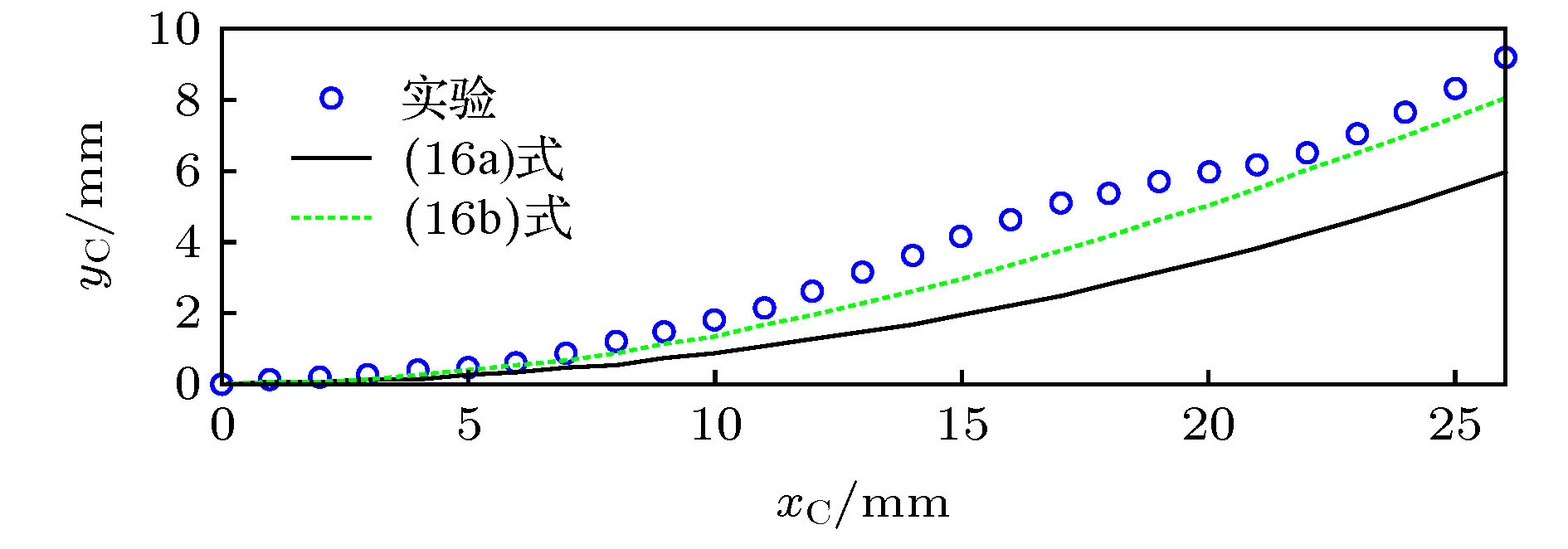

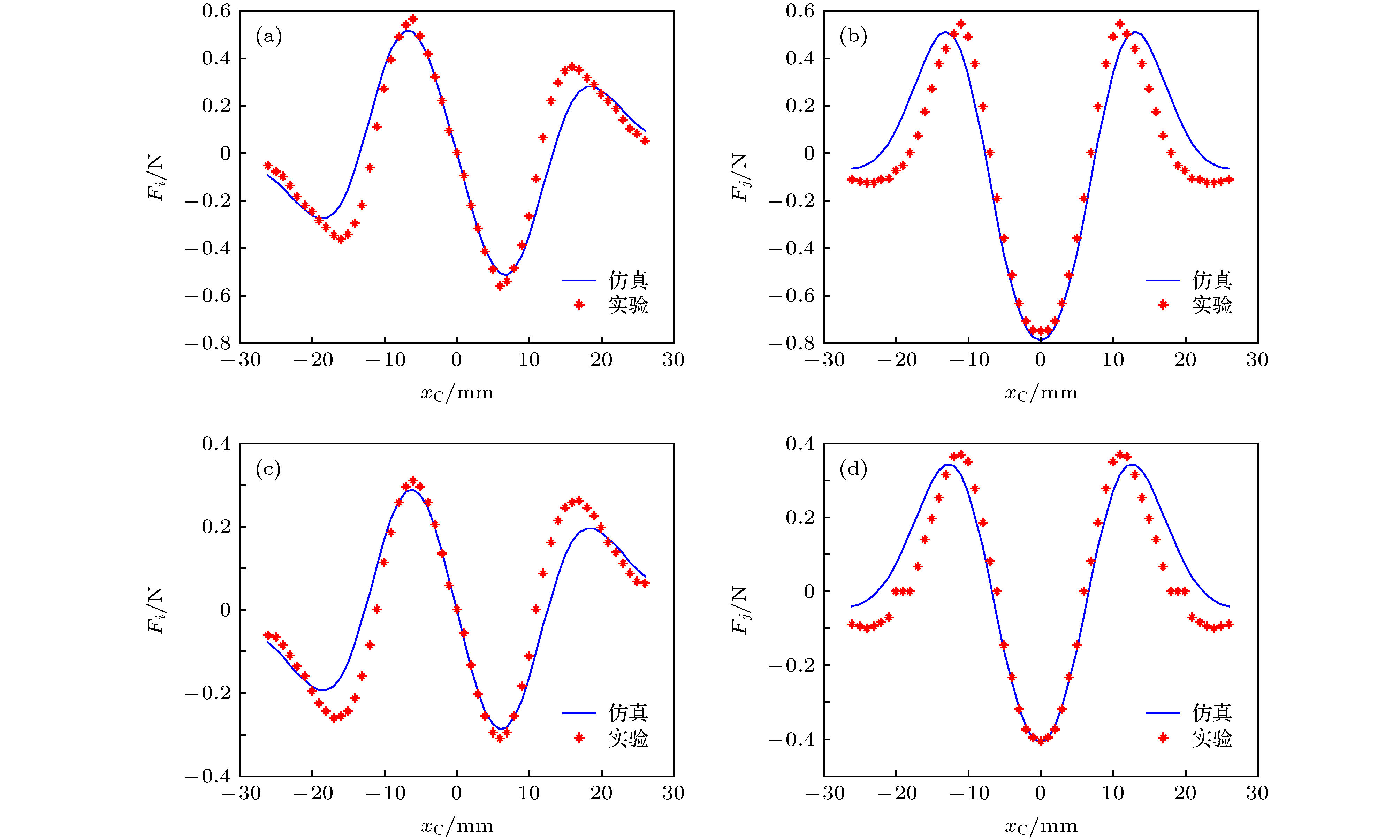

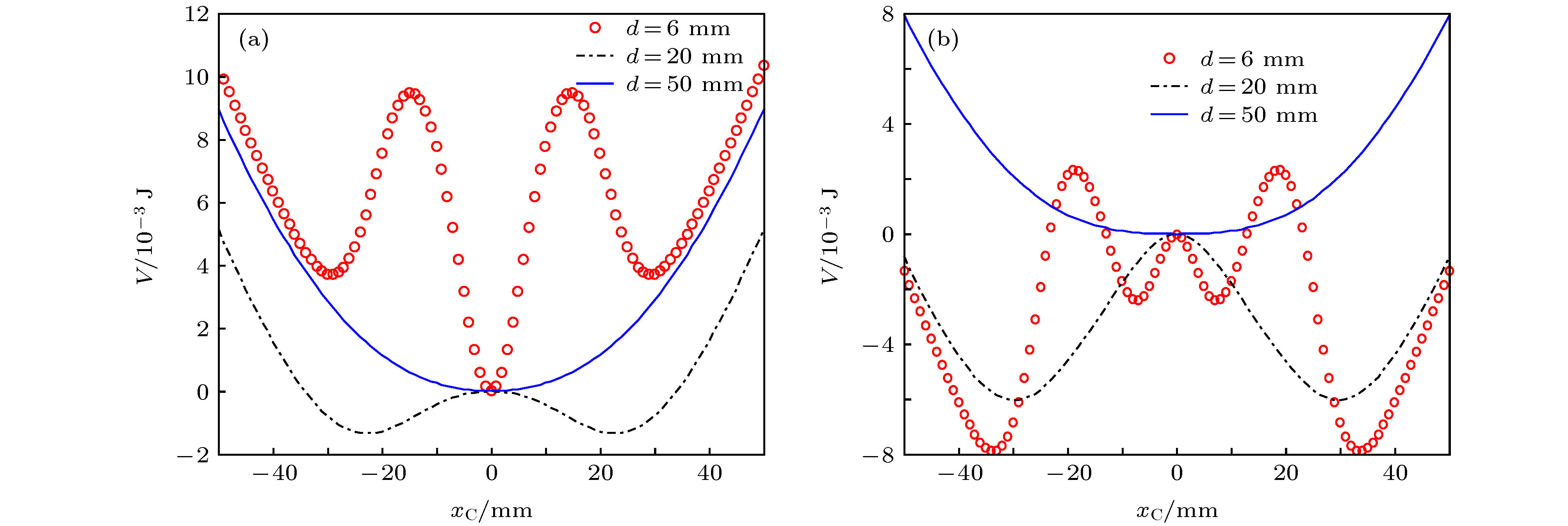

图 9 Fi, Fj随xC的变化关系 (a) Fi随xC的变化关系, d = 5.8 mm; (b)Fj随xC的变化关系, d = 5.8 mm; (c) Fi随xC的变化关系, d = 8.0 mm; (d) Fj随xC的变化关系, d = 8.0 mm

Fig. 9. The curves of Fi and Fj varying with xC: (a) The curves of Fi varying with xC, d = 5.8 mm; (b) the curves of Fj varying with xC, d = 5.8 mm; (c) the curves of Fi varying with xC, d = 8.0 mm; (d) the curves of Fj varying with xC, d = 8.0 mm.

图 11 矩形磁铁(10 mm × 10 mm × 3 mm)与环形磁铁(40 mm (φ1) × 20 mm (φ2) × 3 mm)作用的系统势函数 (a)系统势函数三维图; (b)磁铁间距分别为d = 3 mm, d = 6 mm, d = 20 mm时系统势函数二维图

Fig. 11. The system potential function varying with d when the size of the rectangular magnet is 10 mm × 10 mm × 3 mm and the ring magnet is 40 mm (φ1) × 20 mm (φ2) × 3 mm: (a) Three dimensional diagram of system potential function; (b) two dimensional diagram of system potential function when d = 3 mm, d = 6 mm and d = 20 mm.

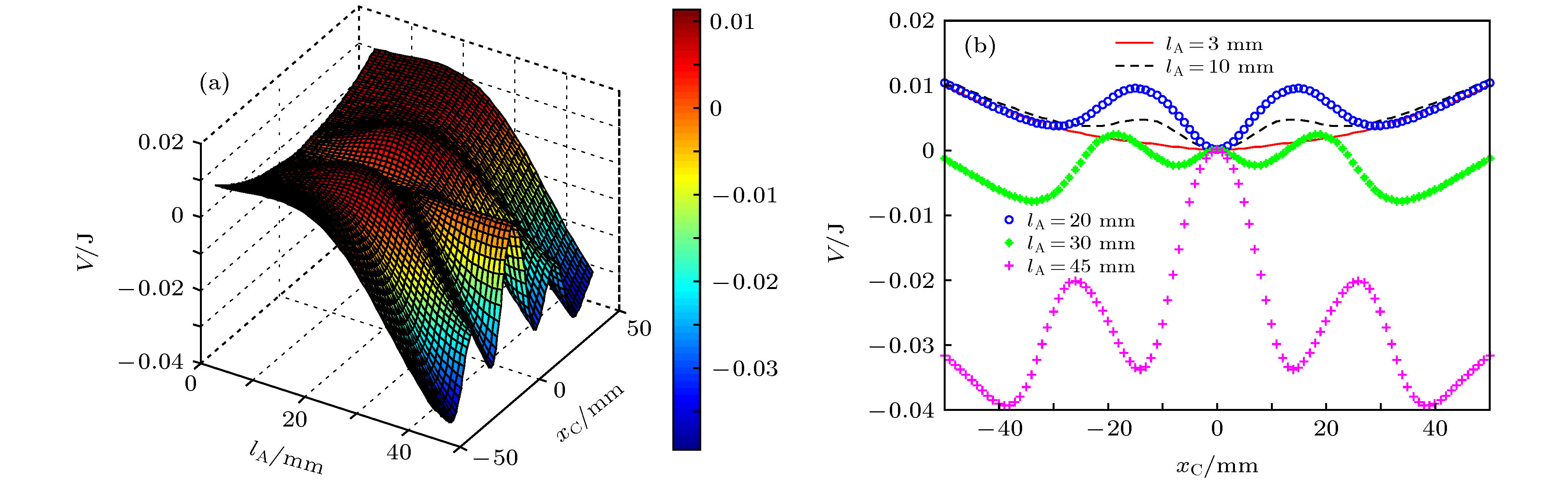

图 13 磁铁间距d = 6 mm, 不同矩形磁铁尺寸与环形磁铁(40 mm(φ1) × 20 mm(φ2) × 3 mm)作用的系统势函数 (a) 系统势函数三维图; (b) 矩形磁铁长度分别为lA = 3 mm, lA = 10 mm, lA = 20 mm, lA = 30 mm, lA = 45 mm时系统势函数二维图

Fig. 13. The system potential function varying with lA when d = 6 mm and the size of the ring magnet is 40 mm(φ1) × 20 mm(φ2) × 3 mm: (a) Three dimensional diagram of system potential function; (b) two dimensional diagram of system potential function when lA = 3 mm, lA = 10 mm, lA = 20 mm, lA = 30 mm and lA = 45 mm.

表 1 悬臂梁、矩形磁铁、环形磁铁的材料和参数

Table 1. Materials and parameters of cantilever beam, rectangular magnet, and ring magnet.

材料 参数 数值 悬臂梁材料: 矽钢 弹性模量EC/GPa 200 密度ρC/kg·m–3 7700 长度lC/mm 60 宽度wC/mm 10 厚度tC/mm 0.15 矩形磁铁材料:

Nd2Fe14B (牌号N35)密度ρA/kg·m–3 7500 长度lA/mm 10 宽度wA/mm 10 厚度tA/mm 3 磁化强度MA/A·m–1 6 × 105 环形磁铁材料:

Nd2Fe14B (牌号N35)密度ρB/kg·m–3 7500 厚度tB/mm 3 外环直径φ1/mm 40 内环直径φ2/mm 20 磁化强度MB/A·m–1 6 × 105 真空磁导率μ0/N·A–2 4π × 10–7 表 2 实验器材及其型号

Table 2. Experimental equipments and models.

实验器材 型号 高斯计 BST100 推拉式测力计 HF-5 激光位移传感器 LK-G5001V -

[1] Daynes S, Weaver P M 2012 Smart Mater. Struct. 21 105019

Google Scholar

Google Scholar

[2] Barbarino S, Bilgen O, Ajaj R M, Friswell M I, Inman D J 2011 J. Intel. Mat. Syst. Str. 22 823

Google Scholar

Google Scholar

[3] 姜伟红 2018 硕士学位论文(哈尔滨: 哈尔滨工业大学)

Jiang W H 2018 M. S. Thesis (Harbin: Harbin Institute of Technology) (in Chinese)

[4] Diaconu C G, Weaver P M, Mattioni F 2008 Thin Wall. Struct. 46 689

Google Scholar

Google Scholar

[5] Daynes S, Nall S J, Weaver P M, Potter K D, Margaris P, Mellor P H 2010 J. Aircraft 47 334

Google Scholar

Google Scholar

[6] 沙山克·普利亚, 丹尼尔·茵曼(黄见秋, 黄庆安, 译) 2010 能量收集技术 (南京: 东南大学出版社) 第 1—4 页

Priya S, Inman D J (Translated by Huang J Q, Huang Q A) 2010 Energy Harvesting Technologies (Nanjing: Southeast University Press) pp1–4 (in Chinese)

[7] 卢有为, 单小彪, 袁江波, 谢涛 2010 机械设计与制造 5 118

Google Scholar

Google Scholar

Lu Y W, Shan X B, Yuan J B, Xie T 2010 Machinery Design & Manufacture 5 118

Google Scholar

Google Scholar

[8] 王治平, 刘俊标, 姜楠, 李博 2010 压电与声光 32 763

Wang Z P, Liu J B, Jiang N, Li B 2010 Piezoelectrics & Acoustooptics 32 763

[9] Challa V R, Prasad M G, Fisher F T 2009 Smart Mater. Struct. 18 095029

Google Scholar

Google Scholar

[10] 陈仲生, 杨拥民 2011 60 074301

Google Scholar

Google Scholar

Chen Z S, Yang Y M 2011 Acta Phys. Sin. 60 074301

Google Scholar

Google Scholar

[11] Podder P, Amann A, Roy S 2015 Sensor Actuat. A-Phys. 227 39

Google Scholar

Google Scholar

[12] Gao Y J, Leng Y G, Fan S B, Lai Z H 2014 Smart Mater. Struct. 23 095003

Google Scholar

Google Scholar

[13] Leng Y G, Tan D, Liu J J, Zhang Y Y, Fan S B 2017 J. Sound Vib. 406 146

Google Scholar

Google Scholar

[14] Zhou S X, Cao J Y, Inman D J, Lin J, Liu S S, Wang Z Z 2014 Appl. Energy 133 33

Google Scholar

Google Scholar

[15] Deng W, Wang Y 2017 Mech. Syst. Signal Pr. 85 591

Google Scholar

Google Scholar

[16] Roundy S, Wright P K, Rabaey J 2003 Comput. Commun. 26 1131

Google Scholar

Google Scholar

[17] DuToit N E, Wardle B L 2005 Integr. Ferroelectri. 45 1126

[18] Roundy S, Wright P K 2004 Smart Mater. Struct. 13 1131

Google Scholar

Google Scholar

[19] Agashe J S, Arnold D P 2008 J. Phys. D: Appl. Phys. 41 105001

Google Scholar

Google Scholar

[20] 张雨阳, 冷永刚, 谭丹, 刘进军, 范胜波 2017 66 220502

Google Scholar

Google Scholar

Zhang Y Y, Leng Y G, Tan D, Liu J J, Fan S B 2017 Acta Phys. Sin. 66 220502

Google Scholar

Google Scholar

[21] 谭丹, 冷永刚, 范胜波, 高毓璣 2015 64 060502

Google Scholar

Google Scholar

Tan D, Leng Y G, Fan S B, Gao Y J 2015 Acta Phys. Sin. 64 060502

Google Scholar

Google Scholar

[22] Tan D, Leng Y G, Gao Y J 2015 Eur. Phys. J.: Spec. Top. 224 2839

Google Scholar

Google Scholar

计量

- 文章访问数: 12923

- PDF下载量: 221

- 被引次数: 0

下载:

下载: