-

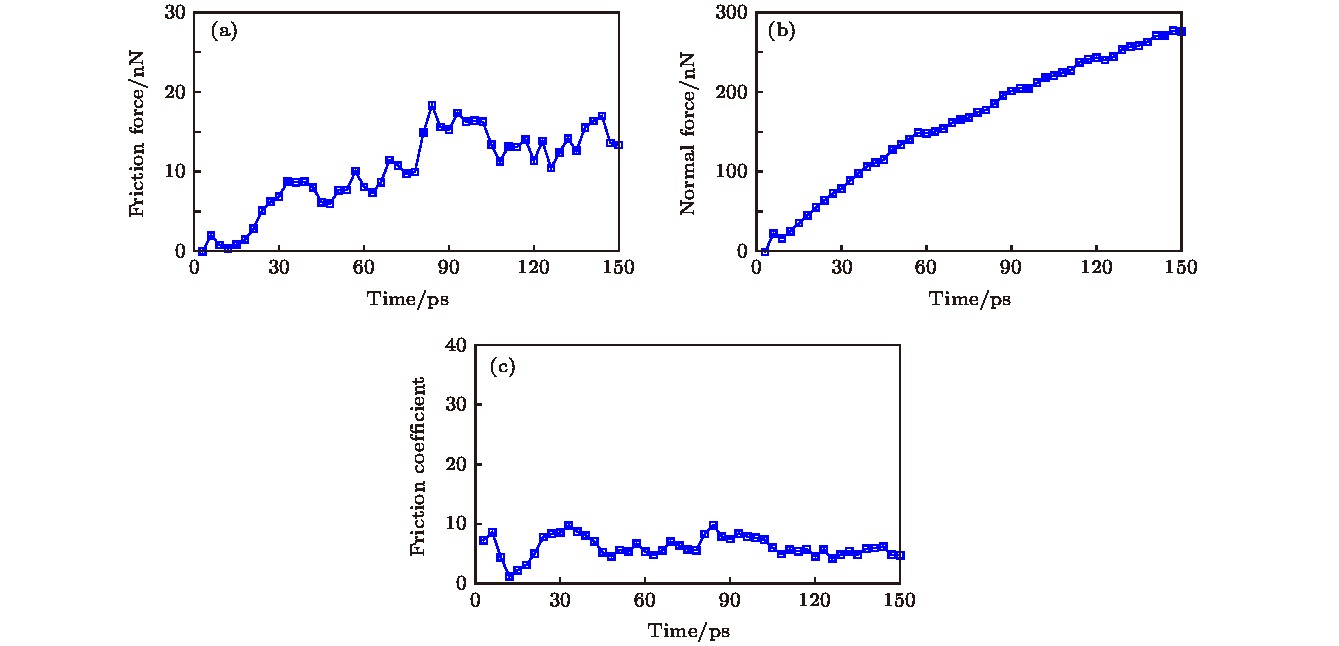

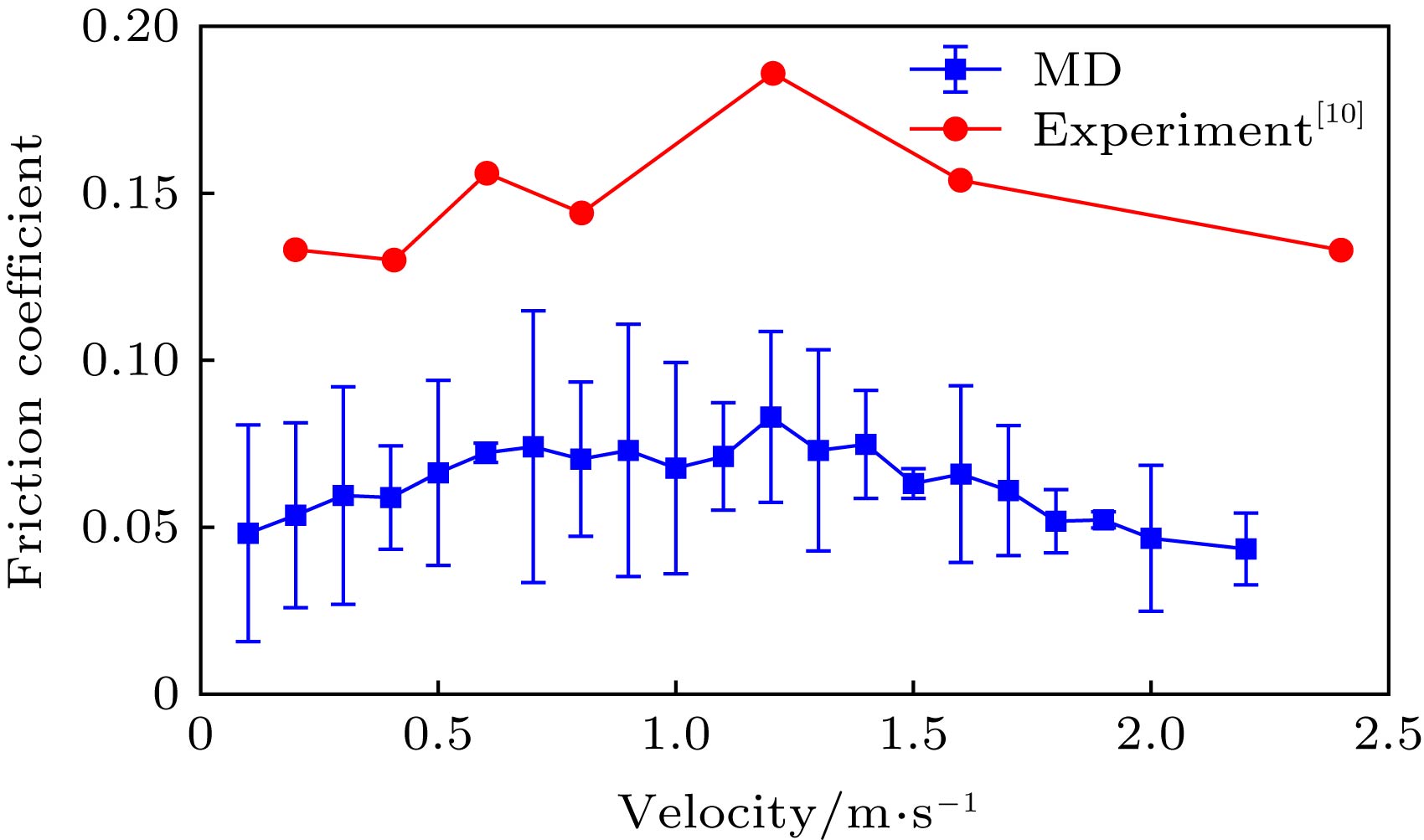

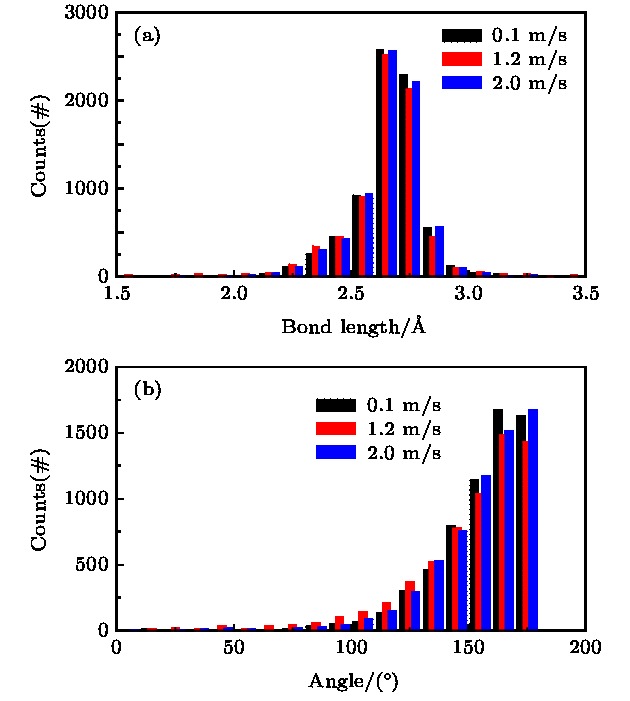

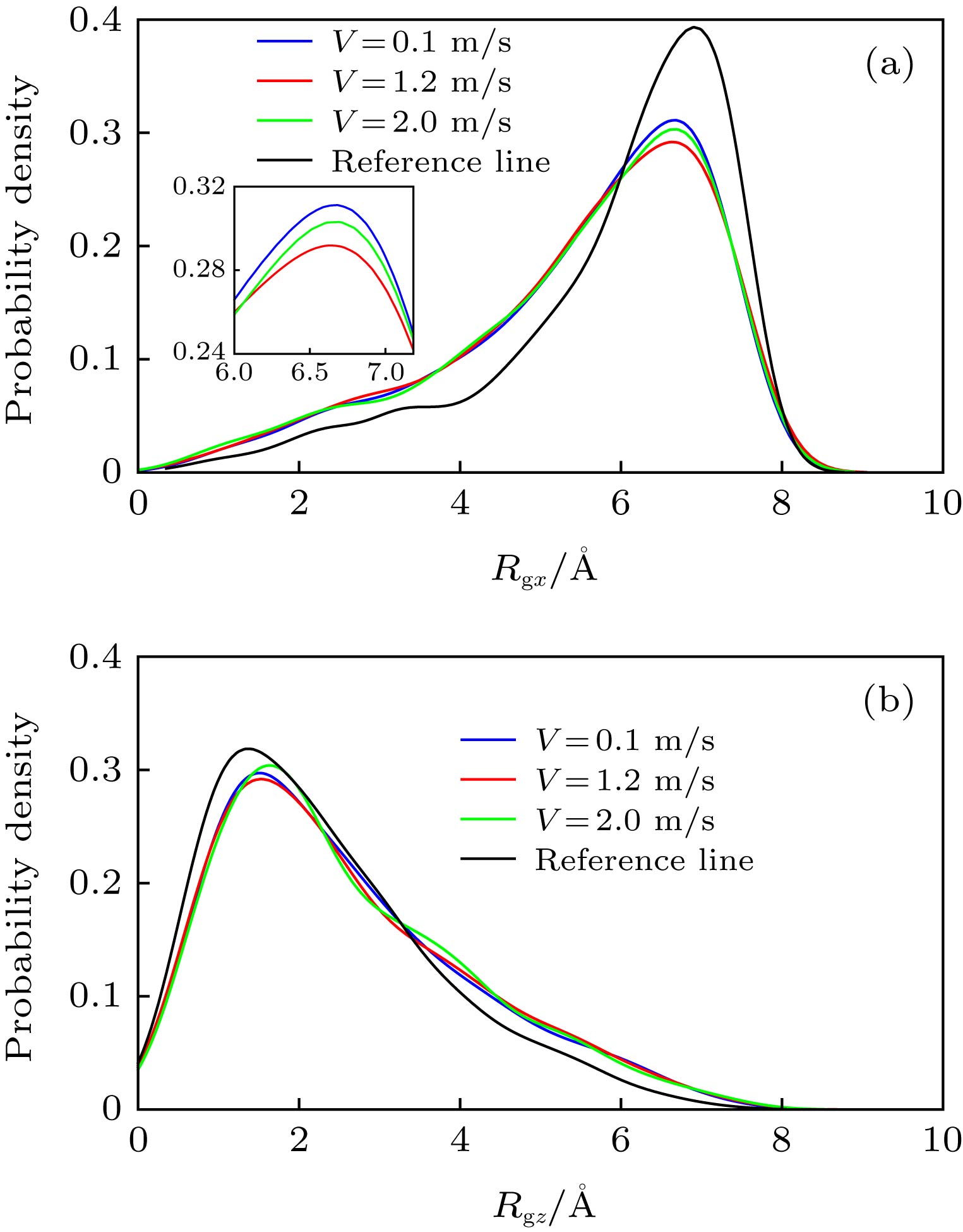

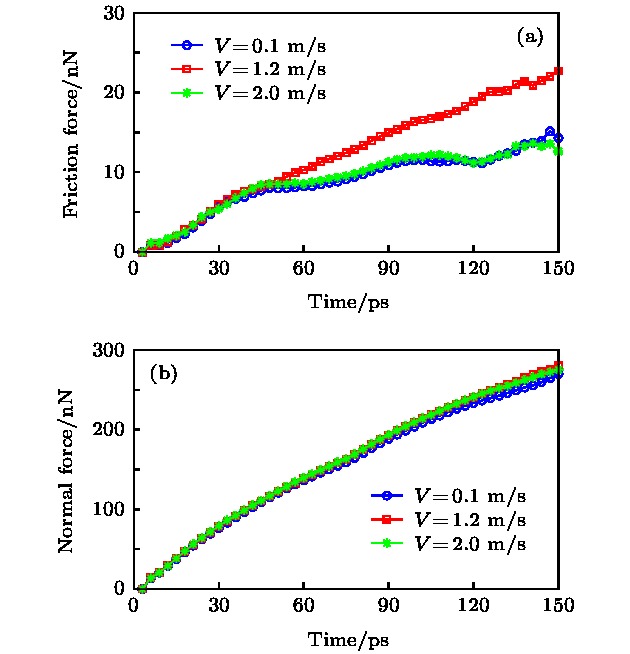

基于分子动力学方法建立了双层聚四氟乙烯(polytetrafluoroethylene, PTFE)摩擦模型, 研究了不同速度下PTFE的摩擦过程. 通过分析不同速度下接触区内下层PTFE分子键长、键角、分子形状的变化及接触过程中摩擦力和正压力的变化, 从微观角度研究了速度对PTFE摩擦系数的影响. 研究结果表明: 随着速度的增加, 接触区内PTFE粒子间的键长变短, 键角变小, 分子链沿x方向的变形量增加. 变形后的PTFE分子产生的回弹力导致上、下层PTFE分子间相互作用力增加, 从而增加了摩擦力. 当速度进一步增大时, 接触区内下层PTFE粒子间的键长和键角多处于平衡位置, 分子链沿x方向的变形量减小. 这很可能是由于接触区内下层PTFE分子沿速度方向倾斜, 使上、下层PTFE分子趋于平行滑动, 从而降低了摩擦力. 不同速度下正压力几乎保持不变. 因此, 当上层PTFE所受外载荷固定时, 摩擦系数随着速度的增加先增大后减小, 临界速度为1.2 m/s, 这与实验研究结果一致.

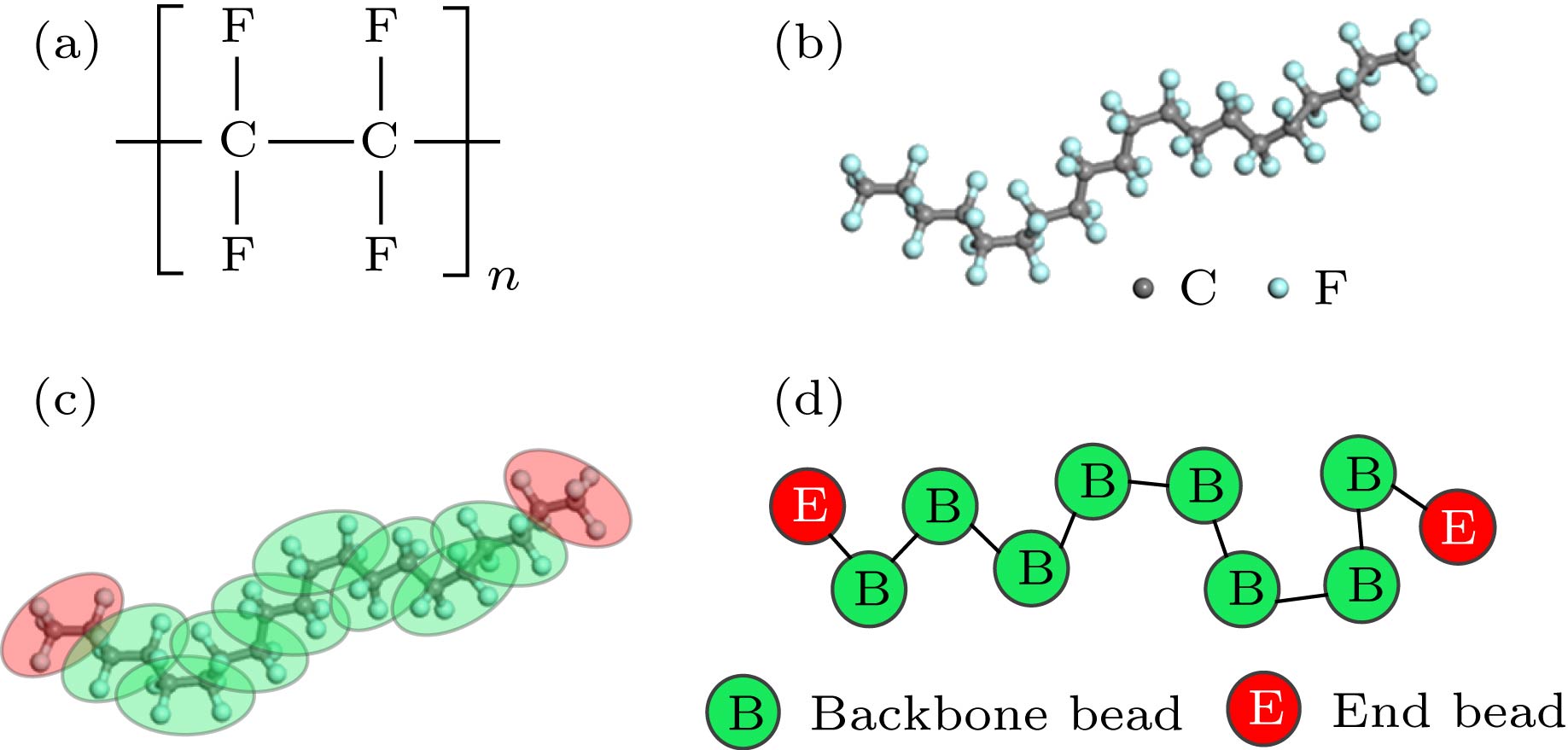

Velocity is an important factor affecting the friction coefficient of polymers. Polytetrafluoroethylene (PTFE), as a typical self-lubricating polymer, has attracted extensive attention because of its low friction coefficient. Currently, the friction coefficient of PTFE is investigated usually by using experimental method. The experimental study which is limited by the functionality and precision of the apparatus is inaccessible to the exploration of the microscopic tribological mechanism of PTFE. Therefore, the coarse-grained molecular dynamics simulation method is adopted in this study. In the coarse-grained model, one PTFE molecule is simplified into ten beads, including two end beads and eight backbone beads. The non-bonding and bonding interactions between beads are described by using Lennard-Jones (L-J) and multi-centered Gaussian-based potential. In order to investigate the effect of velocity on the friction coefficient of PTFE at an atomic level, we build a two-layer PTFE friction model by using the coarse-grained molecular dynamics simulation method. To directly compare the experimental results with the simulation results, we set the value of the externally applied load and the range of the velocities that match each other as closely as possible. The mechanism of how the velocity affects PTFE friction coefficient is obtained at an atomic level through analyzing the bond length distribution, bond angle distribution, the deformation of the bottom PTFE molecules within the contact area, and the friction force and normal force as a function of simulation time. The simulation results show that the bond length and bond angle decrease, the deformation of the bottom PTFE molecules along the x-direction and the friction force increase with velocity increasing. This is because the bounce back caused by the deformed PTFE molecules enhances the friction force. The severer the deformation, the larger the friction force will be. However, when the velocity exceeds a critical velocity, the bond length and bond angle increase, the deformation of the bottom PTFE molecule and the friction force decrease with velocity increasing. This is most likely due to the fact that the bottom PTFE molecules within the contact area tend to tilt along the moving direction of the upper PTFE layer, thereby reducing the angle between the upper and the bottom PTFE molecules to an angle close to the angle of parallel sliding, finally resulting in the decrease of the friction force. The deformations of PTFE molecules along the z-direction are nearly invariable under different velocities. This corresponds to the variation of the normal force. Therefore, for a constant externally applied load, the friction coefficient first increases then decreases with velocity increasing. In addition, the critical velocity is 1.2 m/s, which is in line with the published experimental result. -

Keywords:

- polytetrafluoroethylene /

- friction /

- velocity /

- molecular dynamics simulation

[1] Tian K, Goldsby D L, Carpick R W 2018 Phys. Rev. Lett. 120 186101

Google Scholar

Google Scholar

[2] Dong Y, Duan Z, Tao Y, Wei Z, Gueye B, Zhang Y, Chen Y 2019 Tribol. Int. 136 259

Google Scholar

Google Scholar

[3] 董赟, 段早琦, 陶毅, Gueye Birahima, 张艳, 陈云飞 2019 68 016801

Google Scholar

Google Scholar

Dong Y, Duan Z Q, Tao Y, Gueye B, Zhang Y, Chen Y F 2019 Acta Phys. Sin. 68 016801

Google Scholar

Google Scholar

[4] Li Q, Dong Y, Perez D, Martini A, Carpick R W 2011 Phys. Rev. Lett. 106 126101

Google Scholar

Google Scholar

[5] Sharma N, Kumar N, Dash S, Tyagi A K 2012 AIP Conf. Proc. 1447 651

[6] Sun F, Hou Y, Wang L, Huang L, Qian Z 2017 Int. J. Pave. Res. Tech. 10 343

Google Scholar

Google Scholar

[7] Lin L, Pei X Q, Bennewitz R, Schlarb A K 2018 Tribol. Int. 122 108

Google Scholar

Google Scholar

[8] Xiong X 2018 Ind. Lubr. Tribol. 70 273

Google Scholar

Google Scholar

[9] Barry P R, Jang I, Perry S S, Sawyer W G, Sinnott S B, Phillpot S R 2007 J. Computer-Aided Mater. Des. 14 239

Google Scholar

Google Scholar

[10] Yuan X D, Yang X J 2010 Wear 269 291

Google Scholar

Google Scholar

[11] Harris K L, Pitenis A A, Sawyer W G, Krick B A, Blackman G S, Kasprzak D J, Junk C P 2015 Macromolecules 48 3739

Google Scholar

Google Scholar

[12] 杨学宾, 晋欣桥, 杜志敏, 崔天生, 杨绍侃 2010 内燃机工程 31 105

Google Scholar

Google Scholar

Yang X B, Jin X Q, Du Z M, Cui T S, Yang S K 2010 Chin. Int. Combu. Engine. Eng. 31 105

Google Scholar

Google Scholar

[13] 郭丰镐 1981 机械工程材料 4 5

Guo F G 1981 Mater. Mech. Eng. 4 5

[14] 黄传辉 2008 徐州工程学院学报(自然科学版) 23 7

Google Scholar

Google Scholar

Huang C H 2008 Xuzhou Inst. Technol. (Natural Sciences Edition)

23 7  Google Scholar

Google Scholar

[15] 马姗, 马军, 杨光参 2016 65 148701

Google Scholar

Google Scholar

Ma S, Ma J, Yang G C 2016 Acta Phys. Sin. 65 148701

Google Scholar

Google Scholar

[16] Ewen J P, Heyes D M, Dini D 2018 Friction 6 349

Google Scholar

Google Scholar

[17] Dong Y, Li Q, Martini A 2013 J. Vac. Sci. Technol. A 31 030801

[18] Dong Y, Wang F, Zhu Z, He T 2019 AIP Adv. 9 045213

Google Scholar

Google Scholar

[19] Barry P R, Chiu P Y, Perry S S, Sawyer W G, Sinnott S B, Phillpot S R 2015 Tribol. Lett. 58 50

Google Scholar

Google Scholar

[20] Barry P R, Chiu P Y, Perry S S, Sawyer W G, Phillpot S R, Sinnott S B 2009 J. Phys.: Condens. Matter 21 144201

Google Scholar

Google Scholar

[21] Chiu P Y, Barry P R, Perry S S, Sawyer W G, Phillpot S R, Sinnott S B 2011 Tribol. Lett. 42 193

Google Scholar

Google Scholar

[22] 王曦, 黎明, 叶方富, 周昕 2017 66 150201

Google Scholar

Google Scholar

Wang X, Li M, Ye F F, Zhou X 2017 Acta Phys. Sin. 66 150201

Google Scholar

Google Scholar

[23] Hagita K, Morita H, Doi M, Takano H 2016 Macromolecules 49 1972

Google Scholar

Google Scholar

[24] Thota N, Luo Z, Hu Z, Jiang J 2013 J. Phys. Chem. B 117 9690

Google Scholar

Google Scholar

[25] Zuo Z, Yang Y, Qi X, Su W, Yang X 2014 Wear 320 87

Google Scholar

Google Scholar

[26] Milano G, Mü1ller P F 2005 J. Phys. Chem. B 109 18609

Google Scholar

Google Scholar

[27] Milano G, Goudeau S, Mü1ller P F 2005 J. Polym. Sci. Pol. Phys. 43 871

Google Scholar

Google Scholar

[28] Pan D, Liu C, Qi X, Yang Y, Hao X 2019 Tribol. Int. 133 32

Google Scholar

Google Scholar

[29] Onodera T, Nunoshige J, Kawasaki K, Adachi K, Kurihara K, Kubo M 2017 J. Phys. Chem. C 121 14589

Google Scholar

Google Scholar

[30] Plimpton S 1995 J. Comp. Physiol. 117 1

Google Scholar

Google Scholar

[31] Jang I, Burris D L, Dickrell P L, Barry P R, Santos C, Perry S S, Phillpot S R, Sinnott S B, Sawyer W G 2007 J. Appl. Phys. 102 123509

Google Scholar

Google Scholar

-

Bond type nb i Abi wbi/Å lbci/Å B-B/B-E 2 1 0.3 0.15 2.7 2 0.03 0.2 2.5 Angle type na i Aai wai/(°) θaci/(°) B-B-B/B-B-E 3 1 1.44 30 180 2 1.66 12 180 3 0.12 29 145 -

[1] Tian K, Goldsby D L, Carpick R W 2018 Phys. Rev. Lett. 120 186101

Google Scholar

Google Scholar

[2] Dong Y, Duan Z, Tao Y, Wei Z, Gueye B, Zhang Y, Chen Y 2019 Tribol. Int. 136 259

Google Scholar

Google Scholar

[3] 董赟, 段早琦, 陶毅, Gueye Birahima, 张艳, 陈云飞 2019 68 016801

Google Scholar

Google Scholar

Dong Y, Duan Z Q, Tao Y, Gueye B, Zhang Y, Chen Y F 2019 Acta Phys. Sin. 68 016801

Google Scholar

Google Scholar

[4] Li Q, Dong Y, Perez D, Martini A, Carpick R W 2011 Phys. Rev. Lett. 106 126101

Google Scholar

Google Scholar

[5] Sharma N, Kumar N, Dash S, Tyagi A K 2012 AIP Conf. Proc. 1447 651

[6] Sun F, Hou Y, Wang L, Huang L, Qian Z 2017 Int. J. Pave. Res. Tech. 10 343

Google Scholar

Google Scholar

[7] Lin L, Pei X Q, Bennewitz R, Schlarb A K 2018 Tribol. Int. 122 108

Google Scholar

Google Scholar

[8] Xiong X 2018 Ind. Lubr. Tribol. 70 273

Google Scholar

Google Scholar

[9] Barry P R, Jang I, Perry S S, Sawyer W G, Sinnott S B, Phillpot S R 2007 J. Computer-Aided Mater. Des. 14 239

Google Scholar

Google Scholar

[10] Yuan X D, Yang X J 2010 Wear 269 291

Google Scholar

Google Scholar

[11] Harris K L, Pitenis A A, Sawyer W G, Krick B A, Blackman G S, Kasprzak D J, Junk C P 2015 Macromolecules 48 3739

Google Scholar

Google Scholar

[12] 杨学宾, 晋欣桥, 杜志敏, 崔天生, 杨绍侃 2010 内燃机工程 31 105

Google Scholar

Google Scholar

Yang X B, Jin X Q, Du Z M, Cui T S, Yang S K 2010 Chin. Int. Combu. Engine. Eng. 31 105

Google Scholar

Google Scholar

[13] 郭丰镐 1981 机械工程材料 4 5

Guo F G 1981 Mater. Mech. Eng. 4 5

[14] 黄传辉 2008 徐州工程学院学报(自然科学版) 23 7

Google Scholar

Google Scholar

Huang C H 2008 Xuzhou Inst. Technol. (Natural Sciences Edition)

23 7  Google Scholar

Google Scholar

[15] 马姗, 马军, 杨光参 2016 65 148701

Google Scholar

Google Scholar

Ma S, Ma J, Yang G C 2016 Acta Phys. Sin. 65 148701

Google Scholar

Google Scholar

[16] Ewen J P, Heyes D M, Dini D 2018 Friction 6 349

Google Scholar

Google Scholar

[17] Dong Y, Li Q, Martini A 2013 J. Vac. Sci. Technol. A 31 030801

[18] Dong Y, Wang F, Zhu Z, He T 2019 AIP Adv. 9 045213

Google Scholar

Google Scholar

[19] Barry P R, Chiu P Y, Perry S S, Sawyer W G, Sinnott S B, Phillpot S R 2015 Tribol. Lett. 58 50

Google Scholar

Google Scholar

[20] Barry P R, Chiu P Y, Perry S S, Sawyer W G, Phillpot S R, Sinnott S B 2009 J. Phys.: Condens. Matter 21 144201

Google Scholar

Google Scholar

[21] Chiu P Y, Barry P R, Perry S S, Sawyer W G, Phillpot S R, Sinnott S B 2011 Tribol. Lett. 42 193

Google Scholar

Google Scholar

[22] 王曦, 黎明, 叶方富, 周昕 2017 66 150201

Google Scholar

Google Scholar

Wang X, Li M, Ye F F, Zhou X 2017 Acta Phys. Sin. 66 150201

Google Scholar

Google Scholar

[23] Hagita K, Morita H, Doi M, Takano H 2016 Macromolecules 49 1972

Google Scholar

Google Scholar

[24] Thota N, Luo Z, Hu Z, Jiang J 2013 J. Phys. Chem. B 117 9690

Google Scholar

Google Scholar

[25] Zuo Z, Yang Y, Qi X, Su W, Yang X 2014 Wear 320 87

Google Scholar

Google Scholar

[26] Milano G, Mü1ller P F 2005 J. Phys. Chem. B 109 18609

Google Scholar

Google Scholar

[27] Milano G, Goudeau S, Mü1ller P F 2005 J. Polym. Sci. Pol. Phys. 43 871

Google Scholar

Google Scholar

[28] Pan D, Liu C, Qi X, Yang Y, Hao X 2019 Tribol. Int. 133 32

Google Scholar

Google Scholar

[29] Onodera T, Nunoshige J, Kawasaki K, Adachi K, Kurihara K, Kubo M 2017 J. Phys. Chem. C 121 14589

Google Scholar

Google Scholar

[30] Plimpton S 1995 J. Comp. Physiol. 117 1

Google Scholar

Google Scholar

[31] Jang I, Burris D L, Dickrell P L, Barry P R, Santos C, Perry S S, Phillpot S R, Sinnott S B, Sawyer W G 2007 J. Appl. Phys. 102 123509

Google Scholar

Google Scholar

计量

- 文章访问数: 24367

- PDF下载量: 228

- 被引次数: 0

下载:

下载: