-

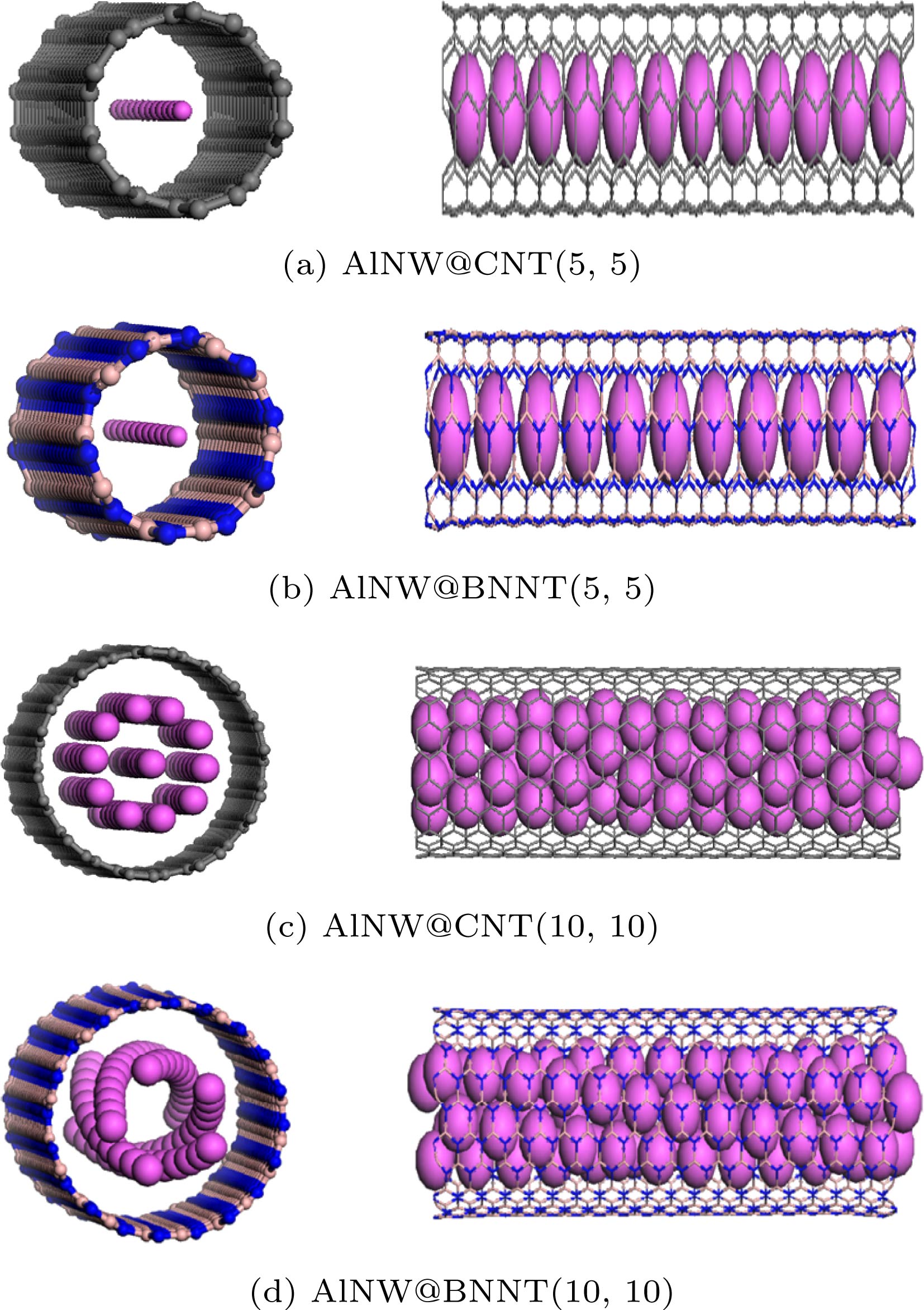

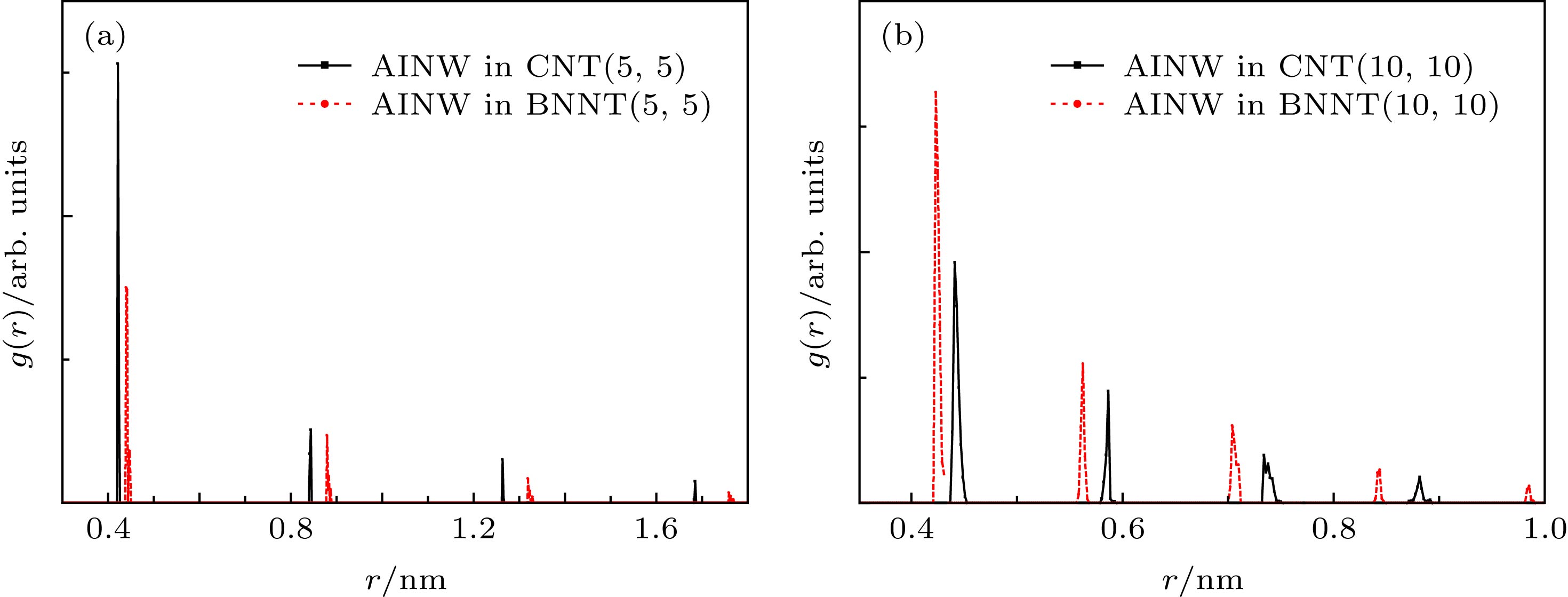

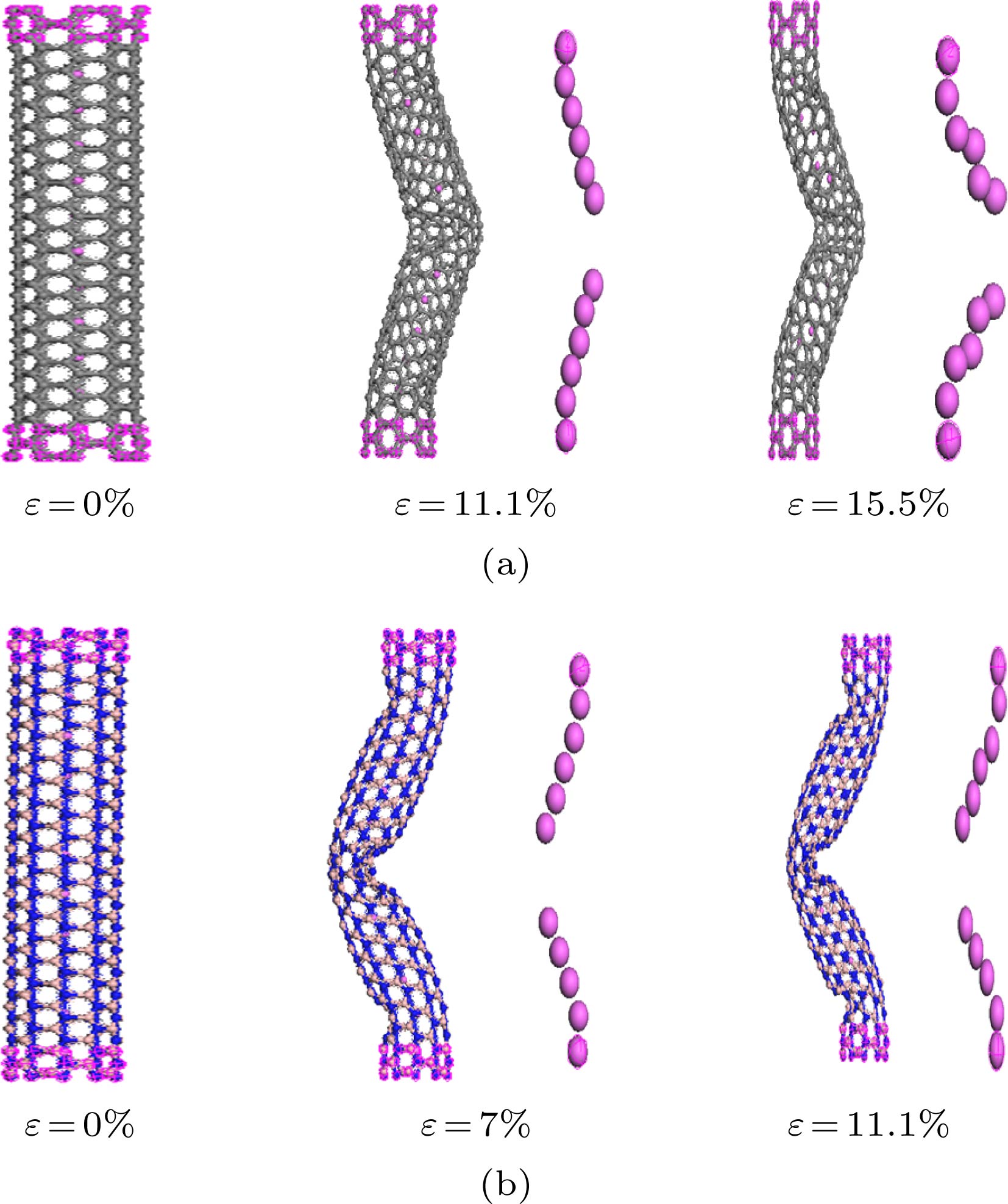

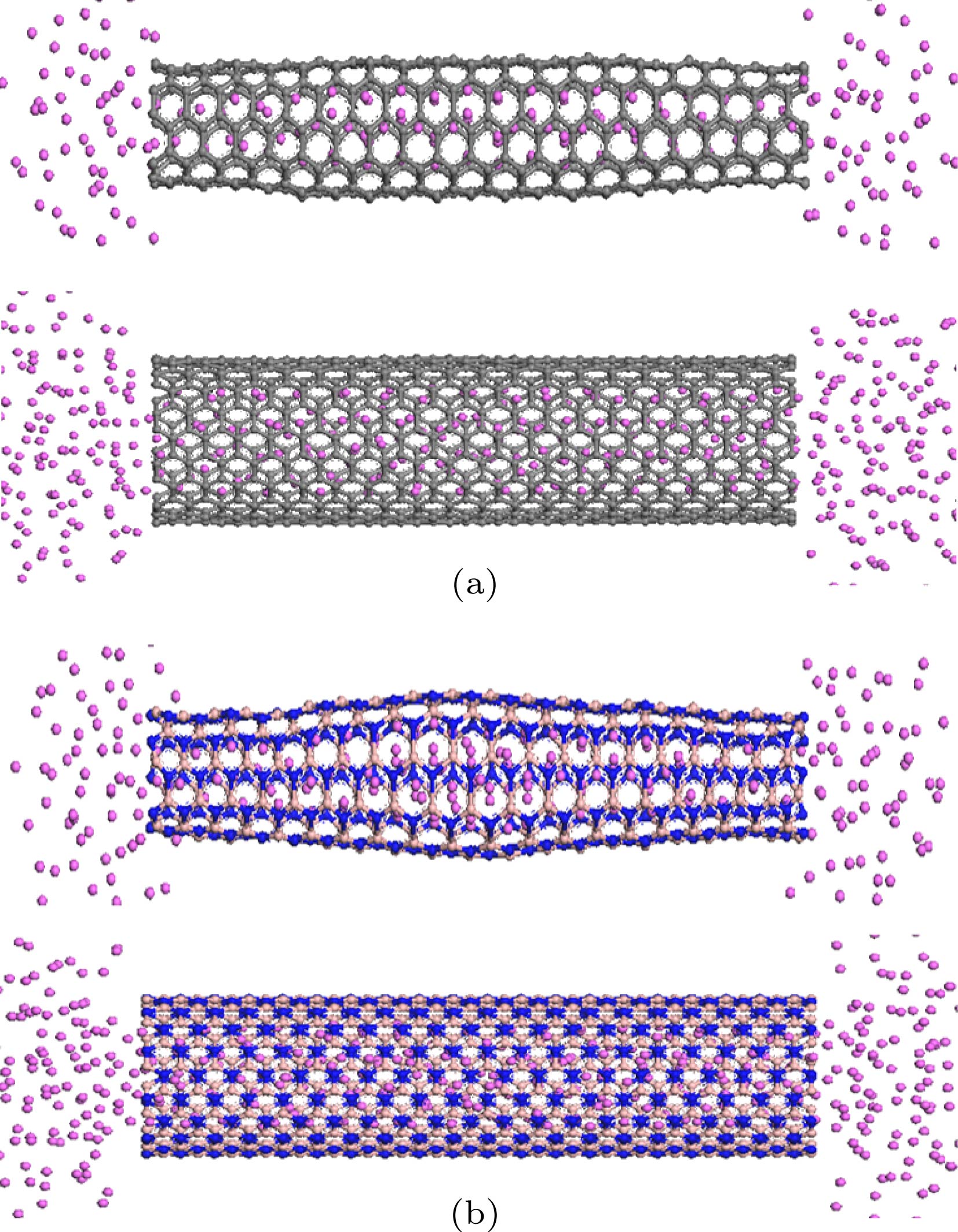

采用分子动力学方法分别对管内充以铝原子碳纳米管(CNT)与氮化硼纳米管(BNNT)进行了结构性能研究. 优化结果显示: (5, 5) CNT和BNNT内均能形成一束一维铝纳米线(AlNW); (10, 10)管内形成的是多束AlNW, 其中(10, 10) CNT内形成的是11束高度轴对称一维AlNW, 而(10, 10) BNNT内形成的是5束螺旋结构形状的AlNW. 进一步分析表明: CNT内的AlNW具有比BNNT内的AlNW较大的原子分布线密度, 但大管径(10, 10)型BNNT内的螺旋状AlNW可以具有比相同管径CNT内纳米线更高的结晶性. 通过对其轴向压缩模拟及其能量分析, 可以发现AlNW@CNT复合结构的屈曲应变明显大于AlNW@BNNT, 且同类型复合结构, 屈曲应变随管径增大而减小, 故较小管径的AlNW@CNT具有更强轴向抗压能力. 能量分析结果表明van der Waals能是维系复合纳米管结构稳定, 增大抗压能力的主要原因.

-

关键词:

- 铝纳米线 /

- 碳纳米管与氮化硼纳米管 /

- 分子动力学 /

- 抗压特性

To know the basic configuration and application characteristics of aluminum (Al) nanostructure, the structure performances of carbon nanotube (CNT) and boron-nitride NT (BNNT) filled with Al atoms are studied through molecular dynamics. Optimization results show that the Al atoms in the tube are arranged neatly into various shapes of nanowires. A bunch of one-dimensional (1D) Al nanowires (AlNWs) is formed in (5, 5) CNT and BNNT, and large beams of AlNWs are formed in (10, 10) NT, including 11 beams of 1D AlNWs with highly axial symmetry in (10, 10) CNT and 5 beams of spiral AlNWs in BNNT (10, 10). Further data analysis for radical distribution function (RDF) shows that AlNWs inside CNT have larger atomic distribution density, but those inside BNNT with larger diameter have better crystallinity than those with similar size inside the CNT. These results can provide a method of designing the nanowires with different structures and shapes in different micro-nano devices (such as nanospring, nanosolenoid, and others). Comparison of the axial compression behaviors of the composite NTs and their energy analysis reveal that the critical buckling strain of AlNW@CNT is significantly larger than that of AlNW@BNNT. For the same type of compound structure, the buckling strain decreases with NT diameter increasing. Therefore, smaller AlNW@CNT has stronger axial compressive resistance. The main reasons are as follows: 1) The AlNW in carbon NTs has a relatively large Al atomic distribution in the axial direction, which is conducive to the formation of σ bond to increase structural stability and mechanical performance. It also plays a decisive role in enhancing compressive performance. 2) The AlNW in the large-diameter boron nitride NTs is helical in shape, and more Al atoms are distributed in the direction of the cross section, thereby relatively reducing the number of axial pressure-bearing atoms. In addition, for the same type of nanotube, a tube with a small diameter results in closer hexagons to the tube wall and larger interaction. These conditions are more conducive to resisting the transverse subsidence under axial pressure. The energy analysis results indicate that the van der Waals force is one of the main causes for NT composite stability and increasing compressive strength. These results can provide a reference for selecting different Al nanowire-reinforced composite structures under different application conditions, such as high temperature, high pressure, oxidation resistance, and others.-

Keywords:

- aluminum nanowires /

- carbon nanotube and boron-nitride nanotube /

- molecular dynamics /

- compressing property

[1] Zhang J M, Wang S F, Xu K W, Ji V 2010 J. Nanosci. Nanotechnol. 10 840

Google Scholar

Google Scholar

[2] Arcidiacono S, Walther J H, Poulikakos D, Passerone D, Koumoutsakos P 2005 Phys. Rev. Lett. 94 105502

Google Scholar

Google Scholar

[3] Hudziak S, Darfeuille A, Zhang R, Peijs T, Mountjoy G, Bertoni G, Baxendale M 2010 Nanotechnology 21 125505

Google Scholar

Google Scholar

[4] Zhao D L, Zhang J M, Li X, Shen Z M 2010 J. Alloys Compd. 505 712

Google Scholar

Google Scholar

[5] Xiao J, Ryu S Y, Huang Y, Hwang K C, Paik U, Rogers J A 2010 Nanotechnology 21 085708

Google Scholar

Google Scholar

[6] Wang L, Zhang H W, Zhang Z Q, Zheng Y G, Wang J B 2007 Appl. Phys. Lett. 91 051122

Google Scholar

Google Scholar

[7] Soldano G, Mariscal M M 2009 Nanotechnology 20 165705

Google Scholar

Google Scholar

[8] Guo S H, Zhu B E, Ou X D, Pan Z Y, Wang Y X 2010 Carbon 48 4129

Google Scholar

Google Scholar

[9] Zhang X Q, Li H, Liew K M 2007 J. Appl. Phys. 102 073709

Google Scholar

Google Scholar

[10] Nishio K, Ozaki T, Morishita T, Mikami M 2008 Phys. Rev. B 77 201401

Google Scholar

Google Scholar

[11] Lü Z Y, Hu Q K, Xu Z X, Wang J J, Chen Z H, Wang Y, Chen M, Zhou K, Zhou Y, Han S T 2019 Adv. Electron. Mater. 5 1800793

Google Scholar

Google Scholar

[12] Cui Z, Han Y W, Huang Q J, Dong J Y, Zhu Y 2018 Nanoscale 10 6806

Google Scholar

Google Scholar

[13] 王文慧, 张孬 2018 67 247302

Google Scholar

Google Scholar

Wang W H, Zhang N 2018 Acta Phys. Sin. 67 247302

Google Scholar

Google Scholar

[14] Chen R, Hochbaum A I, Murphy P, Moore J, Yang P D, Majumdar A 2008 Phys. Rev. Lett. 101 105501

Google Scholar

Google Scholar

[15] Wu Z G, Neaton J B, Grossman J C 2008 Phys. Rev. Lett. 100 246804

Google Scholar

Google Scholar

[16] Blasé X, Fernandez-Serra M V 2008 Phys. Rev. Lett. 100 046802

Google Scholar

Google Scholar

[17] Durgun E, Cakir D, Akman N, Ciraci S 2007 Phys. Rev. Lett. 99 256806

Google Scholar

Google Scholar

[18] Leu P W, Svizhenko A, Cho K 2008 Phys. Rev. B 77 235305

Google Scholar

Google Scholar

[19] Sorokin P B, Avramov P V, Kvashnin A G, Kvashnin D G, Ovchinnikov S G, Fedorov A S 2008 Phys. Rev. B 77 235417

Google Scholar

Google Scholar

[20] 鹿业波, 顾金梅, 刘楚辉, 彭文利 2016 半导体光电 37 370

Lu Y B, Gu J M, Liu C H, Peng W L 2016 Semicond. Optoelectron. 37 370

[21] Hu L, Wu H, Cui Y 2011 MRS Bull. 36 760

Google Scholar

Google Scholar

[22] Cho Y J, Park I J, Lee H J, Kim J G 2015 J. Power Sources 277 370

Google Scholar

Google Scholar

[23] Lin M C, Gong M, Lu B, Wu Y, Wang D Y, Guan M, Angell M, Chen C, Yang J, Hwang B J, Dai H 2015 Nature 520 324

Google Scholar

Google Scholar

[24] Li S, Niu J, Zhao Y C, So K P, Wang C, Wang C A, Li J 2015 Nat. Commun. 6 7872

Google Scholar

Google Scholar

[25] Ju S, Li J, Liu J, Chen P C, Ha Y G, Ishikawa F, Chang H, Zhou C, Facchetti A, Janes D B, Marks T J 2008 Nano Lett. 8 997

Google Scholar

Google Scholar

[26] Fu K K, Wang Z, Dai J, Carter M, Hu L 2016 Chem. Mater. 28 3527

Google Scholar

Google Scholar

[27] Shaijumon M M, Perre E, Daffos B, Taberna P L, Tarascon J M, Simon P 2010 Adv. Mater. 22 4978

Google Scholar

Google Scholar

[28] Das A, Ronen Y, Most Y, Oreg Y, Heiblum M, Shtrikman H 2012 Nat. Phys. 8 887

Google Scholar

Google Scholar

[29] Li L, Xu X, Chew H, Huang X, Dou X, Pan S, Li G, Zhang L 2008 J. Phys. Chem. C 112 5328

Google Scholar

Google Scholar

[30] Lu Y, Tohmyoh H, Saka M 2012 Thin Solid Films 520 3448

Google Scholar

Google Scholar

[31] Sun Y X, Tohmoh H, Saka M 2009 J. Nanosci. Nanotechnol. 9 1972

Google Scholar

Google Scholar

[32] Wang H, Li B 2018 J. Electrochem. Soc. 165 D641

Google Scholar

Google Scholar

[33] Chen Y, Wang Y, Zhu S, Chen C, Danner V A, Li Y, Dai J, Li H, Fu K K, Li T, Liu Y, Hu L 2019 ACS Appl. Mater. Interfaces 11 6009

Google Scholar

Google Scholar

[34] Azuma K, Sakajiri K, Okabe T, Matsumoto H, Kang S, Watanabe J, Tokita M 2017 Jpn. J. Appl. Phys. 56 095002

Google Scholar

Google Scholar

[35] Chen Y, Zou J, Campbell S J, Le Caer G 2004 Appl. Phys. Lett. 84 2430

Google Scholar

Google Scholar

[36] Yuan J H, Liew K M 2009 Carbon 47 713

Google Scholar

Google Scholar

[37] Yuan J H, Liew K M 2009 Carbon 47 1526

Google Scholar

Google Scholar

[38] Jing L, Tay R Y, Li H L, Tsang S H, Huang J F, Tan D L, Zhang B W, Teo E H T, Tok A I Y 2016 Nanoscale 8 11114

Google Scholar

Google Scholar

[39] Xu F F, Bando Y, Golberg D, Hasegawa M, Mitome M 2004 Acta Mater. 52 601

Google Scholar

Google Scholar

[40] Golberg D, Bando Y, Mitome M, Fushimi K, Tang C C 2004 Acta Mater. 52 3295

Google Scholar

Google Scholar

[41] Ashrafi B, Jakubinek M B, Martinez-Rubi Y, Rahmat M, Djokic D, Laqua K, Park D, Kim K S, Simard B, Yousefpour A 2017 Acta Astronaut. 141 57

Google Scholar

Google Scholar

[42] Xu X J G, Gilburd L, Bando Y, Golberg D, Walker G C 2016 J. Phys. Chem. C 120 1945

Google Scholar

Google Scholar

[43] Tokoro H, Fujii S, Oku T 2005 Solid State Commun. 133 681

Google Scholar

Google Scholar

[44] Yuan J H, Liew K M 2010 J. Comput. Theor. Nanosci. 7 1878

Google Scholar

Google Scholar

[45] Kumar S, Srivastava V C, Mandal G K, Pattanayek S K, Sahoo K L 2017 J. Phys. Chem. C 121 20468

Google Scholar

Google Scholar

[46] 袁剑辉, 黄维辉, 史向华, 杨昌虎 2013 稀有金属材料与工程 42 297

Google Scholar

Google Scholar

Yuan J H, Huang W H, Shi X H, Yang C H 2013 Rare Metal. Mat. Eng. 42 297

Google Scholar

Google Scholar

[47] 袁剑辉, 黄维辉, 史向华, 张振华 2012 无机化学学报 28 125

Yuan J H, Huang W H, Shi X H, Zhang Z H 2012 Chin. J. Inorg. Chem. 28 125

[48] Yuan J H, Liew K M 2011 J. Phys. Chem. C 115 431

Google Scholar

Google Scholar

[49] Yuan J H, Liew K M 2011 Nanotechnology 22 085701

Google Scholar

Google Scholar

[50] Yuan J H, Liew K M 2011 Carbon 49 677

Google Scholar

Google Scholar

[51] Yuan J H, Zhang L W, Liew K M 2017 Computat. Mater. Sci. 133 130

Google Scholar

Google Scholar

[52] Yuan J H, Zhang L W, Liew K M 2016 Current Nanosci. 12 636

Google Scholar

Google Scholar

[53] Yuan J H, Zhang L W, Liew K M 2015 RSC Adv. 5 74399

Google Scholar

Google Scholar

[54] Yuan J H, Liew K M 2014 Phys. Chem. Chem. Phys. 16 88

Google Scholar

Google Scholar

[55] Rappe A K, Casewit C J, Colwell K S, Goddard W A, Skiff W M 1992 J. Am. Chem. Soc. 114 10024

Google Scholar

Google Scholar

[56] Rappe A K, Colwell K S, Casewit C 1993 J. Inorg. Chem. 32 3438

Google Scholar

Google Scholar

[57] Srivastava D, Menon M, Cho K 1999 J. Phys. Rev. Lett. 83 2973

Google Scholar

Google Scholar

[58] Casewit C, J, Colwell K S, Rappe A K 1992 J. Am. Chem. Soc. 114 10046

Google Scholar

Google Scholar

-

-

[1] Zhang J M, Wang S F, Xu K W, Ji V 2010 J. Nanosci. Nanotechnol. 10 840

Google Scholar

Google Scholar

[2] Arcidiacono S, Walther J H, Poulikakos D, Passerone D, Koumoutsakos P 2005 Phys. Rev. Lett. 94 105502

Google Scholar

Google Scholar

[3] Hudziak S, Darfeuille A, Zhang R, Peijs T, Mountjoy G, Bertoni G, Baxendale M 2010 Nanotechnology 21 125505

Google Scholar

Google Scholar

[4] Zhao D L, Zhang J M, Li X, Shen Z M 2010 J. Alloys Compd. 505 712

Google Scholar

Google Scholar

[5] Xiao J, Ryu S Y, Huang Y, Hwang K C, Paik U, Rogers J A 2010 Nanotechnology 21 085708

Google Scholar

Google Scholar

[6] Wang L, Zhang H W, Zhang Z Q, Zheng Y G, Wang J B 2007 Appl. Phys. Lett. 91 051122

Google Scholar

Google Scholar

[7] Soldano G, Mariscal M M 2009 Nanotechnology 20 165705

Google Scholar

Google Scholar

[8] Guo S H, Zhu B E, Ou X D, Pan Z Y, Wang Y X 2010 Carbon 48 4129

Google Scholar

Google Scholar

[9] Zhang X Q, Li H, Liew K M 2007 J. Appl. Phys. 102 073709

Google Scholar

Google Scholar

[10] Nishio K, Ozaki T, Morishita T, Mikami M 2008 Phys. Rev. B 77 201401

Google Scholar

Google Scholar

[11] Lü Z Y, Hu Q K, Xu Z X, Wang J J, Chen Z H, Wang Y, Chen M, Zhou K, Zhou Y, Han S T 2019 Adv. Electron. Mater. 5 1800793

Google Scholar

Google Scholar

[12] Cui Z, Han Y W, Huang Q J, Dong J Y, Zhu Y 2018 Nanoscale 10 6806

Google Scholar

Google Scholar

[13] 王文慧, 张孬 2018 67 247302

Google Scholar

Google Scholar

Wang W H, Zhang N 2018 Acta Phys. Sin. 67 247302

Google Scholar

Google Scholar

[14] Chen R, Hochbaum A I, Murphy P, Moore J, Yang P D, Majumdar A 2008 Phys. Rev. Lett. 101 105501

Google Scholar

Google Scholar

[15] Wu Z G, Neaton J B, Grossman J C 2008 Phys. Rev. Lett. 100 246804

Google Scholar

Google Scholar

[16] Blasé X, Fernandez-Serra M V 2008 Phys. Rev. Lett. 100 046802

Google Scholar

Google Scholar

[17] Durgun E, Cakir D, Akman N, Ciraci S 2007 Phys. Rev. Lett. 99 256806

Google Scholar

Google Scholar

[18] Leu P W, Svizhenko A, Cho K 2008 Phys. Rev. B 77 235305

Google Scholar

Google Scholar

[19] Sorokin P B, Avramov P V, Kvashnin A G, Kvashnin D G, Ovchinnikov S G, Fedorov A S 2008 Phys. Rev. B 77 235417

Google Scholar

Google Scholar

[20] 鹿业波, 顾金梅, 刘楚辉, 彭文利 2016 半导体光电 37 370

Lu Y B, Gu J M, Liu C H, Peng W L 2016 Semicond. Optoelectron. 37 370

[21] Hu L, Wu H, Cui Y 2011 MRS Bull. 36 760

Google Scholar

Google Scholar

[22] Cho Y J, Park I J, Lee H J, Kim J G 2015 J. Power Sources 277 370

Google Scholar

Google Scholar

[23] Lin M C, Gong M, Lu B, Wu Y, Wang D Y, Guan M, Angell M, Chen C, Yang J, Hwang B J, Dai H 2015 Nature 520 324

Google Scholar

Google Scholar

[24] Li S, Niu J, Zhao Y C, So K P, Wang C, Wang C A, Li J 2015 Nat. Commun. 6 7872

Google Scholar

Google Scholar

[25] Ju S, Li J, Liu J, Chen P C, Ha Y G, Ishikawa F, Chang H, Zhou C, Facchetti A, Janes D B, Marks T J 2008 Nano Lett. 8 997

Google Scholar

Google Scholar

[26] Fu K K, Wang Z, Dai J, Carter M, Hu L 2016 Chem. Mater. 28 3527

Google Scholar

Google Scholar

[27] Shaijumon M M, Perre E, Daffos B, Taberna P L, Tarascon J M, Simon P 2010 Adv. Mater. 22 4978

Google Scholar

Google Scholar

[28] Das A, Ronen Y, Most Y, Oreg Y, Heiblum M, Shtrikman H 2012 Nat. Phys. 8 887

Google Scholar

Google Scholar

[29] Li L, Xu X, Chew H, Huang X, Dou X, Pan S, Li G, Zhang L 2008 J. Phys. Chem. C 112 5328

Google Scholar

Google Scholar

[30] Lu Y, Tohmyoh H, Saka M 2012 Thin Solid Films 520 3448

Google Scholar

Google Scholar

[31] Sun Y X, Tohmoh H, Saka M 2009 J. Nanosci. Nanotechnol. 9 1972

Google Scholar

Google Scholar

[32] Wang H, Li B 2018 J. Electrochem. Soc. 165 D641

Google Scholar

Google Scholar

[33] Chen Y, Wang Y, Zhu S, Chen C, Danner V A, Li Y, Dai J, Li H, Fu K K, Li T, Liu Y, Hu L 2019 ACS Appl. Mater. Interfaces 11 6009

Google Scholar

Google Scholar

[34] Azuma K, Sakajiri K, Okabe T, Matsumoto H, Kang S, Watanabe J, Tokita M 2017 Jpn. J. Appl. Phys. 56 095002

Google Scholar

Google Scholar

[35] Chen Y, Zou J, Campbell S J, Le Caer G 2004 Appl. Phys. Lett. 84 2430

Google Scholar

Google Scholar

[36] Yuan J H, Liew K M 2009 Carbon 47 713

Google Scholar

Google Scholar

[37] Yuan J H, Liew K M 2009 Carbon 47 1526

Google Scholar

Google Scholar

[38] Jing L, Tay R Y, Li H L, Tsang S H, Huang J F, Tan D L, Zhang B W, Teo E H T, Tok A I Y 2016 Nanoscale 8 11114

Google Scholar

Google Scholar

[39] Xu F F, Bando Y, Golberg D, Hasegawa M, Mitome M 2004 Acta Mater. 52 601

Google Scholar

Google Scholar

[40] Golberg D, Bando Y, Mitome M, Fushimi K, Tang C C 2004 Acta Mater. 52 3295

Google Scholar

Google Scholar

[41] Ashrafi B, Jakubinek M B, Martinez-Rubi Y, Rahmat M, Djokic D, Laqua K, Park D, Kim K S, Simard B, Yousefpour A 2017 Acta Astronaut. 141 57

Google Scholar

Google Scholar

[42] Xu X J G, Gilburd L, Bando Y, Golberg D, Walker G C 2016 J. Phys. Chem. C 120 1945

Google Scholar

Google Scholar

[43] Tokoro H, Fujii S, Oku T 2005 Solid State Commun. 133 681

Google Scholar

Google Scholar

[44] Yuan J H, Liew K M 2010 J. Comput. Theor. Nanosci. 7 1878

Google Scholar

Google Scholar

[45] Kumar S, Srivastava V C, Mandal G K, Pattanayek S K, Sahoo K L 2017 J. Phys. Chem. C 121 20468

Google Scholar

Google Scholar

[46] 袁剑辉, 黄维辉, 史向华, 杨昌虎 2013 稀有金属材料与工程 42 297

Google Scholar

Google Scholar

Yuan J H, Huang W H, Shi X H, Yang C H 2013 Rare Metal. Mat. Eng. 42 297

Google Scholar

Google Scholar

[47] 袁剑辉, 黄维辉, 史向华, 张振华 2012 无机化学学报 28 125

Yuan J H, Huang W H, Shi X H, Zhang Z H 2012 Chin. J. Inorg. Chem. 28 125

[48] Yuan J H, Liew K M 2011 J. Phys. Chem. C 115 431

Google Scholar

Google Scholar

[49] Yuan J H, Liew K M 2011 Nanotechnology 22 085701

Google Scholar

Google Scholar

[50] Yuan J H, Liew K M 2011 Carbon 49 677

Google Scholar

Google Scholar

[51] Yuan J H, Zhang L W, Liew K M 2017 Computat. Mater. Sci. 133 130

Google Scholar

Google Scholar

[52] Yuan J H, Zhang L W, Liew K M 2016 Current Nanosci. 12 636

Google Scholar

Google Scholar

[53] Yuan J H, Zhang L W, Liew K M 2015 RSC Adv. 5 74399

Google Scholar

Google Scholar

[54] Yuan J H, Liew K M 2014 Phys. Chem. Chem. Phys. 16 88

Google Scholar

Google Scholar

[55] Rappe A K, Casewit C J, Colwell K S, Goddard W A, Skiff W M 1992 J. Am. Chem. Soc. 114 10024

Google Scholar

Google Scholar

[56] Rappe A K, Colwell K S, Casewit C 1993 J. Inorg. Chem. 32 3438

Google Scholar

Google Scholar

[57] Srivastava D, Menon M, Cho K 1999 J. Phys. Rev. Lett. 83 2973

Google Scholar

Google Scholar

[58] Casewit C, J, Colwell K S, Rappe A K 1992 J. Am. Chem. Soc. 114 10046

Google Scholar

Google Scholar

计量

- 文章访问数: 11197

- PDF下载量: 90

- 被引次数: 0

下载:

下载: