-

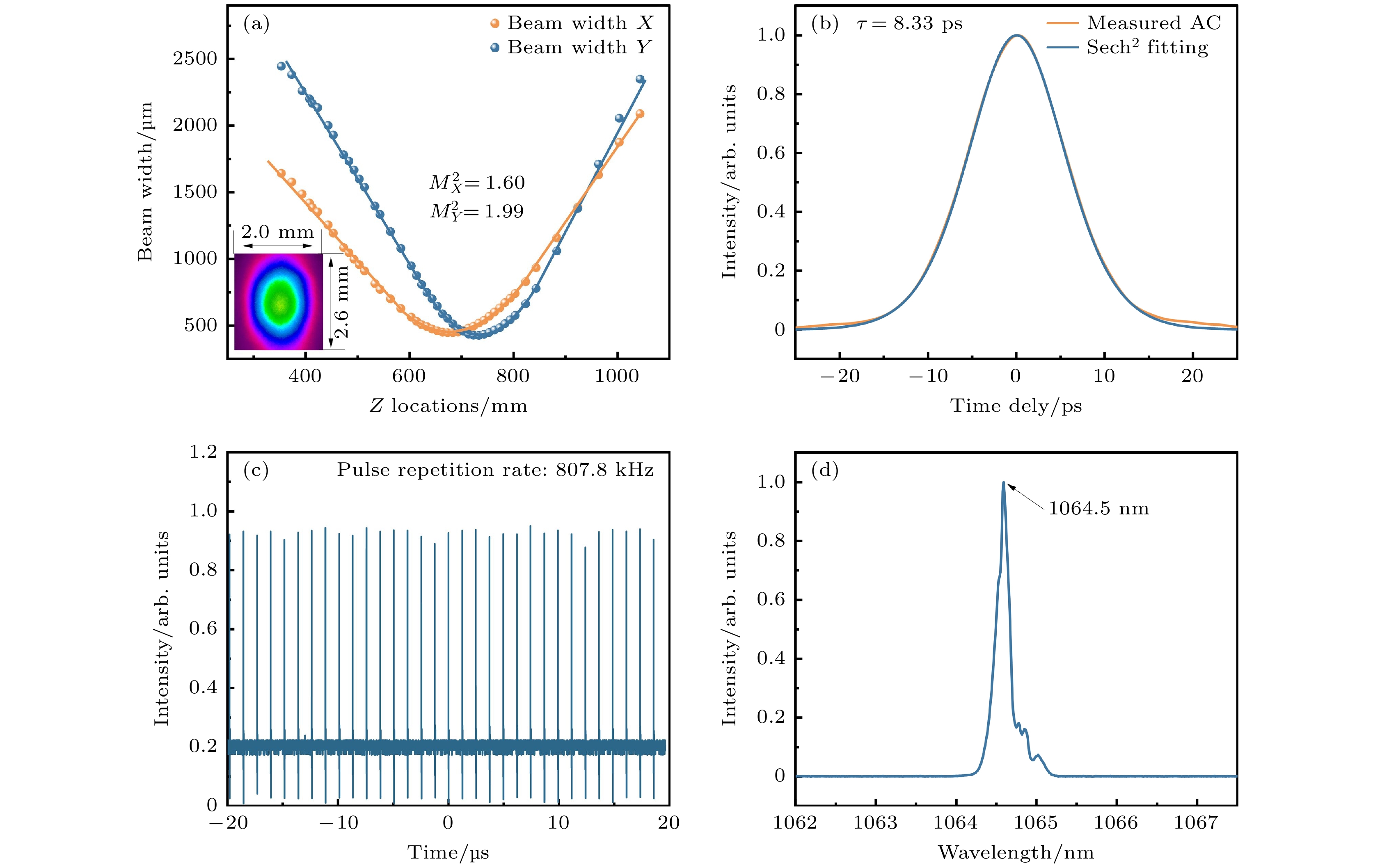

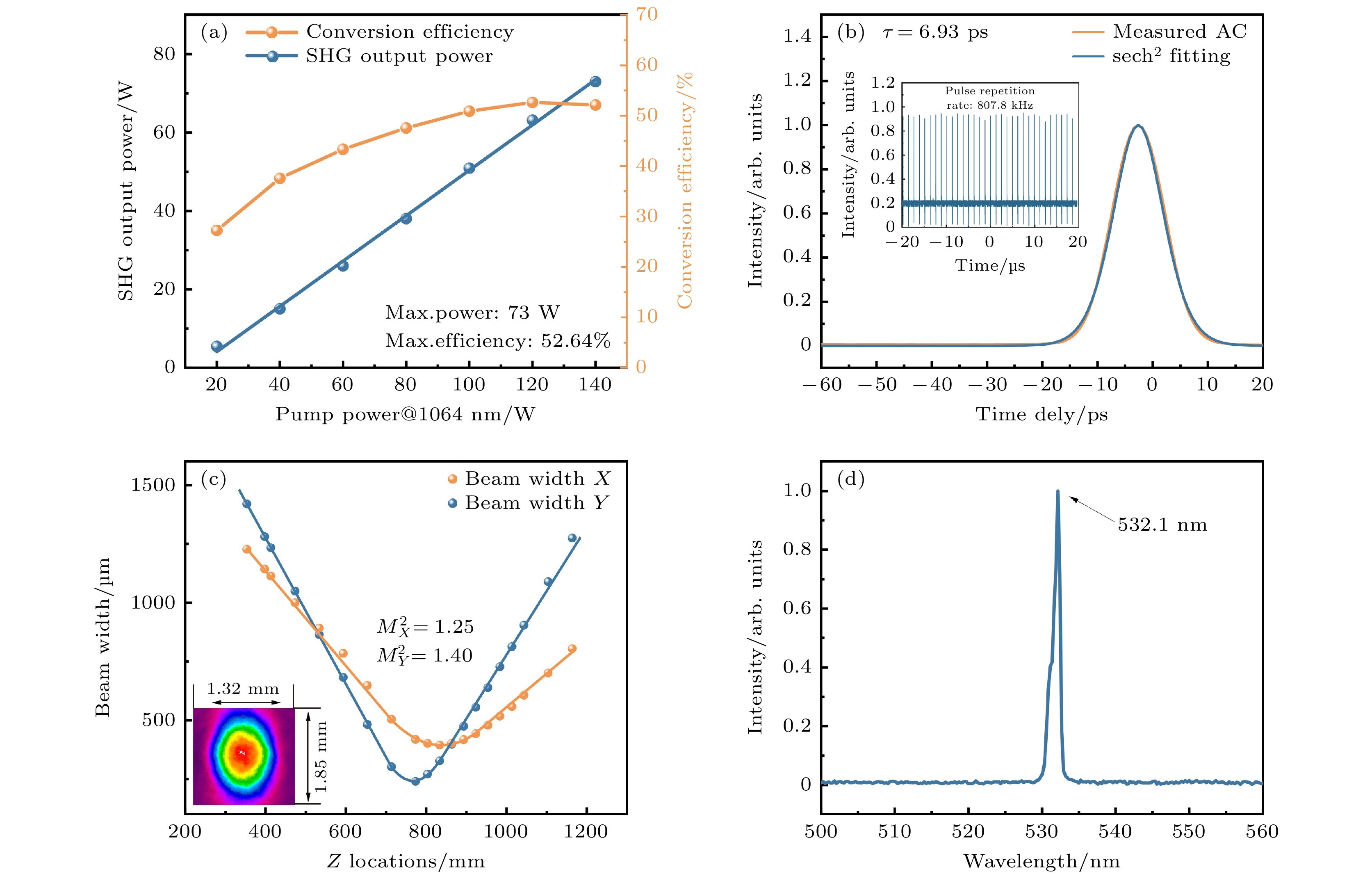

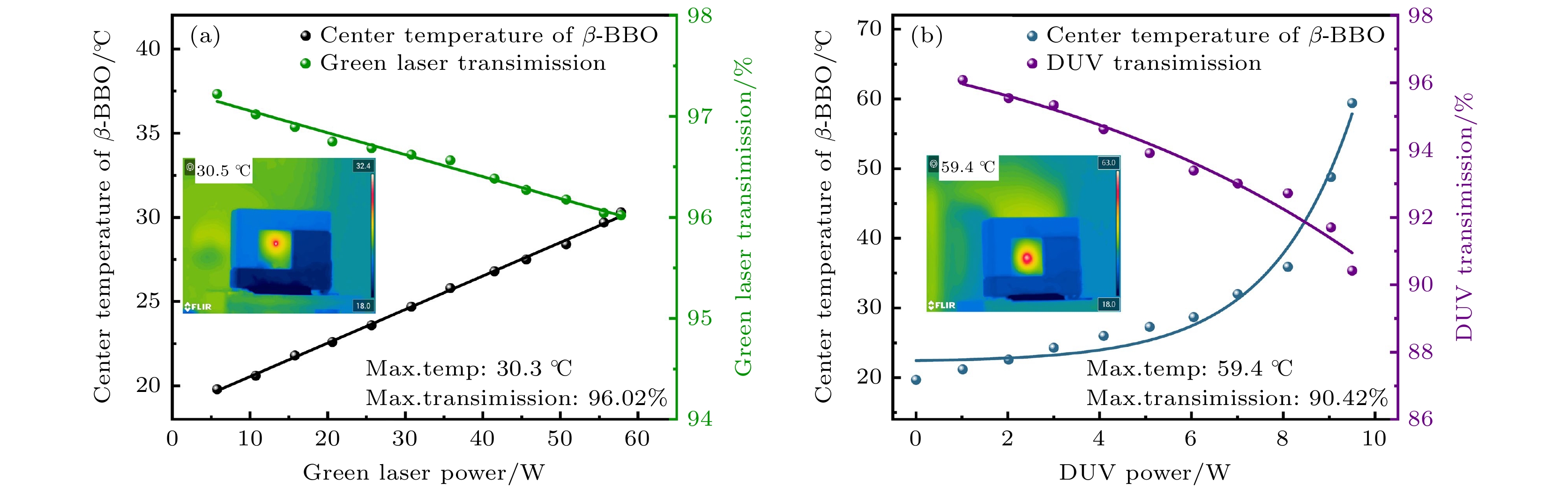

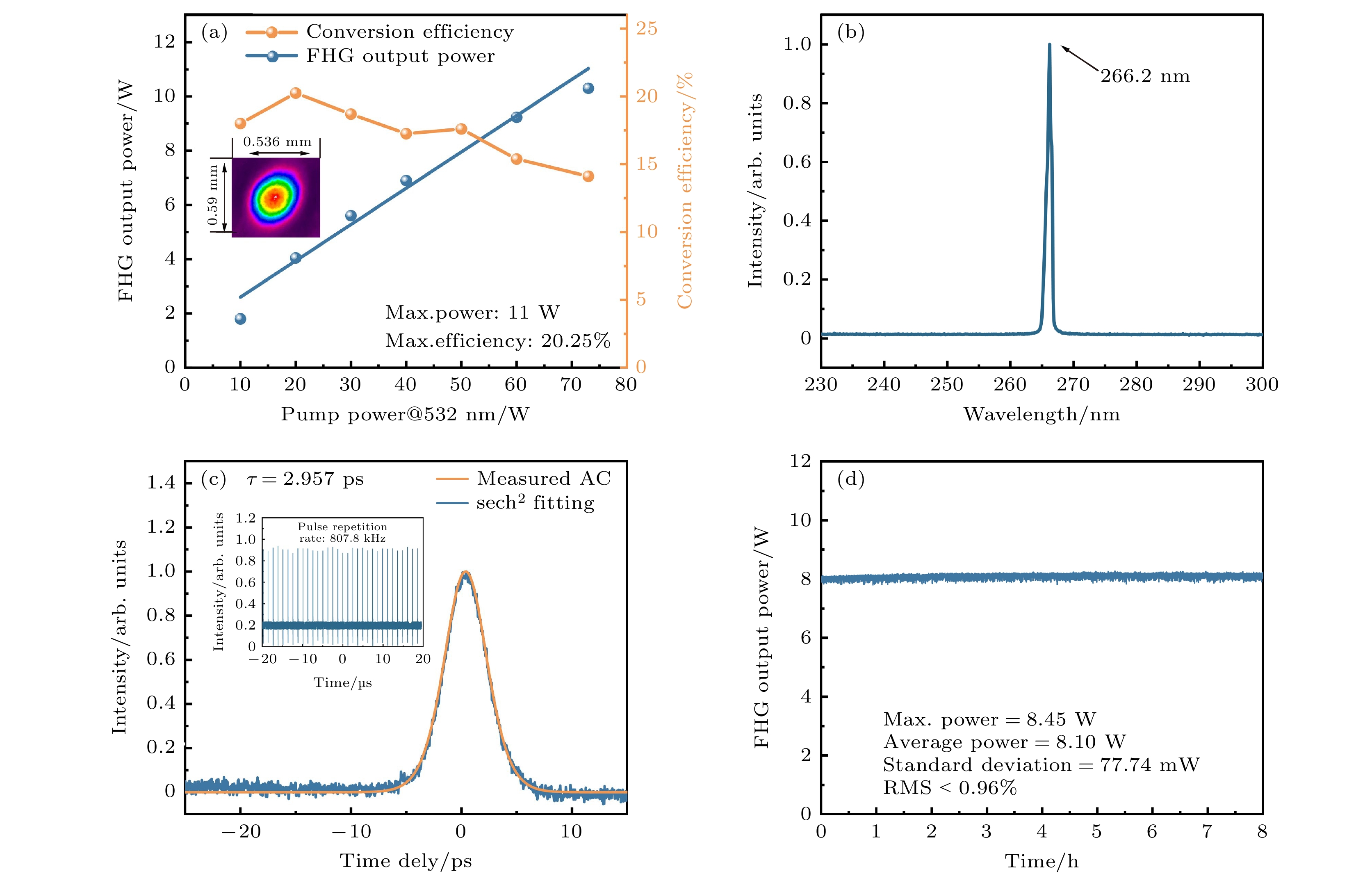

全固态高功率深紫外激光器具有光子能量高、脉冲宽度短和空间分辨率优异等优点, 在科学研究和先进制造等领域展现出重要的应用价值. 本文基于自主研发的全固态Nd:YVO4皮秒MOPA激光放大器(平均功率140 W、重复频率800 kHz、脉冲宽度8.33 ps), 开展了LBO和β-BBO晶体Ⅰ类相位匹配的腔外二倍频与四倍频研究. 双光子吸收是限制深紫外光功率进一步提升的关键因素, 通过研究高功率双波长激光在β-BBO晶体的透过率和温升, 发现高功率深紫外光在β-BBO晶体中存在较强的双光子吸收, 引发的热效应导致相位失配, 严重影响频率转换效率和输出稳定性. 为了进一步提高深紫外功率, 本文采用大尺寸光斑泵浦(光斑尺寸1.5 mm×1 mm) β-BBO晶体方案, 在泵浦峰值功率密度<1.11 GW/cm2的条件下, 有效地抑制了双光子吸收效应引起的热梯度, 实现了平均功率11 W的四倍频深紫外光输出, 单脉冲能量为13.75 μJ. 经过8 h运行, 功率抖动的均方根小于0.96%(@ 8 W). 该光源有望在超快精密加工和高次谐波产生等领域发挥重要作用.

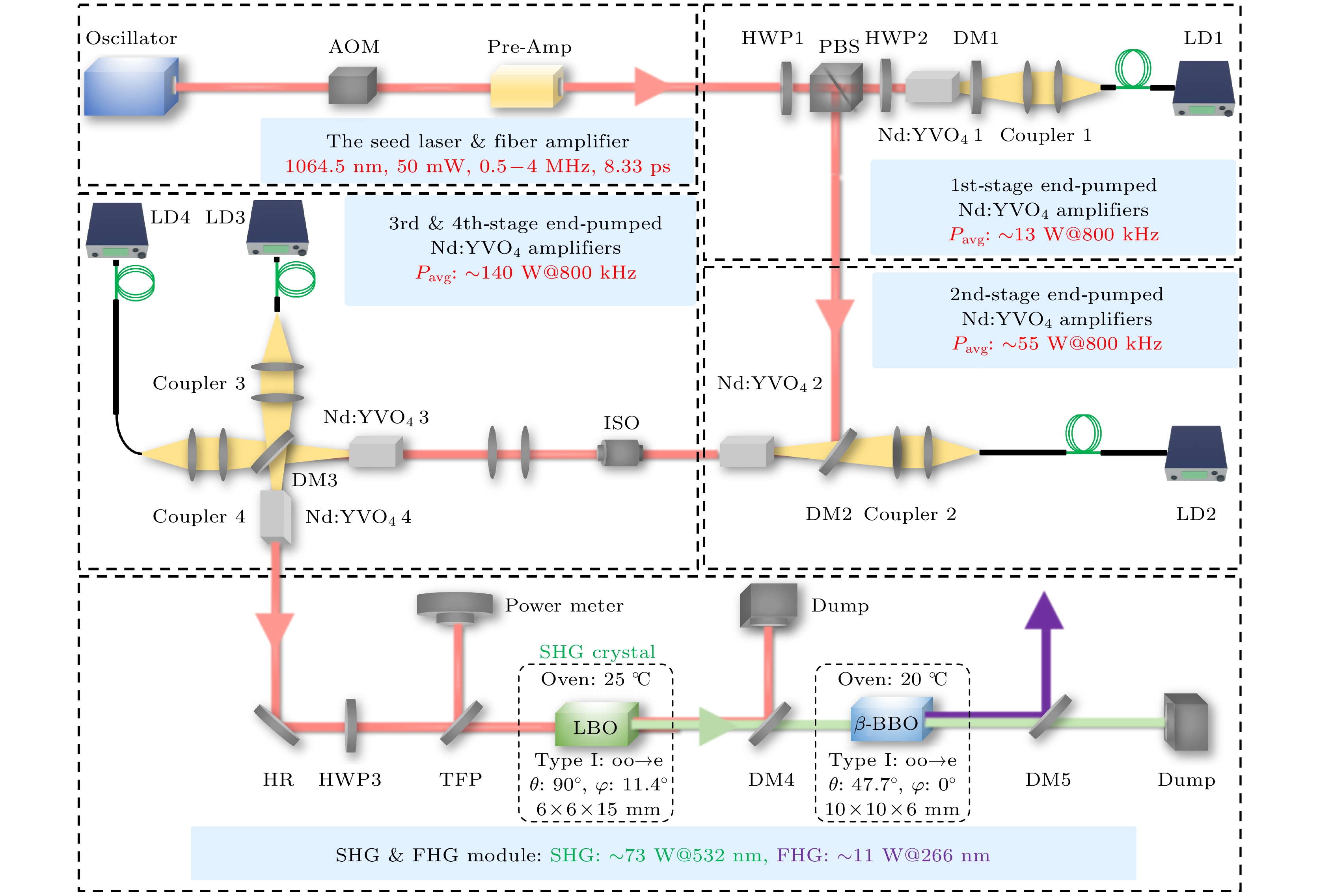

Deep ultraviolet (DUV) picosecond lasers, operating in a 200–280 nm wavelength range, possess significant advantages, such as high photon energy and high resolution. These attributes make them highly promising for applications like semiconductor detection, ensuring the production of high-quality, defect-free semiconductor devices, as well as for advanced scientific research and industrial processing. High-power DUV picosecond lasers are typically generated via nonlinear frequency conversion of infrared lasers based on master oscillator power amplifier (MOPA) configurations. Among various DUV laser technologies, systems based on β-BBO crystals are particularly valuable due to their simple design and cost-effectiveness. However, the linear two-photon absorption, as well as the formation of dynamic color centers in BBO, are significant limitations for high-power, high-repetition-rate UV radiation, leading to thermal effects. Hence, it is important to carefully study the performance characteristics of BBO for high-power, high-repetition-rate pulse generation in the UV at 266 nm. This study presents a high-power, all-solid-state DUV picosecond laser developed using a 1064 nm Nd:YVO4 MOPA amplification architecture. In this experimental setup, a 50 mW, 7.8 ps, 20 MHz all-fiber SESAM mode-locked laser is used as a seed source, achieving 140 W in amplified output power 8.33 ps in pulse duration at 1064 nm via MOPA. In the nonlinear frequency conversion process, the amplified laser pulses are initially focused onto an LBO crystal for secondary harmonic generation (SHG). Precise temperature control of the LBO crystal can generate a 532 nm output with 73 W in power and 6.93 ps in pulse duration, while achieving 52.64% in conversion efficiency. Two-photon absorption is a key factor limiting the further enhancement of deep ultraviolet (DUV) laser power. By investigating the transmittance and temperature rise of a high-power dual-wavelength laser in a β-BBO crystal, the results indicate that strong two-photon absorption occurs under high-power DUV irradiation. This absorption induces significant thermal effects, resulting in a temperature gradient within the crystal and leading to phase mismatch, which severely affects frequency conversion efficiency and output stability. To solve this problem and further increase the DUV output power, a large-spot pumping scheme (spot size: 1.5 mm × 1 mm) is adopted in this work. Under a pump peak power density of less than 1.11 GW/cm2, the thermal gradient caused by two-photon absorption is effectively suppressed, achieving maximum fourth-harmonic output power of 11 W. The corresponding single-pulse energy reaches 13.75 μJ. The root mean square (RMS) jitter, measured in an 8-hour period, is less than 0.96%. This all-solid-state DUV laser demonstrates excellent performance characteristics, including high average power, stability, resolution, and peak power, making it a strong candidate for applications requiring efficient and high-precision processing or detection. By further increasing the pump power and optimizing the temperature control system, the output power of the laser can be significantly enhanced, thereby broadening its applicability and competitiveness in high-end fields such as semiconductor manufacturing, advanced research, and industrial processing. -

Keywords:

- deep ultraviolet /

- picosecond laser /

- β-BBO /

- fourth-harmonic generation

[1] Liu K, Li H, Qu S Z, Liang H K, Wang Q J, Zhang Y 2020 Opt. Express 28 18360

Google Scholar

Google Scholar

[2] Wen N, Zhang S J, Zong N, Gao H W, Bo Y, Peng Q J, Cui D F, Xu Zu Y 2022 Optica Advanced Photonics Congress 2022, Maastricht, Limburg Netherlands, July 24–28, 2022 NpTu1G6

[3] Mutailipu M, Pan S 2020 Angew. Chem. Int. Ed. 59 20302

Google Scholar

Google Scholar

[4] Zhu J L, Liu J M, Xu T L, Yuan S, Zhang Z X, Jiang H, Gu H G, Zhou R J, Liu S Y 2022 Int. J. Extreme Manuf. 4 032001

Google Scholar

Google Scholar

[5] Meshulach D, Dolev I, Yamazaki Y, Tsuchiya K, Kaneko M, Yoshino K, Fujii T 2010 Metrology, Inspection, and Process Control for Microlithography XXIV. SPIE San Jose, California, United States, February 21–25 7638 76380K

[6] Allaria E, Castronovo D, Cinquegrana P, et al. 2013 Nat. Photonics 7 913

Google Scholar

Google Scholar

[7] Cinquegrana P, Demidovich A, Kurdi G, Nikolov I, Sigalotti P, Susnjar P, Danailov M B 2021 High Power Laser Sci. Eng. 9 e61

Google Scholar

Google Scholar

[8] Tanaka S, Arakawa M, Fuchimuka A, et al. 2016 Solid State Lasers XXV: Technology and Devices. SPIE San Francisco, California, United States February 13–18, 9726 424

[9] Fujimoto J, Kobayashi M, Kakizaki K, Oizumi H, Mimura T, Matsunaga T, Mizoguchi H 2017 High-Power Laser Materials Processing: Applications, Diagnostics, and Systems VI. SPIE San Francisco, California, United States January 28–February 2 10097 234

[10] Cui Z J, Sun M Y, Liu De’an, Zhu, J Q 2022 Opt. Express 30 43354

Google Scholar

Google Scholar

[11] Liu Q, Yan X P, Fu X, et al. 2008 Laser Phys. Lett. 6 203

[12] 王子文, 曹雪辰, 张艳林, 程东林, 靳丕铦, 卢华东 2024 中国激光 51 1401003

Google Scholar

Google Scholar

Wang Z W, Cao X C, Zhang Y L, Cheng D L, Jin P X, Lu H D 2024 Chin. J. Lasers 51 1401003

Google Scholar

Google Scholar

[13] 何京良, 卢兴强, 贾玉磊, 满宝元, 祝世宁, 朱永元 2000 49 2106

Google Scholar

Google Scholar

He J L, Lu X Q, Jia Y L, Man B Y, Zhu S N, Zhu Y Y 2000 Acta Phys. Sin. 49 2106

Google Scholar

Google Scholar

[14] Wang N, Zhang J Y, Yu H J, Lin X C, Yang G W 2022 Opt. Express 30 5700

Google Scholar

Google Scholar

[15] 陈国柱, 沈咏, 刘曲, 邹宏新 2014 63 054204

Google Scholar

Google Scholar

Chen G Z, Shen Y, Liu Q, Zou H X 2014 Acta Phys. Sin. 63 054204

Google Scholar

Google Scholar

[16] 郑佳琪, 丛振华, 刘兆军, 王上, 赵智刚 2021 中国激光 48 1201008

Google Scholar

Google Scholar

Zheng J Q, Cong Z H, Liu Z J, Wang S, Zhao Z G 2021 Chin. J. Lasers 48 1201008

Google Scholar

Google Scholar

[17] Orii Y, Kohno K, Tanaka H, Yoshimura M, Mori Y, Nishimae J, Shibuya K 2022 Opt. Express 30 11797

Google Scholar

Google Scholar

[18] Orii Y, Yoshii K, Kohno K, et al. 2023 Opt. Express 31 14705

Google Scholar

Google Scholar

[19] 俞航航, 张志韬, 玄洪文 2024 中国激光 51 0701020

Google Scholar

Google Scholar

Yu H H, Zhang Z T, Xuan H W 2024 Chin. J. Lasers 51 0701020

Google Scholar

Google Scholar

[20] Willenberg B, Brunner F, Phillips C R, Keller U 2020 Optica 7 485

Google Scholar

Google Scholar

[21] Kumar S C, Casals J C, Wei J X, Ebrahim-Zadeh M 2015 Opt. Express 23 28091

Google Scholar

Google Scholar

[22] Takahashi M, Osada A, Dergachev A, et al. 2011 J. Cryst. Growth 318 606

Google Scholar

Google Scholar

[23] R Bhandari, T Taira, A Miyamoto, Y Furukawa, T Tago 2012 Opt. Mater. Express 2 907

Google Scholar

Google Scholar

-

图 1 全固态深紫外皮秒激光器实验装置图. AOM, 声光调制器; Pre-Amp, 光纤预放大模块; HWP, 半波片; PBS, 偏振分光棱镜; TFP, 薄膜偏振片; DM, 双色镜

Fig. 1. All-solid-state DUV picosecond lasers experimental setup. AOM, acoustic optical modulator; Pre-Amp, fiber pre-amplification module; HWP, half-wave plate; PBS, polarizing beam splitter prisms; TFP, thin-film polarizer; DM, dichroic mirror.

-

[1] Liu K, Li H, Qu S Z, Liang H K, Wang Q J, Zhang Y 2020 Opt. Express 28 18360

Google Scholar

Google Scholar

[2] Wen N, Zhang S J, Zong N, Gao H W, Bo Y, Peng Q J, Cui D F, Xu Zu Y 2022 Optica Advanced Photonics Congress 2022, Maastricht, Limburg Netherlands, July 24–28, 2022 NpTu1G6

[3] Mutailipu M, Pan S 2020 Angew. Chem. Int. Ed. 59 20302

Google Scholar

Google Scholar

[4] Zhu J L, Liu J M, Xu T L, Yuan S, Zhang Z X, Jiang H, Gu H G, Zhou R J, Liu S Y 2022 Int. J. Extreme Manuf. 4 032001

Google Scholar

Google Scholar

[5] Meshulach D, Dolev I, Yamazaki Y, Tsuchiya K, Kaneko M, Yoshino K, Fujii T 2010 Metrology, Inspection, and Process Control for Microlithography XXIV. SPIE San Jose, California, United States, February 21–25 7638 76380K

[6] Allaria E, Castronovo D, Cinquegrana P, et al. 2013 Nat. Photonics 7 913

Google Scholar

Google Scholar

[7] Cinquegrana P, Demidovich A, Kurdi G, Nikolov I, Sigalotti P, Susnjar P, Danailov M B 2021 High Power Laser Sci. Eng. 9 e61

Google Scholar

Google Scholar

[8] Tanaka S, Arakawa M, Fuchimuka A, et al. 2016 Solid State Lasers XXV: Technology and Devices. SPIE San Francisco, California, United States February 13–18, 9726 424

[9] Fujimoto J, Kobayashi M, Kakizaki K, Oizumi H, Mimura T, Matsunaga T, Mizoguchi H 2017 High-Power Laser Materials Processing: Applications, Diagnostics, and Systems VI. SPIE San Francisco, California, United States January 28–February 2 10097 234

[10] Cui Z J, Sun M Y, Liu De’an, Zhu, J Q 2022 Opt. Express 30 43354

Google Scholar

Google Scholar

[11] Liu Q, Yan X P, Fu X, et al. 2008 Laser Phys. Lett. 6 203

[12] 王子文, 曹雪辰, 张艳林, 程东林, 靳丕铦, 卢华东 2024 中国激光 51 1401003

Google Scholar

Google Scholar

Wang Z W, Cao X C, Zhang Y L, Cheng D L, Jin P X, Lu H D 2024 Chin. J. Lasers 51 1401003

Google Scholar

Google Scholar

[13] 何京良, 卢兴强, 贾玉磊, 满宝元, 祝世宁, 朱永元 2000 49 2106

Google Scholar

Google Scholar

He J L, Lu X Q, Jia Y L, Man B Y, Zhu S N, Zhu Y Y 2000 Acta Phys. Sin. 49 2106

Google Scholar

Google Scholar

[14] Wang N, Zhang J Y, Yu H J, Lin X C, Yang G W 2022 Opt. Express 30 5700

Google Scholar

Google Scholar

[15] 陈国柱, 沈咏, 刘曲, 邹宏新 2014 63 054204

Google Scholar

Google Scholar

Chen G Z, Shen Y, Liu Q, Zou H X 2014 Acta Phys. Sin. 63 054204

Google Scholar

Google Scholar

[16] 郑佳琪, 丛振华, 刘兆军, 王上, 赵智刚 2021 中国激光 48 1201008

Google Scholar

Google Scholar

Zheng J Q, Cong Z H, Liu Z J, Wang S, Zhao Z G 2021 Chin. J. Lasers 48 1201008

Google Scholar

Google Scholar

[17] Orii Y, Kohno K, Tanaka H, Yoshimura M, Mori Y, Nishimae J, Shibuya K 2022 Opt. Express 30 11797

Google Scholar

Google Scholar

[18] Orii Y, Yoshii K, Kohno K, et al. 2023 Opt. Express 31 14705

Google Scholar

Google Scholar

[19] 俞航航, 张志韬, 玄洪文 2024 中国激光 51 0701020

Google Scholar

Google Scholar

Yu H H, Zhang Z T, Xuan H W 2024 Chin. J. Lasers 51 0701020

Google Scholar

Google Scholar

[20] Willenberg B, Brunner F, Phillips C R, Keller U 2020 Optica 7 485

Google Scholar

Google Scholar

[21] Kumar S C, Casals J C, Wei J X, Ebrahim-Zadeh M 2015 Opt. Express 23 28091

Google Scholar

Google Scholar

[22] Takahashi M, Osada A, Dergachev A, et al. 2011 J. Cryst. Growth 318 606

Google Scholar

Google Scholar

[23] R Bhandari, T Taira, A Miyamoto, Y Furukawa, T Tago 2012 Opt. Mater. Express 2 907

Google Scholar

Google Scholar

计量

- 文章访问数: 915

- PDF下载量: 50

- 被引次数: 0

下载:

下载: