-

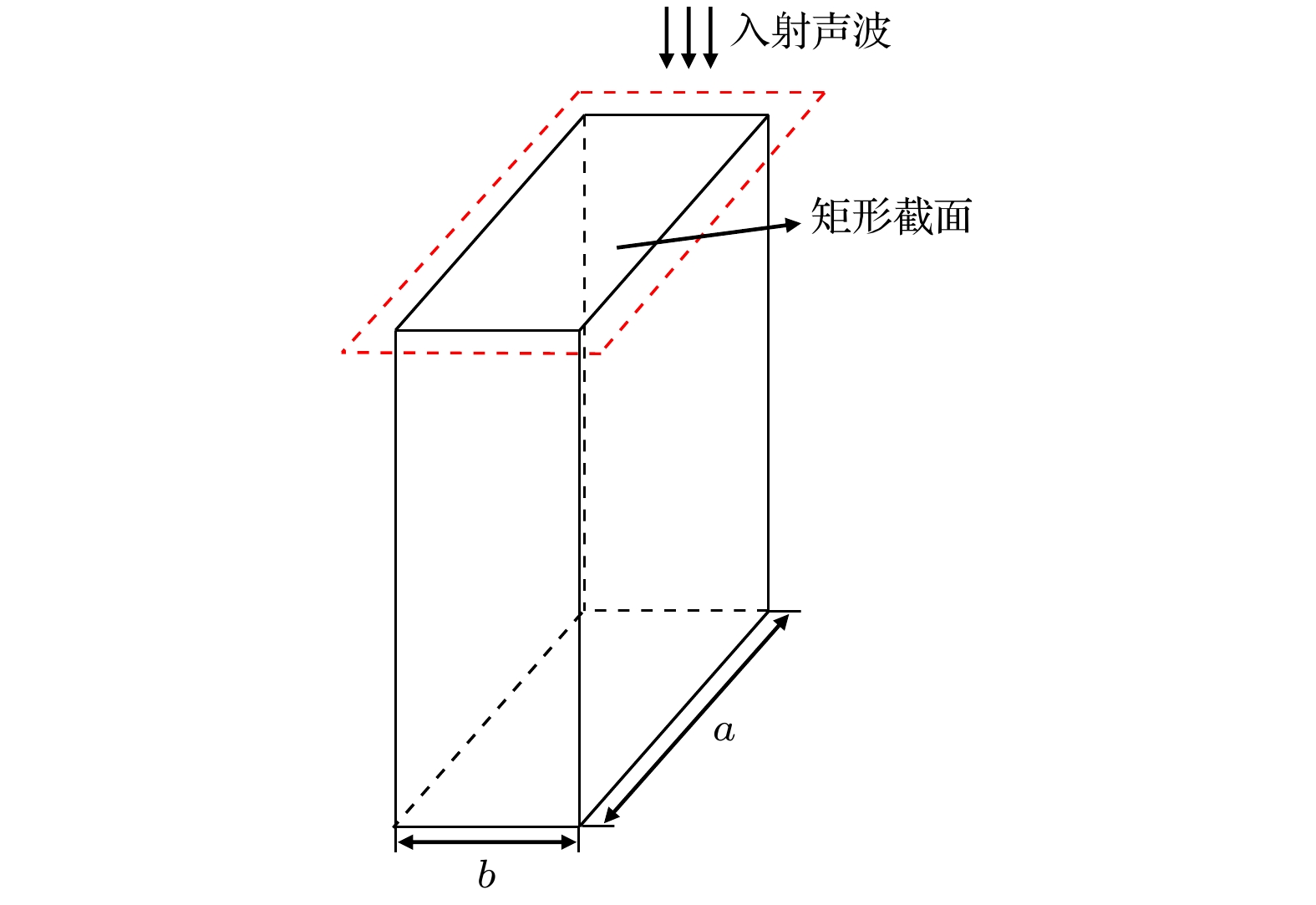

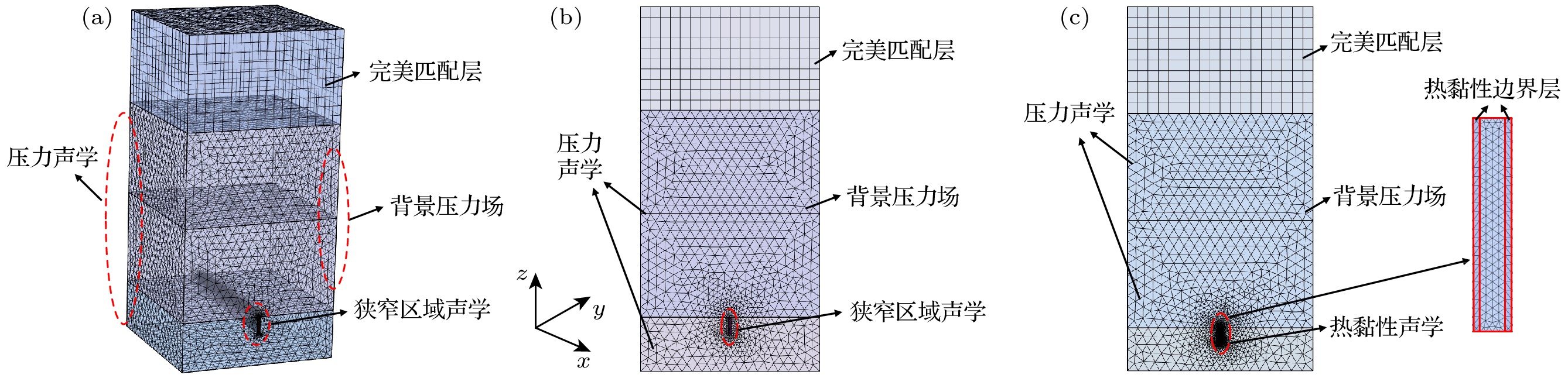

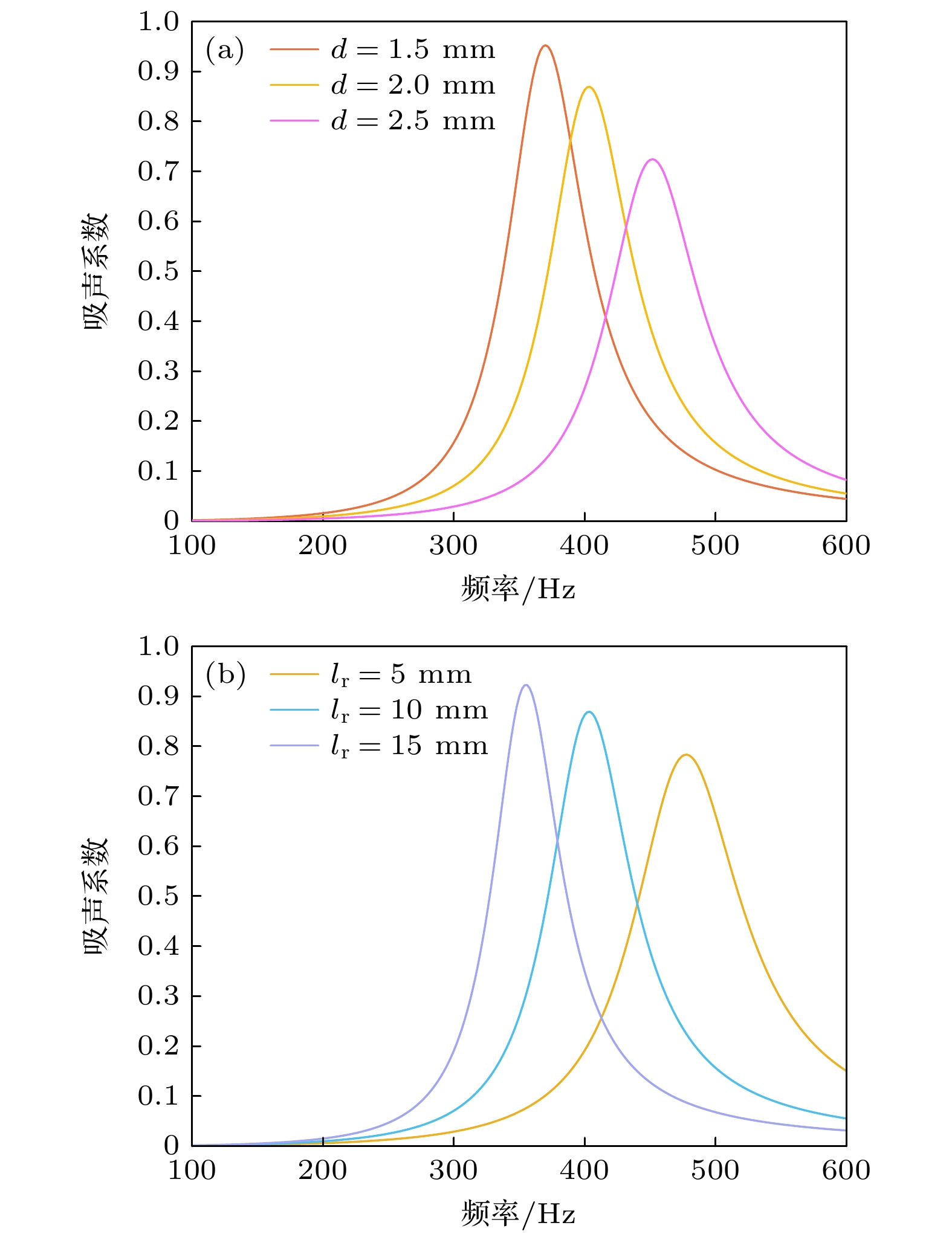

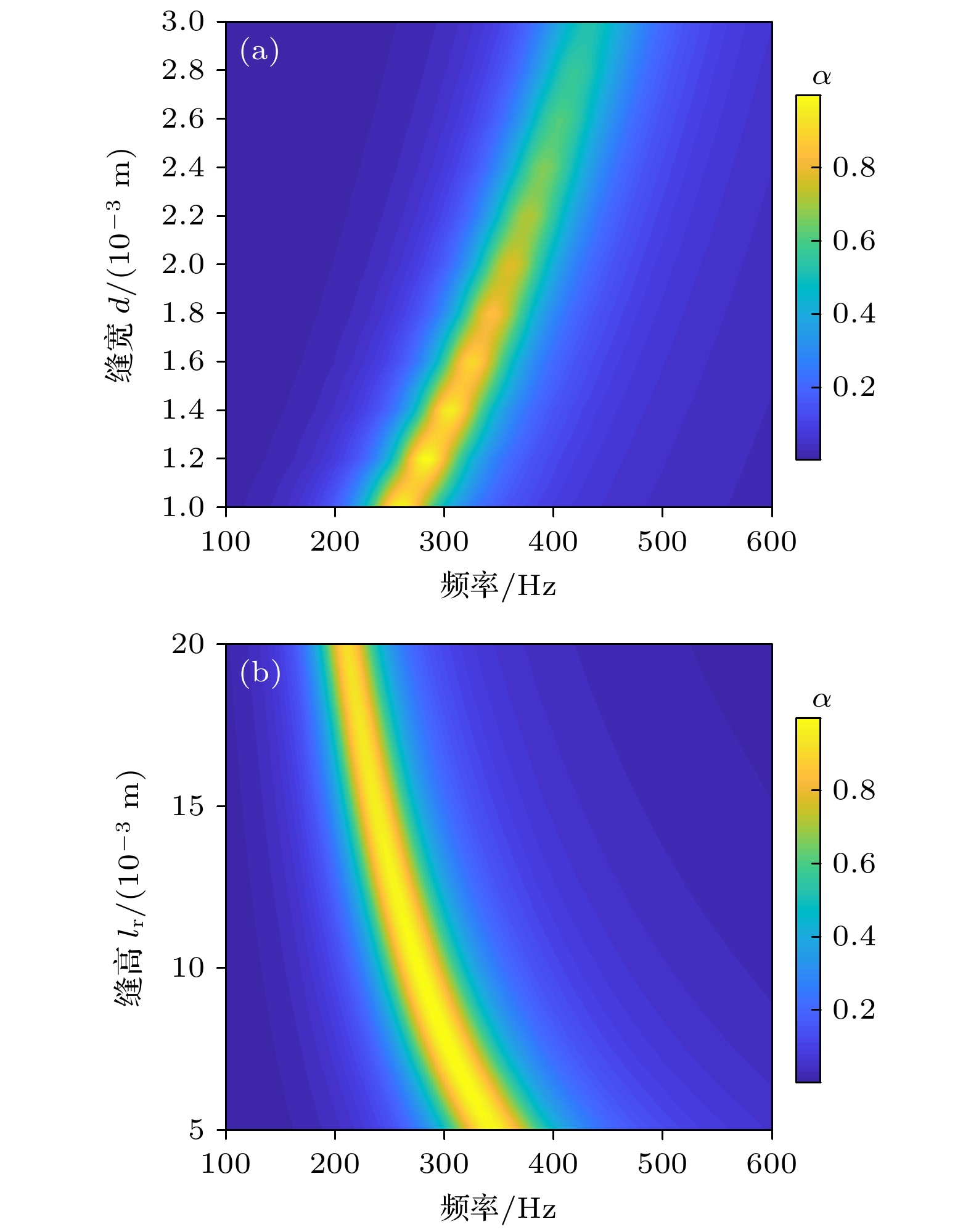

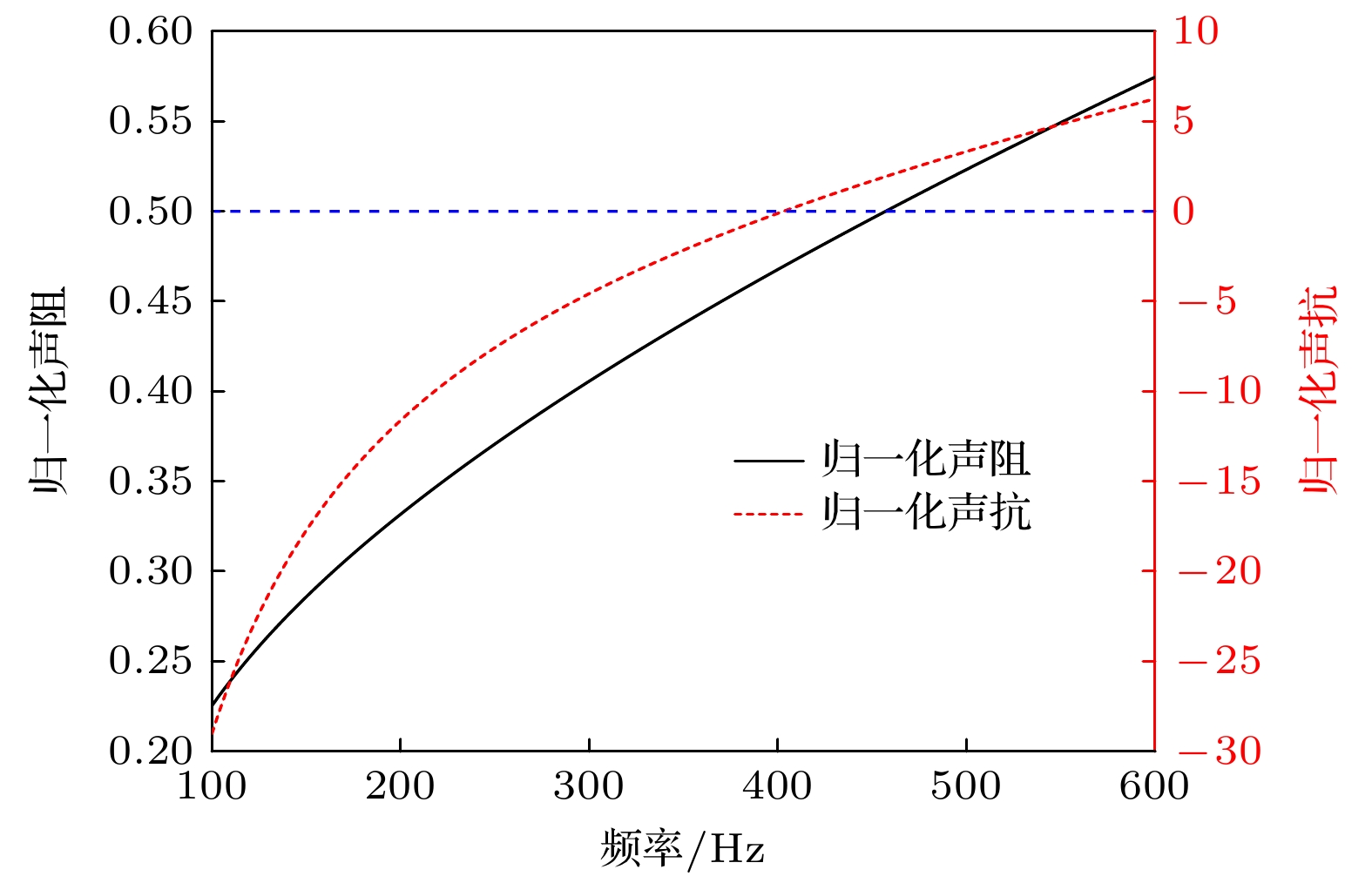

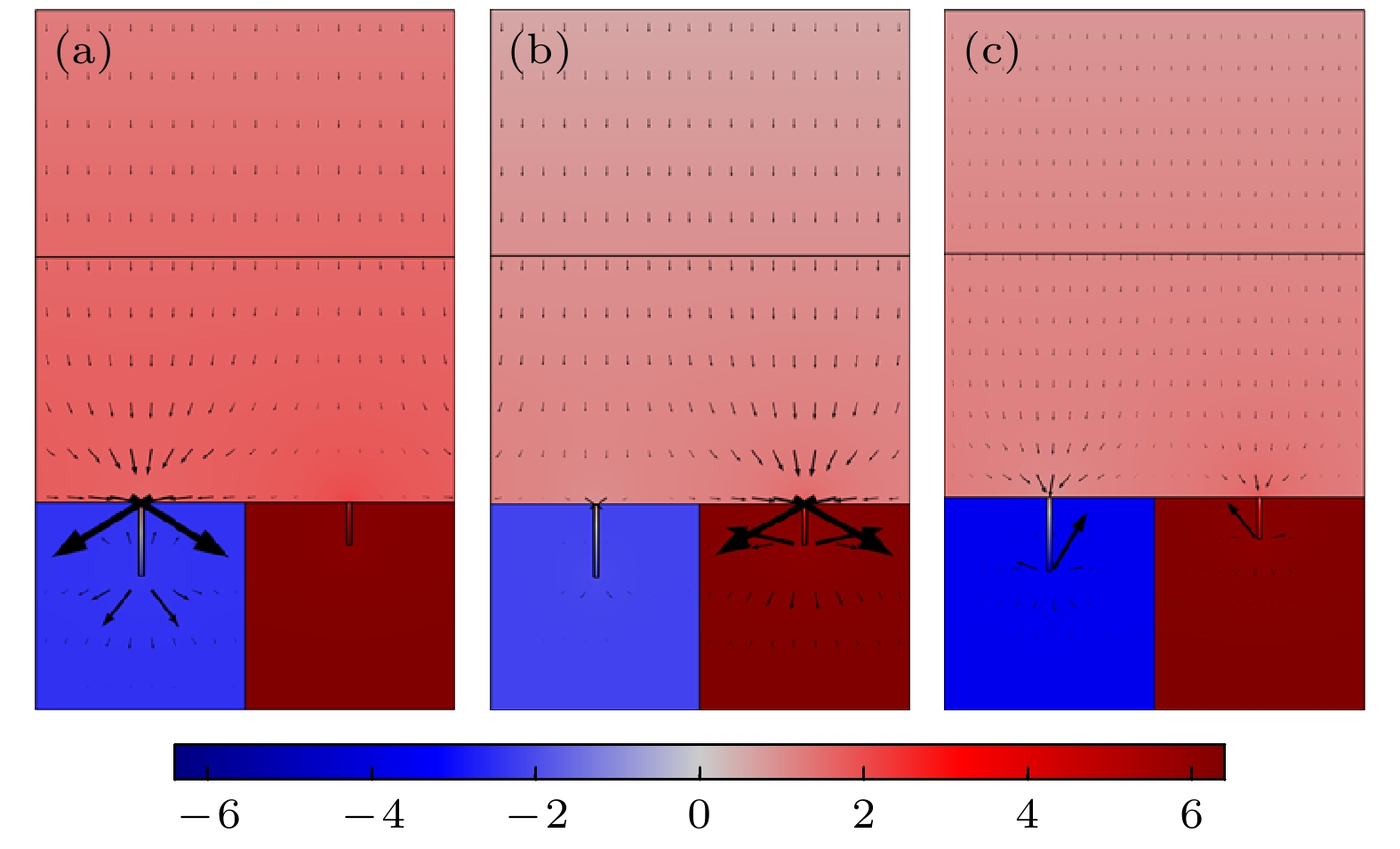

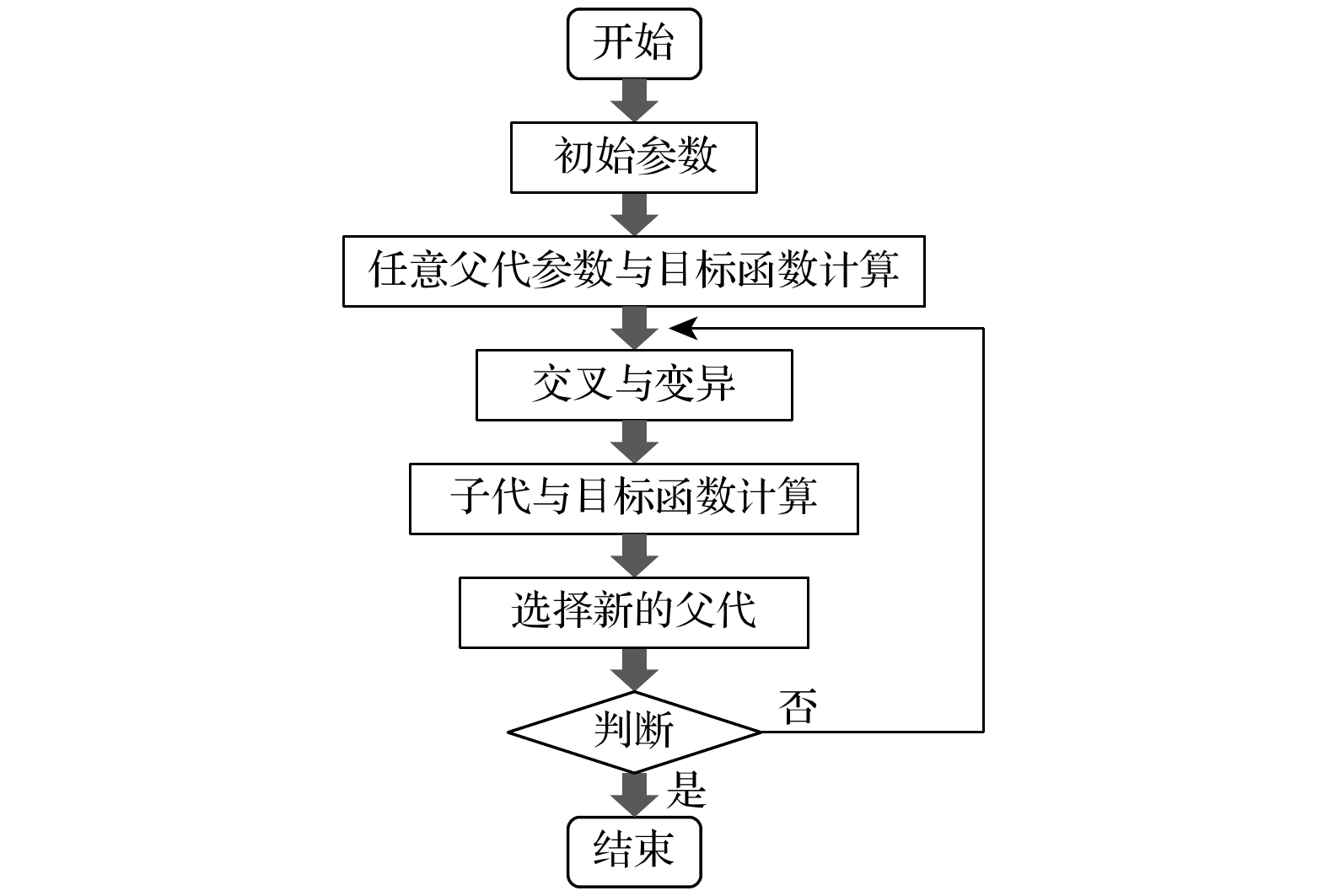

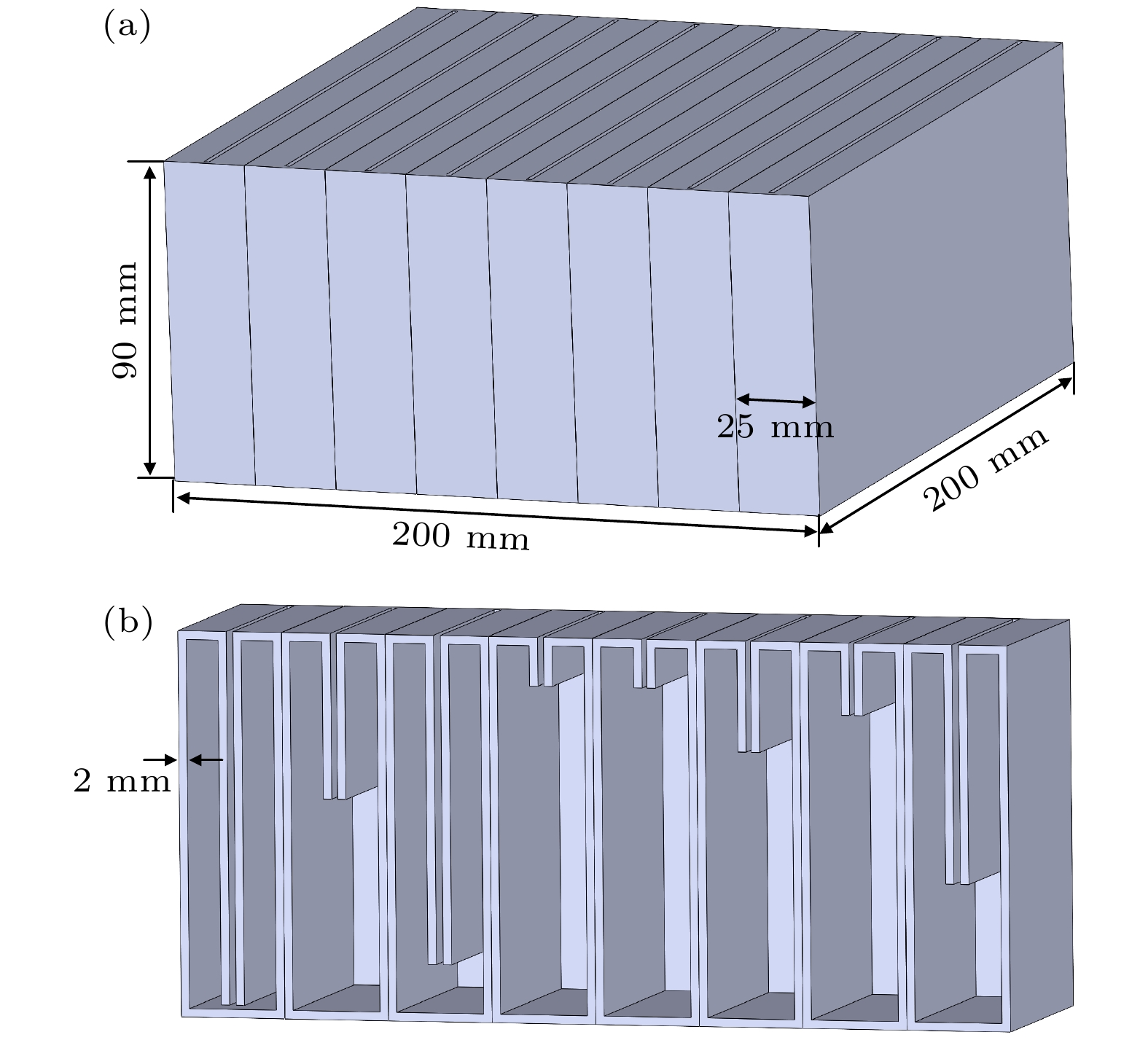

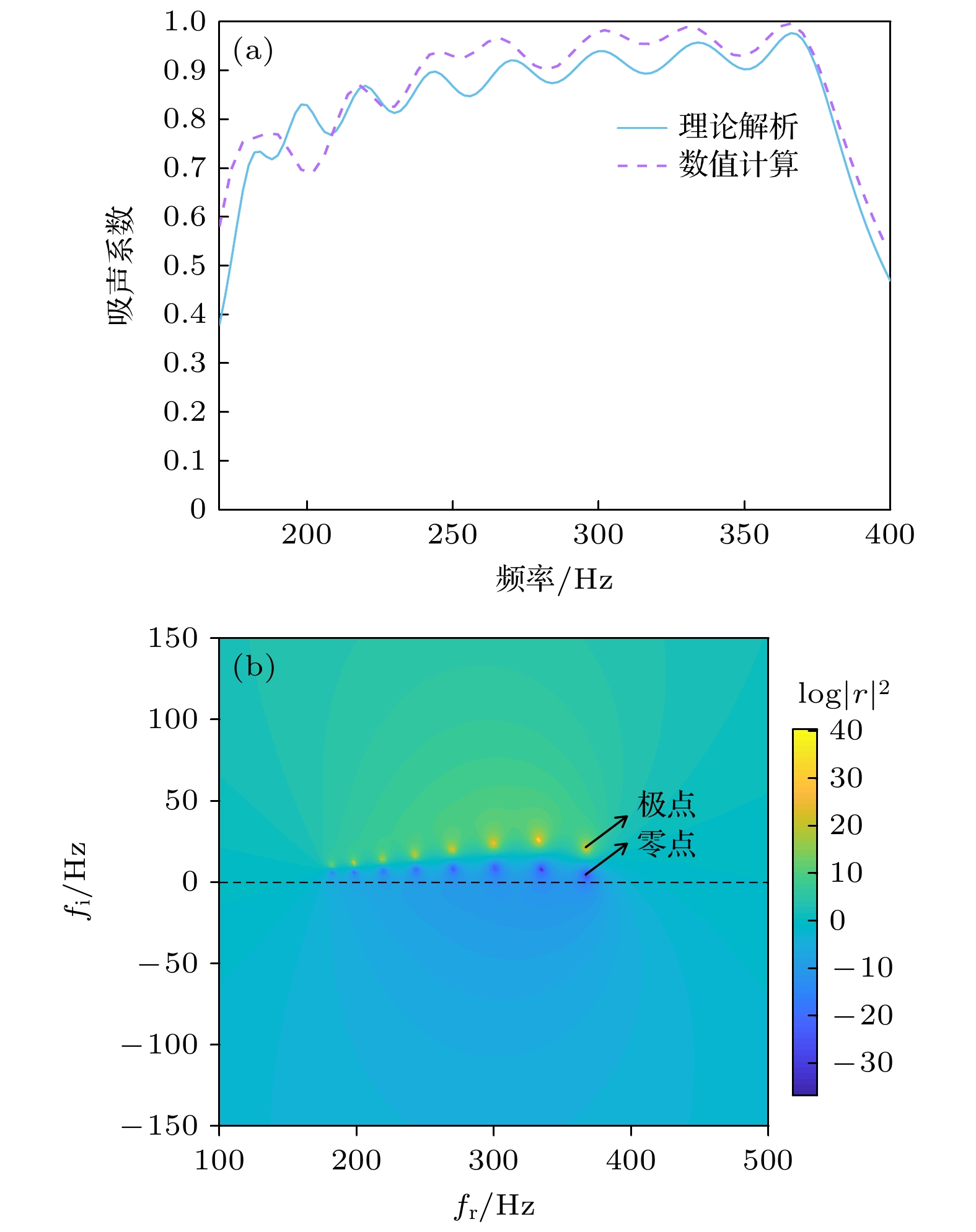

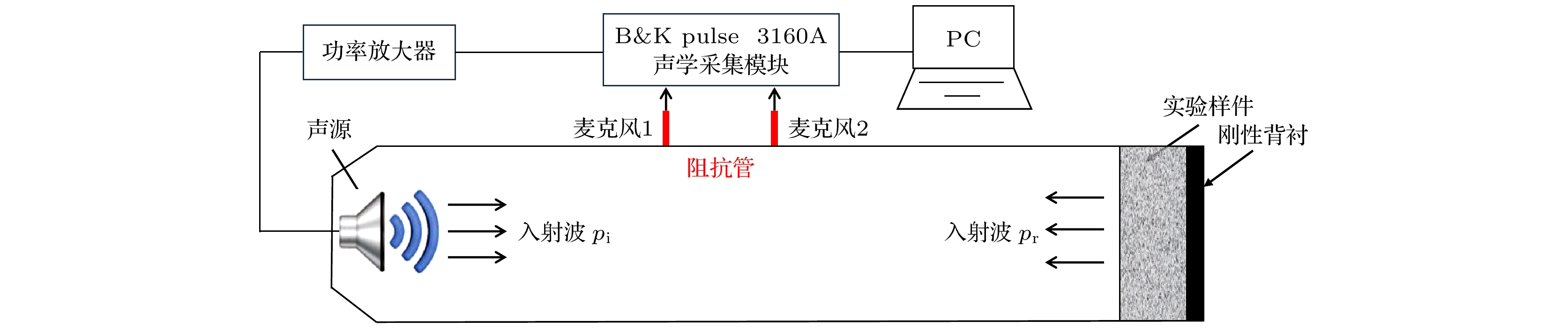

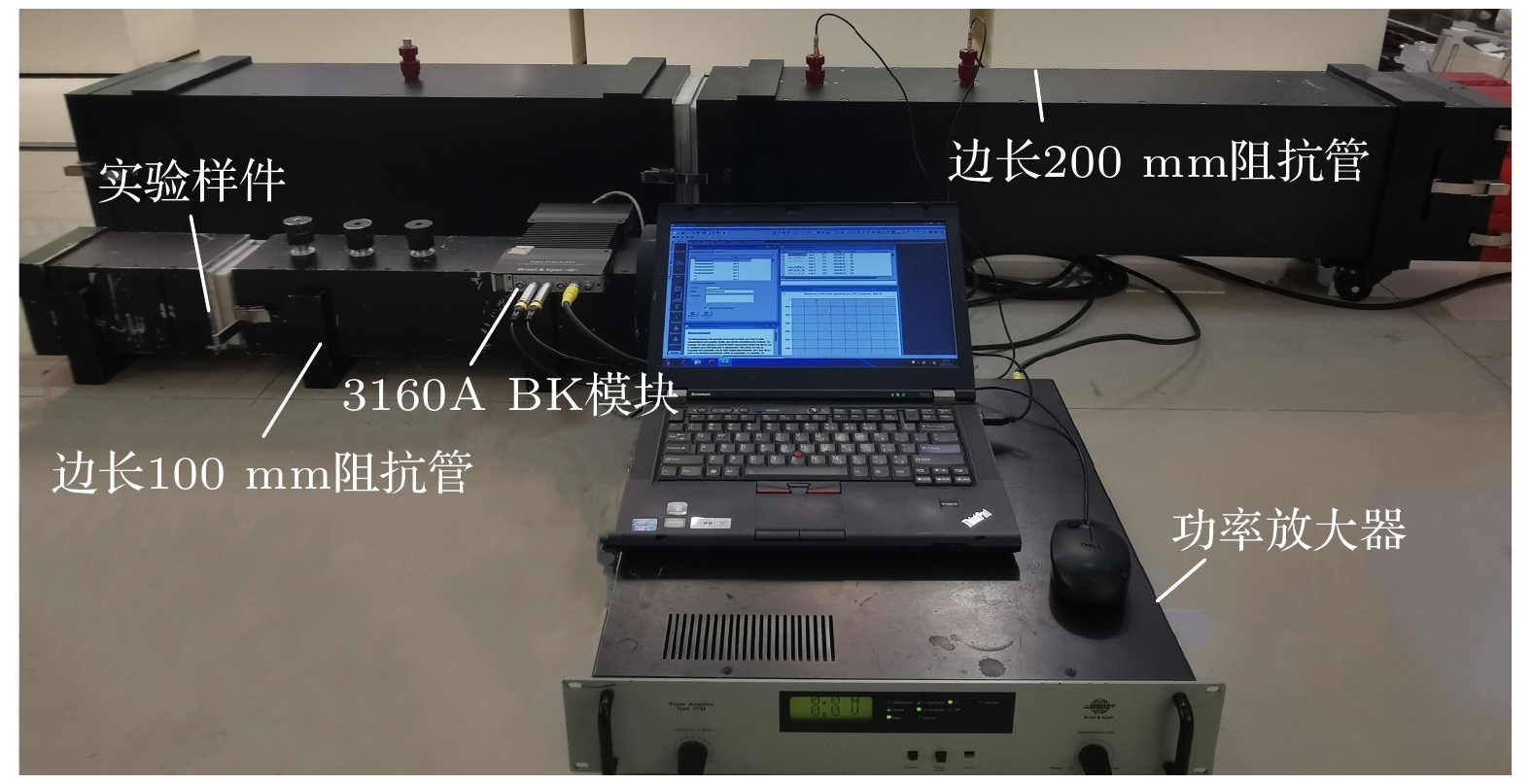

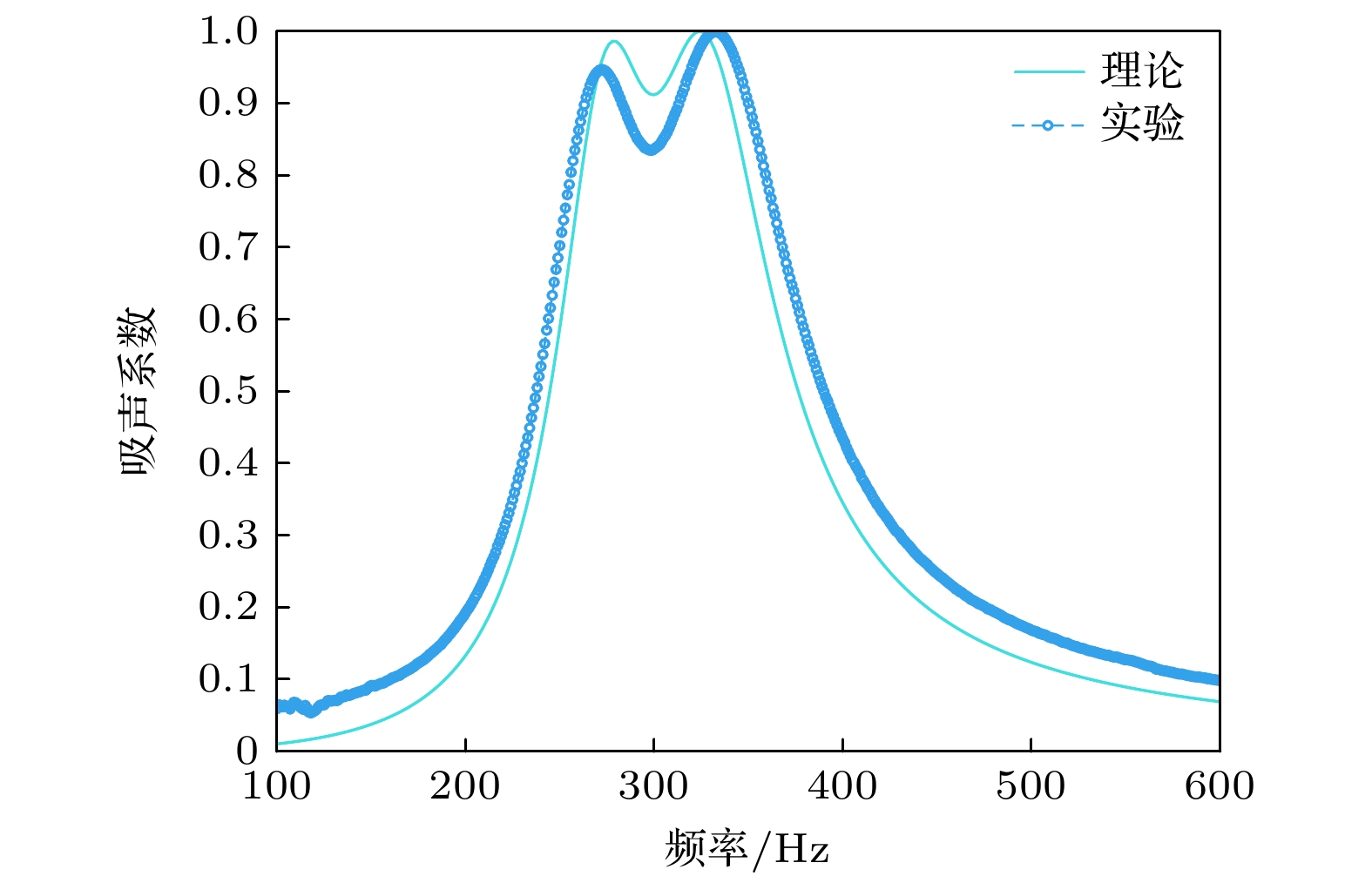

低频噪声一直是噪声控制领域比较棘手的问题, 近年来吸声超结构的蓬勃发展为低频噪声控制提供了新理念. 本文提出了一种内插缝Helmholtz共振腔吸声超结构, 建立了其吸声特性计算的理论解析方法, 并与数值计算方法对比, 验证了解析方法的有效性. 随后, 从吸声曲线、简化等效模型、归一化声阻抗、声压云图与质点速度分布等多角度对吸声特性及吸声机理进行了深入分析. 进一步, 采用差分优化算法开展了多元胞并联耦合宽带优化设计, 优化后典型超结构实现了90 mm厚度下在170—380 Hz低频段内平均吸声系数达到0.86的优异吸声效果. 最后, 制备了若干样件, 开展吸声测试, 实验结果与理论结果符合良好, 验证了解析建模与优化设计方法的准确性. 本文提出的内插缝Helmholtz共振腔吸声超结构具有结构简单、低频吸声性能好, 且易于加工制造等特点, 在低频噪声控制领域具有广阔的应用前景.

-

关键词:

- 吸声超结构 /

- Helmholtz共鸣器 /

- 内插缝 /

- 低频吸声

Low-frequency noise has always been a thorny problem in the field of noise control. In recent years, the development of sound-absorbing metastructures has provided new ideas for controlling low-frequency noise. In this work, we propose a low-frequency sound-absorbing metastructure constructed by Helmholtz resonators with embedded slit. Analytical and numerical models are established to analyze the sound absorption performance and mechanism of the proposed sound-absorbing metastructure, and optimization design is conducted to achieve low-frequency wideband absorption performance. The analytical modeling method and the performance of the proposed sound-absorbing metastructure are also experimentally verified. The main conclusions are summarized as follows. 1) By using transfer matrix method and finite element method, analytical and numerical models for calculating sound absorption coefficient are established. It is shown that analytical predictions are in good agreement with numerical calculations. It is demonstrated that a typical design of a 30-mm-thick single-cell metastructure can achieve a sound absorption coefficient of 0.88 at 404 Hz. Typical designs of two-cell parallel structure and the four-cell parallel structure (both with a thickness of 50 mm) can achieve two and four nearly perfect low-frequency sound absorption peaks in a frequency band of 200–400 Hz, respectively. 2) The low-frequency sound absorption mechanisms of the proposed metastructures are explained from four aspects: simplified equivalent model parameters, normalized acoustic impedance, complex-plane zero/pole distribution, and sound pressure cloud image and particle velocity field distribution. It is demonstrated that the main sound absorption mechanism is related to the thermal viscous loss of sound waves, caused by the inner wall of embedded slit. 3) The design for broadband low-frequency absorption performance is optimized by using differential evolution optimization algorithm. An optimized parallel-multi-cell coupled metastructure with multiple perfect sound absorption peaks below 500 Hz is realized. For a thickness of 90 mm, the sound absorption coefficient curve of an optimized metastructure exhibits 8 almost perfect sound absorption peaks and an average sound absorption coefficient of 0.86 in a frequency range of 170-380 Hz. 4) Experimental samples are fabricated to test sound absorption. Experimental results are basically consistent with the analytical predictions. The results from analytical model, numerical calculations and experimental measurements are mutually verified. In summary, the sound-absorbing metastructures with a thickness of sub-wavelength, proposed in this work, exhibit outstanding sound absorption performance at low frequencies. We demonstrate that they are suitable for low frequency broadband sound absorption below 500 Hz. Owing to their thin thickness and relatively simple construction, they have broad application prospects in practical noise control engineering. -

Keywords:

- sound-absorbing metastructure /

- Helmholtz resonator /

- embedded slit /

- low frequency absorption

[1] Champoux Y, Allard J F 1991 J. Appl. Phys. 70 1975

Google Scholar

Google Scholar

[2] Panneton R 2007 J. Acoust. Soc. Am. 122 217

Google Scholar

Google Scholar

[3] Trompette N, Barbry J, Sgard F, Nelisse H 2009 J. Acoust. Soc. Am. 125 31

Google Scholar

Google Scholar

[4] Climente A, Torrent D, Sánchez-Dehesa J 2012 Appl. Phys. Lett. 100 144103

Google Scholar

Google Scholar

[5] Ma G C, Sheng P 2016 Sci. Adv. 2 1501595

Google Scholar

Google Scholar

[6] 肖勇, 王洋, 赵宏刚, 郁殿龙, 温激鸿 2023 机械工程学报 59 277

Google Scholar

Google Scholar

Xiao Y, Wang Y, Zhao H G, Yu D L, Wen J H 2023 J. Mech. Eng. 59 277

Google Scholar

Google Scholar

[7] Cai X B, Guo Q Q, Hu G K, Yang J 2014 Appl. Phys. Lett. 105 121901

Google Scholar

Google Scholar

[8] Wang Y, Zhao H G, Yang H B, Zhong J, Zhao D, Lu Z L, Wen J H 2018 J. Appl. Phys. 123 185109

Google Scholar

Google Scholar

[9] Wu F, Xiao Y, Yu D, Zhao H, Wang Y, Wen J 2019 Appl. Phys. Lett. 114 151901

Google Scholar

Google Scholar

[10] 吴飞, 黄威, 陈文渊, 肖勇, 郁殿龙, 温激鸿 2020 69 134303

Google Scholar

Google Scholar

Wu F, Huang W, Chen W Y, Xiao Y, Yu D L, Wen J H 2020 Acta Phys. Sin. 69 134303

Google Scholar

Google Scholar

[11] Zhao H G, Wang Y, Yu D L, Yang H B, Zhong J, Wu F, Wen J H 2020 Compos. Struct. 239 111978

Google Scholar

Google Scholar

[12] Jin Y B, Yang Y L, Wen Z H, He L S, Cang Y, Yang B, Djafari-Rouhani B, Li Y, Li Y 2022 Int. J. Mech. Sci. 226 107396

Google Scholar

Google Scholar

[13] Liu C R, Yang Z R, Liu X L, Wu J H, Ma F Y 2023 APL Mater. 11 101122

Google Scholar

Google Scholar

[14] 白宇, 张振方, 杨海滨, 蔡力, 郁殿龙 2023 72 054301

Google Scholar

Google Scholar

Bai Y, Zhang Z F, Yang H B, Cai L, Yu D L 2023 Acta Phys. Sin. 72 054301

Google Scholar

Google Scholar

[15] Liu J W, Yu D L, Yang H B, Shen H J, Wen J H 2020 Chin. Phys. Lett. 37 34301

Google Scholar

Google Scholar

[16] Zhou Z L, Huang S B, Li D T, Zhu J, Li Y 2022 Natl. Sci. Rev. 9 171

Google Scholar

Google Scholar

[17] Almeida G D N, Vergara E F, Barbosa L R, Lenzi A, Birch R S 2021 Appl. Acoust. 183 108312

Google Scholar

Google Scholar

[18] Wu F, Ju Z G, Hu M, Zhang X, Li D, Liu K L 2023 J. Phys. D: Appl. Phys. 56 45401

Google Scholar

Google Scholar

[19] Ma G C, Yang M, Xiao S W, Yang Z Y, Sheng P 2014 Nat. Mater. 13 873

Google Scholar

Google Scholar

[20] Ge H, Yang M, Ma C, Lu M H, Chen Y F, Fang N, Sheng P 2018 Natl. Sci. Rev. 5 159

Google Scholar

Google Scholar

[21] Cummer S A, Christensen J, Alù A 2016 Nat. Rev. Mater. 1 16001

Google Scholar

Google Scholar

[22] Stinson M R 1991 J. Acoust. Soc. Am. 89 550

Google Scholar

Google Scholar

[23] Verdière K, Panneton R, Elkoun S D, Dupont T, Leclaire P 2013 J. Acoust. Soc. Am. 134 4648

Google Scholar

Google Scholar

[24] Guo J W, Zhang X, Fang Y, Jiang Z Y 2021 Compos. Struct. 260 113538

Google Scholar

Google Scholar

[25] Tam C K W, Ju H, Jones M G, Watson W R, Parrott T L 2005 J. Sound Vib. 284 947

Google Scholar

Google Scholar

[26] Zieliński T G, Chevillotte F, Deckers E 2019 Appl. Acoust. 146 261

Google Scholar

Google Scholar

[27] 杜功焕, 朱哲民, 龚秀芬 2012 声学基础(南京: 南京大学出版社)第159页

Du G H, Zhu Z M, Gong X F 2012 Acoustics Foundation (Nanjing: Nanjing University Press) p159

[28] Romero-García V, Theocharis G, Richoux O, Merkel A, Tournat V, Pagneux V 2016 Sci. Rep. 6 19519

Google Scholar

Google Scholar

[29] Lee F C, Chen W H 2001 J. Sound Vib. 248 621

Google Scholar

Google Scholar

[30] Liu J, Herrin D W 2010 Appl. Acoust. 71 120

Google Scholar

Google Scholar

[31] Ruiz H, Claeys C C, Deckers E, Desmet W 2016 Mech. Syst. Signal Pr. 70 904

[32] Romero-García V, Sánchez-Pérez J V, Garcia-Raffi L M 2011 J. Appl. Phys. 110 14904

Google Scholar

Google Scholar

[33] Qamoshi K, Rasuli R 2016 Appl. Phys. A 122 788

Google Scholar

Google Scholar

[34] Storn R, Price K 1997 J. Global Optim. 11 341

Google Scholar

Google Scholar

-

表 1 单个内插缝Helmholtz共振腔结构参数

Table 1. Structural parameters of single slit-embedded Helmholtz resonator.

长L/mm 宽D/mm 高H/mm 缝宽d/mm 缝高lr/mm 100 100 30 2 10 表 2 双元胞并联结构参数

Table 2. Structural parameters of two cells in parallel.

长L/mm 宽D/mm 高H/mm 缝宽d1/mm 缝高lr1/mm 缝宽d2/mm 缝高lr2/mm 50 50 50 1.2 17.3 1.1 9.8 表 3 四元胞并联结构参数

Table 3. Structural parameters of four cells in parallel.

长L/mm 宽D/mm 高H/mm 缝宽d1/mm 缝高lr1/mm 缝宽d2/mm 缝高lr2/mm 缝宽d3/mm 缝高lr3/mm 缝宽d4/mm 缝高lr4/mm 50 50 50 2.7 42.3 1.7 17.9 1.3 8 1.3 4.7 表 4 多元胞并联结构参数

Table 4. Structural parameters of multivariate cells in parallel.

元胞 1 2 3 4 5 6 7 8 缝宽d/mm 1.5 1.4 1.7 1.4 1.1 1.2 1.1 1.5 缝高lr/mm 84 35.1 70.6 10.6 10.3 23.5 15.3 50.6 -

[1] Champoux Y, Allard J F 1991 J. Appl. Phys. 70 1975

Google Scholar

Google Scholar

[2] Panneton R 2007 J. Acoust. Soc. Am. 122 217

Google Scholar

Google Scholar

[3] Trompette N, Barbry J, Sgard F, Nelisse H 2009 J. Acoust. Soc. Am. 125 31

Google Scholar

Google Scholar

[4] Climente A, Torrent D, Sánchez-Dehesa J 2012 Appl. Phys. Lett. 100 144103

Google Scholar

Google Scholar

[5] Ma G C, Sheng P 2016 Sci. Adv. 2 1501595

Google Scholar

Google Scholar

[6] 肖勇, 王洋, 赵宏刚, 郁殿龙, 温激鸿 2023 机械工程学报 59 277

Google Scholar

Google Scholar

Xiao Y, Wang Y, Zhao H G, Yu D L, Wen J H 2023 J. Mech. Eng. 59 277

Google Scholar

Google Scholar

[7] Cai X B, Guo Q Q, Hu G K, Yang J 2014 Appl. Phys. Lett. 105 121901

Google Scholar

Google Scholar

[8] Wang Y, Zhao H G, Yang H B, Zhong J, Zhao D, Lu Z L, Wen J H 2018 J. Appl. Phys. 123 185109

Google Scholar

Google Scholar

[9] Wu F, Xiao Y, Yu D, Zhao H, Wang Y, Wen J 2019 Appl. Phys. Lett. 114 151901

Google Scholar

Google Scholar

[10] 吴飞, 黄威, 陈文渊, 肖勇, 郁殿龙, 温激鸿 2020 69 134303

Google Scholar

Google Scholar

Wu F, Huang W, Chen W Y, Xiao Y, Yu D L, Wen J H 2020 Acta Phys. Sin. 69 134303

Google Scholar

Google Scholar

[11] Zhao H G, Wang Y, Yu D L, Yang H B, Zhong J, Wu F, Wen J H 2020 Compos. Struct. 239 111978

Google Scholar

Google Scholar

[12] Jin Y B, Yang Y L, Wen Z H, He L S, Cang Y, Yang B, Djafari-Rouhani B, Li Y, Li Y 2022 Int. J. Mech. Sci. 226 107396

Google Scholar

Google Scholar

[13] Liu C R, Yang Z R, Liu X L, Wu J H, Ma F Y 2023 APL Mater. 11 101122

Google Scholar

Google Scholar

[14] 白宇, 张振方, 杨海滨, 蔡力, 郁殿龙 2023 72 054301

Google Scholar

Google Scholar

Bai Y, Zhang Z F, Yang H B, Cai L, Yu D L 2023 Acta Phys. Sin. 72 054301

Google Scholar

Google Scholar

[15] Liu J W, Yu D L, Yang H B, Shen H J, Wen J H 2020 Chin. Phys. Lett. 37 34301

Google Scholar

Google Scholar

[16] Zhou Z L, Huang S B, Li D T, Zhu J, Li Y 2022 Natl. Sci. Rev. 9 171

Google Scholar

Google Scholar

[17] Almeida G D N, Vergara E F, Barbosa L R, Lenzi A, Birch R S 2021 Appl. Acoust. 183 108312

Google Scholar

Google Scholar

[18] Wu F, Ju Z G, Hu M, Zhang X, Li D, Liu K L 2023 J. Phys. D: Appl. Phys. 56 45401

Google Scholar

Google Scholar

[19] Ma G C, Yang M, Xiao S W, Yang Z Y, Sheng P 2014 Nat. Mater. 13 873

Google Scholar

Google Scholar

[20] Ge H, Yang M, Ma C, Lu M H, Chen Y F, Fang N, Sheng P 2018 Natl. Sci. Rev. 5 159

Google Scholar

Google Scholar

[21] Cummer S A, Christensen J, Alù A 2016 Nat. Rev. Mater. 1 16001

Google Scholar

Google Scholar

[22] Stinson M R 1991 J. Acoust. Soc. Am. 89 550

Google Scholar

Google Scholar

[23] Verdière K, Panneton R, Elkoun S D, Dupont T, Leclaire P 2013 J. Acoust. Soc. Am. 134 4648

Google Scholar

Google Scholar

[24] Guo J W, Zhang X, Fang Y, Jiang Z Y 2021 Compos. Struct. 260 113538

Google Scholar

Google Scholar

[25] Tam C K W, Ju H, Jones M G, Watson W R, Parrott T L 2005 J. Sound Vib. 284 947

Google Scholar

Google Scholar

[26] Zieliński T G, Chevillotte F, Deckers E 2019 Appl. Acoust. 146 261

Google Scholar

Google Scholar

[27] 杜功焕, 朱哲民, 龚秀芬 2012 声学基础(南京: 南京大学出版社)第159页

Du G H, Zhu Z M, Gong X F 2012 Acoustics Foundation (Nanjing: Nanjing University Press) p159

[28] Romero-García V, Theocharis G, Richoux O, Merkel A, Tournat V, Pagneux V 2016 Sci. Rep. 6 19519

Google Scholar

Google Scholar

[29] Lee F C, Chen W H 2001 J. Sound Vib. 248 621

Google Scholar

Google Scholar

[30] Liu J, Herrin D W 2010 Appl. Acoust. 71 120

Google Scholar

Google Scholar

[31] Ruiz H, Claeys C C, Deckers E, Desmet W 2016 Mech. Syst. Signal Pr. 70 904

[32] Romero-García V, Sánchez-Pérez J V, Garcia-Raffi L M 2011 J. Appl. Phys. 110 14904

Google Scholar

Google Scholar

[33] Qamoshi K, Rasuli R 2016 Appl. Phys. A 122 788

Google Scholar

Google Scholar

[34] Storn R, Price K 1997 J. Global Optim. 11 341

Google Scholar

Google Scholar

计量

- 文章访问数: 5612

- PDF下载量: 558

- 被引次数: 0

下载:

下载: