-

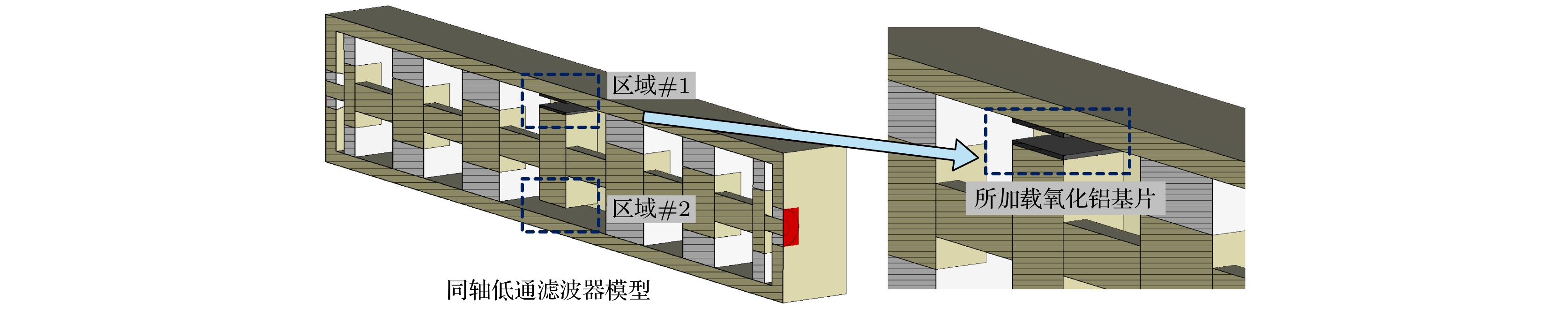

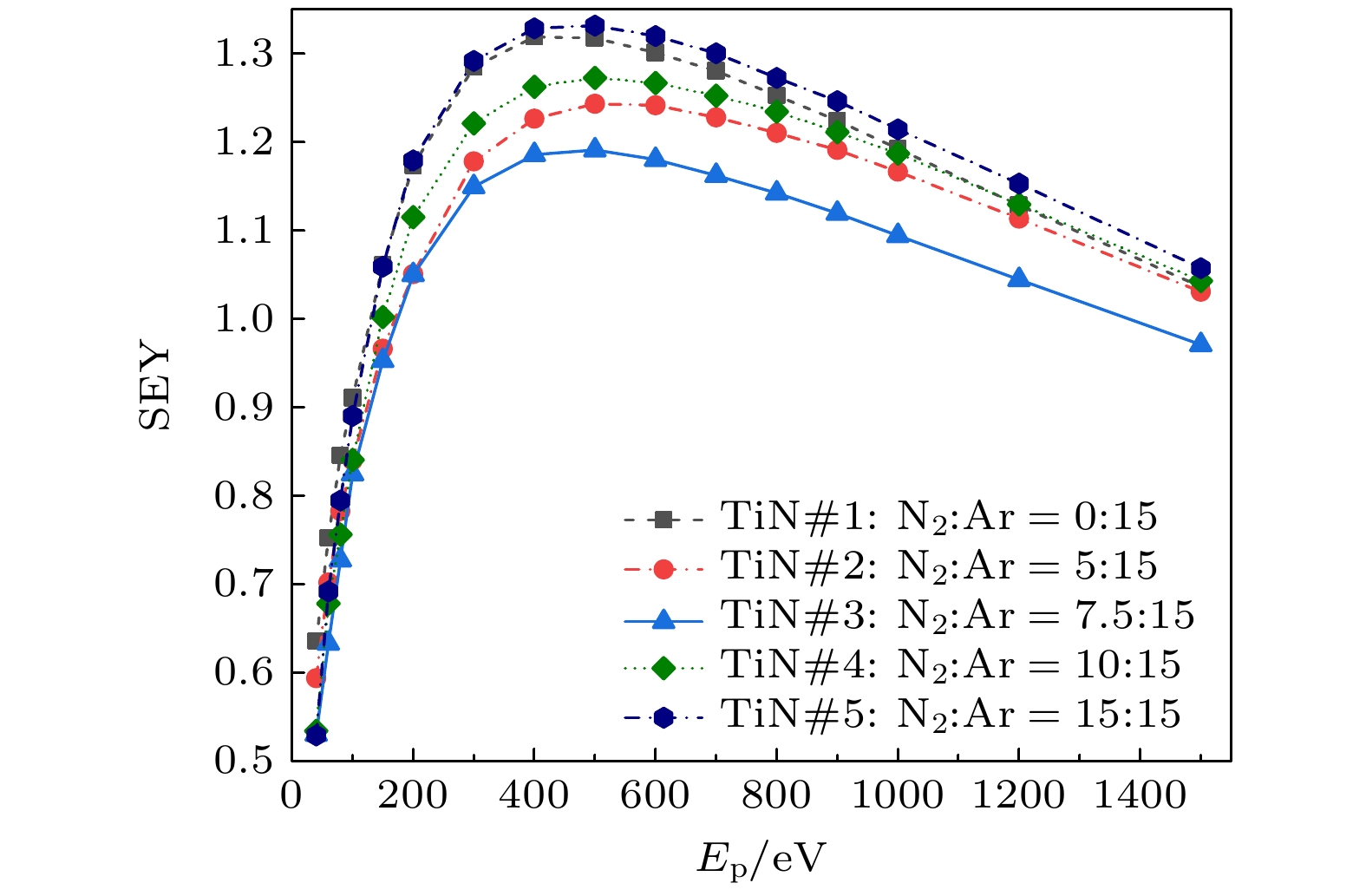

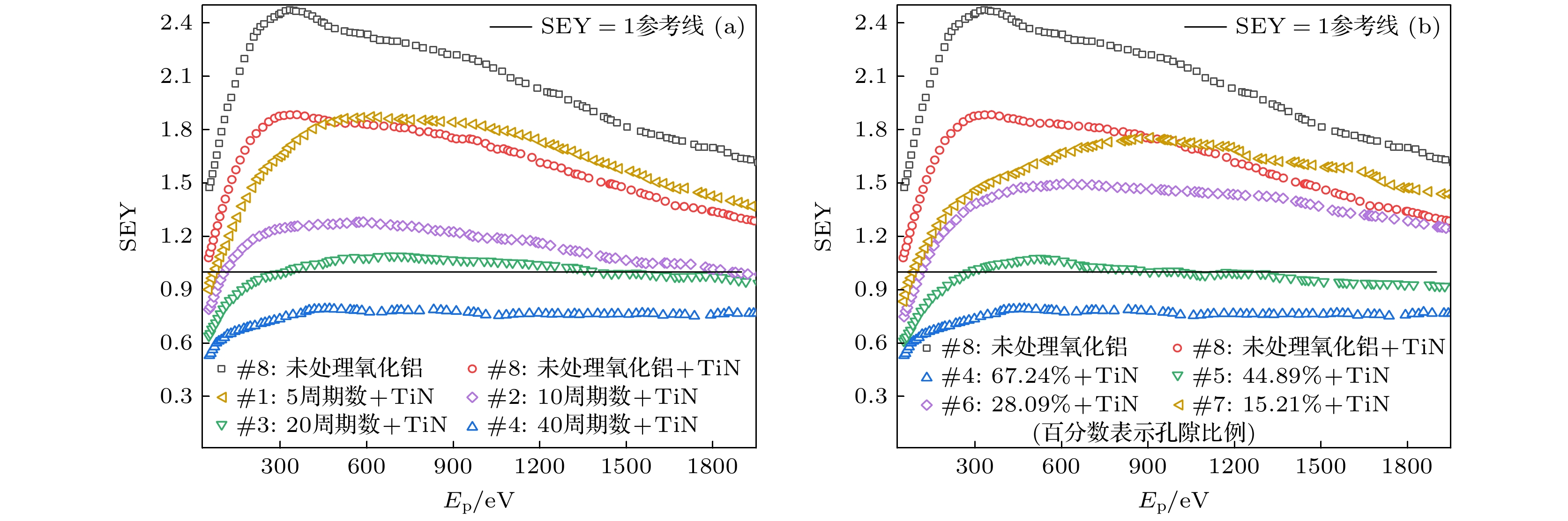

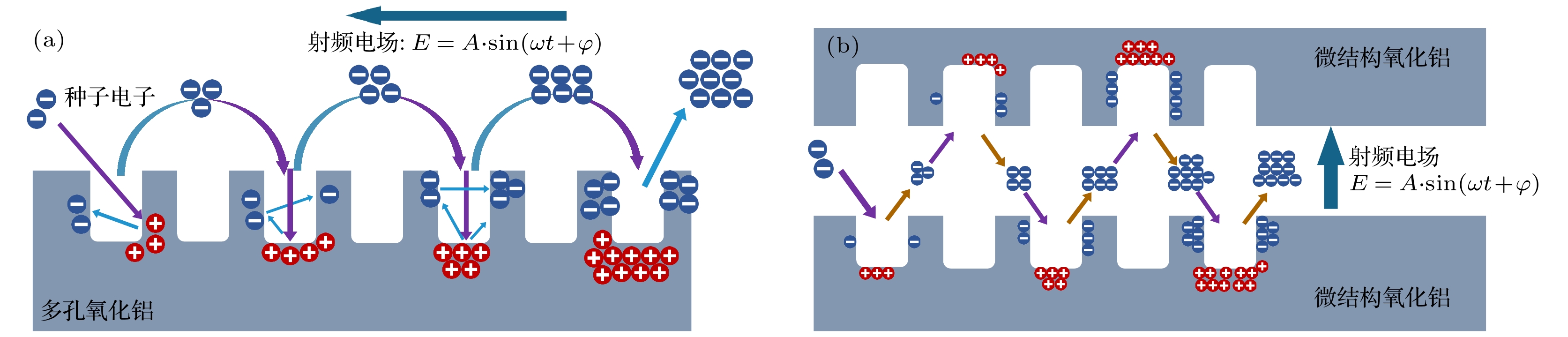

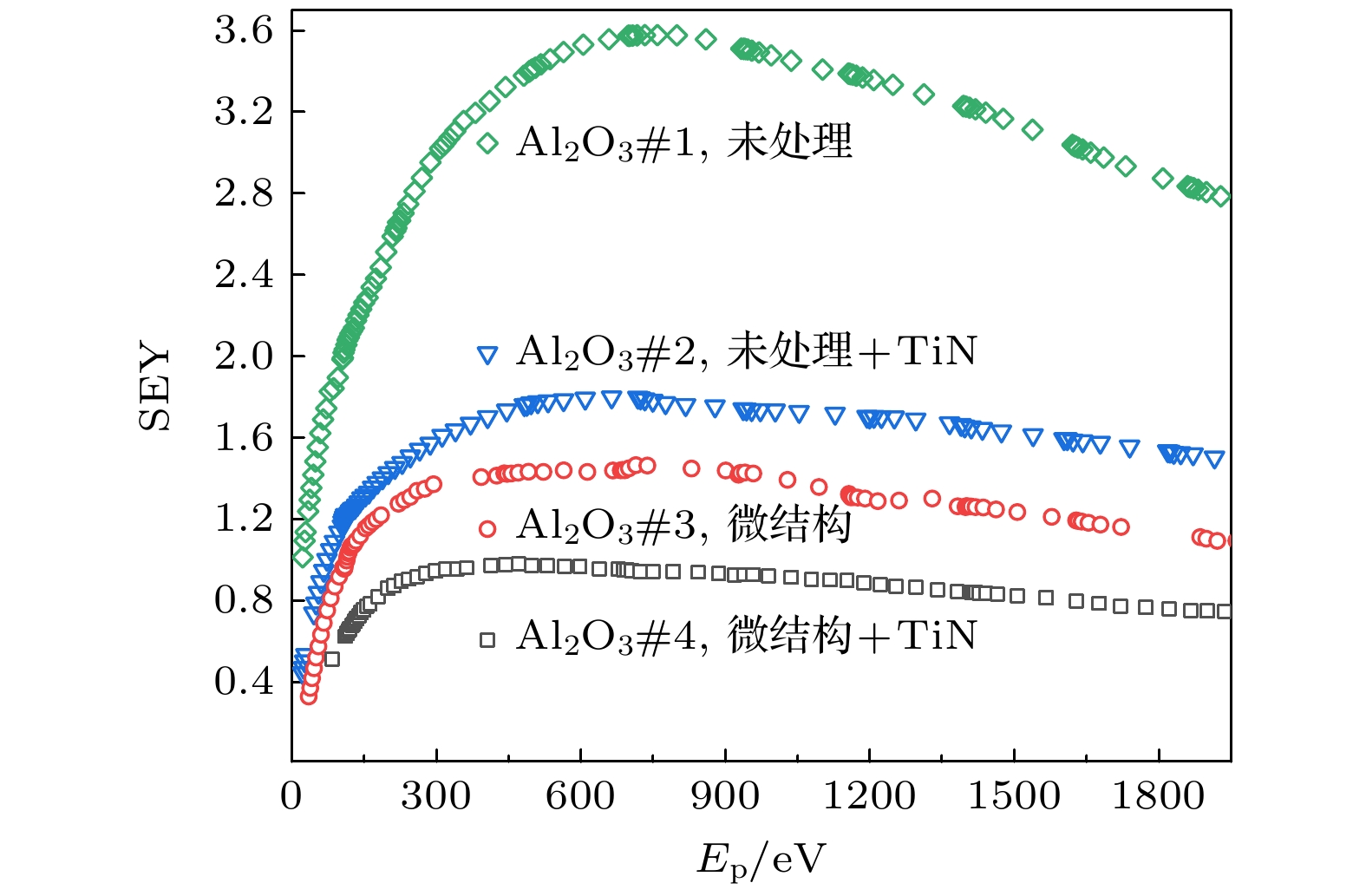

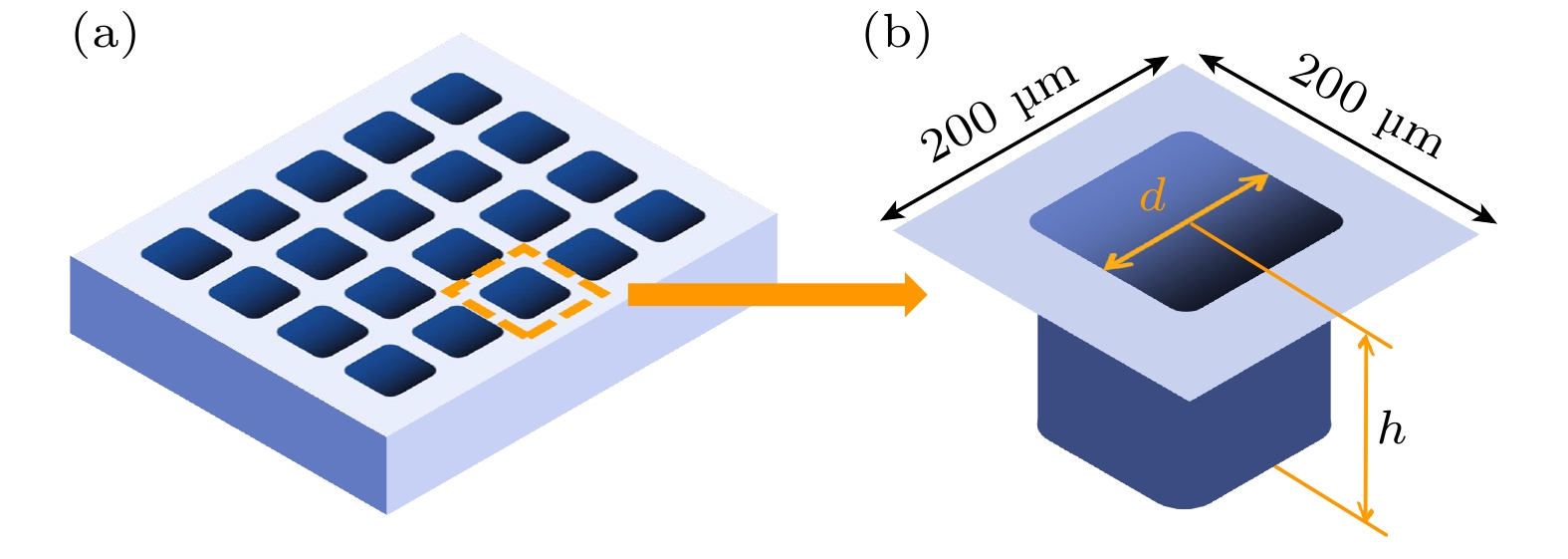

空间大功率微波器件中的二次电子倍增现象会诱发微放电效应, 使得器件性能劣化或失效. 针对加载氧化铝的同轴低通滤波器进行建模, 并通过微放电阈值仿真验证了降低放电敏感表面的二次电子产额(SEY)可有效提升器件微放电阈值. 针对器件中易于发生微放电的氧化铝表面, 应用激光刻蚀制备表面微结构, 获得孔隙比例为67.24%、平均深宽比例为1.57的微孔结构, 氧化铝SEY峰值(δm)由2.46降低至1.10. 应用磁控溅射工艺研究氮化钛(TiN)薄膜低SEY特性, 当N2与Ar流量比为7.5∶15时, TiN薄膜δm低至1.19. 在激光刻蚀微结构氧化铝表面镀覆TiN薄膜, 实现表面SEY的剧烈降低, δm降至0.79. 通过仿真电子束辐照氧化铝表面带电特性, 分析了表面带电水平对SEY的影响规律, 以及低SEY表面抑制微放电的物理机制. 选取填充了纯度为99.5%氧化铝片的同轴滤波器进行验证, 结果表明: 微结构氧化铝表面镀覆TiN薄膜后, 器件微放电阈值由125 W增加至650 W. 研究对于介质填充微波器件微放电效应抑制机理分析具有重要科学意义, 对于提高微波器件微放电阈值具有工程应用价值.For the high-power microwave (HPM) components applied to the space environment, the seed electrons in the components may resonate with the radio-frequency electrical field and may further lead the secondary electron multiplication to occur, triggering off the phenomenon of multipactor. Multipactor deteriorates the performance of the components, and in severe circumstances, it is even possible to result in the failure of the components or the spacecraft. Alumina ceramic possesses good dielectricity, high hardness, good thermal isolation, low dielectric loss, etc., so it is widely used in HPM systems including dielectric windows, and many other microwave components. However, alumina ceramic possesses a relatively high level of secondary electron yield (SEY or δ), indicating that the devastating effect of multipactor discharge is likely to be triggered off inside the alumina-filled HPM components in the space environment. In this work, the model of alumina loaded coaxil low pass fillter is simulated to verify that reducing the SEY of the alumina surface is effective and necessary to improve the multipactor threshold. After that, we use several technologies to achieve an ultralow SEY on the alumina surface. Firstly, a series of microstructures with different porosities and aspect ratios is fabricated. The results indicate that the microstructure with 67.24% porosity and 1.57 aspect ratio shows an excellent low-SEY property, which is able to suppress the SEY peak value (δm) of alumina from 2.46 to 1.10. Then, various process parameters are used to fabricate TiN films on silicon sheets. Experimental results indicate that the TiN film achieves the lowest δm of 1.19 when the gas flow ratio of N2∶Ar is 7.5∶15. Thereafter, we deposit TiN ceramic coating onto the laser-etched microstructure samples, and an ultralow δm of 0.79 is finally achieved on alumina surface. Then we implement a qualitative analysis to explore the influence of surface charge on the secondary electron emission and multipactor for the microstructured alumina surface, discuss the mechanism of low-SEY surfaces mitigating unilateral and bilateral multipactor. For verifying the actual effect of low-SEY technologies on the suppression of multipactor, we use the technologies of constructing microstructure and depositing TiN films on the alumina surface which is filled in the designed coaxial low pass filter. Finally, we obtain a significant improvement in the multipactor threshold for the filter, which increases from 125 W to 650 W, and the improvement is 7.16 dB. This work develops an effective method to reduce SEY for alumina, which is of great scientific significance in revealing the mechanism of multipactor for the dielectric-filled microwave components and also is of engineering application significance in improving the reliability of HPM components.

-

Keywords:

- secondary electron emission /

- alumina /

- multipactor /

- microstructure

[1] Michizono S, Saito Y, Fukuda S, Anami S, Hayashi K 1997 Vacuum 47 625

Google Scholar

Google Scholar

[2] Cummings K A, Risbud S H 2000 J. Phys. Chem. Solids 61 551

Google Scholar

Google Scholar

[3] 宋佰鹏, 范壮壮, 苏国强, 穆海宝, 张冠军, 刘纯亮 2014 强激光与粒子束 26 271

Google Scholar

Google Scholar

Song B P, Fan Z Z, Su G Q, Mu H B, Zhang G J, Liu C L 2014 High Power Laser and Particle Beams 26 271

Google Scholar

Google Scholar

[4] Vague J, Melgarejo J C, Guglielmi M, Boria V E, Anza S, Vicente, C, Moreno M R, Taroncher M, Gimeno M B, Raboso D 2018 IEEE Trans. Microw. Theory Techn. 66 3644

Google Scholar

Google Scholar

[5] 崔万照, 李韵, 张洪太 2019 航天器微波部件微放电分析及其应用 (北京: 北京理工大学出版社) 第5—7页

Cui W Z, Li Y, Zhang H T 2019 Simulation Method of Multipactor and Its Application in Satellite Microwave Components (Beijing: Beijing Institute of Technology Press) pp5–7 (in Chinese)

[6] 董烨, 刘庆想, 庞健, 周海京, 董志伟 2018 67 037901

Google Scholar

Google Scholar

Dong Y, Liu Q X, Pang J, Zhou H J, Dong Z W 2018 Acta Phys. Sin. 67 037901

Google Scholar

Google Scholar

[7] Raboson D 2008 6th International Workshop on Multipactor Corona and Passive Intermodulation Valencia, Spain, September 24–27, 2008

[8] 胡天存, 曹猛, 鲍艳, 张永辉, 马建中, 崔万照 2017 中国空间科学技术 37 54

Google Scholar

Google Scholar

Hu T C, Cao M, Bao Y, Zhang Y H, Ma J Z, Cui W Z 2017 Chinese Space Science and Technology 37 54

Google Scholar

Google Scholar

[9] 翟永贵, 王瑞, 王洪广, 林舒, 陈坤, 李永东 2018 67 353

Google Scholar

Google Scholar

Zhai Y G, Wang R, Wang H G, Lin S, Chen K, Li Y D 2018 Acta Phy. Sin. 67 353

Google Scholar

Google Scholar

[10] 张娜, 崔万照, 曹猛, 王瑞, 胡天存 2020 中国空间科学技术 40 1

Google Scholar

Google Scholar

Zhang N, Cui W Z, Cao M, Wang R, Hu T C 2020 Chinese Space Science and Technology 40 1

Google Scholar

Google Scholar

[11] 李韵, 封国宝, 谢贵柏, 苗光辉, 李小军, 崔万照, 贺永宁 2022 强激光与粒子束 34 29

Google Scholar

Google Scholar

Li Y, Feng G B, Xie G B, Miao G H, Li X J, Cui W Z, He Y N 2022 High Power Laser and Particle Beams 34 29

Google Scholar

Google Scholar

[12] Vaughan J R M 1988 IEEE Trans. Electron. Dev. 35 1172

Google Scholar

Google Scholar

[13] Michizono S 2007 IEEE Trans. Dielectr. Electr. Insul. 14 583

Google Scholar

Google Scholar

[14] Song B P, Shen W W, Mu H B, Deng J B, Hao X W, Zhang G J 2013 IEEE Trans. Plasma. Sci. 41 2117

Google Scholar

Google Scholar

[15] 雷杨俊, 肖定全, 唐兵华 2006 硅酸盐学报 34 713

Google Scholar

Google Scholar

Lei Y J, Xiao D Q, Tang B H 2006 J. Chin. Ceram. Soc. 34 713

Google Scholar

Google Scholar

[16] Suharyanto, Yamano Y, Kobayashi S, Michizono S, Saito Y 2006 IEEE Trans. Dielectr. Electr. Insul. 13 72

Google Scholar

Google Scholar

[17] Cazaux J 2010 Appl. Surf. Sci. 257 1002

Google Scholar

Google Scholar

[18] 王丹, 叶鸣, 冯鹏, 贺永宁, 崔万照 2019 68 067901

Google Scholar

Google Scholar

Wang D, Ye M, Feng P, He Y N, Cui W Z 2019 Acta Phys. Sin. 68 067901

Google Scholar

Google Scholar

[19] Gineste T, Belhaj M, Teyssedre G, Puech J 2015 Appl. Surf. Sci. 359 398

Google Scholar

Google Scholar

[20] Wang D, He Y N, Cui W Z 2018 J. Appl. Phys. 124 053301

Google Scholar

Google Scholar

[21] Ladarola G 2014 Ph. D. Dissertation (Napoli: Università degli Studi di Napoli Federico II)

[22] [23] Rumolo G, Ruggiero F, Zimmermann F 2001 Phys. Rev. Spec. Top-Ac 4 012801

Google Scholar

Google Scholar

[24] 张洪涛, 董海义, 杨奇 2014 真空 51 61

Google Scholar

Google Scholar

Zhang H T, Dong H Y, Yang Q 2014 Vacuum 51 61

Google Scholar

Google Scholar

[25] Michizono S, Kinbara A, Saito Y, Yamaguchi S, Anami S, Matuda N 1992 J. Vac. Sci. Technol. A 10 1180

Google Scholar

Google Scholar

[26] Ye M, Wang D, Li Y, He Y N, Cui W Z, Daneshmand M 2017 J. Appl. Phys. 121 074902

Google Scholar

Google Scholar

[27] Cai Y H, Wang D, Qi K C, He Y N 2022 Rev. Sci. Instrum. 93 055103

Google Scholar

Google Scholar

[28] Wang D, He Y N, Ye M, Peng W B, Cui W Z 2017 J. Appl. Phys. 122 153302

Google Scholar

Google Scholar

[29] Braga D, Poumellec B, Cannas V, Blaise G, Ren Y, Kristensen M 2004 J. Appl. Phys. 96 885

Google Scholar

Google Scholar

-

图 3 四组氧化铝加载器件在不同输入功率下的电子数量变化过程仿真 (a) 第1组(δm = 4.3, Epm = 500 eV); (b) 第2组(δm = 3.6, Epm = 450 eV); (c) 第3组(δm = 2.5, Epm = 400 eV); (d) 第4组(δm = 1.2, Epm = 300 eV)

Fig. 3. Simulated evolution of electron number for the four groups alumina-loaded devices with various input powers: (a) Group 1 (δm = 4.3, Epm = 500 eV); (b) group 2 (δm = 3.6, Epm = 450 eV); (c) group 3 (δm = 2.5, Epm = 400 eV); (d) group 4 (δm = 1.2, Epm = 300 eV).

图 4 激光刻蚀微结构氧化铝样品三维轮廓 (a)—(d) 样品#1—#4, 孔隙比例相似但深度不同; (d)—(g) 样品#4—#7, 深度相似但孔隙比例不同; (h)样品#8, 未经处理的原始氧化铝

Fig. 4. 3D morphologies of laser-etched porous alumina samples: (a)–(d) Sample #1 to #4, similar porosity but different depths; (d)–(g) sample #4 to #7, similar depth but different porosity; (h) sample #8, untreated original alumina.

表 1 器件加载不同SEY氧化铝微放电阈值仿真结果

Table 1. Simulated multipactor threshold of the alumina-loaded devices with various SEY.

参数 第1组 第2组 第3组 第4组 δm 4.3 3.6 2.5 1.2 微放电阈值/W 82.52 139.65 223.43 426.54 表 2 激光刻蚀微结构的特征参数测量结果

Table 2. Measured feature parameters of laser-etched microstructures.

参数 #1 #2 #3 #4 #5 #6 #7 实际微孔边长/μm 158 160 161 164 134 106 78 微孔平均深度/μm 34 112 198 257 264 259 272 实际孔隙比例/% 62.41 64.00 64.80 67.24 44.89 28.09 15.21 表 3 微结构氧化铝样品表面镀覆TiN薄膜前后SEY特征参数统计

Table 3. Feature parameters of SEY for microstructure alumina samples with/without TiN coated.

参数 #1 #2 #3 #4 #5 #6 #7 #8 镀TiNδm 1.87 1.28 1.09 0.79 1.07 1.49 1.75 1.87 镀TiN Epm/eV 615 588 694 470 528 605 908 357 无镀层δm 2.12 1.75 1.39 1.10 1.50 1.70 2.09 2.46 Δδm 0.25 0.47 0.30 0.31 0.43 0.21 0.34 0.59 表 4 器件插入损耗和微放电阈值测试结果

Table 4. Measurement results of insertion loss and multipactor threshold for the fabricated devices.

插入损耗和微放电阈值 器件#1 器件#2 器件#3 器件#4 插入损耗/dB 0.17 0.18 0.24 0.24 插入损耗增量/dB — 0.01 0.07 0.07 微放电阈值/W 125 375 425 650 微放电阈值提升幅度/dB — 4.77 5.31 7.16 -

[1] Michizono S, Saito Y, Fukuda S, Anami S, Hayashi K 1997 Vacuum 47 625

Google Scholar

Google Scholar

[2] Cummings K A, Risbud S H 2000 J. Phys. Chem. Solids 61 551

Google Scholar

Google Scholar

[3] 宋佰鹏, 范壮壮, 苏国强, 穆海宝, 张冠军, 刘纯亮 2014 强激光与粒子束 26 271

Google Scholar

Google Scholar

Song B P, Fan Z Z, Su G Q, Mu H B, Zhang G J, Liu C L 2014 High Power Laser and Particle Beams 26 271

Google Scholar

Google Scholar

[4] Vague J, Melgarejo J C, Guglielmi M, Boria V E, Anza S, Vicente, C, Moreno M R, Taroncher M, Gimeno M B, Raboso D 2018 IEEE Trans. Microw. Theory Techn. 66 3644

Google Scholar

Google Scholar

[5] 崔万照, 李韵, 张洪太 2019 航天器微波部件微放电分析及其应用 (北京: 北京理工大学出版社) 第5—7页

Cui W Z, Li Y, Zhang H T 2019 Simulation Method of Multipactor and Its Application in Satellite Microwave Components (Beijing: Beijing Institute of Technology Press) pp5–7 (in Chinese)

[6] 董烨, 刘庆想, 庞健, 周海京, 董志伟 2018 67 037901

Google Scholar

Google Scholar

Dong Y, Liu Q X, Pang J, Zhou H J, Dong Z W 2018 Acta Phys. Sin. 67 037901

Google Scholar

Google Scholar

[7] Raboson D 2008 6th International Workshop on Multipactor Corona and Passive Intermodulation Valencia, Spain, September 24–27, 2008

[8] 胡天存, 曹猛, 鲍艳, 张永辉, 马建中, 崔万照 2017 中国空间科学技术 37 54

Google Scholar

Google Scholar

Hu T C, Cao M, Bao Y, Zhang Y H, Ma J Z, Cui W Z 2017 Chinese Space Science and Technology 37 54

Google Scholar

Google Scholar

[9] 翟永贵, 王瑞, 王洪广, 林舒, 陈坤, 李永东 2018 67 353

Google Scholar

Google Scholar

Zhai Y G, Wang R, Wang H G, Lin S, Chen K, Li Y D 2018 Acta Phy. Sin. 67 353

Google Scholar

Google Scholar

[10] 张娜, 崔万照, 曹猛, 王瑞, 胡天存 2020 中国空间科学技术 40 1

Google Scholar

Google Scholar

Zhang N, Cui W Z, Cao M, Wang R, Hu T C 2020 Chinese Space Science and Technology 40 1

Google Scholar

Google Scholar

[11] 李韵, 封国宝, 谢贵柏, 苗光辉, 李小军, 崔万照, 贺永宁 2022 强激光与粒子束 34 29

Google Scholar

Google Scholar

Li Y, Feng G B, Xie G B, Miao G H, Li X J, Cui W Z, He Y N 2022 High Power Laser and Particle Beams 34 29

Google Scholar

Google Scholar

[12] Vaughan J R M 1988 IEEE Trans. Electron. Dev. 35 1172

Google Scholar

Google Scholar

[13] Michizono S 2007 IEEE Trans. Dielectr. Electr. Insul. 14 583

Google Scholar

Google Scholar

[14] Song B P, Shen W W, Mu H B, Deng J B, Hao X W, Zhang G J 2013 IEEE Trans. Plasma. Sci. 41 2117

Google Scholar

Google Scholar

[15] 雷杨俊, 肖定全, 唐兵华 2006 硅酸盐学报 34 713

Google Scholar

Google Scholar

Lei Y J, Xiao D Q, Tang B H 2006 J. Chin. Ceram. Soc. 34 713

Google Scholar

Google Scholar

[16] Suharyanto, Yamano Y, Kobayashi S, Michizono S, Saito Y 2006 IEEE Trans. Dielectr. Electr. Insul. 13 72

Google Scholar

Google Scholar

[17] Cazaux J 2010 Appl. Surf. Sci. 257 1002

Google Scholar

Google Scholar

[18] 王丹, 叶鸣, 冯鹏, 贺永宁, 崔万照 2019 68 067901

Google Scholar

Google Scholar

Wang D, Ye M, Feng P, He Y N, Cui W Z 2019 Acta Phys. Sin. 68 067901

Google Scholar

Google Scholar

[19] Gineste T, Belhaj M, Teyssedre G, Puech J 2015 Appl. Surf. Sci. 359 398

Google Scholar

Google Scholar

[20] Wang D, He Y N, Cui W Z 2018 J. Appl. Phys. 124 053301

Google Scholar

Google Scholar

[21] Ladarola G 2014 Ph. D. Dissertation (Napoli: Università degli Studi di Napoli Federico II)

[22] [23] Rumolo G, Ruggiero F, Zimmermann F 2001 Phys. Rev. Spec. Top-Ac 4 012801

Google Scholar

Google Scholar

[24] 张洪涛, 董海义, 杨奇 2014 真空 51 61

Google Scholar

Google Scholar

Zhang H T, Dong H Y, Yang Q 2014 Vacuum 51 61

Google Scholar

Google Scholar

[25] Michizono S, Kinbara A, Saito Y, Yamaguchi S, Anami S, Matuda N 1992 J. Vac. Sci. Technol. A 10 1180

Google Scholar

Google Scholar

[26] Ye M, Wang D, Li Y, He Y N, Cui W Z, Daneshmand M 2017 J. Appl. Phys. 121 074902

Google Scholar

Google Scholar

[27] Cai Y H, Wang D, Qi K C, He Y N 2022 Rev. Sci. Instrum. 93 055103

Google Scholar

Google Scholar

[28] Wang D, He Y N, Ye M, Peng W B, Cui W Z 2017 J. Appl. Phys. 122 153302

Google Scholar

Google Scholar

[29] Braga D, Poumellec B, Cannas V, Blaise G, Ren Y, Kristensen M 2004 J. Appl. Phys. 96 885

Google Scholar

Google Scholar

计量

- 文章访问数: 5933

- PDF下载量: 130

- 被引次数: 0

下载:

下载: