-

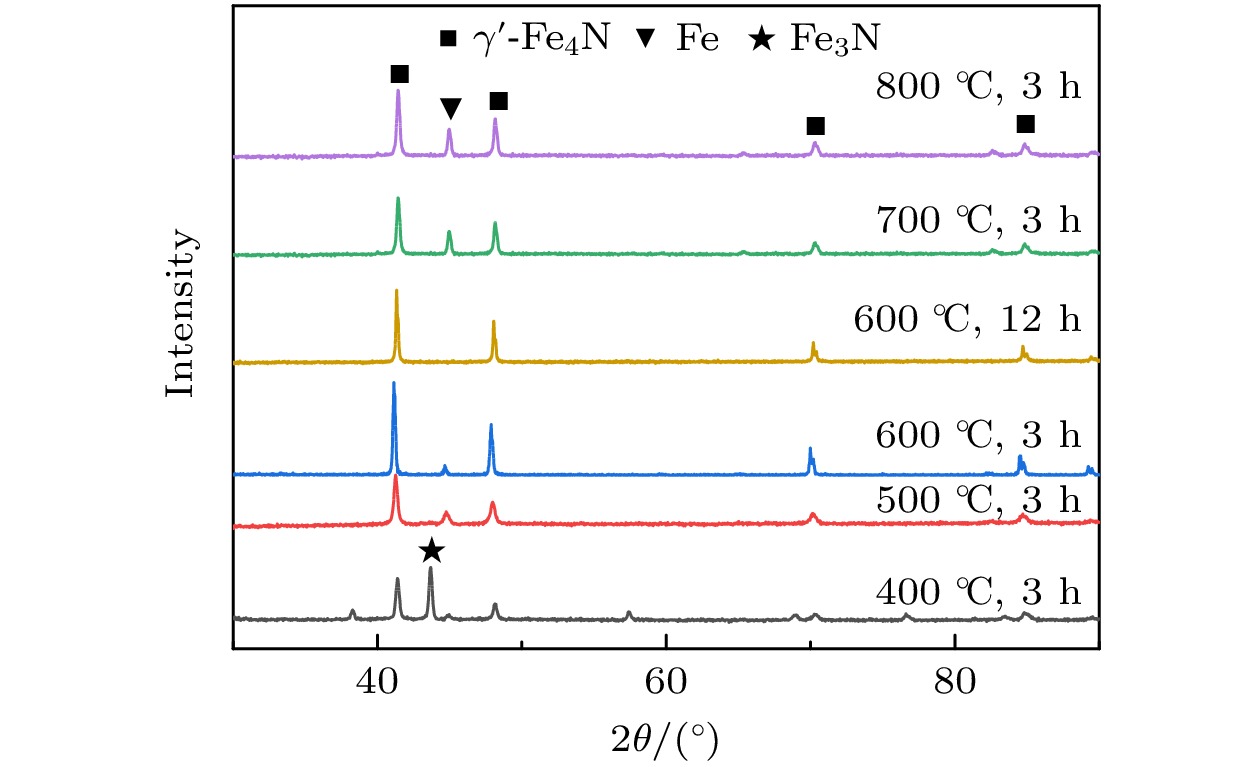

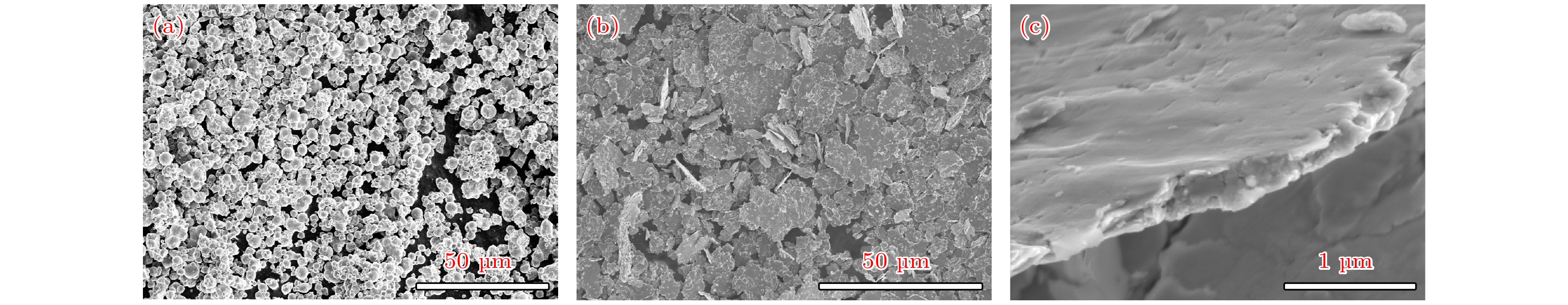

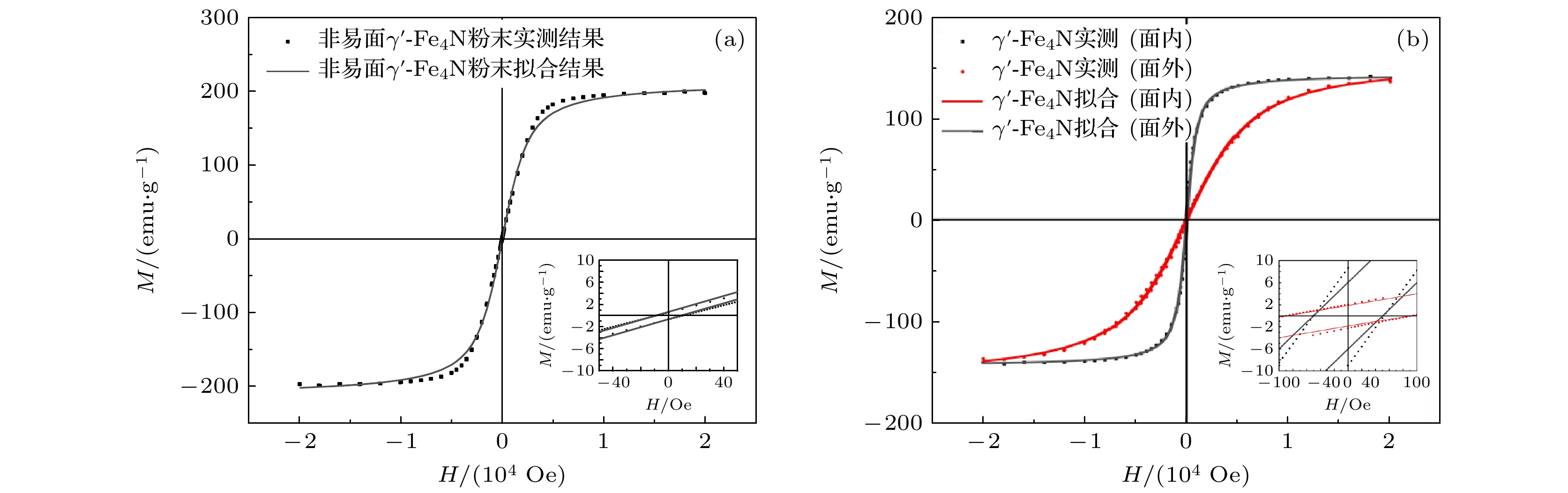

软磁复合材料在光伏逆变器、新能源汽车及充电桩等新兴电力电子行业的应用前景广阔. 目前研究者们聚焦于开发新型软磁复合材料, 达到匹配以SiC和GaN为主的第3代高频宽禁带半导体的目标. 本文利用氨气氮化羰基铁粉制备得到高电阻率的γ'-Fe4N, 并证实其具备优异的软磁性能, 对γ'-Fe4N进行球磨处理使其成为静磁易面γ'-Fe4N粉体, 所获得的易面粉体与聚氨酯(PU)混合制成软磁复合材料. 与未球磨静磁易面化处理的非易面γ'-Fe4N复合材料相比, 静磁易面γ'-Fe4N软磁复合材料具有更高的磁导率, 更低的功率损耗. 与同类软磁复合材料相比, 通过氮化工艺降低磁性铁颗粒内涡流效应, 静磁易面γ'-Fe4N软磁复合材料具有优异的高频软磁性能. 静磁易面γ'-Fe4N为软磁复合材料匹配第3代宽禁带半导体的高频应用提供了一种新思路.Soft magnetic composite materials are prepared by mixing magnetic materials and insulating materials, which possess both the excellent magnetism of magnetic materials and the low resistivity of insulating materials. They possess broad application prospects in emerging power electronics industries such as photovoltaic inverters, new energy vehicles, and charging stations. The third-generation high-frequency wide bandgap semiconductors, mainly composed of SiC and GaN, have the operating frequency of soft magnetic materials raised to MHz. However, current soft magnetic materials have significant core losses at high frequencies. Therefore, people are focus their attention on developing new soft magnetic composite materials to reduce iron core losses at high frequencies. In this paper, γ'-Fe4N with high resistivity is prepared by nitriding carbonyl iron powders, showing its excellent soft magnetic properties, and the γ'-Fe4N is ball-milled to become easy plane γ'-Fe4N powder. Compared with the none easy plane γ'-Fe4N powders, the none easy plane γ'-Fe4N powders are spherical in shape, the easy plane γ'-Fe4N powders exhibit a high aspect to thickness ratio in sheet shape. The obtained easy plane powders are mixed with polyurethane insulation to make the soft magnetic composite. There is a significant difference between the in-plane and out-of-plane hysteresis loop of the magnetostatic easy plane γ'-Fe4N soft magnetic composite, and the in-plane hysteresis loop is more easily magnetized to saturation state. The degree of plane orientation is 98.46%. The fitting analysis results of the Jiles-Atherton model also prove its easy plane characteristic, and has higher effective permeability and lower power loss than the counterparts of the none easy plane γ'-Fe4N composite that is not ball-milled. After loss separation, it is found that in a low frequency range, hysteresis loss is the main loss, while in a high frequency range, the excess loss will surpass the hysteresis loss, acting as the main loss, the magnetostatic easy plane γ'-Fe4N soft magnetic composites material reduces hysteresis loss and excess loss. Comparing with similar soft magnetic composites, the eddy current effect in magnetic iron particles is reduced by nitriding process, and the magnetostatic easy plane γ'-Fe4N soft magnetic composite has excellent high-frequency soft magnetic properties. Magnetostatic easy plane γ'-Fe4N provides a new idea for the high-frequency application of soft magnetic composites matching the third generation wide bandgap semiconductors.

-

Keywords:

- γ'-Fe4N /

- nitride /

- ball-milled /

- power loss

[1] Silveyra J M, Ferrara E, Huber D L, Monson T C 2018 Science 362 418

Google Scholar

Google Scholar

[2] Périgo E A, Weidenfeller B, Kollár P, Füzer J 2018 Appl. Phys. Rev. 5 031301

Google Scholar

Google Scholar

[3] Sun Z W 2013 M. S. Thesis (Beijing: Beijing University of Technology) (in Chinese)

[4] Shirane G, Takei W J, Ruby S L 1962 Phys. Rev. 126 49

Google Scholar

Google Scholar

[5] Peng X, Yu S, Chang J, Ge M, Li J, Ellis T, Yang Y, Xu J, Hong B, Jin D, Jin H, Wang X, Ge H 2020 J. Magn. Magn. Mater. 500 166407

Google Scholar

Google Scholar

[6] Wu X L, Zhong W, Jiang H Y, Tang N J, Zou W Q, Du Y W 2004 J. Magn. Magn. Mater. 281 77

Google Scholar

Google Scholar

[7] Wallace W E, Huang M Q 1994 J. Appl. Phys. 76 6648

Google Scholar

Google Scholar

[8] Kim T K, Takahashi M 1972 Appl. Phys. Lett. 20 492

Google Scholar

Google Scholar

[9] Coey J M D, Smith P A I 1999 J. Magn. Magn. Mater. 200 405

Google Scholar

Google Scholar

[10] 成泰民, 孙腾, 张龙燕, 张新欣, 朱林, 李林 2015 64 156301

Google Scholar

Google Scholar

Cheng T M, Sun T, Zhang L Y, Zhang X X, Zhu L, Li L 2015 Acta Phys. Sin. 64 156301

Google Scholar

Google Scholar

[11] 李贞, 李庆民, 李长云, 孙秋芹, 娄杰 2011 中国电机工程学报 31 124

Li Z, Li Q M, Li C Y, Sun Q Q, Lou J 2011 Proceed. CSEE 31 124

[12] Yu M J, Xu Y, Mao Q, Li F, Wang C 2016 J. Alloys Compd. 656 362

Google Scholar

Google Scholar

[13] 瞿志学, 王群, 孙忠巍, 潘伟 2013 稀有金属材料与工程 42 126

Google Scholar

Google Scholar

Qu Z X, Wang Q, Sun Z W, Pan W 2013 Rare Metal Mater. Eng. 42 126

Google Scholar

Google Scholar

[14] Narahara A, Ito K, Suemasu T, Takahashi Y K, Ranajikanth A, Hono K 2009 Appl. Phys. Lett. 94 202502

Google Scholar

Google Scholar

[15] 卢启海, 唐晓莉, 宋玉哲, 左显维, 韩根亮, 闫鹏勋, 刘维民 2019 68 118101

Lu Q H, Tang X L, Song Y Z, Zuo X W, Han G L, Yan P X, Liu W M 2019 Acta Phys. Sin. 68 118101

[16] 薛德胜, 陈子瑜, 李发伸 1996 兰州大学学报(自然科学版) 32 49

Xue D S, Chen Z Y, Li F S 1996 J. Lanzhou Univ. (Natural Sciences) 32 49

[17] Zhao Z J, Xue D S, Li F S 2001 J. Magn. Magn. Mater. 232 155

Google Scholar

Google Scholar

[18] 薛德胜, 李发伸 1997 中国科学(A辑) 27 275

Xue D S, Li F S 1997 Sci. China (Ser. A) 27 275

[19] Zhang C, Liu X, Li M, Liu C, Li H, Meng X, Rehman K M U 2017 J. Mater. Sci. Mater. Electron. 29 1254

[20] Wang G W 2022 Ph. D. Dissertation (Lanzhou: Lanzhou University) (in Chinese)

[21] Wu P, Zhang Y D, Hao H B, Qiao L, Liu X, Wang T, Li F S 2022 J. Magn. Magn. Mater. 549 168962

Google Scholar

Google Scholar

[22] Takanori Tsutaoka 2003 J. Appl. Phys. 93 2789

Google Scholar

Google Scholar

[23] Kollár P, Vojtek V, Birčáková Z, Füzer J, Fáberová M, Bureš R 2014 J. Magn. Magn. Mater. 353 65

Google Scholar

Google Scholar

[24] Taghvaei A H, Shokrollahi H, Janghorban K 2009 Mater. Des. 30 3989

Google Scholar

Google Scholar

[25] Taghvaei A H, Ebrahimi A, Gheisari K 2010 J. Magn. Magn. Mater. 322 3748

Google Scholar

Google Scholar

[26] Chiriac H 2003 IEEE Trans. Magn. 39 3040

Google Scholar

Google Scholar

[27] Liu H J, Su H L, Geng W B, Sun Z G, Song T T, Tong X C, Zou Z Q, Wu Y C, Du Y W 2016 J. Supercond. Nov. Magn. 29 463

Google Scholar

Google Scholar

[28] 熊政伟, 杨江, 王雨, 杨陆, 管弦, 曹林洪, 王进, 高志鹏 2022 71 157502

Google Scholar

Google Scholar

Xiong Z W, Yang J, Wang Y, Yang L, Guan X, Cao L H, Wang J, Gao Z P 2022 Acta Phys. Sin. 71 157502

Google Scholar

Google Scholar

[29] Yao Z, Peng Y, Xia C, Yi X, Mao S, Zhang M 2020 J. Alloys Compd. 827 154345

Google Scholar

Google Scholar

[30] Peng Y, Yi Y, Li L, Ai H, Wang X, Chen L 2017 J. Magn. Magn. Mater. 428 148

Google Scholar

Google Scholar

[31] Liu J H, Peng X L, Hong B, Xu J C, Han Y B, Li J, Ge H L, Yang Y T, Wang X Q 2021 J. Magn. Magn. Mater. 532 167994

Google Scholar

Google Scholar

-

图 5 (a) 易面和非易面γ'-Fe4N复合物的磁谱实测结果; (b) 易面γ'-Fe4N复合物的磁谱拟合结果与实测结果; (c) 非易面 γ'-Fe4N复合物的磁谱拟合结果及实测结果

Fig. 5. (a) Magnetic spectrum measurement of easy plane and none plane γ'-Fe4N composite; (b) magnetic spectrum measurement and fitting results of easy plane γ'-Fe4N composite; (c) magnetic spectrum measurement and fitting results of none easy plane γ'-Fe4N composite.

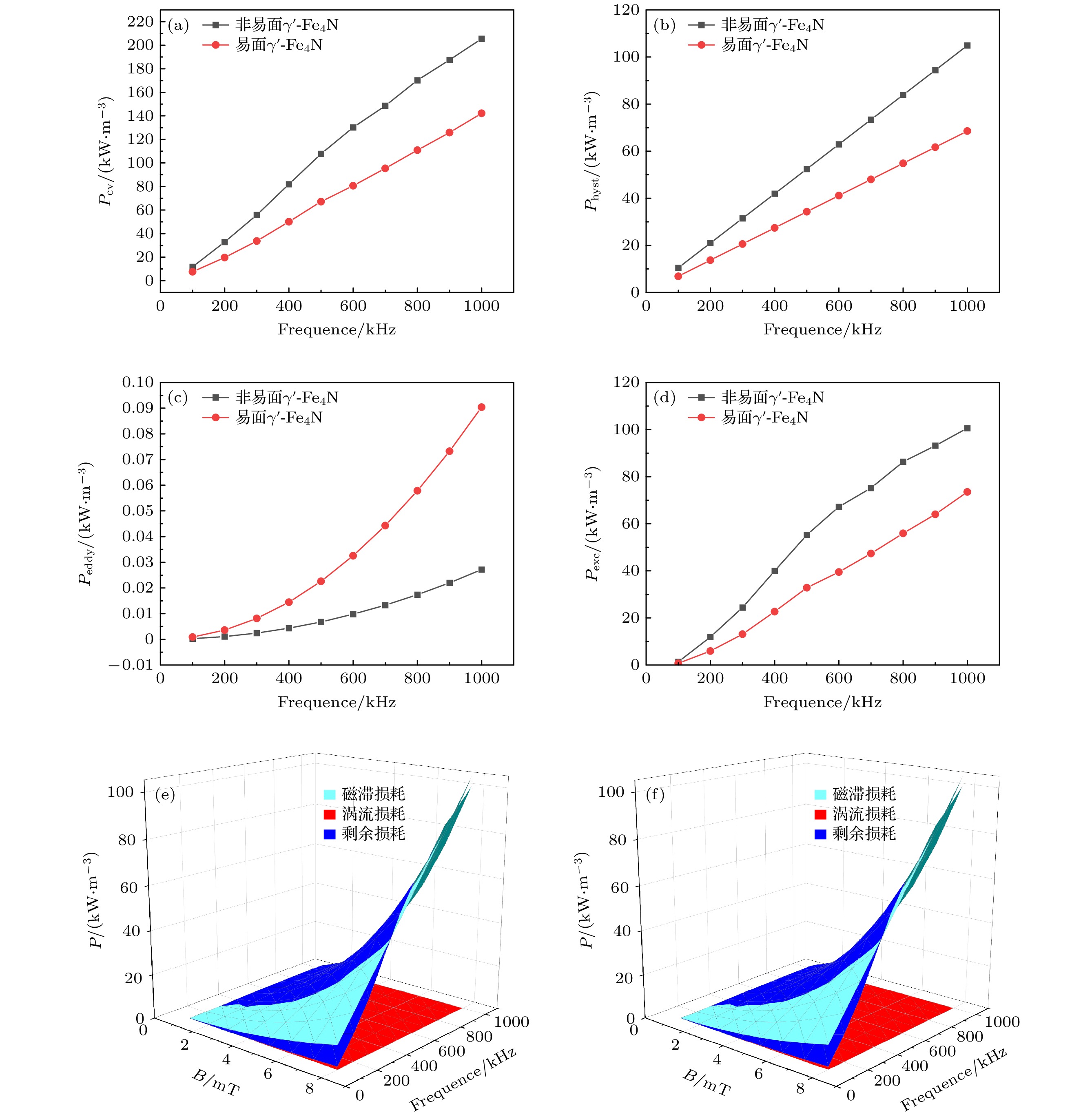

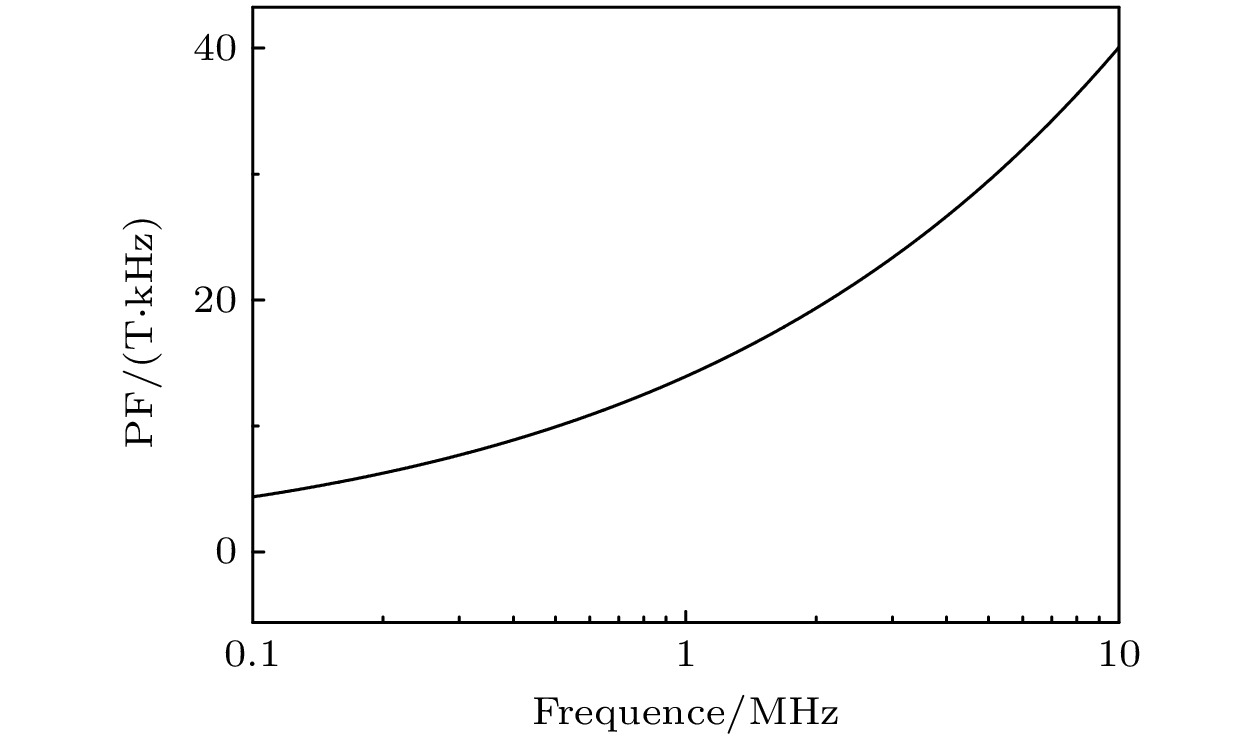

图 6 B = 8 mT下易面和非易面γ'-Fe4N复合物的损耗 (a) 总损耗; (b) 磁滞损耗; (c) 涡流损耗; (d) 剩余损耗; (e) 非易面γ'-Fe4N复合物的损耗分离结果; (f) 易面γ'-Fe4N复合物的损耗分离结果

Fig. 6. Losses of easy plane and none plane γ'-Fe4N composite at B = 8 mT: (a) Total losses; (b) hysteresis losses; (c) eddy current losses; (d) residual losses; (e) depletion separation results of none easy plane γ'-Fe4N composite; (f) depletion separation results of easy plane γ'-Fe4N composite.

表 1 非易面γ'-Fe4N粉末及易面γ'-Fe4N的J-A拟合参数

Table 1. J-A fitting parameters of none easy plane γ'-Fe4N powder and easy plane γ'-Fe4N composite.

非易面

γ'-Fe4N易面γ'-Fe4N

(面内)易面γ'-Fe4N

(面外)J-A拟合参数

a/10460.0 3.2 20.0 J-A拟合参数

k/1033.1 4.0 12.0 Mr/(emu·g–1) 3.496 8.840 2.170 Hc/Oe 31.658 51.293 91.460 表 2 易面及非易面γ'-Fe4N复合物的磁谱拟合参数

Table 2. Magnetic spectral fitting parameters of easy plane γ'-Fe4N and none easy plane γ'-Fe4N composite.

畴壁移动 畴内转动 $ {\chi }_{{\rm{d}}0} $ $ {\omega }_{{\rm{d}}0}/10 $10 β/1010 $ {\chi }_{{\rm{s}}0} $ $ {\omega }_{{\rm{s}}0}/10 $10 $ \vartheta $ 易面γ'-Fe4N

复合物6.0 0.3 5.8 4.7 0.7 1.2 非易面γ'-Fe4N

复合物5.8 4.0 10.0 3.7 1.3 1.5 表 3 非易面γ'-Fe4N复合材料和易面γ'-Fe4N复合物损耗分离的拟合参数

Table 3. Simulated parameters for loss separation of none easy plane γ'-Fe4N composite and easy plane γ'-Fe4N composite.

Physt/(kW·m–3) Peddy/(kW·m–3) Pex/(kW·m–3) chyst h $ {c}_{{\rm{e}}{\rm{d}}{\rm{d}}{\rm{y}}}^{{\rm{i}}{\rm{n}}{\rm{t}}{\rm{e}}{\rm{r}}} $/10–10 $ {c}_{{\rm{e}}{\rm{d}}{\rm{d}}{\rm{y}}}^{{\rm{i}}{\rm{n}}{\rm{t}}{\rm{r}}{\rm{a}}} $/10–6 cexc x y 非易面γ'-Fe4N复合物 3.6383 2.1652 9.24 0.424 1.1965 2.1431 1.0731 易面γ'-Fe4N复合物 5.3096 2.3315 5.00 1.412 0.027678 2.1479 1.3235 -

[1] Silveyra J M, Ferrara E, Huber D L, Monson T C 2018 Science 362 418

Google Scholar

Google Scholar

[2] Périgo E A, Weidenfeller B, Kollár P, Füzer J 2018 Appl. Phys. Rev. 5 031301

Google Scholar

Google Scholar

[3] Sun Z W 2013 M. S. Thesis (Beijing: Beijing University of Technology) (in Chinese)

[4] Shirane G, Takei W J, Ruby S L 1962 Phys. Rev. 126 49

Google Scholar

Google Scholar

[5] Peng X, Yu S, Chang J, Ge M, Li J, Ellis T, Yang Y, Xu J, Hong B, Jin D, Jin H, Wang X, Ge H 2020 J. Magn. Magn. Mater. 500 166407

Google Scholar

Google Scholar

[6] Wu X L, Zhong W, Jiang H Y, Tang N J, Zou W Q, Du Y W 2004 J. Magn. Magn. Mater. 281 77

Google Scholar

Google Scholar

[7] Wallace W E, Huang M Q 1994 J. Appl. Phys. 76 6648

Google Scholar

Google Scholar

[8] Kim T K, Takahashi M 1972 Appl. Phys. Lett. 20 492

Google Scholar

Google Scholar

[9] Coey J M D, Smith P A I 1999 J. Magn. Magn. Mater. 200 405

Google Scholar

Google Scholar

[10] 成泰民, 孙腾, 张龙燕, 张新欣, 朱林, 李林 2015 64 156301

Google Scholar

Google Scholar

Cheng T M, Sun T, Zhang L Y, Zhang X X, Zhu L, Li L 2015 Acta Phys. Sin. 64 156301

Google Scholar

Google Scholar

[11] 李贞, 李庆民, 李长云, 孙秋芹, 娄杰 2011 中国电机工程学报 31 124

Li Z, Li Q M, Li C Y, Sun Q Q, Lou J 2011 Proceed. CSEE 31 124

[12] Yu M J, Xu Y, Mao Q, Li F, Wang C 2016 J. Alloys Compd. 656 362

Google Scholar

Google Scholar

[13] 瞿志学, 王群, 孙忠巍, 潘伟 2013 稀有金属材料与工程 42 126

Google Scholar

Google Scholar

Qu Z X, Wang Q, Sun Z W, Pan W 2013 Rare Metal Mater. Eng. 42 126

Google Scholar

Google Scholar

[14] Narahara A, Ito K, Suemasu T, Takahashi Y K, Ranajikanth A, Hono K 2009 Appl. Phys. Lett. 94 202502

Google Scholar

Google Scholar

[15] 卢启海, 唐晓莉, 宋玉哲, 左显维, 韩根亮, 闫鹏勋, 刘维民 2019 68 118101

Lu Q H, Tang X L, Song Y Z, Zuo X W, Han G L, Yan P X, Liu W M 2019 Acta Phys. Sin. 68 118101

[16] 薛德胜, 陈子瑜, 李发伸 1996 兰州大学学报(自然科学版) 32 49

Xue D S, Chen Z Y, Li F S 1996 J. Lanzhou Univ. (Natural Sciences) 32 49

[17] Zhao Z J, Xue D S, Li F S 2001 J. Magn. Magn. Mater. 232 155

Google Scholar

Google Scholar

[18] 薛德胜, 李发伸 1997 中国科学(A辑) 27 275

Xue D S, Li F S 1997 Sci. China (Ser. A) 27 275

[19] Zhang C, Liu X, Li M, Liu C, Li H, Meng X, Rehman K M U 2017 J. Mater. Sci. Mater. Electron. 29 1254

[20] Wang G W 2022 Ph. D. Dissertation (Lanzhou: Lanzhou University) (in Chinese)

[21] Wu P, Zhang Y D, Hao H B, Qiao L, Liu X, Wang T, Li F S 2022 J. Magn. Magn. Mater. 549 168962

Google Scholar

Google Scholar

[22] Takanori Tsutaoka 2003 J. Appl. Phys. 93 2789

Google Scholar

Google Scholar

[23] Kollár P, Vojtek V, Birčáková Z, Füzer J, Fáberová M, Bureš R 2014 J. Magn. Magn. Mater. 353 65

Google Scholar

Google Scholar

[24] Taghvaei A H, Shokrollahi H, Janghorban K 2009 Mater. Des. 30 3989

Google Scholar

Google Scholar

[25] Taghvaei A H, Ebrahimi A, Gheisari K 2010 J. Magn. Magn. Mater. 322 3748

Google Scholar

Google Scholar

[26] Chiriac H 2003 IEEE Trans. Magn. 39 3040

Google Scholar

Google Scholar

[27] Liu H J, Su H L, Geng W B, Sun Z G, Song T T, Tong X C, Zou Z Q, Wu Y C, Du Y W 2016 J. Supercond. Nov. Magn. 29 463

Google Scholar

Google Scholar

[28] 熊政伟, 杨江, 王雨, 杨陆, 管弦, 曹林洪, 王进, 高志鹏 2022 71 157502

Google Scholar

Google Scholar

Xiong Z W, Yang J, Wang Y, Yang L, Guan X, Cao L H, Wang J, Gao Z P 2022 Acta Phys. Sin. 71 157502

Google Scholar

Google Scholar

[29] Yao Z, Peng Y, Xia C, Yi X, Mao S, Zhang M 2020 J. Alloys Compd. 827 154345

Google Scholar

Google Scholar

[30] Peng Y, Yi Y, Li L, Ai H, Wang X, Chen L 2017 J. Magn. Magn. Mater. 428 148

Google Scholar

Google Scholar

[31] Liu J H, Peng X L, Hong B, Xu J C, Han Y B, Li J, Ge H L, Yang Y T, Wang X Q 2021 J. Magn. Magn. Mater. 532 167994

Google Scholar

Google Scholar

计量

- 文章访问数: 8153

- PDF下载量: 150

- 被引次数: 0

下载:

下载: