-

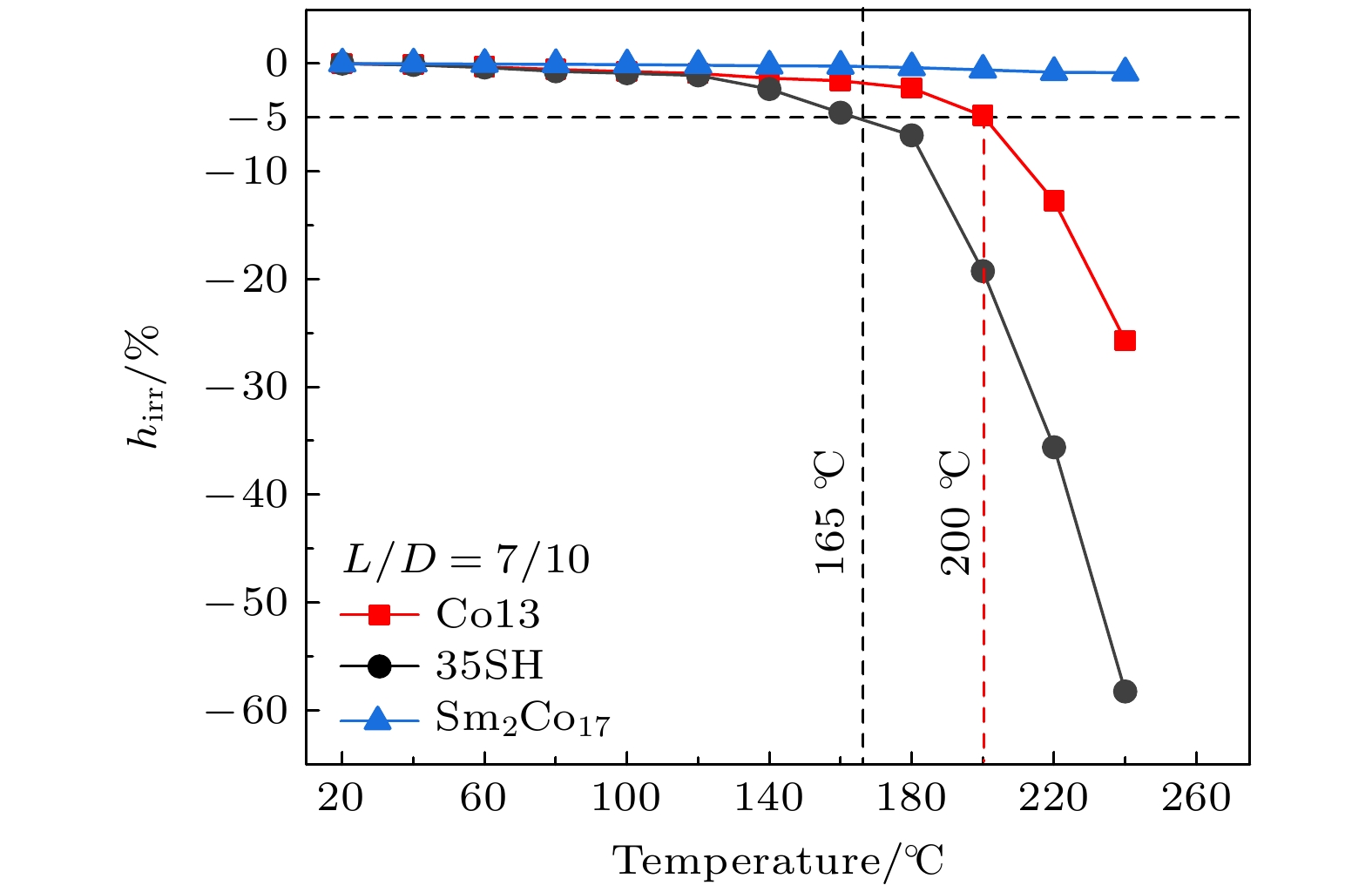

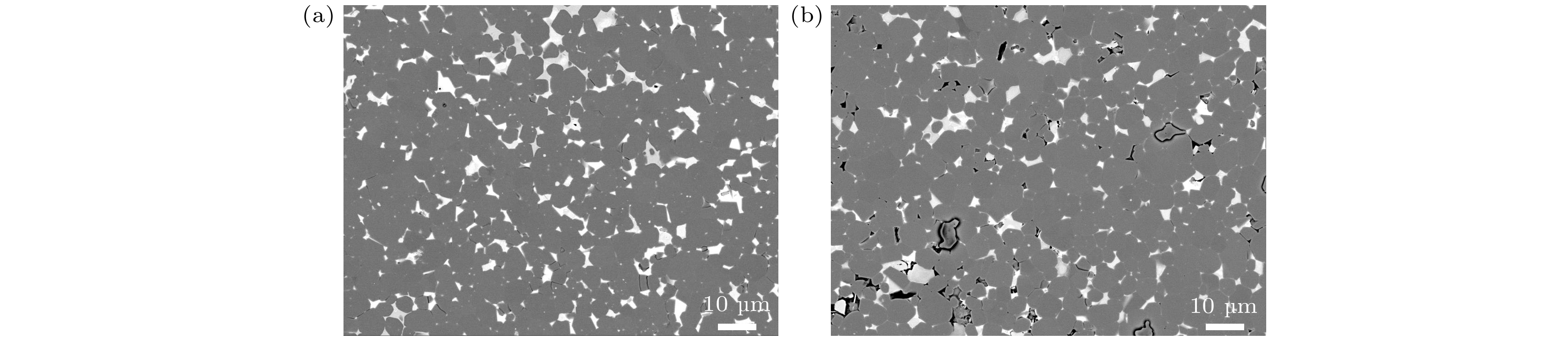

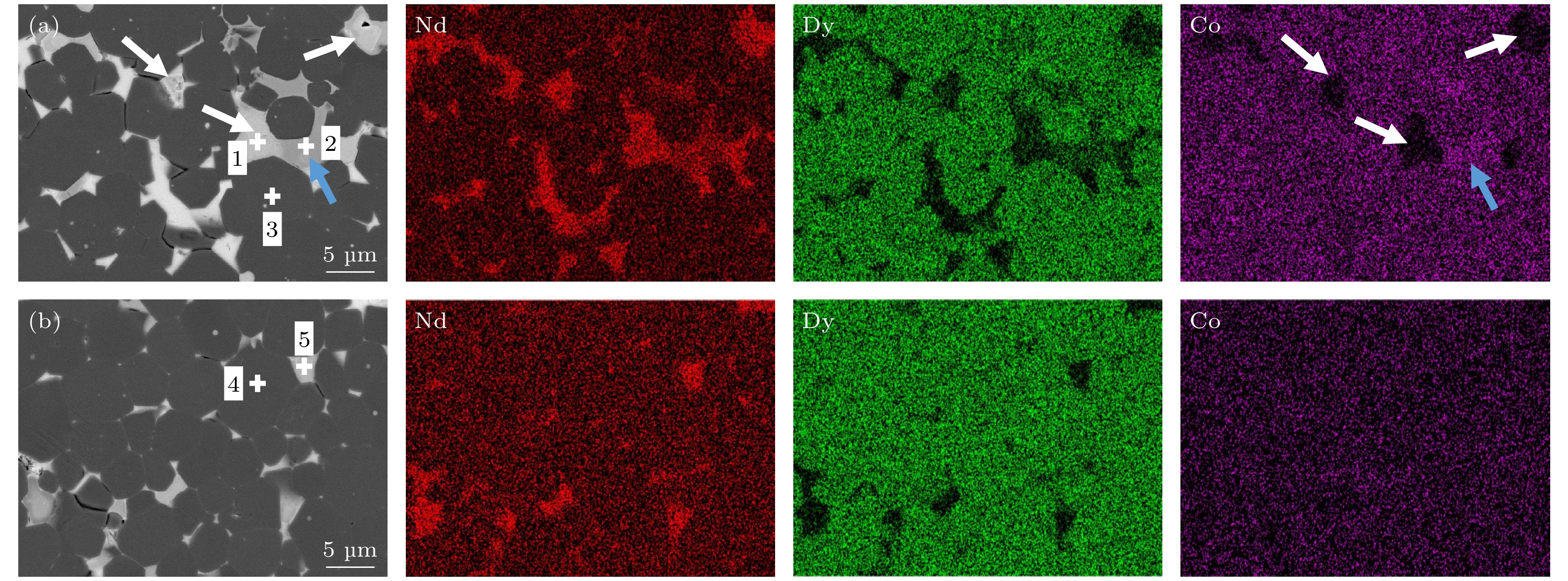

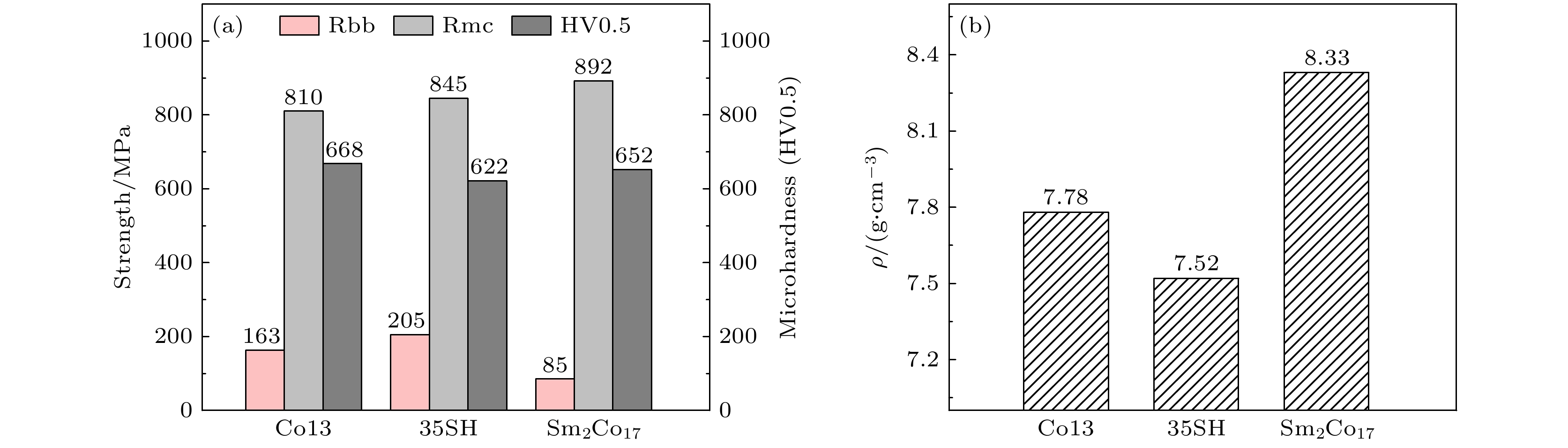

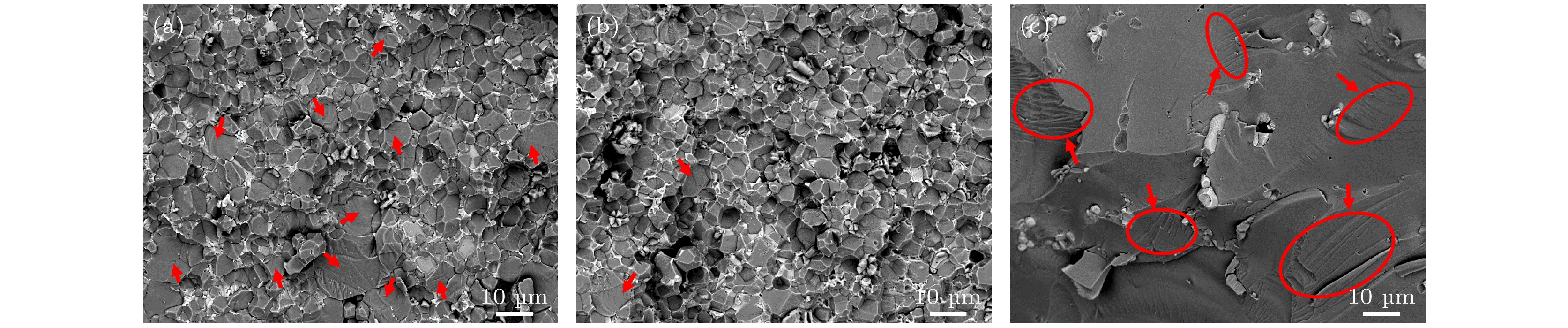

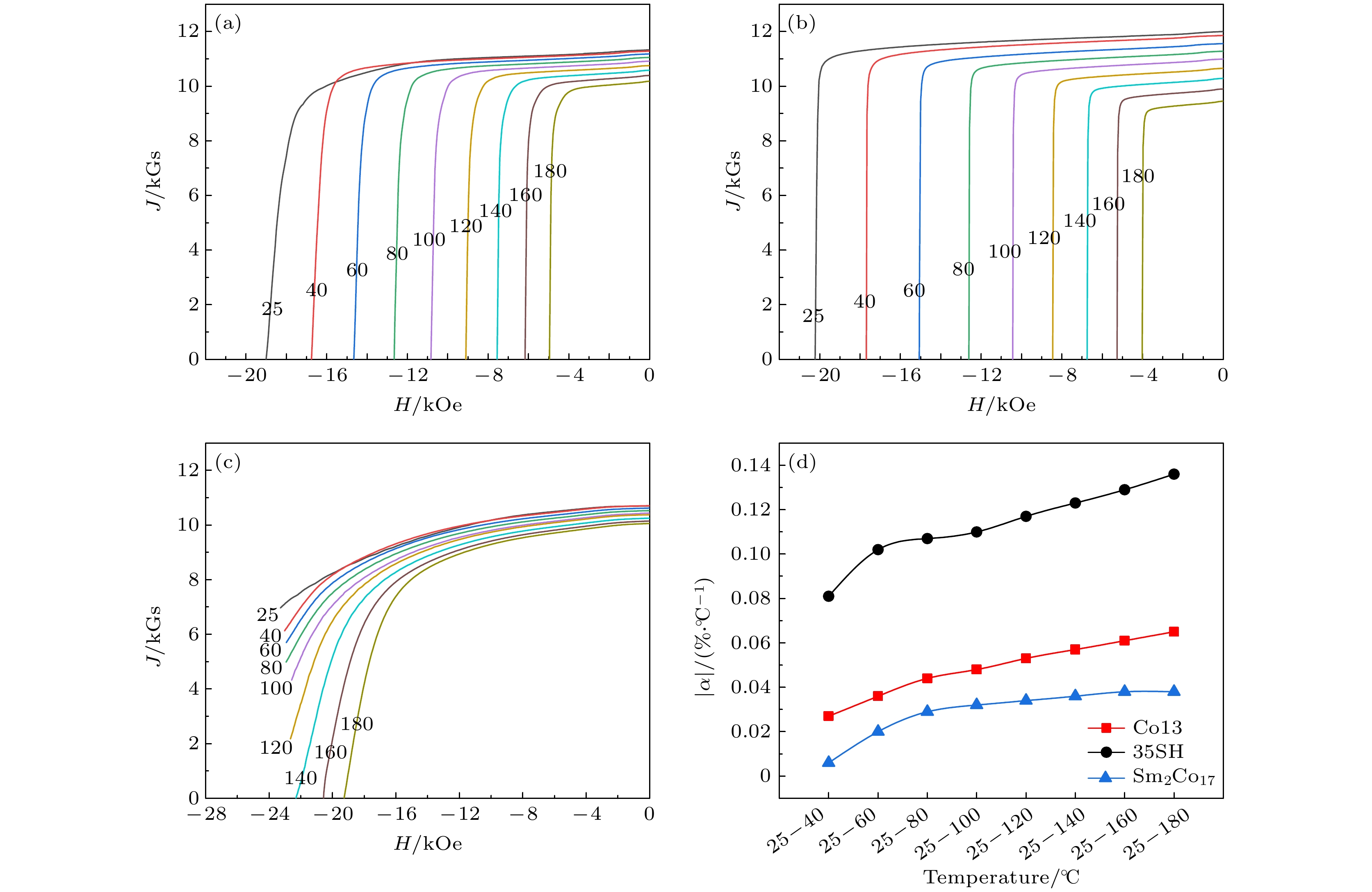

本文采用速凝甩带-氢破-气流磨-取向成型-烧结回火等工序, 同时添加Dy和Co元素, 制备了烧结Nd25.5Dy6.5Co13FebalM1.05B0.98磁体(Co13磁体), 室温下磁能积(BH)max = 30.88 MGOe, 矫顽力Hcj = 19.01 kOe. 与Nd30Dy1.5Co0.5FebalM1.05B0.98(35SH)磁体相比, Co13磁体的室温磁性能略低, 但温度稳定性显著提升, 剩磁温度系数α从–0.136 %/℃提升至–0.065 %/℃ (室温—180 ℃); 居里温度TC从310 ℃升高至约454 ℃; 最高使用温度TW从165℃提升到约200 ℃. 力学性能测试和断口分析表明, Co13磁体中由于Co含量较高, 主相晶粒发生解理断裂的比例提高, 抗弯强度与35SH磁体相比, 虽然有所降低, 但是仍为2:17型Sm-Co磁体的近2倍. Co13磁体发生解理断裂的原因, 可能是Co元素在2∶14∶1主相中择优取代Fe, 导致晶格畸变, 降低了主相晶粒强度. 微观组织分析表明, Co13磁体晶界相中存在高Co区, 其成分接近(Nd, Dy)(Fe, Co)3, 这可能是导致矫顽力较低的原因之一.The sintered Nd25.5Dy6.5Co13FebalM1.05B0.98 magnet (Co13 magnet) and Nd30Dy1.5Co0.5FebalM1.05B0.98 magnet (35SH magnet) are prepared by strip casting, hydrogen decrepitation, jet milling, orienting compression, sintering and annealling. The maximum energy product (BH)max and coercivity Hcj of Co13 magnet at room temperature are 30.88 MGOe and 19.01 kOe, which are lower than those of 35SH magnet. By adding Co and Dy, the remanence temperature coefficient α , curie temperature TC, and max operating temperature TW significantly increase form –0.136%/℃ to –0.065%/℃ (25–180 ℃), 310 ℃ to 454 ℃, and 160 ℃ to 200 ℃ respectively. Mechanical property test and fracture analysis show that owing to the high content of Co in the magnet, the proportion of cleavage fracture in the main phase grains increases, and the bending strength Rbb decreases compared with the Rbb of 35SH magnet, which is nearly twice that of 2∶17 type Sm-Co magnet. The reason for Rbb decreasing might be that Co element preferentially replaces Fe in the 2∶14∶1 main phase, which leads the lattice to be distorted and the grain strength of the main phase to decrease. The microstructure analysis shows that there exists a high Co region in the grain boundary phase of Co13 magnet, and its composition is close to (Nd,Dy)(Fe,Co)3, which might be one of the reasons for coercivity Hcj decreasing.

-

Keywords:

- sintered Nd-Fe-B /

- temperature stability /

- maximum operating temperature /

- mechanical Properties

[1] Brown D, Ma B M, Chen Z M 2002 J. Magn. Magn. Mater. 248 432

[2] Nakamura H, Hirota K, Shimao M, Minowa T, Honshima M 2005 IEEE. T. Magn. 41 3844

Google Scholar

Google Scholar

[3] 朱明刚, 孙旭, 刘荣辉, 徐会兵 2020 中国工程科学 22 37

Google Scholar

Google Scholar

Zhu M G, Sun X, Liu R H, Xu H B 2020 Strateg. Study CAE 22 37

Google Scholar

Google Scholar

[4] Hono K, Sepehri-Amin H 2012 Scripta Mater. 67 530

Google Scholar

Google Scholar

[5] Coey J 2020 Engineering 6 118

[6] Matsuura Y 2006 J. Magn. Magn. Mater. 303 344

Google Scholar

Google Scholar

[7] Givord D, Li H S, Moreau J M 1984 Solid State Commun. 50 497

Google Scholar

Google Scholar

[8] Hu Z H, Cheng X H, Zhu M G, Li W, Lian F Z 2008 Rare Metals 27 358

Google Scholar

Google Scholar

[9] Gutfleisch O, Willard M A, Brück E, Chen C H, Sankar S G, Liu J P 2011 Adv. Mater. 23 821

Google Scholar

Google Scholar

[10] Kronmüller H, Goll D 2002 Scripta Mater. 47 545

Google Scholar

Google Scholar

[11] Machida H, Fujiwara T, Kamada R, Morimoto Y, Takezawa M 2017 AIP Adv. 7 056223

Google Scholar

Google Scholar

[12] 孙威 2015 博士学位论文(北京: 钢铁研究总院)

Sun W 2015 Ph. D. Dissertation (Beijing: Central Iron & Steel Research Institute) (in Chinese)

[13] 周寿增, 郭灿杰, 呼琴, 李春和 1988 北京钢铁学院学报 10 317

Google Scholar

Google Scholar

Zhou S Z, Guo C J, Hu Q, Li C H 1988 J. Beijing Univ. Iron Steel Tech. 10 317

Google Scholar

Google Scholar

[14] ARAI S, SHIBATA T 1985 IEEE T. Magn. 21 1952

Google Scholar

Google Scholar

[15] Kronmuller H 1987 Phys. Status Solidi B 144 385

[16] Li L, Dong S Z, Han R, Song K K, Li D, Zhu M G, Li W, Sun W 2019 J. Rare Earth 37 628

Google Scholar

Google Scholar

[17] Sagawa M, Hirosawa S, Tokuhara K, Yamamoto H, Fujimura S 1987 J. Appl. Phys. 61 3559

Google Scholar

Google Scholar

[18] Hirosawa S, Matsuura Y, Yamamoto H, Fujimura S, Sagawa M 1986 J. Appl. Phys. 59 873

Google Scholar

Google Scholar

[19] Ma B M, Narasimhan, K, Hurt J 1986 IEEE. T. Magn. 22 1081

Google Scholar

Google Scholar

[20] Li W, Jiang L, Wang D, Sun T D, Zhu J H 1986 J. Alloys Compd. 126 95

[21] Kablov E N, Petrakov A F, Piskorskii V P, Valeev V A, Nazarova N V 2007 Met. Sci. Heat Treat. 49 159

Google Scholar

Google Scholar

[22] 蒋建华, 曾振鹏 1999 稀有金属材料与工程 28 144

Google Scholar

Google Scholar

Jiang J H, Zeng Z P 1999 Rare Metals Eng. 28 144

Google Scholar

Google Scholar

[23] Li W, Li A H, Wang H J, Pan W, Chang H W 2009 J. Appl. Phys. 105 07A703

Google Scholar

Google Scholar

[24] Wang H J, Li A H, Li W 2006 J. Magn. Magn. Mater. 307 268

Google Scholar

Google Scholar

[25] Wang H J, Li a H, Li W 2007 Intermetallics 15 985

[26] XB/T 507—2009 2: 17 Type Samarium Uobalt Uermanent Uagnetic Material (in Chinese) [XB/T 507—2009 2: 17型钐钴永磁材料]

[27] GYB-2 2016 钢铁研究总院

GYB-2 2016 Central Iron & Steel Research Institute (in Chinese)

[28] GB/T 13560 2017 烧结钕铁硼永磁材料

GB/T 13560—2017 Sintered Neodymium Iron Boron Permanent Magnets (in Chinese)

[29] Wu Y Y, Skokov K, Schfer L, Maccari F, Aubert A, Xu H, Wu H C, Jiang C B, Gutfleisch O 2022 Acta Mater. 235 118062

Google Scholar

Google Scholar

[30] Popov A G, Kolodkin D A, Gaviko V S, Vasilenko D Y, Shitov A V 2018 Met. Sci. Heat Treat. 60 528

Google Scholar

Google Scholar

-

图 1 样品在不同温度下的退磁曲线和剩磁温度系数随温度区间的变化 (a) Co13的退磁曲线; (b) 35SH的退磁曲线; (c) Sm2Co17的退磁曲线; (d)剩磁温度系数随温度的变化

Fig. 1. Demagnetization curve and remanence temperature coefficient of samples at different temperatures: (a) Demagnetization curve of Co13 magnet; (b) demagnetization curve of 35SH magnet; (c) demagnetization curve of Sm2Co17 magnet; (d) remanence temperature coefficient.

表 1 样品在不同温度区间内的剩磁温度系数α(%·℃–1)

Table 1. Remanence temperature coefficient α in different temperature ranges(%·℃–1).

Sample Temperature ranges/℃ 25—40 25—60 25—80 25—100 25—120 25—140 25—160 25—180 Co13 –0.027 –0.036 –0.044 –0.048 –0.053 –0.057 –0.061 –0.065 35SH –0.081 –0.102 –0.107 –0.110 –0.117 –0.123 –0.129 –0.136 Sm2Co17 –0.006 –0.020 –0.029 –0.032 –0.034 –0.036 –0.038 –0.038 表 2 两种磁体在不同位置的Nd/Dy/Fe/Co元素含量(%)

Table 2. Nd/Dy/Fe/Co element content of two magnets at different positions(%).

Samples Positions Elements content Nd Dy Co Fe Co13 1 89.75 2.13 0.98 7.13 2 39.52 6.77 19.37 34.34 3 21.51 6.02 13.06 59.41 35SH 4 20.50 1.16 0.69 77.65 5 79.20 0.90 0.52 19.38 表 3 磁体的抗弯强度、抗压强度和显微硬度

Table 3. Bending strength, compressive strength and Vickers hardness of magnets.

Samples Rbb/MPa Rmc/MPa HV0.5 1# 2# 3# Avg. 1# 2# 3# Avg. 1# 2# 3# Avg. Co13 162 167 159 163 800 815 814 810 665 677 661 668 35SH 210 200 206 205 841 845 849 845 625 630 611 622 Sm2Co17 92 81 83 85 891 883 901 892 640 661 654 652 -

[1] Brown D, Ma B M, Chen Z M 2002 J. Magn. Magn. Mater. 248 432

[2] Nakamura H, Hirota K, Shimao M, Minowa T, Honshima M 2005 IEEE. T. Magn. 41 3844

Google Scholar

Google Scholar

[3] 朱明刚, 孙旭, 刘荣辉, 徐会兵 2020 中国工程科学 22 37

Google Scholar

Google Scholar

Zhu M G, Sun X, Liu R H, Xu H B 2020 Strateg. Study CAE 22 37

Google Scholar

Google Scholar

[4] Hono K, Sepehri-Amin H 2012 Scripta Mater. 67 530

Google Scholar

Google Scholar

[5] Coey J 2020 Engineering 6 118

[6] Matsuura Y 2006 J. Magn. Magn. Mater. 303 344

Google Scholar

Google Scholar

[7] Givord D, Li H S, Moreau J M 1984 Solid State Commun. 50 497

Google Scholar

Google Scholar

[8] Hu Z H, Cheng X H, Zhu M G, Li W, Lian F Z 2008 Rare Metals 27 358

Google Scholar

Google Scholar

[9] Gutfleisch O, Willard M A, Brück E, Chen C H, Sankar S G, Liu J P 2011 Adv. Mater. 23 821

Google Scholar

Google Scholar

[10] Kronmüller H, Goll D 2002 Scripta Mater. 47 545

Google Scholar

Google Scholar

[11] Machida H, Fujiwara T, Kamada R, Morimoto Y, Takezawa M 2017 AIP Adv. 7 056223

Google Scholar

Google Scholar

[12] 孙威 2015 博士学位论文(北京: 钢铁研究总院)

Sun W 2015 Ph. D. Dissertation (Beijing: Central Iron & Steel Research Institute) (in Chinese)

[13] 周寿增, 郭灿杰, 呼琴, 李春和 1988 北京钢铁学院学报 10 317

Google Scholar

Google Scholar

Zhou S Z, Guo C J, Hu Q, Li C H 1988 J. Beijing Univ. Iron Steel Tech. 10 317

Google Scholar

Google Scholar

[14] ARAI S, SHIBATA T 1985 IEEE T. Magn. 21 1952

Google Scholar

Google Scholar

[15] Kronmuller H 1987 Phys. Status Solidi B 144 385

[16] Li L, Dong S Z, Han R, Song K K, Li D, Zhu M G, Li W, Sun W 2019 J. Rare Earth 37 628

Google Scholar

Google Scholar

[17] Sagawa M, Hirosawa S, Tokuhara K, Yamamoto H, Fujimura S 1987 J. Appl. Phys. 61 3559

Google Scholar

Google Scholar

[18] Hirosawa S, Matsuura Y, Yamamoto H, Fujimura S, Sagawa M 1986 J. Appl. Phys. 59 873

Google Scholar

Google Scholar

[19] Ma B M, Narasimhan, K, Hurt J 1986 IEEE. T. Magn. 22 1081

Google Scholar

Google Scholar

[20] Li W, Jiang L, Wang D, Sun T D, Zhu J H 1986 J. Alloys Compd. 126 95

[21] Kablov E N, Petrakov A F, Piskorskii V P, Valeev V A, Nazarova N V 2007 Met. Sci. Heat Treat. 49 159

Google Scholar

Google Scholar

[22] 蒋建华, 曾振鹏 1999 稀有金属材料与工程 28 144

Google Scholar

Google Scholar

Jiang J H, Zeng Z P 1999 Rare Metals Eng. 28 144

Google Scholar

Google Scholar

[23] Li W, Li A H, Wang H J, Pan W, Chang H W 2009 J. Appl. Phys. 105 07A703

Google Scholar

Google Scholar

[24] Wang H J, Li A H, Li W 2006 J. Magn. Magn. Mater. 307 268

Google Scholar

Google Scholar

[25] Wang H J, Li a H, Li W 2007 Intermetallics 15 985

[26] XB/T 507—2009 2: 17 Type Samarium Uobalt Uermanent Uagnetic Material (in Chinese) [XB/T 507—2009 2: 17型钐钴永磁材料]

[27] GYB-2 2016 钢铁研究总院

GYB-2 2016 Central Iron & Steel Research Institute (in Chinese)

[28] GB/T 13560 2017 烧结钕铁硼永磁材料

GB/T 13560—2017 Sintered Neodymium Iron Boron Permanent Magnets (in Chinese)

[29] Wu Y Y, Skokov K, Schfer L, Maccari F, Aubert A, Xu H, Wu H C, Jiang C B, Gutfleisch O 2022 Acta Mater. 235 118062

Google Scholar

Google Scholar

[30] Popov A G, Kolodkin D A, Gaviko V S, Vasilenko D Y, Shitov A V 2018 Met. Sci. Heat Treat. 60 528

Google Scholar

Google Scholar

计量

- 文章访问数: 6206

- PDF下载量: 95

- 被引次数: 0

下载:

下载: